transmission oil NISSAN TIIDA 2010 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 213 of 3745

AT-196

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Engine Speed Does Not Return to Idle (Light Braking D4→ D3)INFOID:0000000005397407

SYMPTOM:

Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 on “Cruise Test — Part

1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-405, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Overrun clutch control valve

- Overrun clutch reducing valve

- Overrun clutch solenoid valve

Revision: January 20102010 Versa

Page 217 of 3745

AT-200

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

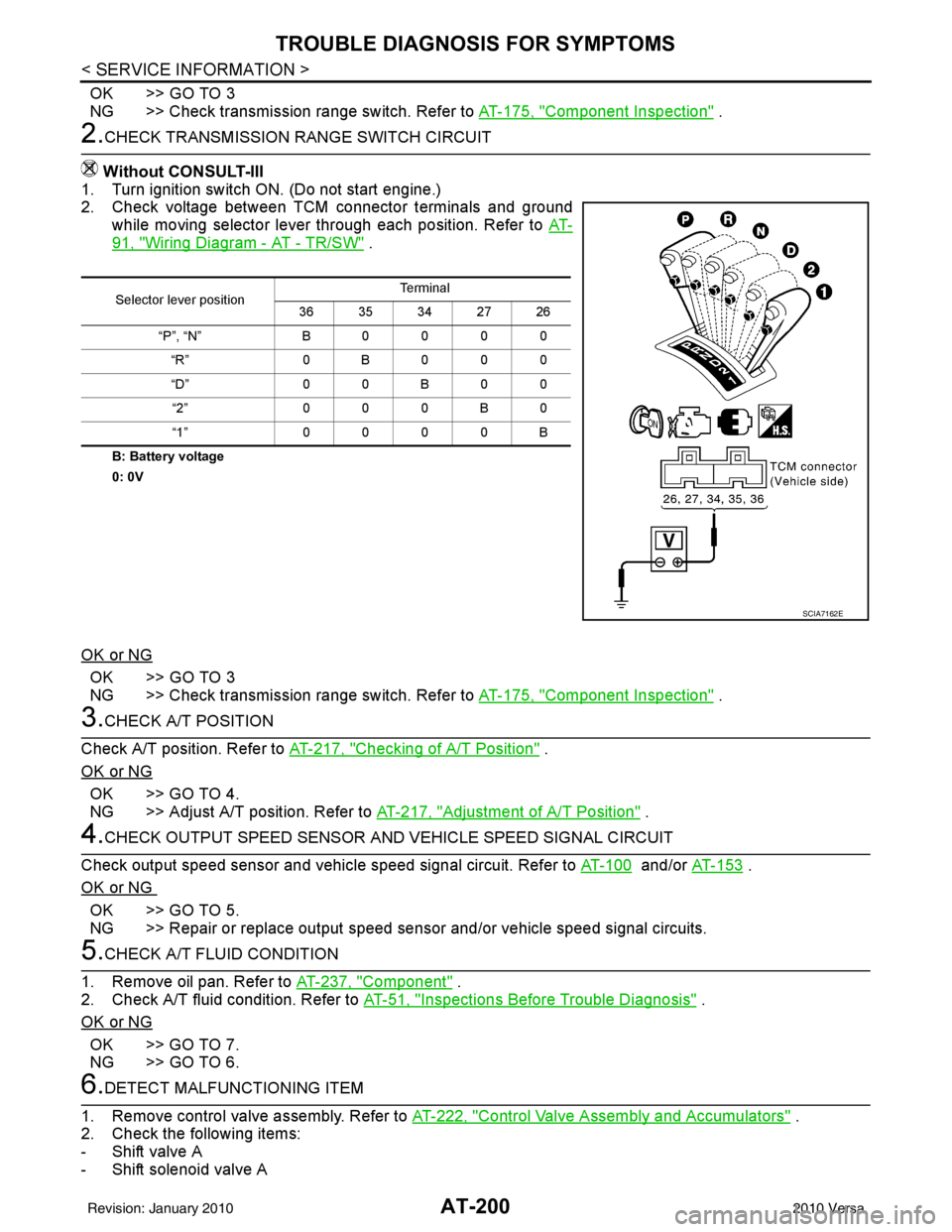

2.CHECK TRANSMISSION RANGE SWITCH CIRCUIT

Without CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Check voltage between TCM connector terminals and ground

while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 3

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

3.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 4.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

4.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and/or AT-153 .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace output speed sens or and/or vehicle speed signal circuits.

