specifications NISSAN TIIDA 2010 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 818 of 3745

BODY REPAIRBL-309

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

• The spot weld on HSS panels is harder than that of an ordi- nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

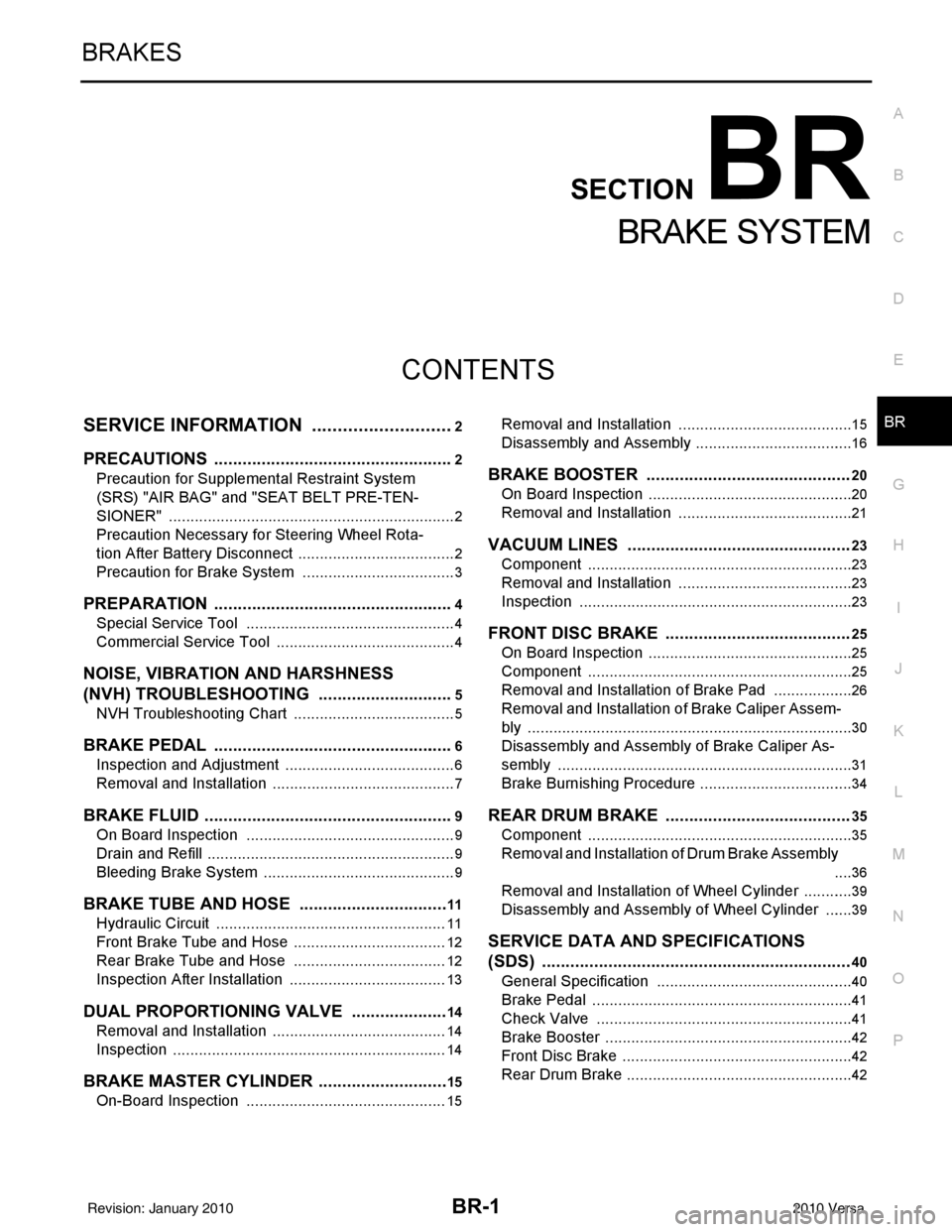

2. Precautions in spot welding HSS This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according tothe metal thickness.

• The panel surfaces must fit flush to each other, leaving no gaps.

• Follow the specifications for the proper welding pitch.

Unit: mm

Rear fender hemming process

1. A wheel arch is to be installed and hemmed over left and right outer wheel house.

2. In order to hem the wheel arch, it is necessary to repair any damaged or defaced parts around outer wheel house.

CAUTION:

Ensure that the area that is to be glued around outer wheelhouse is undamaged or defaced.

Procedure of the hemming process

PIIA0145E

PIIA0146E

PIIA0147E

Thickness (t) Minimum pitch ( )

0.6 (0.024)

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.6 (0.063)

1.8 (0.071) 10 (0.39) or over

12 (0.47) or over

18 (0.71) or over

20 (0.79) or over

27 (1.06) or over

31 (1.22) or over

PIIA0148E

Revision: January 20102010 Versa

Page 849 of 3745

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Brake System ....................................3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

BRAKE PEDAL .............................................. .....6

Inspection and Adjustment .................................. ......6

Removal and Installation ...........................................7

BRAKE FLUID ................................................ .....9

On Board Inspection ........................................... ......9

Drain and Refill ..........................................................9

Bleeding Brake System .............................................9

BRAKE TUBE AND HOSE ................................11

Hydraulic Circuit .................................................. ....11

Front Brake Tube and Hose ....................................12

Rear Brake Tube and Hose ....................................12

Inspection After Installation .....................................13

DUAL PROPORTIONING VALVE .....................14

Removal and Installation .........................................14

Inspection ............................................................ ....14

BRAKE MASTER CYLINDER ........................ ....15

On-Board Inspection ........................................... ....15

Removal and Installation ..................................... ....15

Disassembly and Assembly .....................................16

BRAKE BOOSTER ...........................................20

On Board Inspection ............................................ ....20

Removal and Installation .........................................21

VACUUM LINES ...............................................23

Component ..............................................................23

Removal and Installation .........................................23

Inspection ................................................................23

FRONT DISC BRAKE .......................................25

On Board Inspection ............................................ ....25

Component ..............................................................25

Removal and Installation of Brake Pad ...................26

Removal and Installation of Brake Caliper Assem-

bly ........................................................................ ....

