specifications NISSAN TIIDA 2010 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 1209 of 3745

![NISSAN TIIDA 2010 Service Service Manual CVT-176

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005398014

*1: Refer to MA-14, "Fluids and Lubric NISSAN TIIDA 2010 Service Service Manual CVT-176

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005398014

*1: Refer to MA-14, "Fluids and Lubric](/img/5/57397/w960_57397-1208.png)

CVT-176

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000005398014

*1: Refer to MA-14, "Fluids and Lubricants" .

Vehicle Speed When Shifting GearsINFOID:0000000005398015

Numerical value data are reference values.

CAUTION:

Lock-up clutch is engaged when vehicle speed is approximately 18 km/h (11 MPH) to 90 km/h (56 MPH).

Stall SpeedINFOID:0000000005398016

Line PressureINFOID:0000000005398017

Applied model

MR18DE engine

CVT model RE0F08B

CVT assembly Model code number 1XC6C

Transmission gear ratio “D” position

Variable

Reverse 2.689

Final drive 5.473

Recommended fluid NISSAN CVT Fluid NS-2*1

Fluid capacity 7.4 liter (7-7/8 US qt, 6-1/2 Imp qt)

CAUTION:

• Use only Genuine NISSAN CVT Fluid NS-2. Do not mix with other fluid.

• Using CVT fluid other than Genuine NISSAN CVT Fluid NS-2 will deteriorate in driveability and CVT durability, and may dam- age the CVT, which is not covered by the warranty.

Engine type Throttle position Shift pattern Engine speed (rpm)

At 40 km/h (25 MPH) At 60 km/h (37 MPH)

MR18DE 8/8

“D” position

Overdrive-off mode “L” position 3,600 - 4,500

4,400 - 5,300

2/8 “D” position

1,300 - 3,100 1,400 - 3,500

Overdrive-off mode 2,200 - 3,000 2,800 - 3,600

“L” position 3,100 - 4,000 3,800 - 4,700

Stall speed 2,600 - 3,150 rpm

Engine speed Line pressure kPa (kg/cm

2 , psi)

“R”, “D” and “L” positions

At idle 650 (6.63, 94.3)

At stall 4,250 (43.35, 616.3)

Revision: January 20102010 Versa

Page 1210 of 3745

![NISSAN TIIDA 2010 Service Service Manual SERVICE DATA AND SPECIFICATIONS (SDS)CVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Solenoid ValvesINFOID:0000000005398018

CVT Fluid Temperature SensorINFOID:0000000005398 NISSAN TIIDA 2010 Service Service Manual SERVICE DATA AND SPECIFICATIONS (SDS)CVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Solenoid ValvesINFOID:0000000005398018

CVT Fluid Temperature SensorINFOID:0000000005398](/img/5/57397/w960_57397-1209.png)

SERVICE DATA AND SPECIFICATIONS (SDS)CVT-177

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Solenoid ValvesINFOID:0000000005398018

CVT Fluid Temperature SensorINFOID:0000000005398019

Primary Speed SensorINFOID:0000000005398020

Secondary Speed SensorINFOID:0000000005398021

Removal and InstallationINFOID:0000000005398022

Name Resistance (Approx.) Terminal

secondary pressure solenoid valve 3 - 9 Ω3

Line pressure solenoid valve 2

Torque converter clutch solenoid valve 12

Lock-up select solenoid valve 6 - 19Ω 13

NameCondition CONSULT-III “DATA MONI TOR” (Approx.) Resistance (Approx.)

AT F T E M P S E N 20

°C (68 °F) 2.0 V 6.5 kΩ

80 °C (176 °F) 1.0 V 0.9 kΩ

Name ConditionData (Approx.)

Primary speed sensor When driving [“L” position, 20 km/h (12 MPH)]. 1250 Hz

NameConditionData (Approx.)