5.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift solenoid valve A

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B0000 “R” 0B000

“D” 0 0 B 0 0

“2” 000B0

“1” 0000B

SCIA7162E

Revision: January 20102010 Versa

Page 220 of 3745

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-203

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

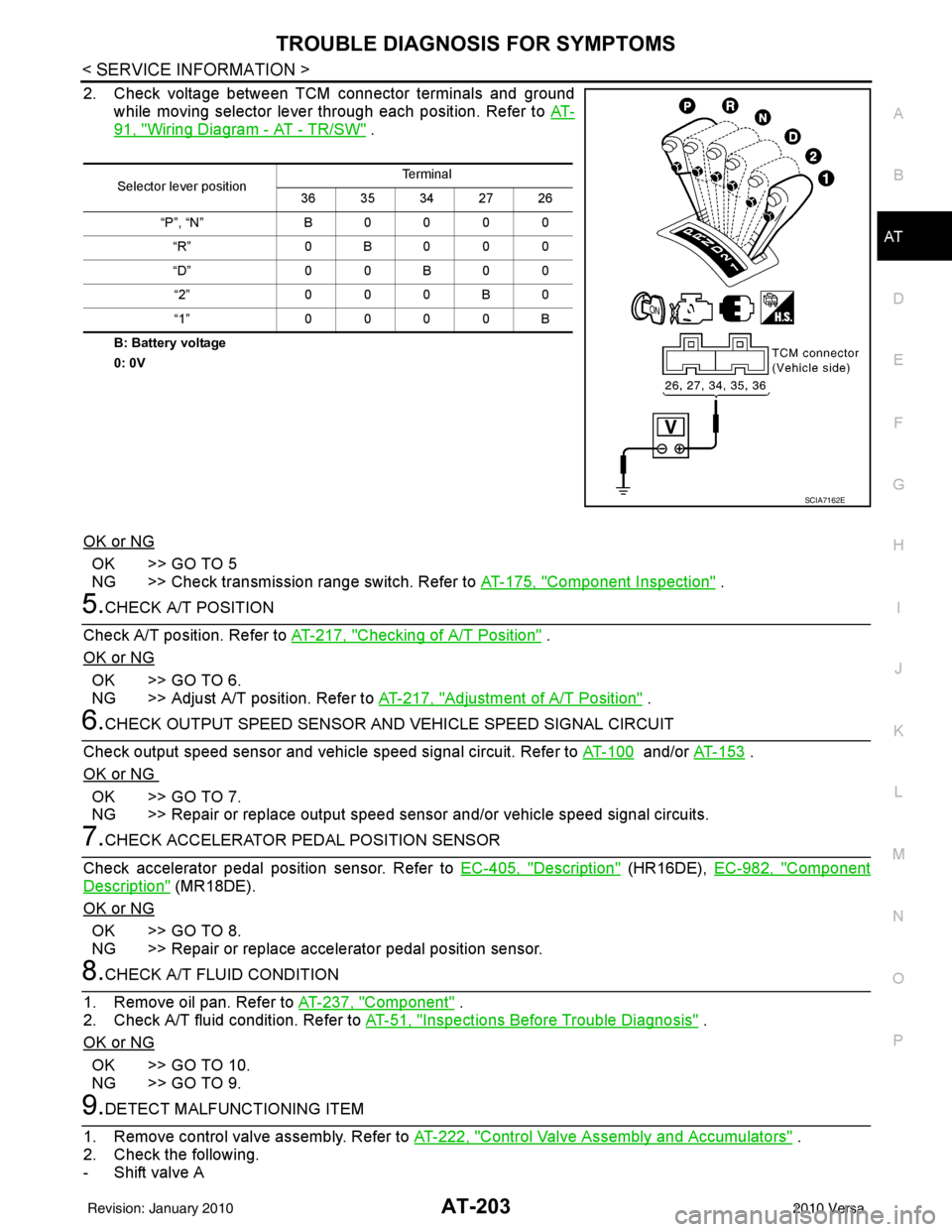

2. Check voltage between TCM connector terminals and ground while moving selector lever through each position. Refer to AT-

91, "Wiring Diagram - AT - TR/SW" .