30

Disassembly and Assembly of Brake Caliper As-

sembly .....................................................................

31

Brake Burnishing Procedure ....................................34

REAR DRUM BRAKE .......................................35

Component .......................................................... ....35

Removal and Installation of Drum Brake Assembly

....

36

Removal and Installation of Wheel Cylinder ............39

Disassembly and Assembly of Wheel Cylinder .......39

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

40

General Specification ..............................................40

Brake Pedal .............................................................41

Check Valve ............................................................41

Brake Booster ..........................................................42

Front Disc Brake ......................................................42

Rear Drum Brake .....................................................42

Revision: January 20102010 Versa

Page 862 of 3745

BR-14

< SERVICE INFORMATION >

DUAL PROPORTIONING VALVE

DUAL PROPORTIONING VALVE

Removal and InstallationINFOID:0000000005396987

Removal

1. Remove cowl top . Refer to EI-22, "Removal and Installation".

2. Disconnect brake lines from dual proportioning valve. • Mark brake lines for installation.

3. Remove dual proportioning valve bolt and dual proportioning valve.

4. Remove two bolts and bracket.

Installation

Installation is in the reverse order of removal.

• When installing brake lines to the dual proportioning valve, tighten to specifications. Refer to BR-11,

"Hydraulic Circuit".

InspectionINFOID:0000000005396988

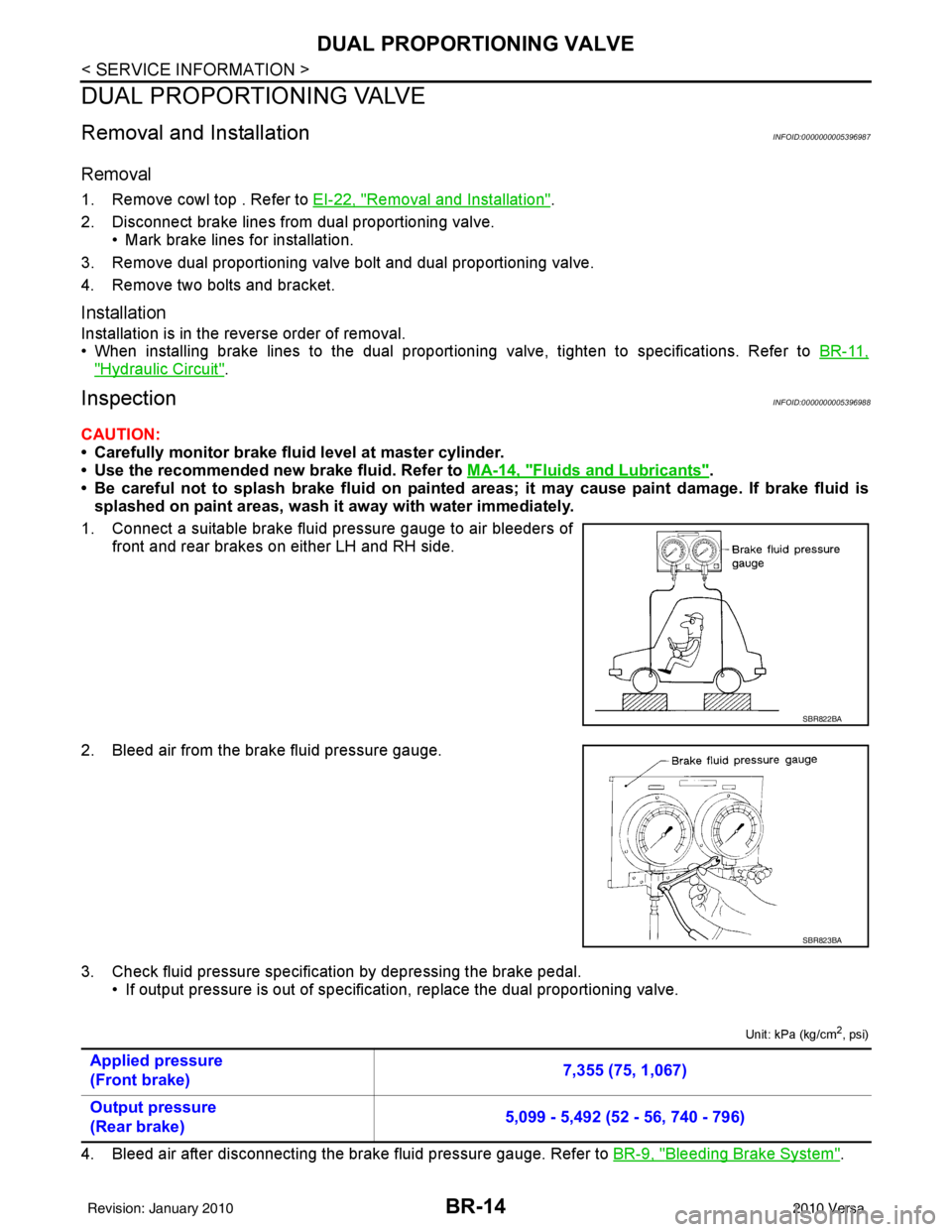

CAUTION:

• Carefully monitor brake fluid level at master cylinder.

