NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3061 of 3745

LT-66

< SERVICE INFORMATION >

COMBINATION SWITCH

Terminal and Reference Value for BCM

INFOID:0000000005394949

Refer to BCS-12, "Terminal and Reference Value for BCM" .

CONSULT-III Function (BCM)INFOID:0000000005394950

Refer to LT-13, "CONSULT-III Function (BCM)" .

Combination Switch InspectionINFOID:0000000005394951

1.SYSTEM CHECK

Referring to table below, check which sy stem malfunctioning switch belongs to.

>> Check the system to which the switch belongs, and GO TO 2.

2.SYSTEM CHECK

With CONSULT-III

CAUTION:

If CONSULT-III is used with no connection of CONSULT-III CONVERTER, malfunctions might be

detected in self-diagnosis depending on cont rol unit which carry out CAN communication.

1. Connect CONSULT-III, and select “COM B SW” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR”.

3. Select “START”, and confirm that other switches in the system operate normally.

Example: When turn signal LH is inoperative, confirm that PASSING, HEAD LAMP 2 or FRONT FOG (if

equipped) turn ON-OFF normally.

Without CONSULT-III

Operating combination switch, and confirm that other switches in the system operate normally.

Example: When a turn signal switch is inoperative, confirm that FRONT WIPER LO or FRONT WIPER INT

turn ON-OFF normally.

Check results

Other switches in the system operate normall y.>>Replace lighting switch or wiper switch.

Other switches in the system do not operate normally.>>GO TO 3.

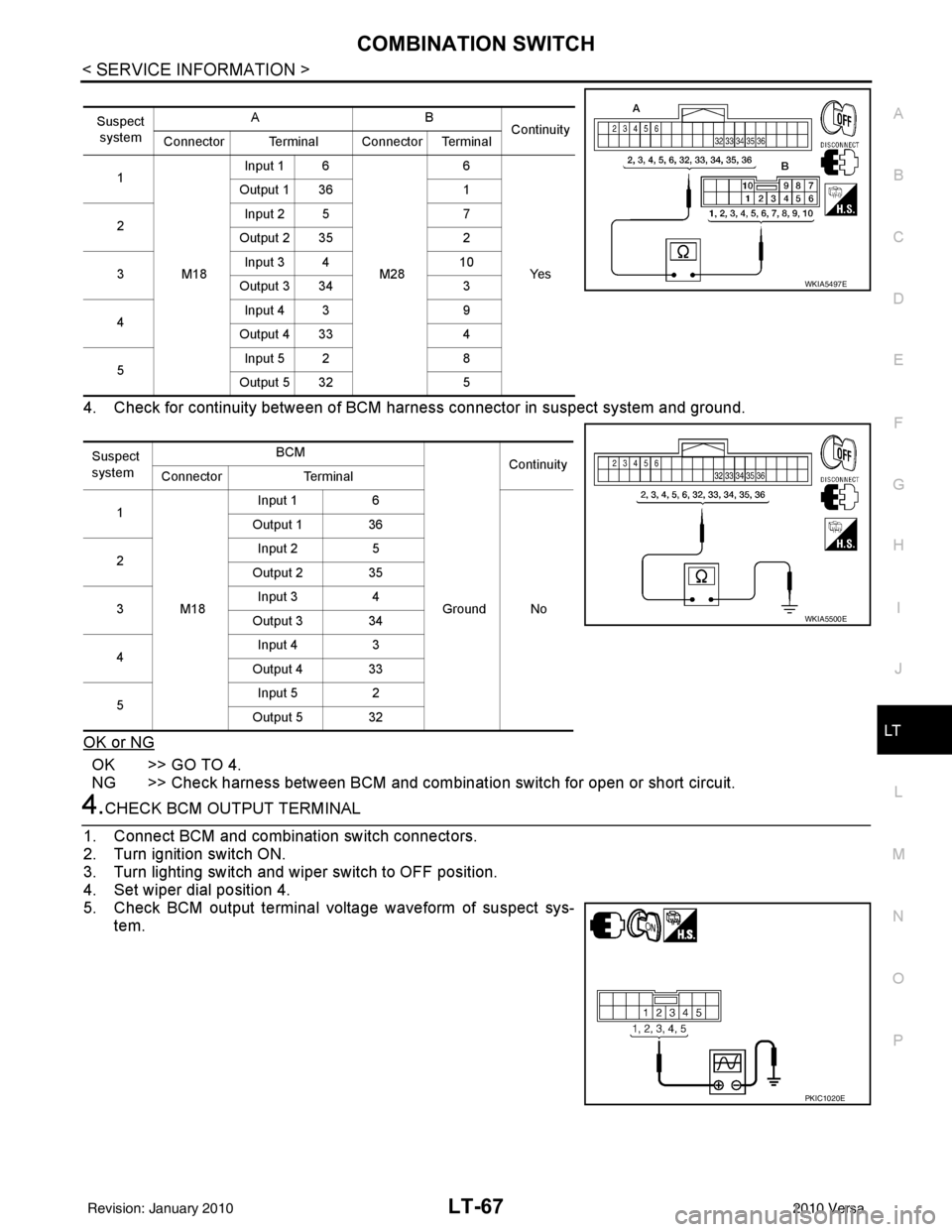

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM connector and combination switch connector.