B: Battery voltage

0: 0V

OK or NG

OK >> GO TO 5

NG >> Check transmission range switch. Refer to AT-175, "

Component Inspection" .

5.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 6.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

6.CHECK OUTPUT SPEED SENSOR AND VEHICLE SPEED SIGNAL CIRCUIT

Check output speed sensor and vehicle speed signal circuit. Refer to AT-100

and/or AT- 1 5 3 .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace output speed sensor and/or vehicle speed signal circuits.

7.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-405, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 8.

NG >> Repair or replace accelerator pedal position sensor.

8.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 9.

9.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following.

- Shift valve A

Selector lever position Te r m i n a l

36 35 34 27 26

“P”, “N” B 0 0 0 0

“R” 0B000

“D” 0 0 B 0 0

“2” 0 0 0 B 0

“1” 0 0 0 0 B

SCIA7162E

Revision: January 20102010 Versa

Page 242 of 3745

ON-VEHICLE SERVICEAT-225

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

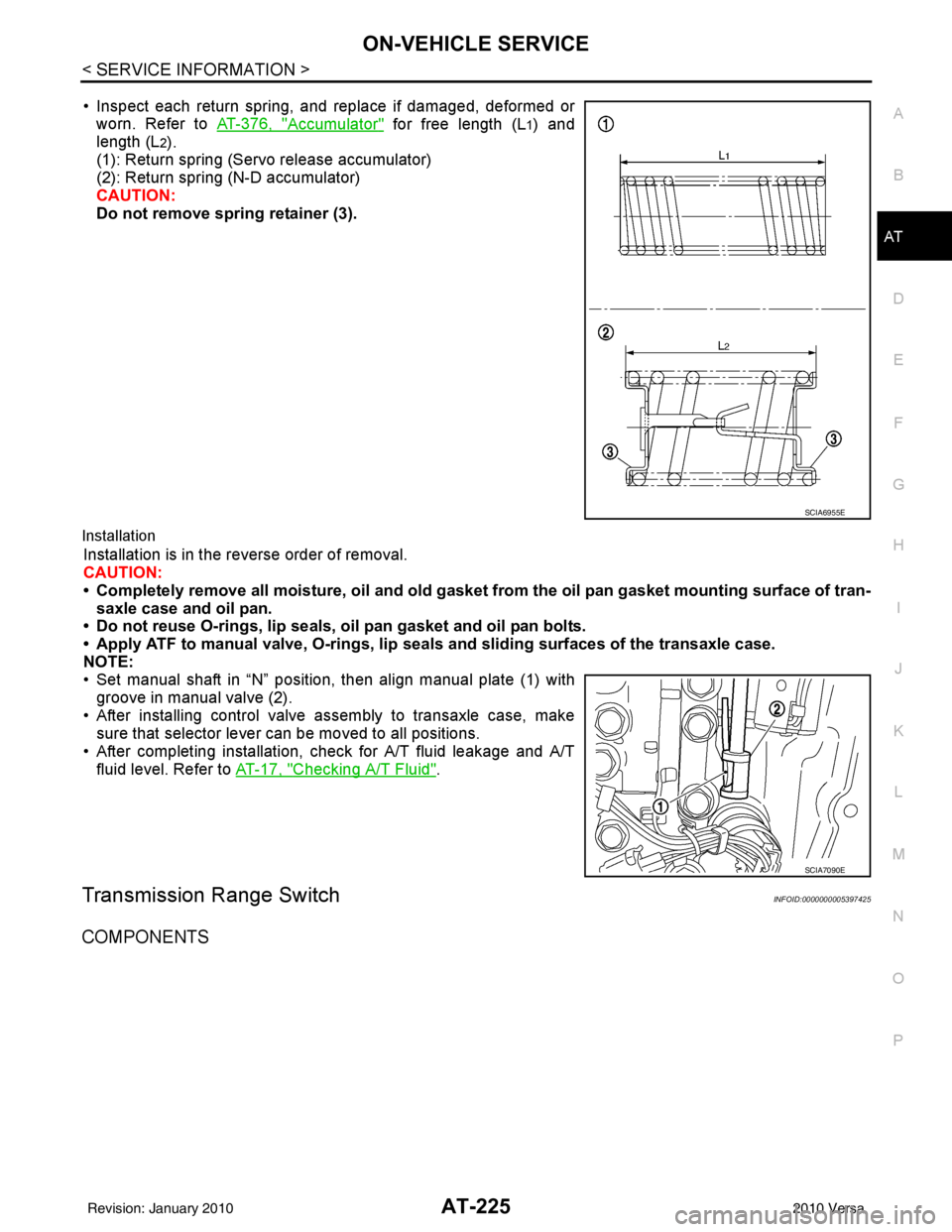

• Inspect each return spring, and replace if damaged, deformed or worn. Refer to AT-376, "

Accumulator" for free length (L1) and

length (L

2).

(1): Return spring (Servo release accumulator)

(2): Return spring (N-D accumulator)

CAUTION:

Do not remove spring retainer (3).

Installation

Installation is in the reverse order of removal.

CAUTION:

• Completely remove all moisture, oil and old gasket from the oil pan gasket mounting surface of tran-

saxle case and oil pan.

• Do not reuse O-rings, lip seals, oil pan gasket and oil pan bolts.

• Apply ATF to manual valve, O-rings, lip seals and sliding surfaces of the transaxle case.

NOTE:

• Set manual shaft in “N” position, then align manual plate (1) with groove in manual valve (2).

• After installing control valve assembly to transaxle case, make sure that selector lever can be moved to all positions.

• After completing installation, check for A/T fluid leakage and A/T fluid level. Refer to AT-17, "

Checking A/T Fluid".

Transmission Range SwitchINFOID:0000000005397425

COMPONENTS

SCIA6955E

SCIA7090E

Revision: January 20102010 Versa

Page 252 of 3745

TRANSAXLE ASSEMBLYAT-235

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• When replacing an engine or transmission you must make sure any dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive

train components.

• Do not reuse O-rings and copper washers. Refer to "COMPONENTS".

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the bolts for th e torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-156