• Use the recommended new brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on paint areas, wash it away with water immediately.

1. Connect a suitable brake fluid pressure gauge to air bleeders of front and rear brakes on either LH and RH side.

2. Bleed air from the brake fluid pressure gauge.

3. Check fluid pressure specific ation by depressing the brake pedal.

• If output pressure is out of specification, replace the dual proportioning valve.

Unit: kPa (kg/cm2, psi)

4. Bleed air after disconnecting the brake fluid pressure gauge. Refer to BR-9, "Bleeding Brake System".

SBR822BA

SBR823BA

Applied pressure

(Front brake) 7,355 (75, 1,067)

Output pressure

(Rear brake) 5,099 - 5,492 (52 - 56, 740 - 796)

Revision: January 20102010 Versa

Page 872 of 3745

BR-24

< SERVICE INFORMATION >

VACUUM LINES

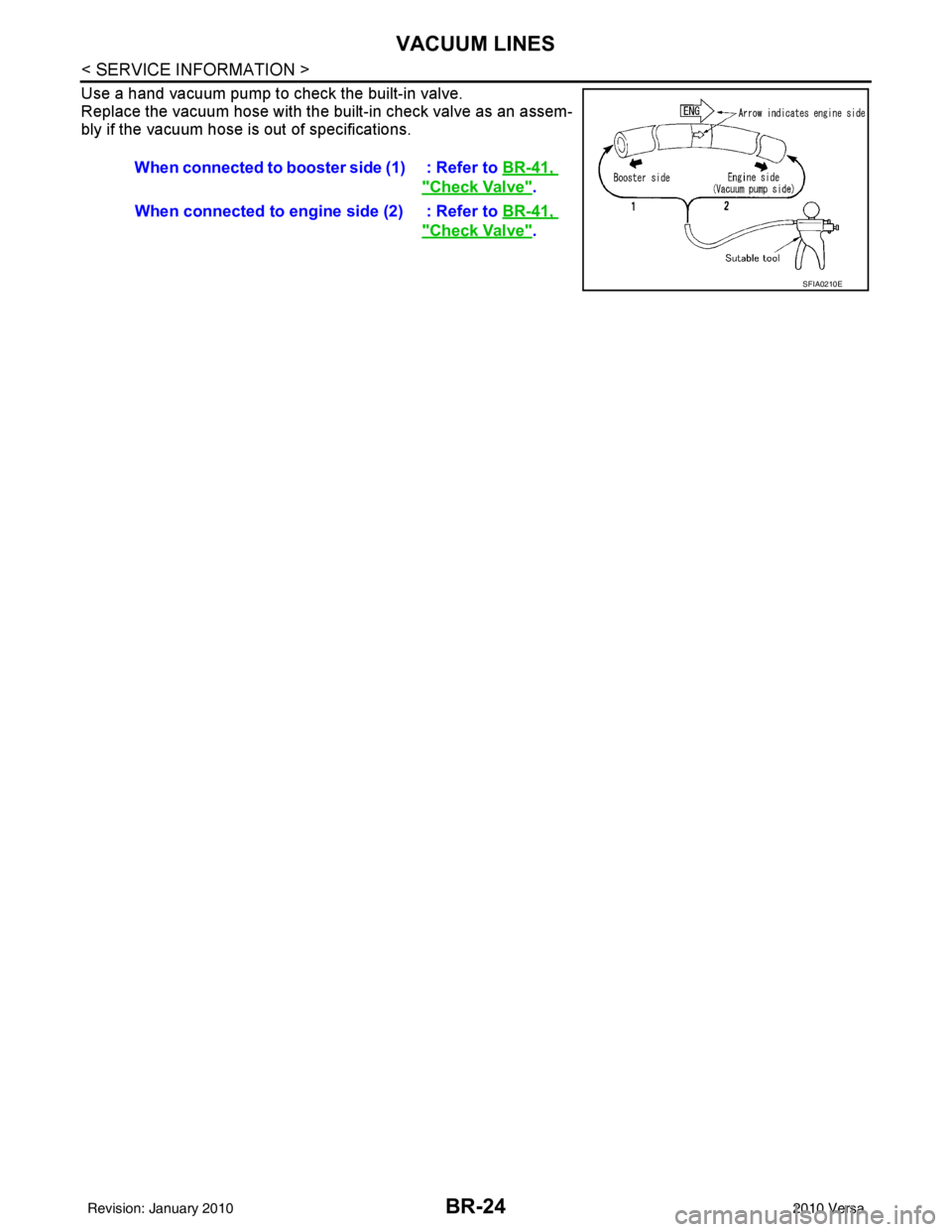

Use a hand vacuum pump to check the built-in valve.

Replace the vacuum hose with the built-in check valve as an assem-

bly if the vacuum hose is out of specifications.When connected to booster side (1) : Refer to BR-41,

"Check Valve".

When connected to engine side (2) : Refer to BR-41,

"Check Valve".