3. Check for continuity between BCM harness connecto r of the suspect system and the corresponding com-

bination switch harness connector.

System 1 System 2System 3System 4 System 5

— FRONT WASHER FRONT WIPER LO TURN LHTURN RH

FRONT WIPER HI —FRONT WIPER INT PASSINGHEAD LAMP 1

INT VOLUME 1 ——HEAD LAMP 2 HI BEAM

— INT VOLUME 3 ——LIGHT SW 1ST

INT VOLUME 2 ——FRONT FOG —

Revision: January 20102010 Versa

Page 3062 of 3745

COMBINATION SWITCHLT-67

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

4. Check for continuity between of BCM har ness connector in suspect system and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combinat ion switch for open or short circuit.

4.CHECK BCM OUTPUT TERMINAL

1. Connect BCM and combination switch connectors.

2. Turn ignition switch ON.

3. Turn lighting switch and wiper switch to OFF position.

4. Set wiper dial position 4.

5. Check BCM output terminal voltage waveform of suspect sys- tem.

Suspect

system AB

Continuity

Connector Terminal Connector Terminal

1

M18Input 1 6

M286

Ye s

Output 1 36

1

2 Input 2 5

7

Output 2 35 2

3 Input 3 4

10

Output 3 34 3

4 Input 4 3

9

Output 4 33 4

5 Input 5 2

8

Output 5 32 5

Suspect

system BCM

Continuity

Connector Terminal

1

M18 Input 1

6

Ground No

Output 1 36

2 Input 2

5

Output 2 35

3 Input 3

4

Output 3 34

4 Input 4

3

Output 4 33

5 Input 5

2

Output 5 32

WKIA5497E

WKIA5500E

PKIC1020E

Revision: January 20102010 Versa

Page 3063 of 3745

LT-68

< SERVICE INFORMATION >

COMBINATION SWITCH

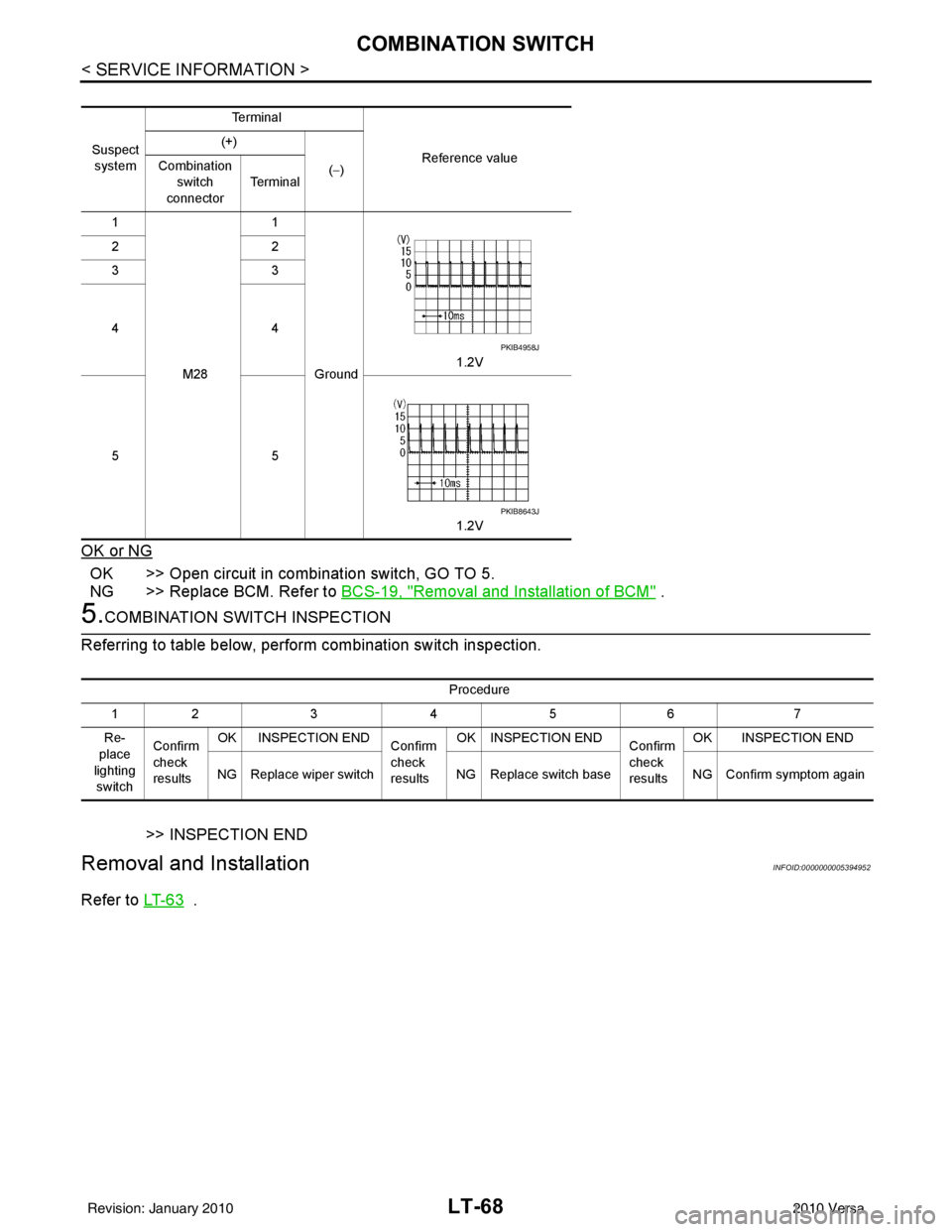

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM" .

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

>> INSPECTION END

Removal and InstallationINFOID:0000000005394952

Refer to LT- 6 3 .

Suspect

system Te r m i n a l

Reference value

(+)

(−)