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

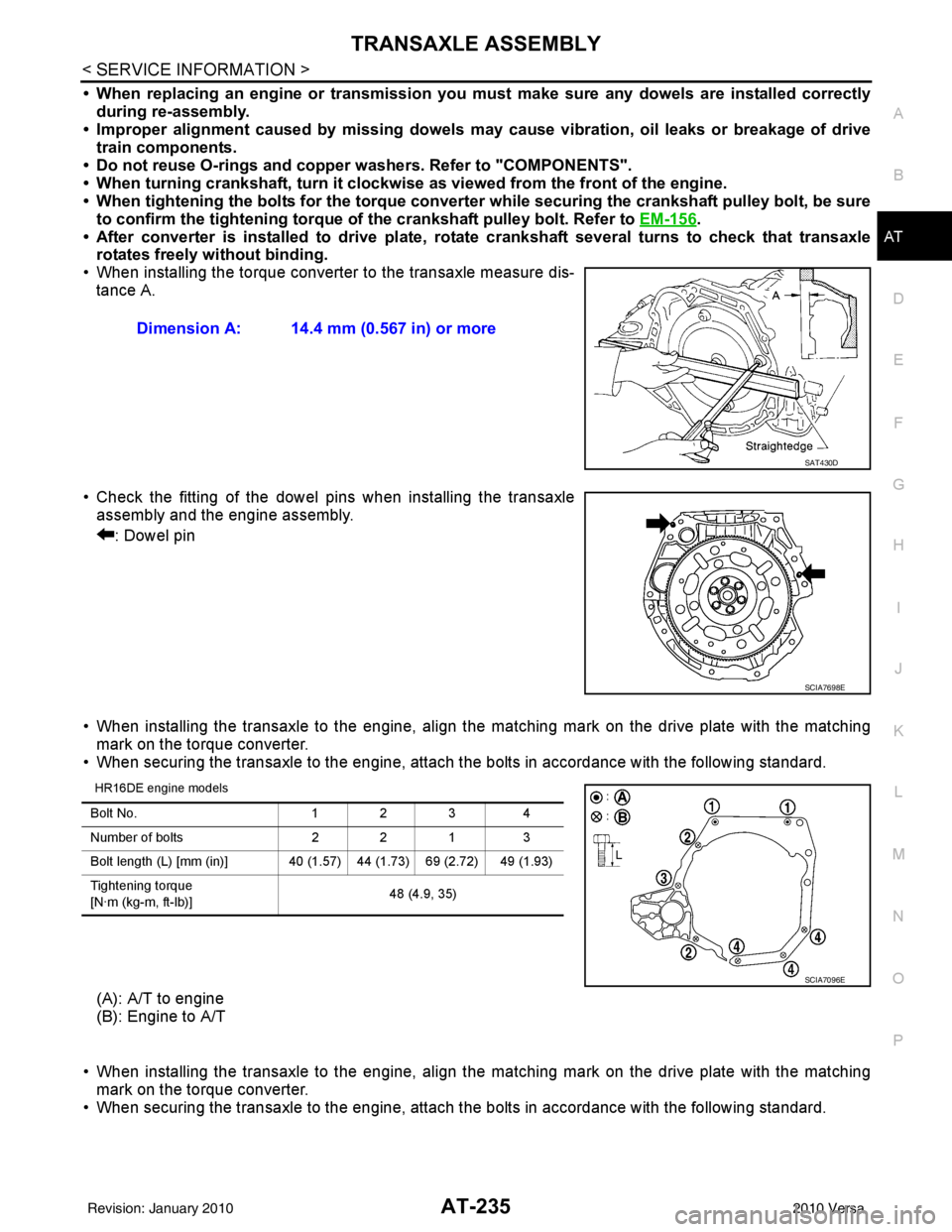

• When installing the torque converter to the transaxle measure dis- tance A.