SFIA0210E

Revision: January 20102010 Versa

Page 880 of 3745

BR-32

< SERVICE INFORMATION >

FRONT DISC BRAKE

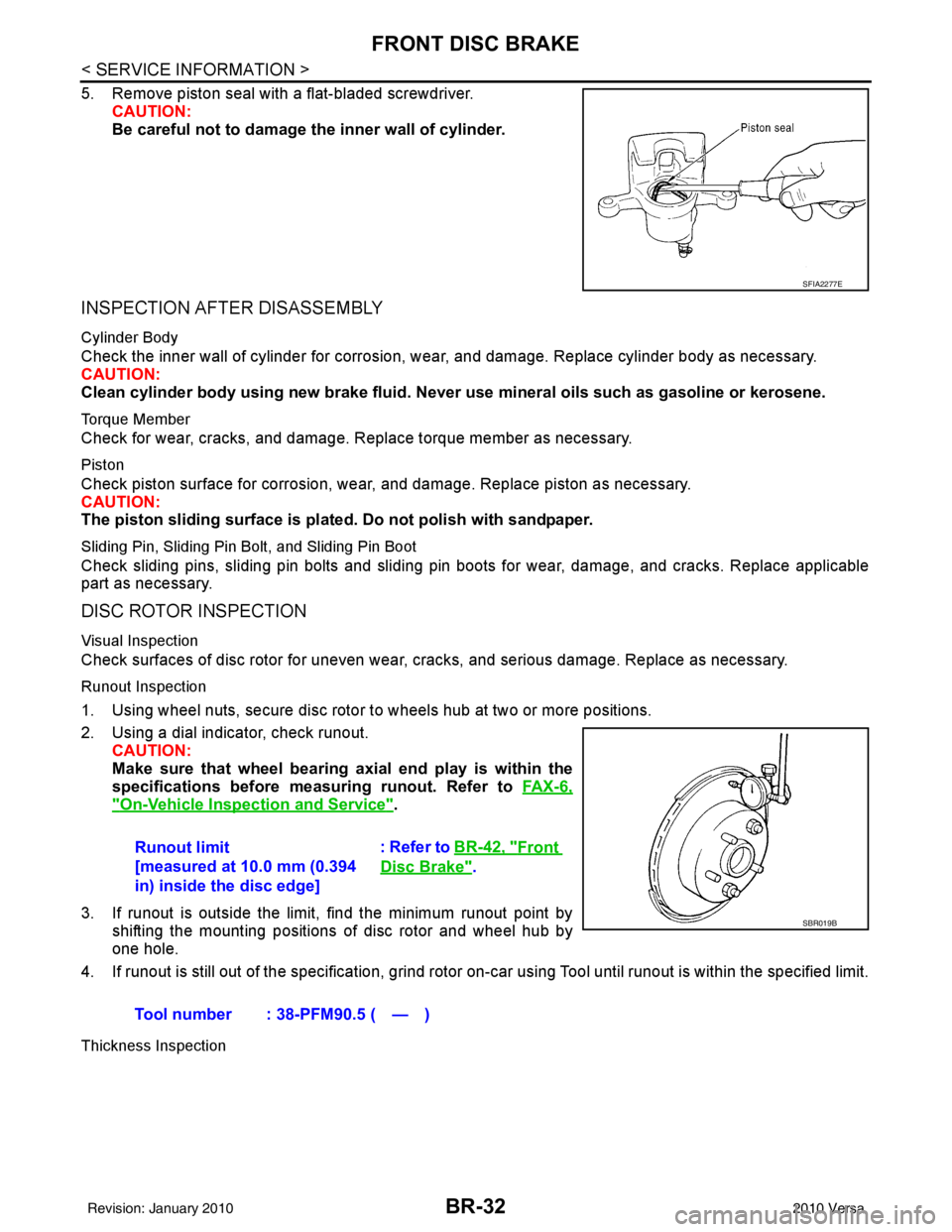

5. Remove piston seal with a flat-bladed screwdriver.CAUTION:

Be careful not to damage the inner wall of cylinder.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, w ear, and damage. Replace cylinder body as necessary.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. R eplace torque member as necessary.

Piston

Check piston surface for corrosion, wear, and damage. Replace piston as necessary.

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check sliding pins, sliding pin bolts and sliding pin boots for wear, damage, and cracks. Replace applicable

part as necessary.

DISC ROTOR INSPECTION

Visual Inspection

Check surfaces of disc rotor for uneven wear, cr acks, and serious damage. Replace as necessary.