Combination

switch

connector Te r m i n a l

1

M28 1

Ground 1.2V

22

33

44

55

1.2V

PKIB4958J

PKIB8643J

Procedure

12 3 4 5 6 7

Re-

place

lighting switch Confirm

check

results

OK INSPECTION END

Confirm

check

resultsOK INSPECTION END

Confirm

check

resultsOK INSPECTION END

NG Replace wiper switch NG Replace switch baseNG Confirm symptom again

Revision: January 20102010 Versa

Page 3064 of 3745

STOP LAMPLT-69

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

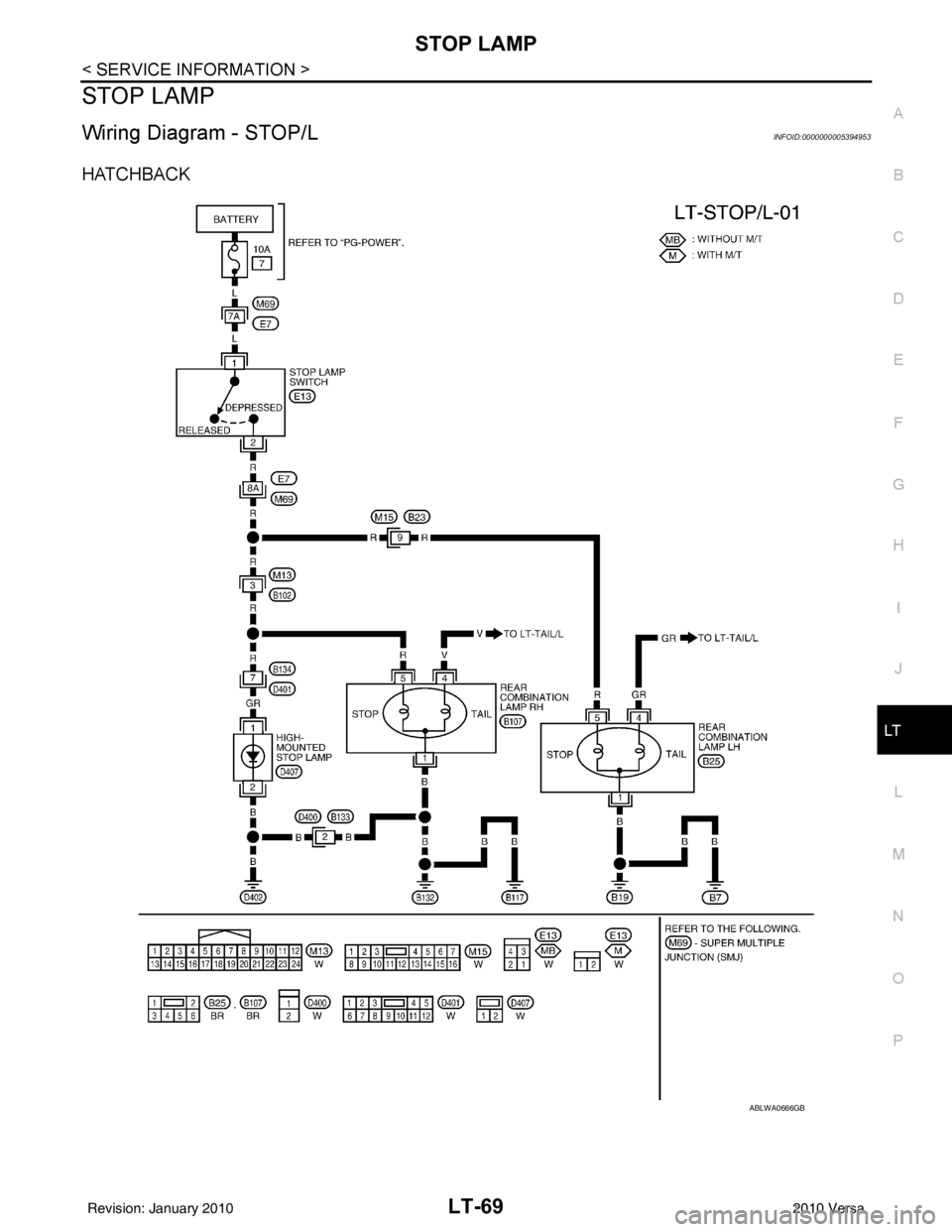

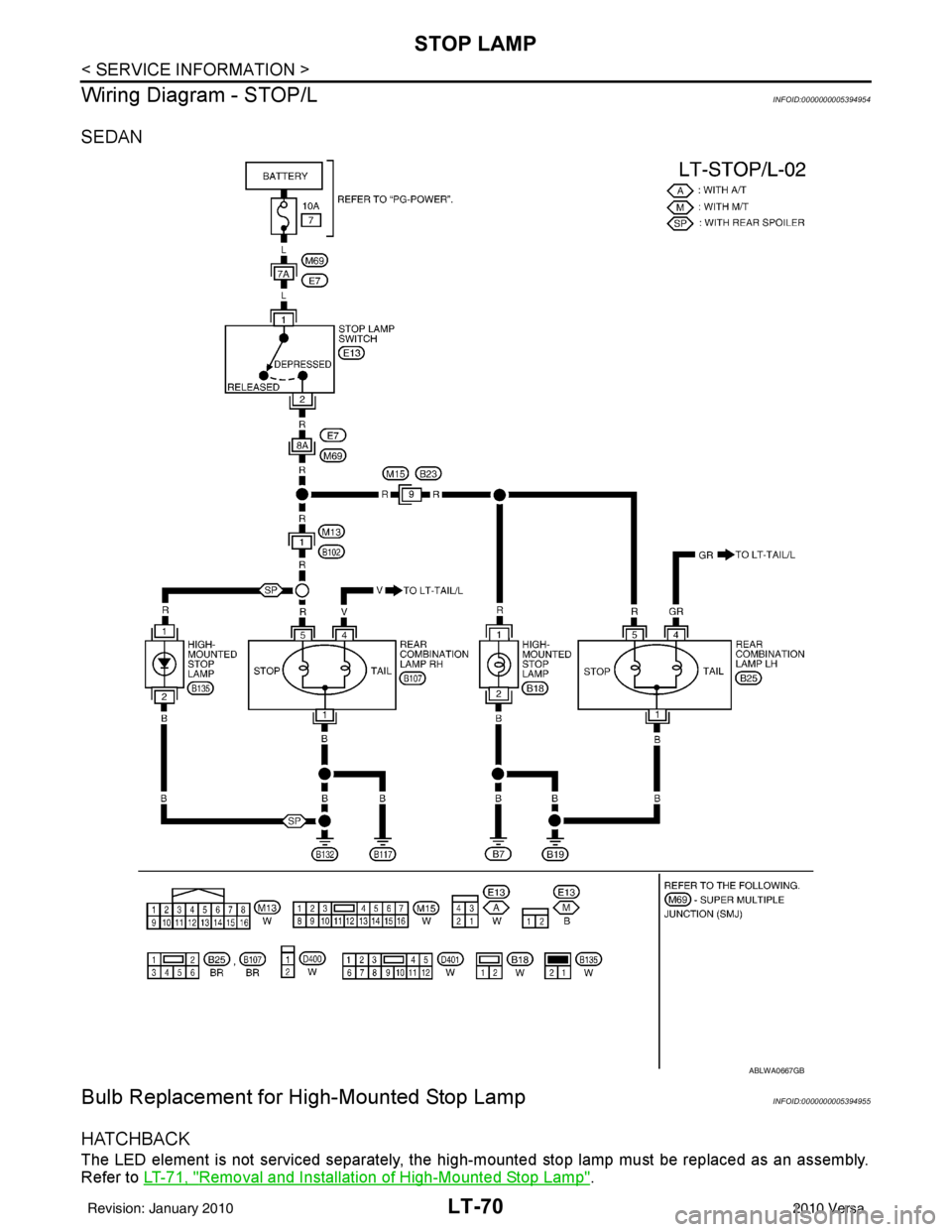

STOP LAMP

Wiring Diagram - STOP/LINFOID:0000000005394953

HATCHBACK

ABLWA0666GB

Revision: January 20102010 Versa

Page 3065 of 3745

LT-70

< SERVICE INFORMATION >

STOP LAMP

Wiring Diagram - STOP/L

INFOID:0000000005394954

SEDAN

Bulb Replacement for High-Mounted Stop LampINFOID:0000000005394955

HATCHBACK

The LED element is not serviced separately, the hi gh-mounted stop lamp must be replaced as an assembly.

Refer to LT-71, "

Removal and Installation of High-Mounted Stop Lamp".

ABLWA0667GB

Revision: January 20102010 Versa

Page 3066 of 3745

STOP LAMPLT-71

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

SEDAN - WITH REAR AIR SPOILER

The LED element is not serviced separately, the hi gh-mounted stop lamp must be replaced as an assembly.

