NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3361 of 3745

MTC-82

< SERVICE INFORMATION >

REFRIGERANT LINES

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of low-pressure flexible hose and high-pressure flexible hose with a new ones, andapply compressor oil when installing.

• When recharging refrigerant, check for leaks. Refer to MTC-92, "

Checking of Refrigerant Leaks".

Removal and Installation for Compressor Clutch - Type 1INFOID:0000000005716140

REMOVAL

1. Remove the compressor. Refer to MTC-79, "Removal and Installation of Compressor - HR16DE".

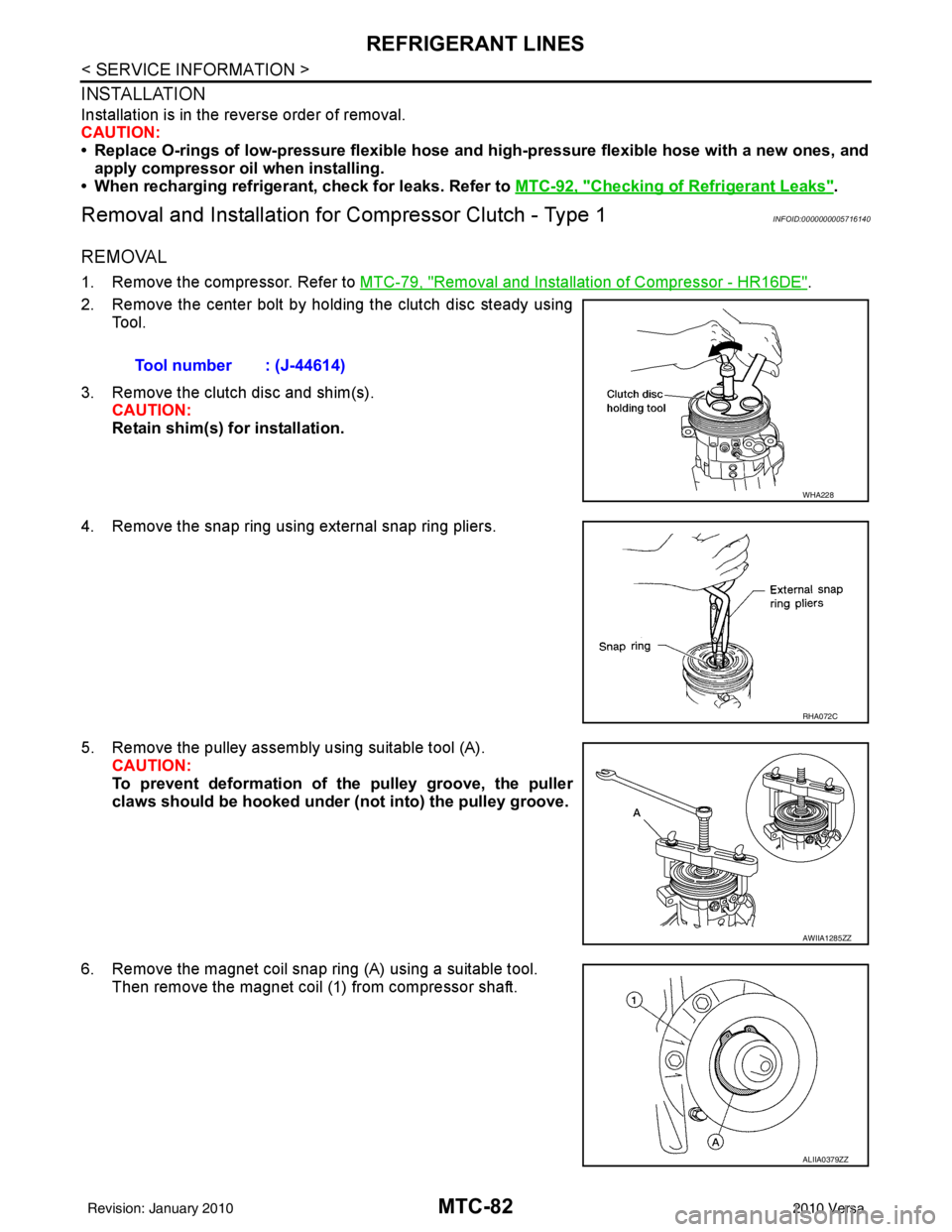

2. Remove the center bolt by holding the clutch disc steady using Tool.

3. Remove the clutch disc and shim(s). CAUTION:

Retain shim(s) for installation.