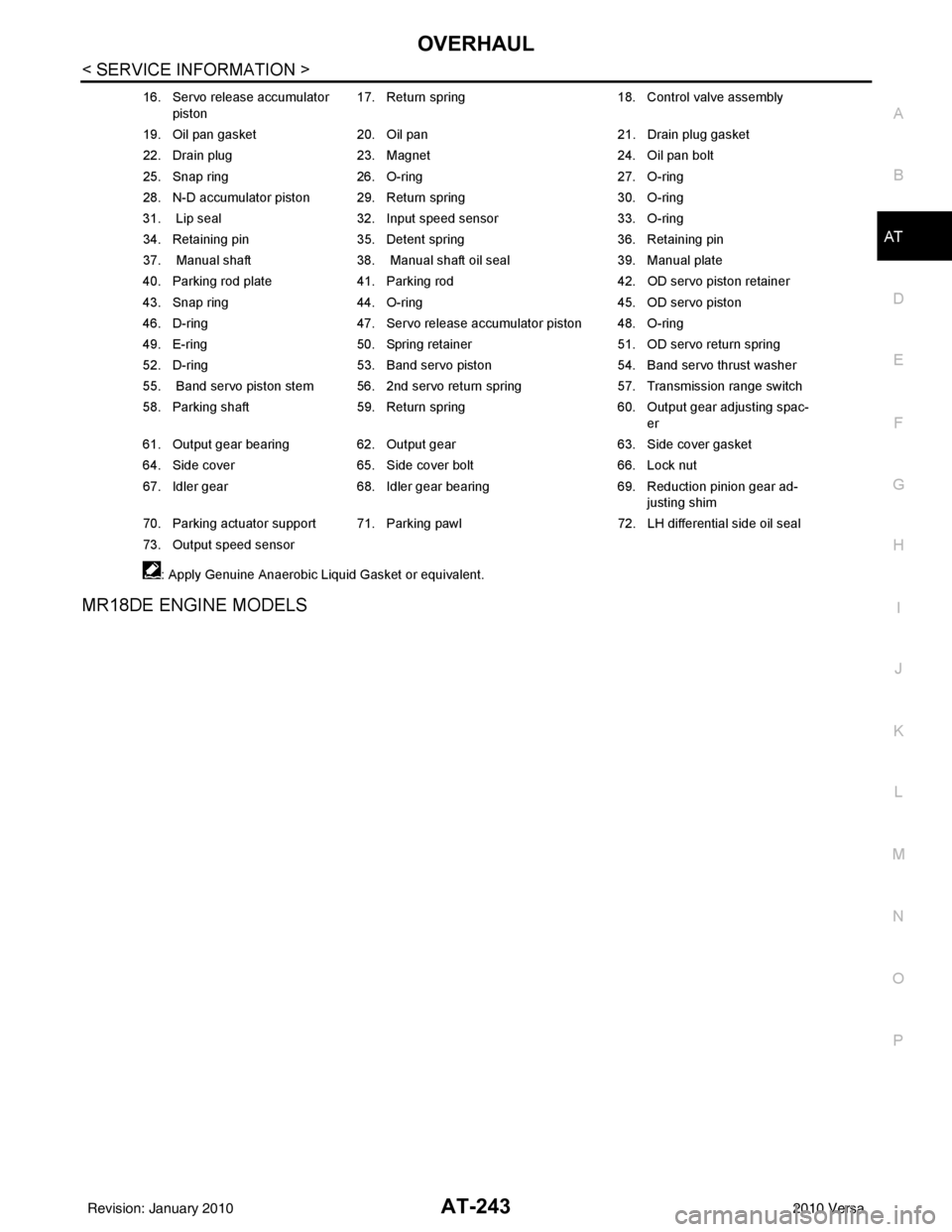

• Check the fitting of the dowel pins when installing the transaxle assembly and the engine assembly.

: Dowel pin

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard.

HR16DE engine models

(A): A/T to engine

(B): Engine to A/T

• When installing the transaxle to the engine, align the matching mark on the drive plate with the matching mark on the torque converter.

• When securing the transaxle to the engine, attach the bolts in accordance with the following standard. Dimension A: 14.4 mm (0.567 in) or more

SAT430D

SCIA7698E

Bolt No.

1 2 34

Number of bolts 2 2 13

Bolt length (L) [mm (in)] 40 (1.5 7) 44 (1.73) 69 (2.72) 49 (1.93)

Tightening torque

[N·m (kg-m, ft-lb)] 48 (4.9, 35)

SCIA7096E

Revision: January 20102010 Versa

Page 260 of 3745

OVERHAULAT-243

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

MR18DE ENGINE MODELS

16. Servo release accumulator piston 17. Return spring

18. Control valve assembly

19. Oil pan gasket 20. Oil pan 21. Drain plug gasket

22. Drain plug 23. Magnet 24. Oil pan bolt

25. Snap ring 26. O-ring 27. O-ring

28. N-D accumulator piston 29. Return spring 30. O-ring

31. Lip seal 32. Input speed sensor 33. O-ring

34. Retaining pin 35. Detent spring 36. Retaining pin

37. Manual shaft 38. Manual shaft oil seal 39. Manual plate

40. Parking rod plate 41. Parking rod 42. OD servo piston retainer

43. Snap ring 44. O-ring 45. OD servo piston

46. D-ring 47. Servo release accumulator piston 48. O-ring

49. E-ring 50. Spring retainer 51. OD servo return spring

52. D-ring 53. Band servo piston 54. Band servo thrust washer

55. Band servo piston stem 56. 2nd servo return spring 57. Transmission range switch

58. Parking shaft 59. Return spring 60. Output gear adjusting spac-

er

61. Output gear bearing 62. Output gear 63. Side cover gasket

64. Side cover 65. Side cover bolt 66. Lock nut

67. Idler gear 68. Idler gear bearing 69. Reduction pinion gear ad-

justing shim

70. Parking actuator support 71. Parking pawl 72. LH differential side oil seal

73. Output speed sensor

: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Revision: January 20102010 Versa