Refer to LT-71, "

Removal and Installation of High-Mounted Stop Lamp".

1. Installation is in the reverse order of removal.

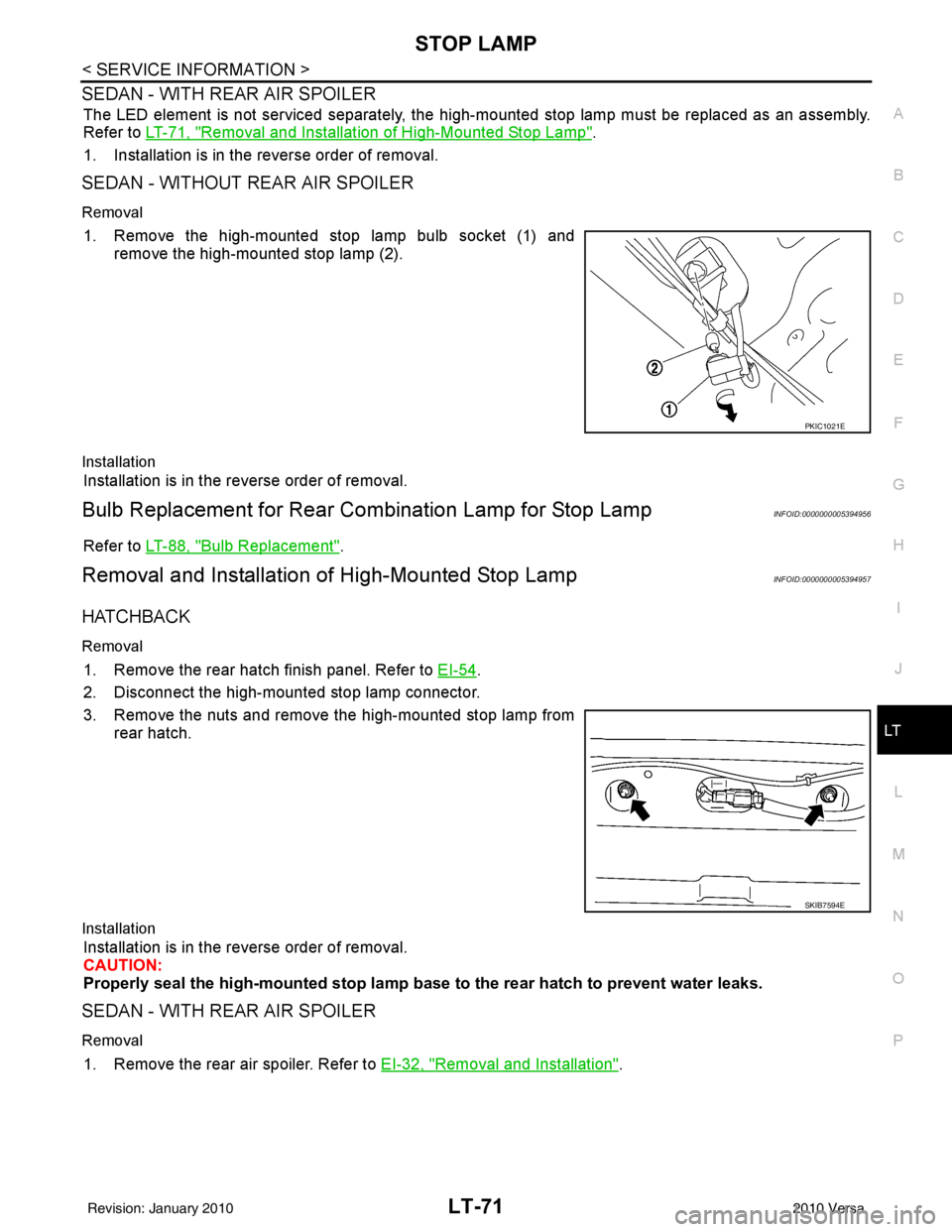

SEDAN - WITHOUT REAR AIR SPOILER

Removal

1. Remove the high-mounted stop lamp bulb socket (1) and remove the high-mounted stop lamp (2).

Installation

Installation is in the reverse order of removal.

Bulb Replacement for Rear Co mbination Lamp for Stop LampINFOID:0000000005394956

Refer to LT-88, "Bulb Replacement".

Removal and Installation of High-Mounted Stop LampINFOID:0000000005394957

HATCHBACK

Removal

1. Remove the rear hatch finish panel. Refer to EI-54.

2. Disconnect the high-mounted stop lamp connector.

3. Remove the nuts and remove the high-mounted stop lamp from rear hatch.

Installation

Installation is in the reverse order of removal.

CAUTION:

Properly seal the high-mounted stop lamp base to the rear hatch to prevent water leaks.