4. Remove the snap ring using external snap ring pliers.

5. Remove the pulley assembly using suitable tool (A). CAUTION:

To prevent deformation of th e pulley groove, the puller

claws should be ho oked under (not into) the pulley groove.

6. Remove the magnet coil snap ring (A) using a suitable tool. Then remove the magnet coil (1) from compressor shaft.Tool number : (J-44614)

WHA228

RHA072C

AWIIA1285ZZ

ALIIA0379ZZ

Revision: January 20102010 Versa

Page 3362 of 3745

REFRIGERANT LINESMTC-83

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

INSPECTION AFTER REMOVAL

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the cont act surface of the pulley shows signs of excessive

grooving, replace the clutch disc and pulley. The c ontact surfaces of the pulley assembly should be cleaned

with a suitable solvent before installation.

Coil

Check the magnet coil for a loose connection or cracked insulation.

INSTALLATION

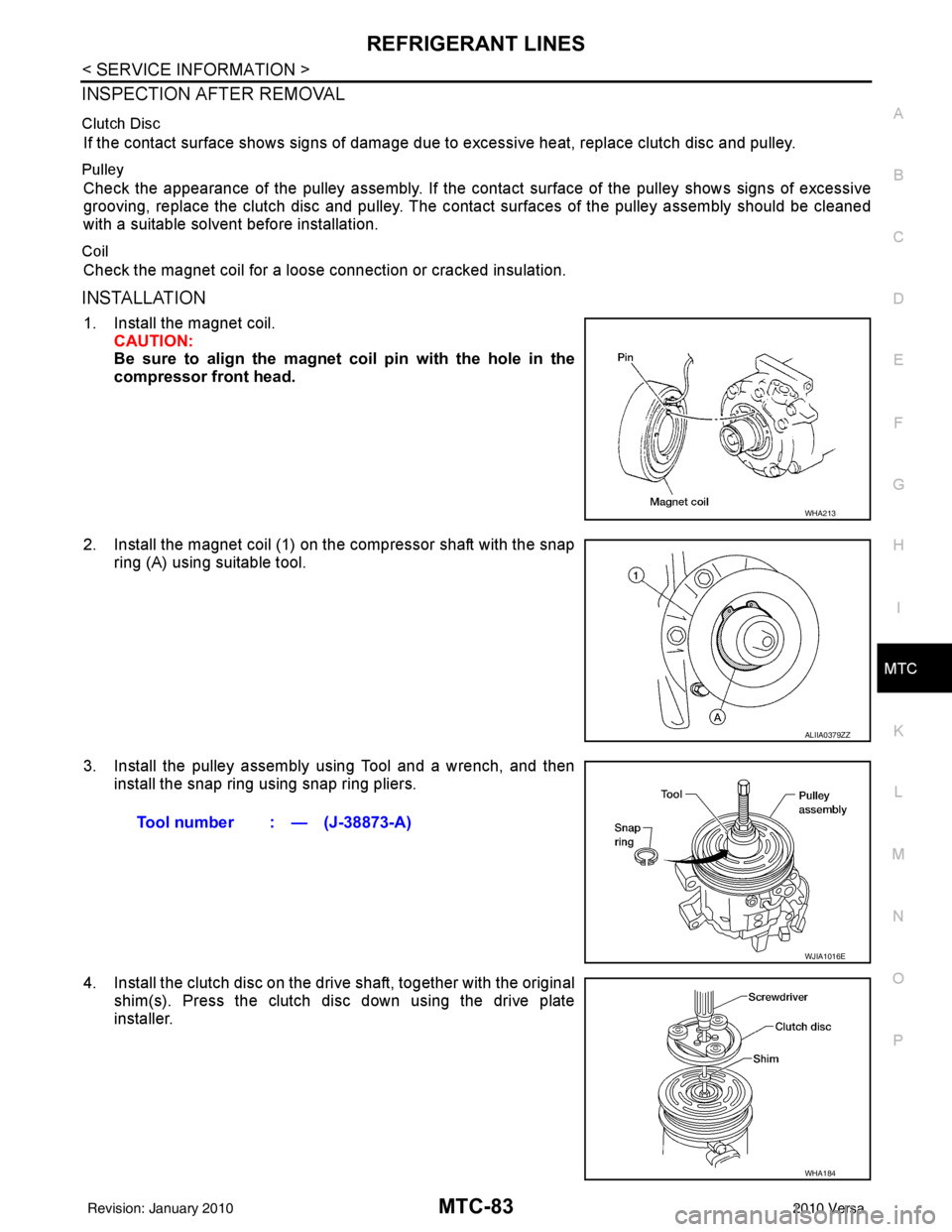

1. Install the magnet coil. CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

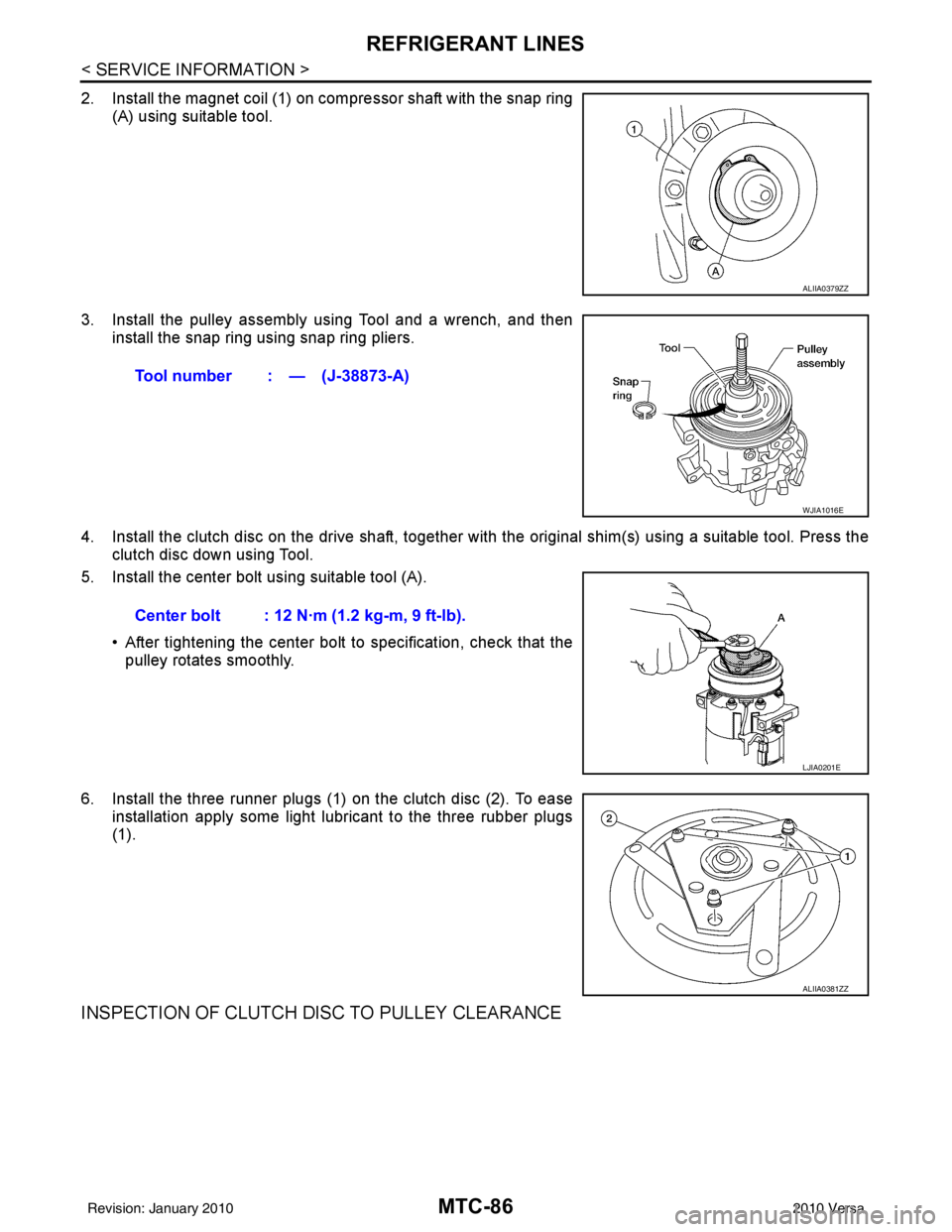

2. Install the magnet coil (1) on the compressor shaft with the snap ring (A) using suitable tool.

3. Install the pulley assembly using Tool and a wrench, and then install the snap ring using snap ring pliers.

4. Install the clutch disc on the drive shaft, together with the original shim(s). Press the clutch disc down using the drive plate

installer.

WHA213

ALIIA0379ZZ

Tool number : — (J-38873-A)