Page 267 of 3745

AT-250

< SERVICE INFORMATION >

OVERHAUL

Oil Channel

INFOID:0000000005397432

HR16DE ENGINE MODELS

19. Oil pan 20. Drain plug gasket21. Drain plug

22. Magnet 23. Oil pan bolt24. Snap ring

25. O-ring 26. O-ring27. N-D accumulator piston

28. Return spring 29. O-ring 30. Lip seal

31. Input speed sensor 32. O-ring 33. Retaining pin

34. Detent spring 35. Retaining pin 36. Manual shaft

37. Manual shaft oil seal 38. Manual plate 39. Parking rod plate

40. Parking rod 41. OD servo piston retainer42. Snap ring

43. O-ring 44. OD servo piston45. D-ring

46. Servo piston retainer 47. O-ring48. E-ring

49. Spring retainer 50. OD servo return spring 51. D-ring

52. Band servo piston 53. Band servo thrust washer 54. Band servo piston stem

55. 2nd servo return spring 56. Transmission range switch57. Parking shaft

58. Return spring 59. Thrust needle bearing60. Seal ring

61. Output shaft 62. Output shaft bearing63. Output shaft adjusting shim

64. Side cover 65. Side cover bolt 66. Lock nut

67. Idler gear 68. Idler gear bearing69. Reduction pinion gear adjusting

shim

70. Parking actuator support 71. Parking pawl 72. LH differential side oil seal

73. Output speed sensor

: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Revision: January 20102010 Versa