Secondary speed sensor When driving [“D” position, 20 km/h (12 MPH)]. 570 Hz

Distance between end of converter housing and torque converter 14.4 mm (0.57 in)

Revision: January 20102010 Versa

Page 1220 of 3745

DI-10

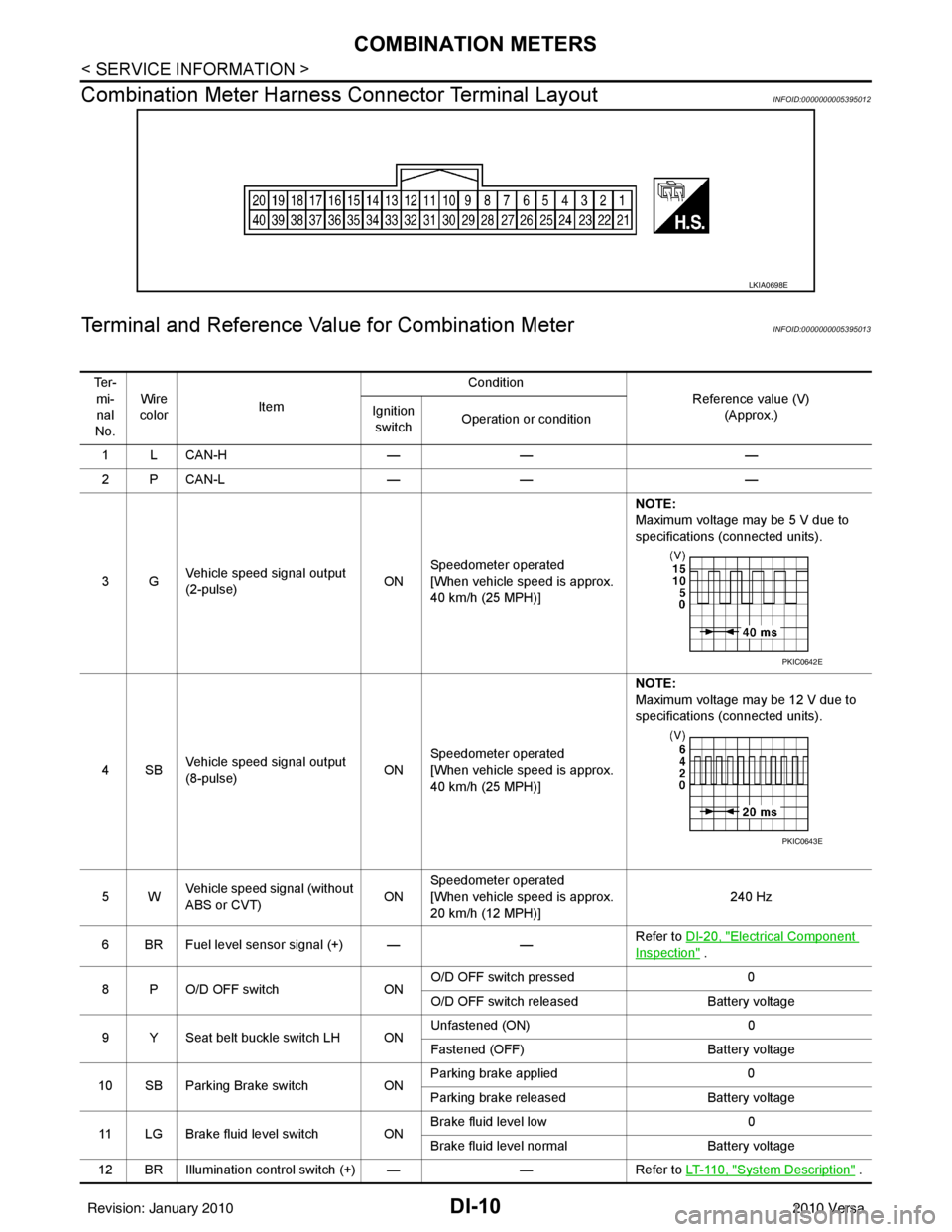

< SERVICE INFORMATION >

COMBINATION METERS

Combination Meter Harness Connector Terminal Layout

INFOID:0000000005395012

Terminal and Reference Va lue for Combination MeterINFOID:0000000005395013

LKIA0698E

Te r -

mi-nal

No. Wire

color Item Condition

Reference value (V)(Approx.)