WJIA1016E

WHA184

Revision: January 20102010 Versa

Page 3363 of 3745

MTC-84

< SERVICE INFORMATION >

REFRIGERANT LINES

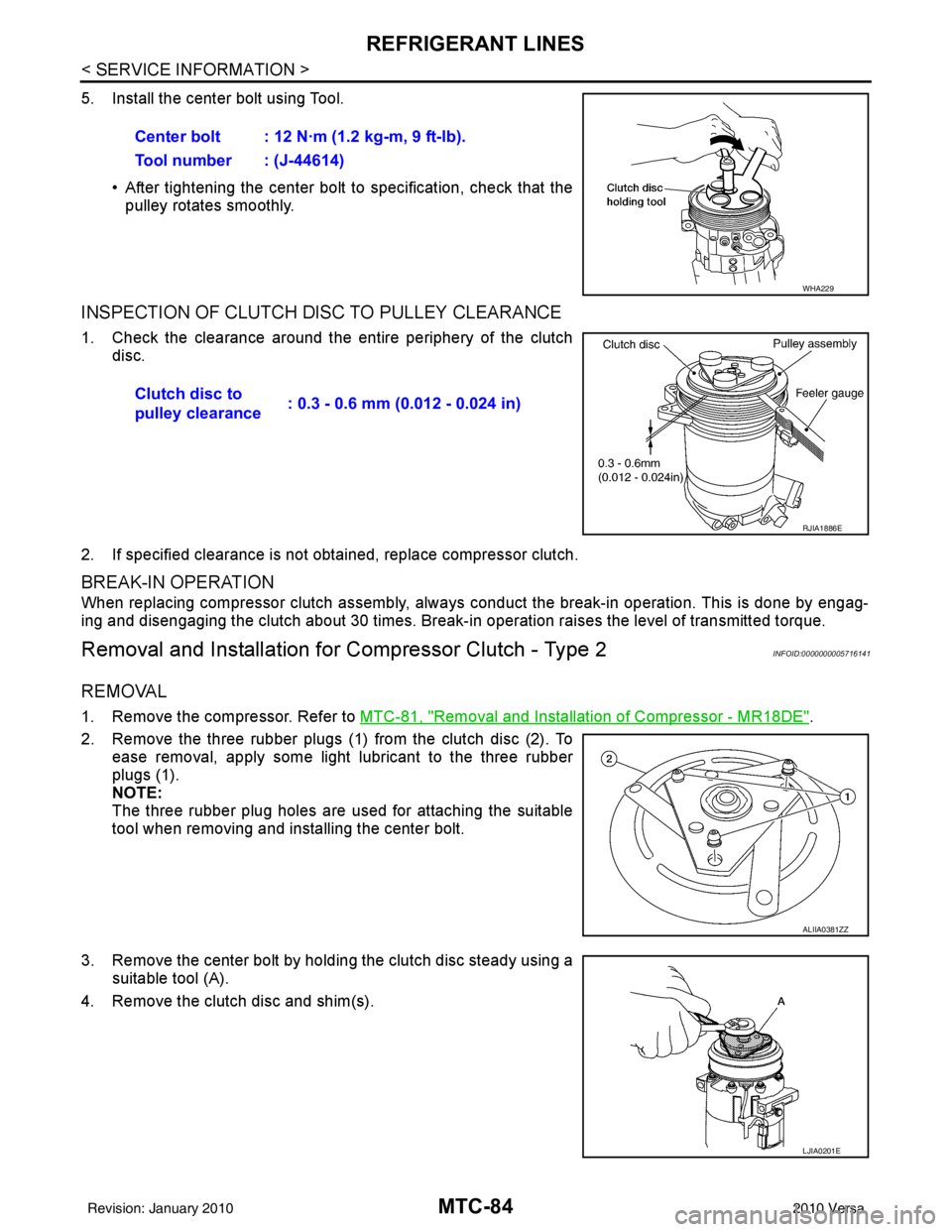

5. Install the center bolt using Tool.• After tightening the center bolt to specification, check that the

pulley rotates smoothly.

INSPECTION OF CLUTCH DISC TO PULLEY CLEARANCE

1. Check the clearance around the entire periphery of the clutch

disc.

2. If specified clearance is not obtained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Compressor Clutch - Type 2INFOID:0000000005716141