SEDAN - WITH REAR AIR SPOILER

Removal

1. Remove the rear air spoiler. Refer to EI-32, "Removal and Installation".

PKIC1021E

SKIB7594E

Revision: January 20102010 Versa

Page 3067 of 3745

LT-72

< SERVICE INFORMATION >

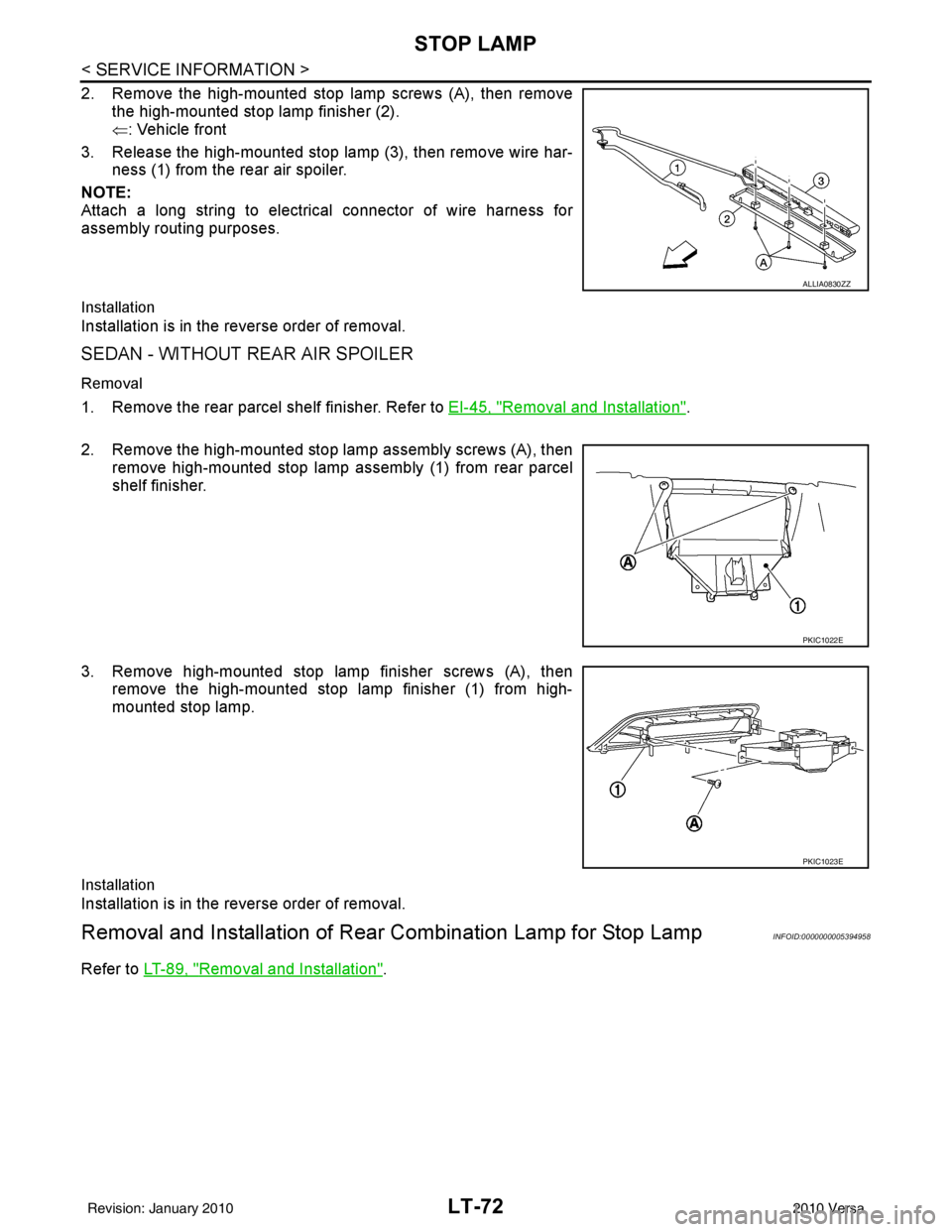

STOP LAMP

2. Remove the high-mounted stop lamp screws (A), then removethe high-mounted stop lamp finisher (2).

⇐: Vehicle front

3. Release the high-mounted stop lamp (3), then remove wire har- ness (1) from the rear air spoiler.

NOTE:

Attach a long string to electrical connector of wire harness for

assembly routing purposes.

Installation

Installation is in the reverse order of removal.

SEDAN - WITHOUT REAR AIR SPOILER

Removal

1. Remove the rear parcel shelf finisher. Refer to EI-45, "Removal and Installation".

2. Remove the high-mounted stop lamp assembly screws (A), then remove high-mounted stop lamp assembly (1) from rear parcel

shelf finisher.

3. Remove high-mounted stop lamp finisher screws (A), then remove the high-mounted stop lamp finisher (1) from high-

mounted stop lamp.

Installation

Installation is in the reverse order of removal.

Removal and Installation of Rear Combination Lamp for Stop LampINFOID:0000000005394958

Refer to LT-89, "Removal and Installation".