Ignition

switch Operation or condition

1LCAN-H —— —

2PCAN-L —— —

3G Vehicle speed signal output

(2-pulse) ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)] NOTE:

Maximum voltage may be 5 V due to

specifications (connected units).

4SB Vehicle speed signal output

(8-pulse) ONSpeedometer operated

[When vehicle speed is approx.

40 km/h (25 MPH)] NOTE:

Maximum voltage may be 12 V due to

specifications (connected units).

5W Vehicle speed signal (without

ABS or CVT) ONSpeedometer operated

[When vehicle speed is approx.

20 km/h (12 MPH)] 240 Hz

6 BR Fuel level sensor signal (+) — —Refer to DI-20, "

Electrical Component

Inspection" .

8 P O/D OFF switch ONO/D OFF switch pressed

0

O/D OFF switch released Battery voltage

9 Y Seat belt buckle switch LH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake applied

0

Parking brake released Battery voltage

11 LG Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

12 BR Illumination control switch (+) — —Refer to LT- 11 0 , "

System Description" .

PKIC0642E

PKIC0643E

Revision: January 20102010 Versa

Page 1272 of 3745

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

FUEL PRESSURE .......................................... ..496

Inspection ............................................................ ..496

EVAP LEAK CHECK ........................................498

Inspection ............................................................ ..498

ON-VEHICLE REPAIR ...............................500

EVAP CANISTER .............................................500

Exploded View .................................................... ..500

Removal and Installation .......................................500

Inspection ............................................................ ..501

SERVICE DATA AND SPECIFICATIONS

(SDS) ......... ................................. ................

502

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

502

Idle Speed ........................................................... ..502

Ignition Timing .......................................................502

Calculated Load Value ..........................................502

Mass Air Flow Sensor ...........................................502

MR18DE

SERVICE INFORMATION .. .......................

503

INDEX FOR DTC ............................................ ..503

U0101-U1001 ...................................................... ..503

P0011-P0075 ........................................................503

P0101-P0128 ........................................................503

P0130-P0183 ........................................................504

P0222-P0420 ........................................................504

P0441-P0463 ........................................................505

P0500-P0643 ........................................................505

P0705-P0734 ........................................................506

P0740-P0840 ........................................................506

P0850-P1574 ........................................................507

P1610-P1615 ........................................................507

P1715-P1805 ........................................................507

P2100-P2A00 ........................................................508

PRECAUTIONS ................................................509

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ..

509

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ..

509

Precaution for Procedure without Cowl Top Cover ..510

On Board Diagnosis (OBD) System of Engine and

A/T, CVT ...............................................................

510

Precaution .............................................................510

PREPARATION ................................................514

Special Service Tool ........................................... ..514

Commercial Service Tool ......................................514

ENGINE CONTROL SYSTEM ..........................516

Schematic ........................................................... ..516

Multiport Fuel Injection (MFI) System ...................516

Electronic Ignition (EI) System ..............................519

Fuel Cut Control (at No Load and High Engine

Speed) ................................................................. ..

519

AIR CONDITIONING CUT CONTROL ............521

Input/Output Signal Chart ......................................521

System Description ................................................521

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ............................................................

522

System Description ................................................522

Component Description .........................................523

CAN COMMUNICATION .................................524

System Description ................................................524

EVAPORATIVE EMISSION SYSTEM .............525

Description .............................................................525

Component Inspection ...........................................527

Exploded View .......................................................529

Removal and Installation .......................................529

How to Detect Fuel Vapor Leakage .......................530

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ....................................................