REMOVAL

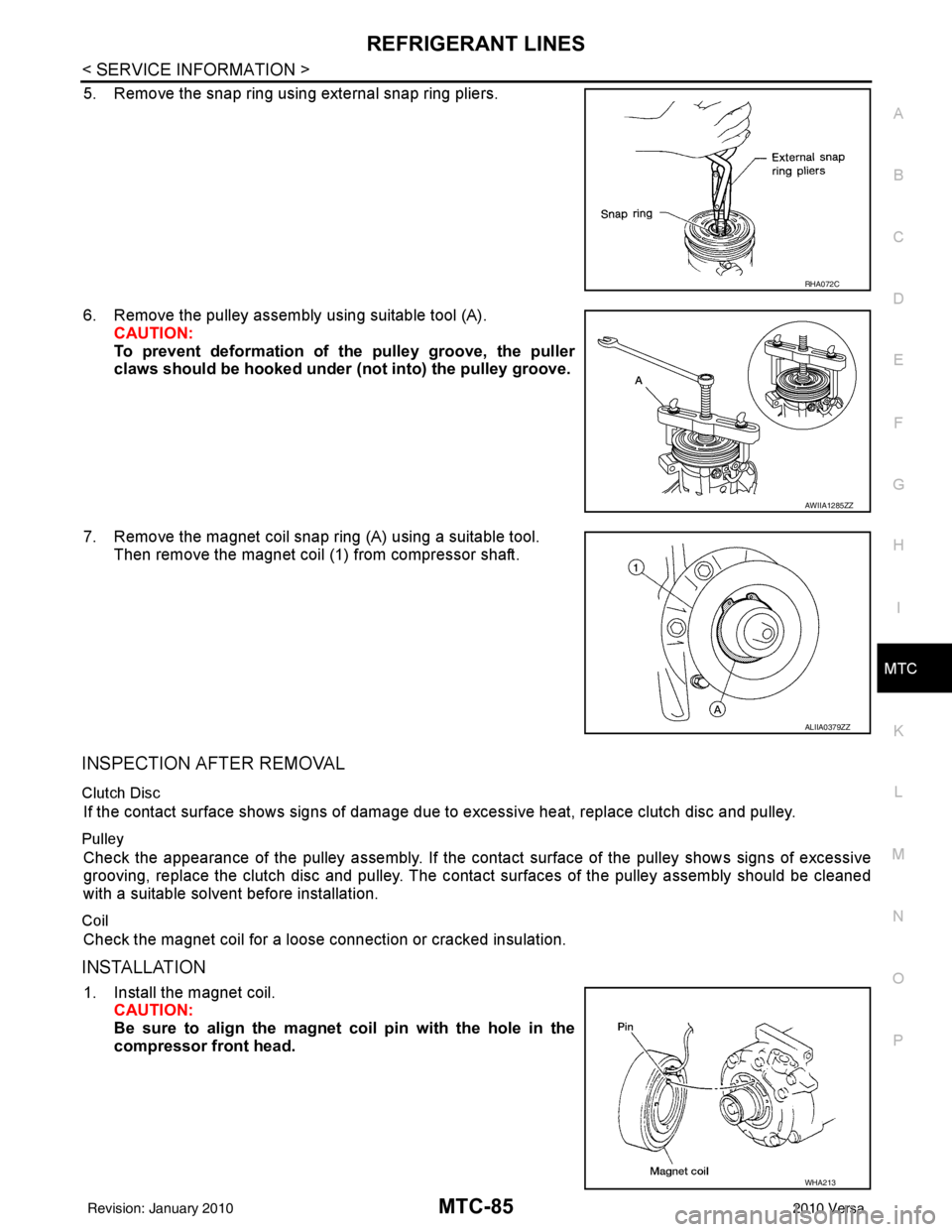

1. Remove the compressor. Refer to MTC-81, "Removal and Installation of Compressor - MR18DE".

2. Remove the three rubber plugs (1) from the clutch disc (2). To ease removal, apply some light lubricant to the three rubber

plugs (1).

NOTE:

The three rubber plug holes are used for attaching the suitable

tool when removing and installing the center bolt.

3. Remove the center bolt by holding the clutch disc steady using a suitable tool (A).

4. Remove the clutch disc and shim(s). Center bolt : 12 N·m (1.2 kg-m, 9 ft-lb).

Tool number : (J-44614)

WHA229

Clutch disc to

pulley clearance

: 0.3 - 0.6 mm (0.012 - 0.024 in)

RJIA1886E

ALIIA0381ZZ

LJIA0201E

Revision: January 20102010 Versa

Page 3364 of 3745

REFRIGERANT LINESMTC-85

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

5. Remove the snap ring using external snap ring pliers.

6. Remove the pulley assembly using suitable tool (A). CAUTION:

To prevent deformation of the pulley groove, the puller

claws should be hooked under (not into) the pulley groove.

7. Remove the magnet coil snap ring (A) using a suitable tool. Then remove the magnet coil (1) from compressor shaft.

INSPECTION AFTER REMOVAL

Clutch Disc

If the contact surface shows signs of damage due to excessive heat, replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If the cont act surface of the pulley shows signs of excessive

grooving, replace the clutch disc and pulley. The c ontact surfaces of the pulley assembly should be cleaned

with a suitable solvent before installation.

Coil

Check the magnet coil for a loose connection or cracked insulation.

INSTALLATION

1. Install the magnet coil. CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

RHA072C

AWIIA1285ZZ

ALIIA0379ZZ

WHA213

Revision: January 20102010 Versa

Page 3365 of 3745

MTC-86

< SERVICE INFORMATION >

REFRIGERANT LINES

2. Install the magnet coil (1) on compressor shaft with the snap ring(A) using suitable tool.

3. Install the pulley assembly using Tool and a wrench, and then install the snap ring using snap ring pliers.

4. Install the clutch disc on the drive shaft, together wit h the original shim(s) using a suitable tool. Press the

clutch disc down using Tool.