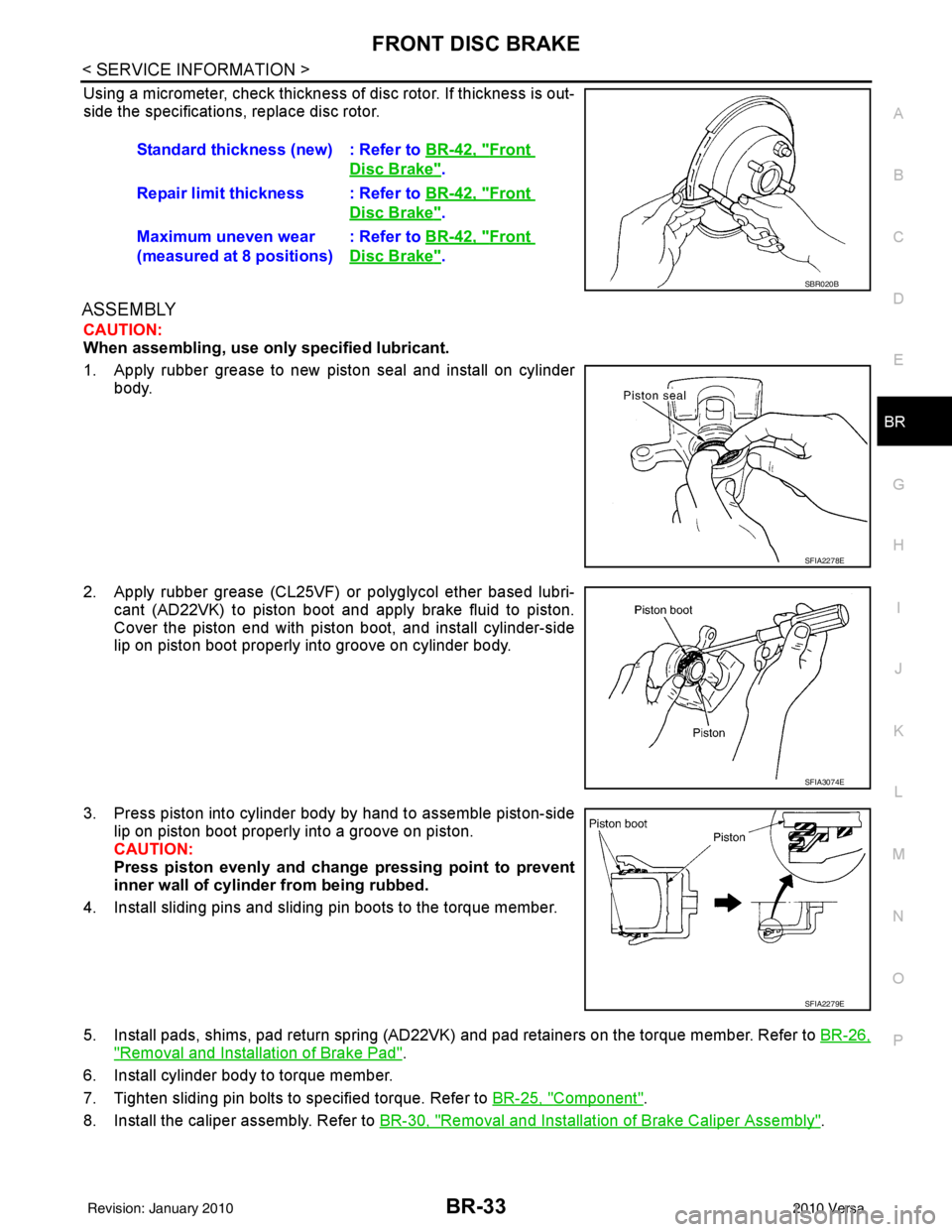

Runout Inspection

1. Using wheel nuts, secure disc rotor to wheels hub at two or more positions.

2. Using a dial indicator, check runout.

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer to FA X - 6 ,

"On-Vehicle Inspection and Service".

3. If runout is outside the limit, find the minimum runout point by shifting the mounting positions of disc rotor and wheel hub by

one hole.

4. If runout is still out of the specification, grind rotor on-car using Tool until runout is within the specified limit.

Thickness Inspection

SFIA2277E

Runout limit

[measured at 10.0 mm (0.394

in) inside the disc edge] : Refer to BR-42, "Front

Disc Brake".

Tool number : 38-PFM90.5 ( — )