532

System Description ................................................532

Diagnosis Procedure .............................................532

Component Inspection ...........................................535

POSITIVE CRANKCASE VENTILATION .......538

Description .............................................................538

Component Inspection ...........................................538

NVIS (NISSAN VEHICLE IMMOBILIZER SYS-

TEM-NATS) .....................................................

540

Description .............................................................540

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..541

Introduction ............................................................541

Two Trip Detection Logic .......................................541

Emission-related Diagnostic Information ...............542

Malfunction Indicator Lamp (MIL) ..........................565

OBD System Operation Chart ...............................568

BASIC SERVICE PROCEDURE .....................574

Basic Inspection ....................................................574

Idle Speed and Ignition Timing Check ...................578

Procedure After Replacing ECM ...........................579

VIN Registration ....................................................580

Accelerator Pedal Released Position Learning .....580

Throttle Valve Closed Position Learning ...............580

Idle Air Volume Learning .......................................580

Fuel Pressure Check .............................................582

TROUBLE DIAGNOSIS ..................................585

Trouble Diagnosis Introduction ..............................585

DTC Inspection Priority Chart ................................590

Fail-Safe Chart ......................................................590

Symptom Matrix Chart ...........................................592

Engine Control Component Parts Location ...........596

Vacuum Hose Drawing ..........................................602

Circuit Diagram ......................................................603

Revision: January 20102010 Versa

Page 1279 of 3745

EC-14

Wiring Diagram ....................................................1010

Diagnosis Procedure ...........................................1011

Component Inspection .........................................1013

Removal and Installation .....................................1013

FUEL PUMP ....................................................1014

Description ...........................................................1014

CONSULT-III Reference Value in Data Monitor

Mode ....................................................................

1014

Wiring Diagram ....................................................1015

Diagnosis Procedure ...........................................1016

Component Inspection .........................................1018

Removal and Installation .....................................1018

IGNITION SIGNAL ..........................................1019

Component Description .......................................1019

Wiring Diagram ....................................................1020

Diagnosis Procedure ...........................................1023

Component Inspection .........................................1026

Removal and Installation .....................................1027

REFRIGERANT PRESSURE SENSOR .........1028

Component Description .......................................1028

Wiring Diagram ....................................................1029

Diagnosis Procedure ............................................1030

Removal and Installation ......................................1032

MIL AND DATA LINK CONNECTOR .............1033

Wiring Diagram ....................................................1033

SERVICE DATA AND SPECIFICATIONS

(SDS) ..............................................................

1035

Fuel Pressure .......................................................1035

Idle Speed and Ignition Timing ............................1035

Calculated Load Value .........................................1035

Mass Air Flow Sensor ..........................................1035

Intake Air Temperature Se nsor ............................1035

Engine Coolant Temperature Sensor ..................1035

Air Fuel Ratio (A/F) Sensor 1 Heater ...................1036

Heated Oxygen sensor 2 Heater .........................1036

Crankshaft Position Sensor (POS) ......................1036

Camshaft Position Sensor (PHASE) ....................1036

Throttle Control Motor ...... ....................................1036

Fuel Injector .........................................................1036

Fuel Pump ............................................................1036

Revision: January 20102010 Versa

Page 1767 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-502

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000005398 NISSAN TIIDA 2010 Service Service Manual EC-502

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000005398](/img/5/57397/w960_57397-1766.png)

EC-502

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Idle SpeedINFOID:0000000005398655

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Ignition TimingINFOID:0000000005398656

*: Under the following conditions

• A/C switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000005398657

Mass Air Flow SensorINFOID:0000000005398658

*: Engine is warmed up to normal operating temperature and running under no load.Transmission

ConditionSpecification

A/T No load* (in P or N position) 700 ± 50 rpm

M/T No load* (in Neutral position) 650 ± 50 rpm

Transmission ConditionSpecification

A/T No load* (in P or N position) 6 ± 5 °BTDC

M/T No load* (in Neutral position) 6 ± 5 °BTDC

Condition Specification (Using CONSULT-III or GST)