ALLIA0830ZZ

PKIC1022E

PKIC1023E

Revision: January 20102010 Versa

Page 3068 of 3745

BACK-UP LAMPLT-73

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

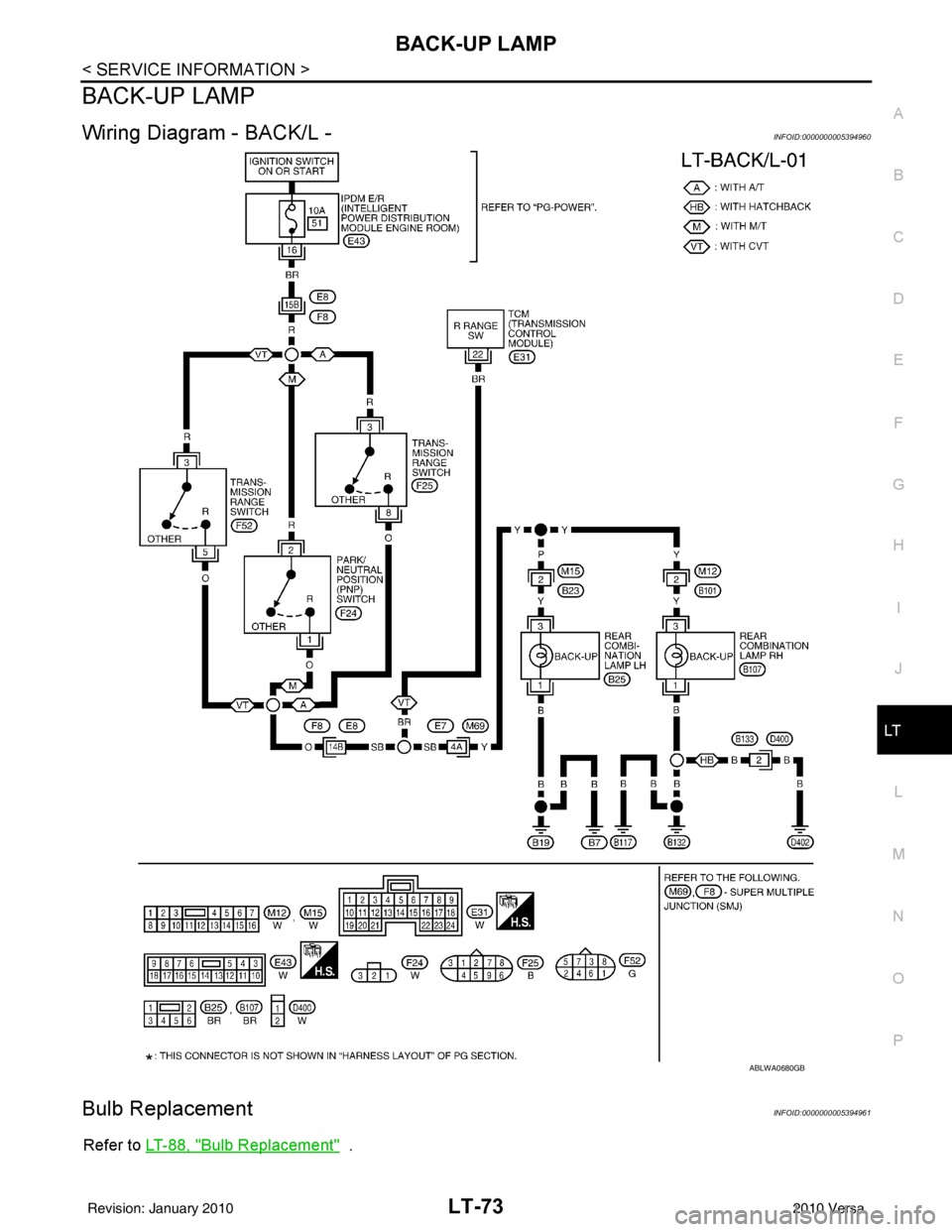

BACK-UP LAMP

Wiring Diagram - BACK/L -INFOID:0000000005394960

Bulb ReplacementINFOID:0000000005394961

Refer to LT-88, "Bulb Replacement" .

ABLWA0680GB

Revision: January 20102010 Versa

Page 3069 of 3745

LT-74

< SERVICE INFORMATION >

BACK-UP LAMP

Removal and Installation

INFOID:0000000005394962

Refer to LT-89, "Removal and Installation" .