SBR019B

Revision: January 20102010 Versa

Page 881 of 3745

FRONT DISC BRAKEBR-33

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

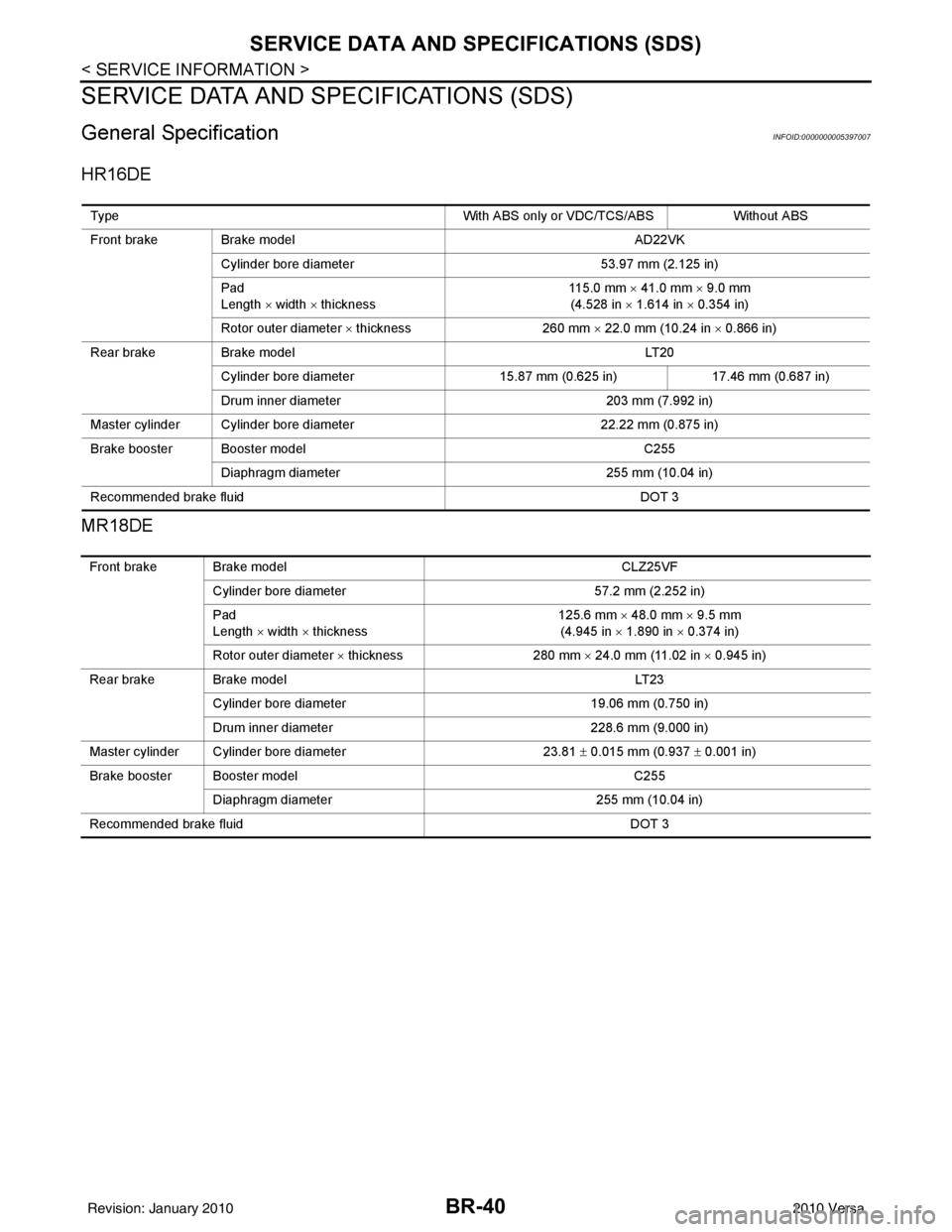

Using a micrometer, check thickness of disc rotor. If thickness is out-

side the specifications, replace disc rotor.

ASSEMBLY

CAUTION:

When assembling, use only specified lubricant.

1. Apply rubber grease to new piston seal and install on cylinder body.

2. Apply rubber grease (CL25VF) or polyglycol ether based lubri- cant (AD22VK) to piston boot and apply brake fluid to piston.

Cover the piston end with piston boot, and install cylinder-side

lip on piston boot properly into groove on cylinder body.

3. Press piston into cylinder body by hand to assemble piston-side lip on piston boot properly into a groove on piston.

CAUTION:

Press piston evenly and change pressing point to prevent

inner wall of cylinder from being rubbed.

4. Install sliding pins and sliding pin boots to the torque member.

5. Install pads, shims, pad return spring (AD22VK) and pad retainers on the torque member. Refer to BR-26,

"Removal and Installation of Brake Pad".

6. Install cylinder body to torque member.

7. Tighten sliding pin bolts to specified torque. Refer to BR-25, "

Component".

8. Install the caliper assembly. Refer to BR-30, "

Removal and Installation of Brake Caliper Assembly".

Standard thickness (new) : Refer to

BR-42, "

Front

Disc Brake".

Repair limit thickness : Refer to BR-42, "

Front

Disc Brake".

Maximum uneven wear

(measured at 8 positions) : Refer to

BR-42, "

Front

Disc Brake".

SBR020B

SFIA2278E

SFIA3074E

SFIA2279E

Revision: January 20102010 Versa

Page 888 of 3745

BR-40

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005397007

HR16DE

MR18DE

TypeWith ABS only or VDC/TCS/ABSWithout ABS

Front brake Brake model AD22VK

Cylinder bore diameter 53.97 mm (2.125 in)

Pad

Length × width × thickness 115.0 mm ×

41.0 mm × 9.0 mm

(4.528 in × 1.614 in × 0.354 in)

Rotor outer diameter × thickness 260 mm × 22.0 mm (10.24 in × 0.866 in)

Rear brake Brake model LT20

Cylinder bore diameter 15.87 mm (0.625 in)17.46 mm (0.687 in)

Drum inner diameter 203 mm (7.992 in)

Master cylinder Cylinder bore diameter 22.22 mm (0.875 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Front brake Brake modelCLZ25VF

Cylinder bore diameter 57.2 mm (2.252 in)

Pad

Length × width × thickness 125.6 mm

× 48.0 mm × 9.5 mm

(4.945 in × 1.890 in × 0.374 in)

Rotor outer diameter × thickness 280 mm × 24.0 mm (11.02 in × 0.945 in)

Rear brake Brake model LT23

Cylinder bore diameter 19.06 mm (0.750 in)

Drum inner diameter 228.6 mm (9.000 in)

Master cylinder Cylinder bore diameter 23.81 ± 0.015 mm (0.937 ± 0.001 in)

Brake booster Booster model C255

Diaphragm diameter 255 mm (10.04 in)