Page 276 of 3745

DISASSEMBLYAT-259

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

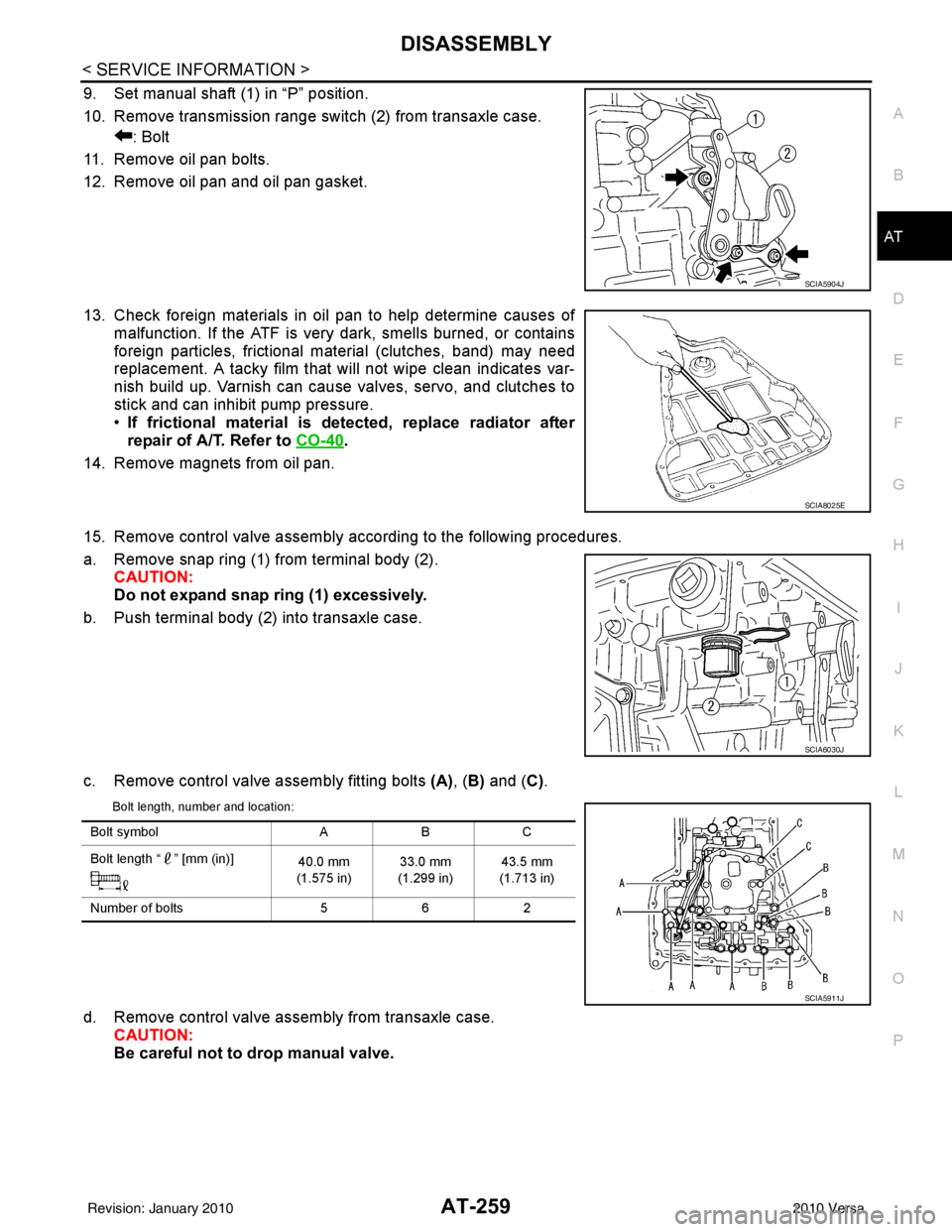

9. Set manual shaft (1) in “P” position.

10. Remove transmission range switch (2) from transaxle case. : Bolt

11. Remove oil pan bolts.

12. Remove oil pan and oil pan gasket.

13. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, frictional material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If frictional material is detected, replace radiator after

repair of A/T. Refer to CO-40

.

14. Remove magnets from oil pan.

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2). CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

c. Remove control valve assembly fitting bolts (A), (B) and ( C).

Bolt length, number and location:

d. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve.

SCIA5904J

SCIA8025E

SCIA6030J

Bolt symbol ABC

Bolt length “ ” [mm (in)] 40.0 mm

(1.575 in) 33.0 mm

(1.299 in) 43.5 mm

(1.713 in)

Number of bolts 562

SCIA5911J

Revision: January 20102010 Versa

Page 1044 of 3745

![NISSAN TIIDA 2010 Service Owners Manual PRECAUTIONSCVT-11

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend NISSAN TIIDA 2010 Service Owners Manual PRECAUTIONSCVT-11

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend](/img/5/57397/w960_57397-1043.png)

PRECAUTIONSCVT-11

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

When connecting pin connectors make sure that there are not

any bends or breaks on TCM pin terminal.

• Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. CVT-46, "

TCM Terminal and Reference Value".

• After performing each TROUBL E DIAGNOSIS, perform “DTC

Confirmation Procedure”.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

• Always use the specified br and of CVT fluid. Refer to MA-14, "