At idle 10 – 35 %

At 2,500 rpm 10 – 35 %

Supply voltageBattery voltage (11 – 14 V)

Output voltage at idle 0.9 – 1.3V*

Mass air flow (Using CONSULT-III or GST) 1.0 – 4.0 g·m/sec at idle*

2.0 – 10.0 g·m/sec at 2,500 rpm*

Revision: January 20102010 Versa

Page 1846 of 3745

![NISSAN TIIDA 2010 Service Service Manual BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with NISSAN TIIDA 2010 Service Service Manual BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with](/img/5/57397/w960_57397-1845.png)

BASIC SERVICE PROCEDUREEC-581

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Electric load switch: OFF

[Air conditioner, headlamp, rear window defogger]

On vehicles equipped with daytime light systems, if the parking brake is applied before the engine is

started the headlamp will not be illuminated.

• Steering wheel: Neutral (Straight-ahead position)

• Vehicle speed: Stopped

• Transmission: Warmed-up

- Models with CONSULT-III (A/T and CVT models)

• Drive vehicle until “FLUID TEMP SE” in “DATA MONI TOR” mode of “A/T” or “CVT” system indicates less

than 0.9 V.

- Models without CONSULT-III (A/T and CVT models) and M/T models

• Drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-III

1. Perform EC-580, "Accelerator Pedal Released Position Learning".

2. Perform EC-580, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEA RN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-III screen. If “CMPLT” is not displayed, Idle Air Vol-

ume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to

the DIAGNOSTIC PROCEDURE below.

8. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the specifications.

Refer to EC-574, "

Basic Inspection".

Without CONSULT-III

NOTE:

•It is better to count the time accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

1. Perform EC-580, "

Accelerator Pedal Released Position Learning".

2. Perform EC-580, "

Throttle Valve Closed Position Learning".

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic PREP ARATION (previously mentioned) are in good order.

5. Turn ignition switch OFF and wait at least 10 seconds.

6. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

7. Repeat the following procedure quick ly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

8. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 20 seconds until the MIL stops blinking and turned ON.

9. Fully release the accelerator pedal within 3 seconds after the MIL turned ON.

10. Start engine and let it idle.

Item Specification

Idle speed M/T: 700

± 50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

Ignition timing M/T: 13

± 5 ° BTDC (in Neutral position)

A/T: 13 ± 5° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

Revision: January 20102010 Versa

Page 1847 of 3745

![NISSAN TIIDA 2010 Service Service Manual EC-582

< SERVICE INFORMATION >[MR18DE]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the

specificat NISSAN TIIDA 2010 Service Service Manual EC-582

< SERVICE INFORMATION >[MR18DE]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the

specificat](/img/5/57397/w960_57397-1846.png)

EC-582

< SERVICE INFORMATION >[MR18DE]

BASIC SERVICE PROCEDURE

11. Wait 20 seconds.

12. Rev up the engine two or three times and make sure that idle speed and ignition timing are within the

specifications. Refer to EC-574, "

Basic Inspection".

13. If idle speed and ignition timing are not within the specification, Idle Air Volume Learning will not be carried out successfully. In this case, find the cause of the incident by referring to the DIAGNOSTIC PROCE-

DURE below.

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1. Check that throttle valve is fully closed.

2. Check PCV valve operation.

3. Check that downstream of throttl e valve is free from air leakage.

4. When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and eliminate the cause of the incident.

It is useful to perform EC-624

.

5. If any of the following conditions occur after the engine has st arted, eliminate the cause of the

incident and perform Idle Air Volume Learning all over again:

- Engine stalls.

- Erroneous idle.