Recommended brake fluid DOT 3

Revision: January 20102010 Versa

Page 889 of 3745

SERVICE DATA AND SPECIFICATIONS (SDS)BR-41

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

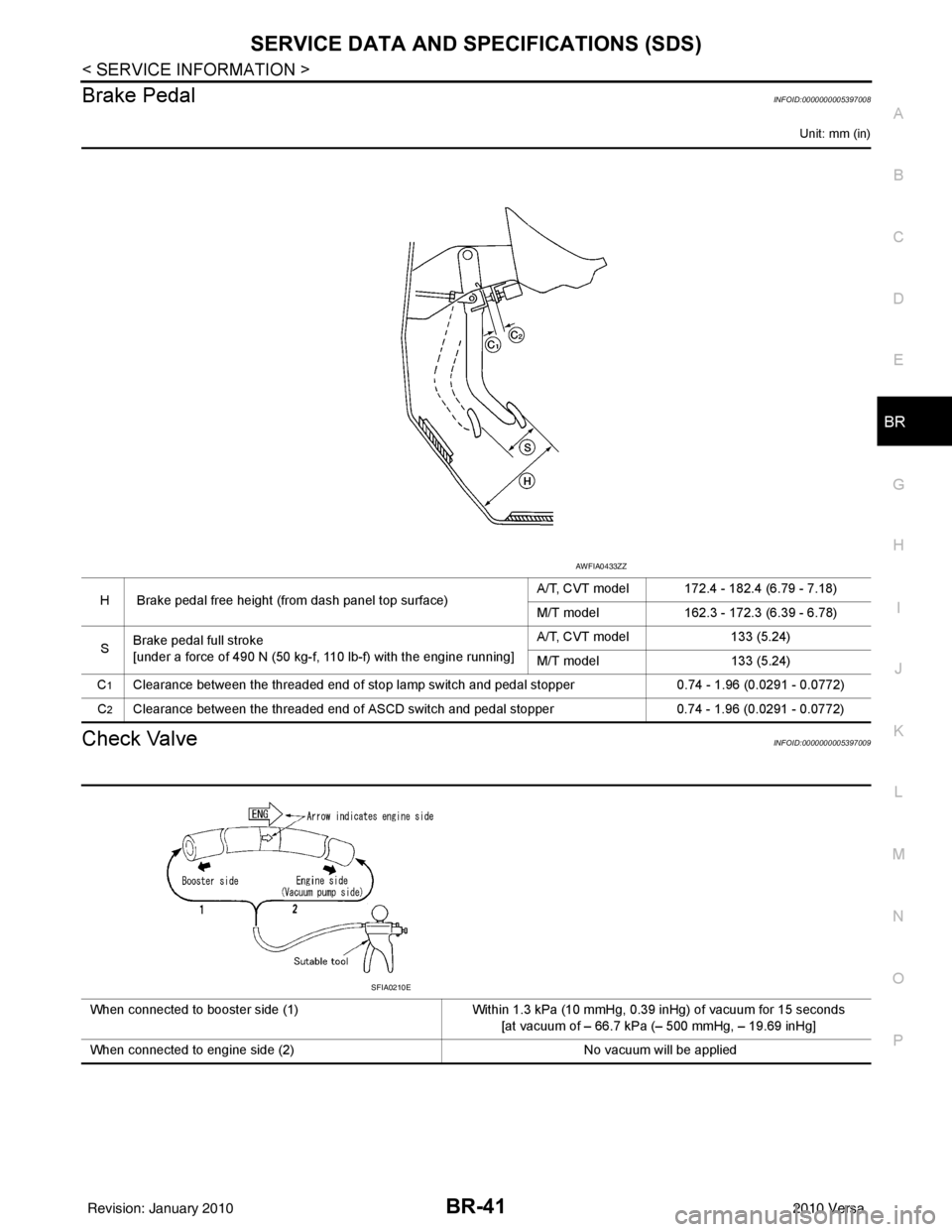

Brake PedalINFOID:0000000005397008

Unit: mm (in)

Check ValveINFOID:0000000005397009

H Brake pedal free height (from dash panel top surface) A/T, CVT model 172.4 - 182.4 (6.79 - 7.18)

M/T model

162.3 - 172.3 (6.39 - 6.78)

S Brake pedal full stroke

[under a force of 490 N (50 kg-f, 110 lb-f) with the engine running] A/T, CVT model

133 (5.24)

M/T model 133 (5.24)

C

1Clearance between the threaded end of stop lamp switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772)

C

2Clearance between the threaded end of ASCD switch and pedal stopper 0.74 - 1.96 (0.0291 - 0.0772)

AWFIA0433ZZ

When connected to booster side (1)Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 seconds

[at vacuum of – 66.7 kPa (– 500 mmHg, – 19.69 inHg]