Revision: January 20102010 Versa

Page 3070 of 3745

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-75

< SERVICE INFORMATION >

C

D E

F

G H

I

J

L

M A

B

LT

N

O P

PARKING, LICENSE PLATE AND TAIL LAMPS

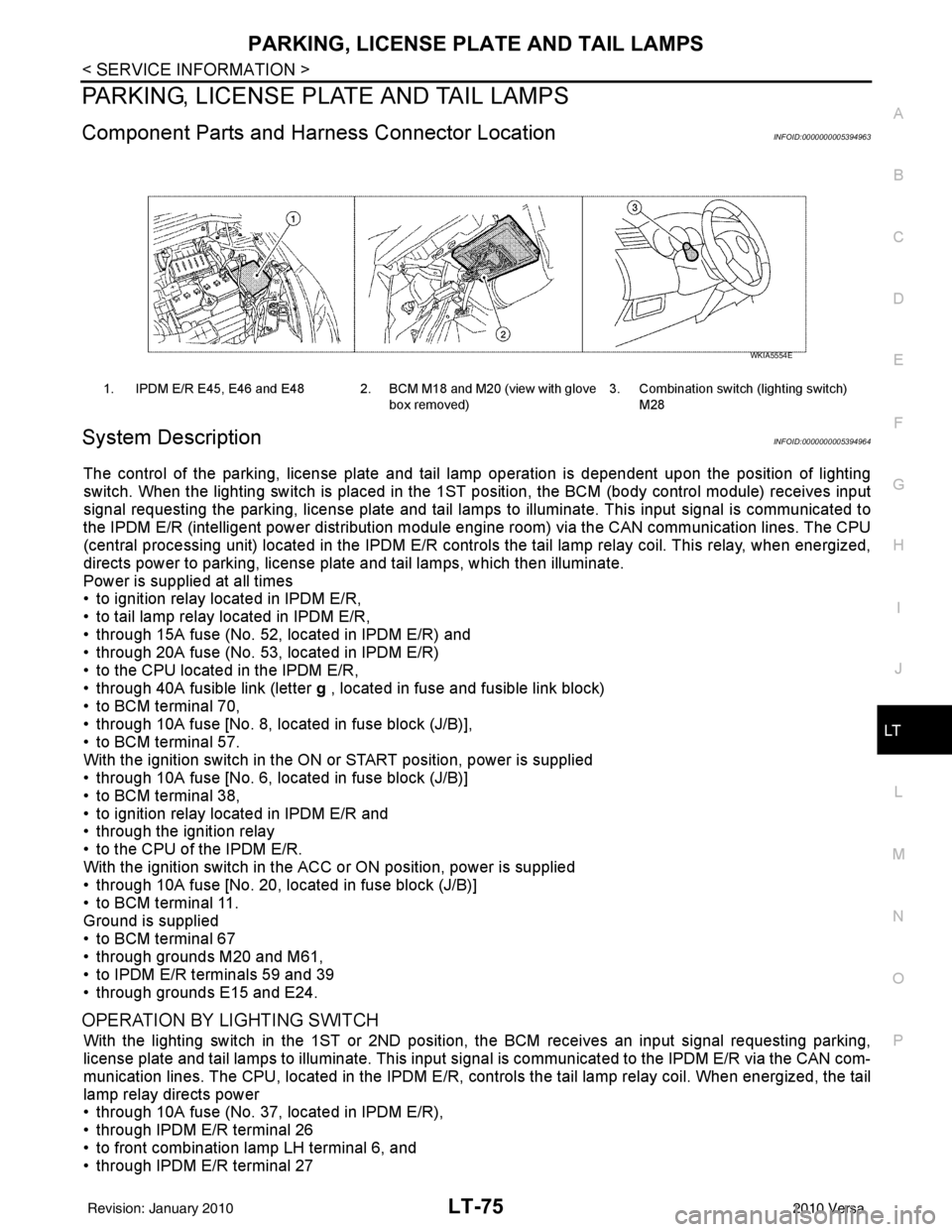

Component Parts and Har ness Connector LocationINFOID:0000000005394963

System DescriptionINFOID:0000000005394964

The control of the parking, license plate and tail lamp operation is dependent upon the position of lighting

switch. When the lighting switch is placed in the 1ST position, the BCM (body control module) receives input

signal requesting the parking, license plate and tail lamps to illuminate. This input signal is communicated to

the IPDM E/R (intelligent power distribution module engine room) via the CAN communication lines. The CPU

(central processing unit) located in the IPDM E/R contro ls the tail lamp relay coil. This relay, when energized,

directs power to parking, license plate and tail lamps, which then illuminate.

Power is supplied at all times

• to ignition relay located in IPDM E/R,

• to tail lamp relay located in IPDM E/R,

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to the CPU located in the IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)],

• to BCM terminal 57.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• to ignition relay located in IPDM E/R and

• through the ignition relay

• to the CPU of the IPDM E/R.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M20 and M61,

• to IPDM E/R terminals 59 and 39

• through grounds E15 and E24.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND positi on, the BCM receives an input signal requesting parking,

license plate and tail lamps to illuminate. This input si gnal is communicated to the IPDM E/R via the CAN com-

munication lines. The CPU, located in the IPDM E/R, c ontrols the tail lamp relay coil. When energized, the tail

lamp relay directs power

• through 10A fuse (No. 37, located in IPDM E/R),

• through IPDM E/R terminal 26

• to front combination lamp LH terminal 6, and

• through IPDM E/R terminal 27

1. IPDM E/R E45, E46 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting switch)

M28

WKIA5554E

Revision: January 20102010 Versa