Fuel Pressure CheckINFOID:0000000005532411

FUEL PRESSURE RELEASE

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode with CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT-III

Item Specification

Idle speed M/T: 700 ±

50 rpm (in Neutral position)

A/T: 700 ± 50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

Ignition timing M/T: 13

± 5 ° BTDC (in Neutral position)

A/T: 13 ± 5 ° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

SEC897C

Revision: January 20102010 Versa

Page 2052 of 3745

![NISSAN TIIDA 2010 Service Service Manual DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-787

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

12.CHECK IGNITION TIMING

Check the following items. Re NISSAN TIIDA 2010 Service Service Manual DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-787

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

12.CHECK IGNITION TIMING

Check the following items. Re](/img/5/57397/w960_57397-2051.png)

DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-787

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

12.CHECK IGNITION TIMING

Check the following items. Refer to EC-574, "

Basic Inspection".

OK or NG

OK >> GO TO 13.

NG >> Follow the EC-574, "

Basic Inspection".

13.CHECK AIR FUEL RATIO (A/F) SENS OR 1 CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect air fuel ratio (A/F ) sensor 1 harness connector (1).

- Air fuel ratio (A/F) sensor 1 (2)

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals. Refer to Wiring Diagram.

5. Check harness continuity between ECM terminals 49, 53 or A/F sensor 1 terminals 1, 2 and ground.

Refer to Wiring Diagram.

6. Also check harness for short to power.

OK or NG

OK >> GO TO 14.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

14.CHECK AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Refer to EC-652, "

Component Inspection".

OK or NG

OK >> GO TO 16.

NG >> GO TO 15.

15.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

• Before installing new A/F senso r, clean exhaust system threads using Oxygen Sensor Thread

Cleaner tool J-43897-18 or J-43897-12 and approved anti-seize lubricant.

>> INSPECTION END

16.CHECK MASS AIR FLOW SENSOR

Items Specifications

Target idle speed A/T: 700 ±

50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13 ±

5° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in Neutral position)

M/T: 13 ± 5 ° BTDC (in Neutral position)

A/F sensor 1 terminal ECM terminal

14 9

25 3

Continuity should exist.

Continuity should not exist.

BBIA0699E

Revision: January 20102010 Versa

Page 2072 of 3745

![NISSAN TIIDA 2010 Service Service Manual DTC P0420 THREE WAY CATALYST FUNCTIONEC-807

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 5.

NG >> Follow the

EC-574, "

Basic Inspection".

5.CHECK FUEL INJECTO NISSAN TIIDA 2010 Service Service Manual DTC P0420 THREE WAY CATALYST FUNCTIONEC-807

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 5.

NG >> Follow the

EC-574, "

Basic Inspection".

5.CHECK FUEL INJECTO](/img/5/57397/w960_57397-2071.png)

DTC P0420 THREE WAY CATALYST FUNCTIONEC-807

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 5.

NG >> Follow the

EC-574, "

Basic Inspection".

5.CHECK FUEL INJECTOR

1. Stop engine and turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminals 25, 29, 30, 31 and ground with CONSULT-III or tester. Refer to Wiring Diagram for fuel injectors, EC-1010, "

Wiring Diagram".

OK or NG

OK >> GO TO 6.

NG >> Perform EC-1011, "

Diagnosis Procedure".

6.CHECK FUNCTION OF IGNITION COIL-I

CAUTION:

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump (1) fuse in IPDM E/R (2) to release fuel pres- sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoid the electri- cal discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is

generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coilwithin 50 cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20 kV or more.

Items Specifications

Target idle speed A/T: 700 ±

50 rpm (in P or N position)

CVT: 700 ± 50 rpm (in P or N position)

M/T: 700 ± 50 rpm (in Neutral position)

Ignition timing A/T: 13 ±

5° BTDC (in P or N position)

CVT: 13 ± 5 ° BTDC (in P or N position)

M/T: 13 ± 5 ° BTDC (in Neutral position)

Voltage: Battery voltage

Spark should be generated.

PBIB2958E

PBIB2325E

Revision: January 20102010 Versa