When connected to engine side (2) No vacuum will be applied

SFIA0210E

Revision: January 20102010 Versa

Page 890 of 3745

BR-42

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

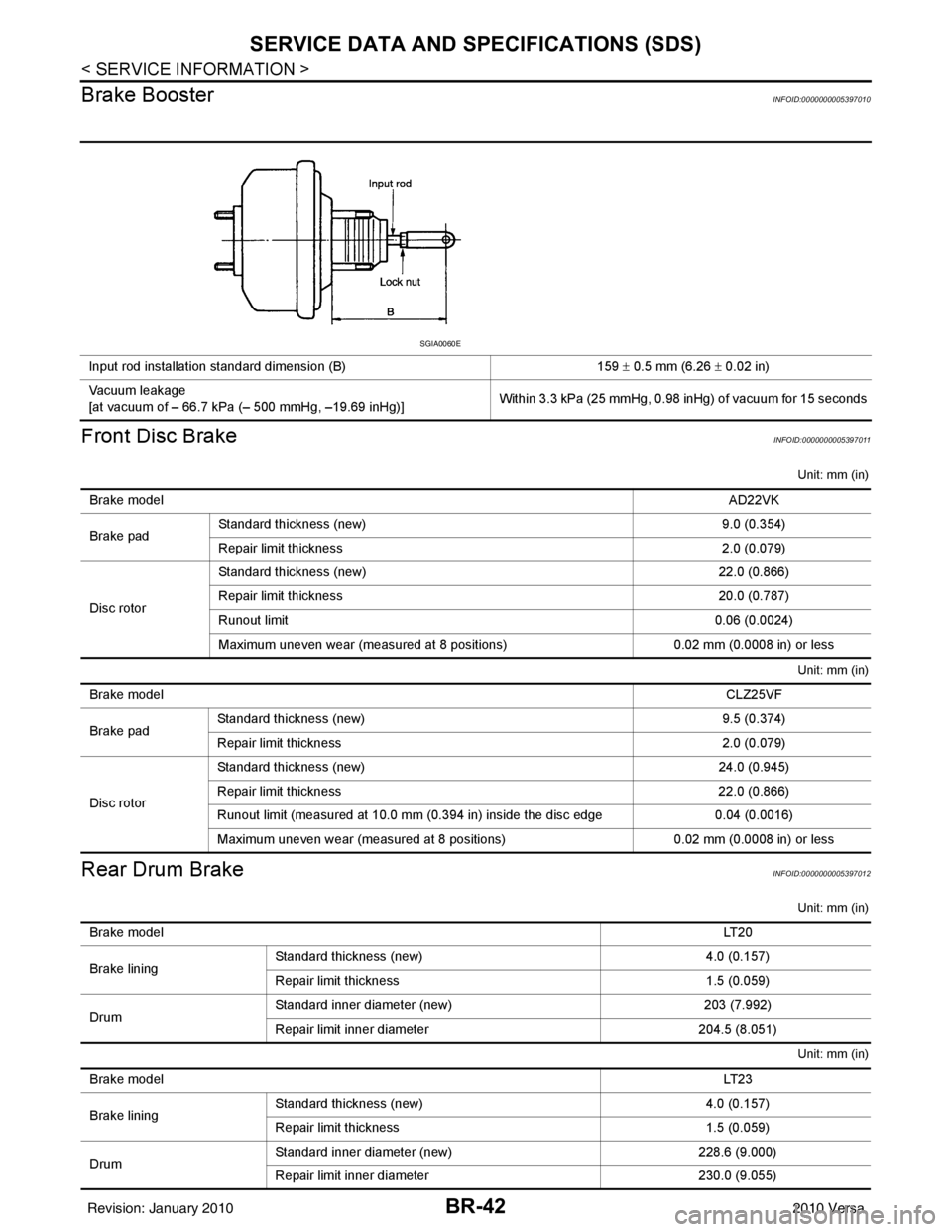

Brake Booster

INFOID:0000000005397010

Front Disc BrakeINFOID:0000000005397011

Unit: mm (in)

Unit: mm (in)

Rear Drum BrakeINFOID:0000000005397012

Unit: mm (in)

Unit: mm (in)

Input rod installation standard dimension (B) 159 ± 0.5 mm (6.26 ± 0.02 in)

Vacuum leakage

[at vacuum of – 66.7 kPa (– 500 mmHg, –19.69 inHg)] Within 3.3 kPa (25 mmHg, 0.98 inHg) of vacuum for 15 seconds

SGIA0060E

Brake model

AD22VK

Brake pad Standard thickness (new)

9.0 (0.354)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

22.0 (0.866)

Repair limit thickness 20.0 (0.787)

Runout limit 0.06 (0.0024)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model CLZ25VF

Brake pad Standard thickness (new)

9.5 (0.374)

Repair limit thickness 2.0 (0.079)

Disc rotor Standard thickness (new)

24.0 (0.945)

Repair limit thickness 22.0 (0.866)

Runout limit (measured at 10.0 mm (0.394 in) inside the disc edge 0.04 (0.0016)

Maximum uneven wear (measured at 8 positions) 0.02 mm (0.0008 in) or less

Brake model LT 2 0

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

Revision: January 20102010 Versa

Page 916 of 3745

![NISSAN TIIDA 2010 Service Owners Manual BRC-26

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Wheel Sensor SystemINFOID:0000000005397040

INSPECTION PROCEDURE

1.CONNECTOR NISSAN TIIDA 2010 Service Owners Manual BRC-26

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Wheel Sensor SystemINFOID:0000000005397040

INSPECTION PROCEDURE

1.CONNECTOR](/img/5/57397/w960_57397-915.png)

BRC-26

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS FOR

SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Wheel Sensor SystemINFOID:0000000005397040

INSPECTION PROCEDURE

1.CONNECTOR INSPECTION

Disconnect the ABS actuator and electric unit (control unit) connector E33 and wheel sensor of malfunctioning

code.

Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace as necessary.

2.CHECK WHEEL SENSOR OUTPUT SIGNAL

1. Connect ABS active wheel sensor tester (J-45741) to wheel sensor using appropriate adapter.

2. Turn on the ABS active wheel sensor tester power switch. NOTE:

The green POWER indicator should illuminate. If the POWER indicator does not illuminate, replace the

battery in the ABS active wheel sensor tester before proceeding.

3. Spin the wheel of the vehicle by hand and observe the red SENSOR indicator on the ABS active wheel

sensor tester. The red SENSOR indicator should flash on and off to indicate an output signal.

NOTE:

If the red SENSOR indicator illuminates but does not flash, reverse the polarity of the tester leads and

retest.

Does the ABS active wheel sensor tester detect a signal?

YES >> GO TO 3.

NO >> Replace the wheel sensor. Refer to BRC-34, "

Removal and Installation".

3.CHECK TIRES

Check for inflation pressure, wear and size of each tire. Refer to WT-28

.

Are tire pressure and size correct and is tire wear within specifications?

YES >> GO TO 4.

NO >> Adjust tire pressure or replace tire(s).

4.CHECK WHEEL BEARINGS

Check wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" or RAX-6, "On-Vehi-

cle Inspection and Service".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace as necessary. Refer to FA X - 6 , "

Removal and Installation" or RAX-6, "Removal

and Installation".

5.CHECK WIRING HARNESS FOR SHORT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and elec tric unit (control unit) connec-

tor and wheel sensor connector of malfunction code No.

3. Check continuity between wheel sensor harness connector ter- minals and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair the circuit.

6.CHECK WIRING HARNESS FOR OPEN CIRCUIT Continuity should not exist.

WFIA0498E

Revision: January 20102010 Versa