Flu-

ids and Lubricants".

• Use lint-free paper, not cloth rags, during work.

• After replacing the CVT fluid, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

Service Notice or PrecautionINFOID:0000000005397764

CVT FLUID COOLER SERVICE

If CVT fluid contains friction material (clutches, brakes , etc.), or if an CVT is replaced, inspect and clean the

CVT fluid cooler mounted in the radiator or replace the radiator. Flush cooler lines using cleaning solvent and

compressed air after repair. For CVT fluid cooler cleaning procedure, refer to CVT-15, "

CVT Fluid Cooler

Cleaning". For radiator replacement, refer to CO-40.

OBD-II SELF-DIAGNOSIS

• CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the malfunction indi cator lamp (MIL). Refer to the table on CVT-48, "

CONSULT-III

Function (TRANSMISSION)" for the indicator used to display each self-diagnostic result.

• The self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM memo- ries.

Always perform the procedure on CVT-27, "

OBD-II Diagnostic Trouble Code (DTC)" to complete the

repair and avoid unnecessary blinking of the MIL.

For details of OBD-II, refer to EC-541, "

Introduction".

• Certain systems and components, especially those re lated to OBD, may use the new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-66

.

ATFTEMP COUNT Conversion Table INFOID:0000000005709762

SEF291H

MEF040DA

SEF217U

Revision: January 20102010 Versa

Page 1048 of 3745

![NISSAN TIIDA 2010 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN TIIDA 2010 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57397/w960_57397-1047.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005397768

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005397769

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: January 20102010 Versa