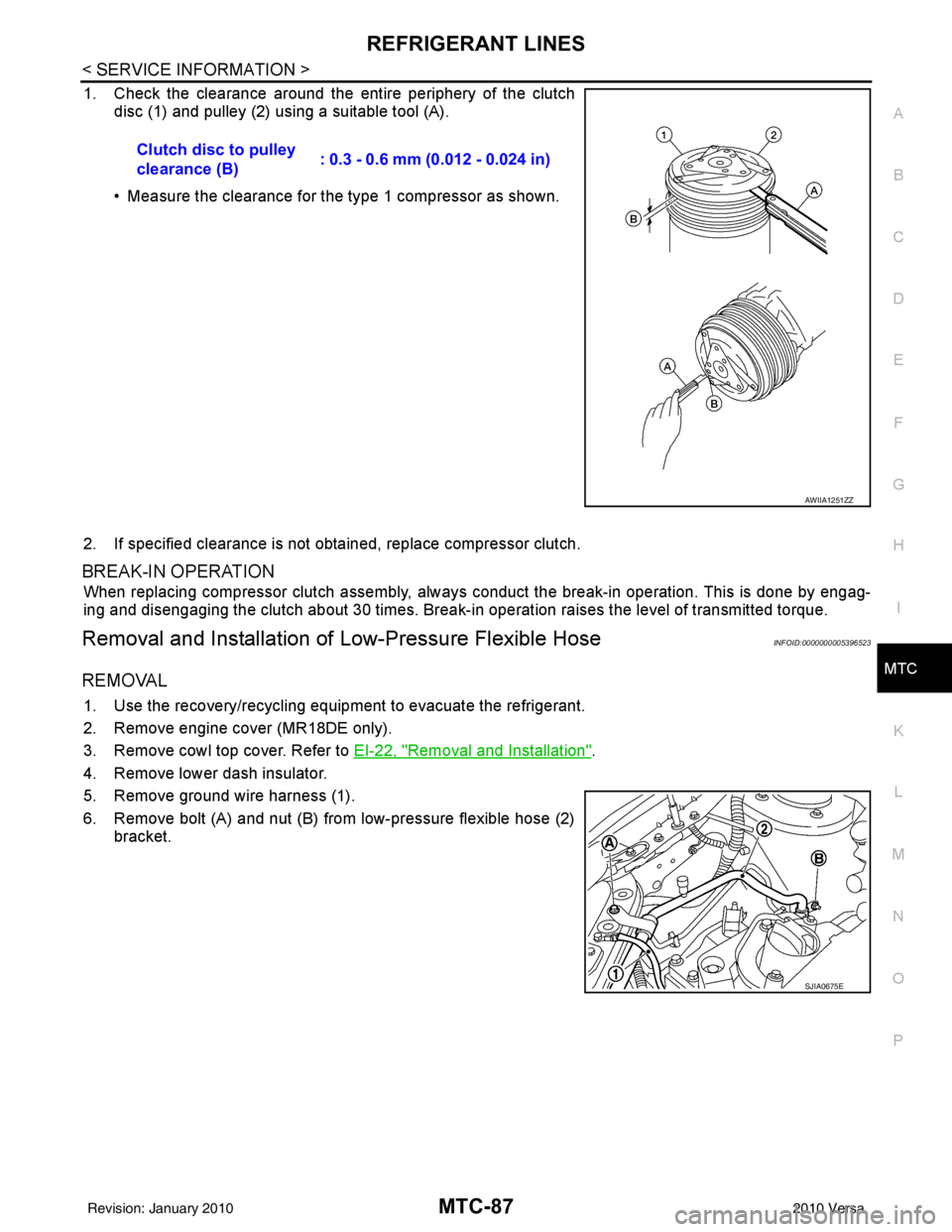

5. Install the center bolt using suitable tool (A).

• After tightening the center bolt to specification, check that the

pulley rotates smoothly.

6. Install the three runner plugs (1) on the clutch disc (2). To ease installation apply some light lubricant to the three rubber plugs

(1).

INSPECTION OF CLUTCH DISC TO PULLEY CLEARANCE

ALIIA0379ZZ

Tool number : — (J-38873-A)

WJIA1016E

Center bolt : 12 N·m (1.2 kg-m, 9 ft-lb).

LJIA0201E

ALIIA0381ZZ

Revision: January 20102010 Versa

Page 3366 of 3745

REFRIGERANT LINESMTC-87

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

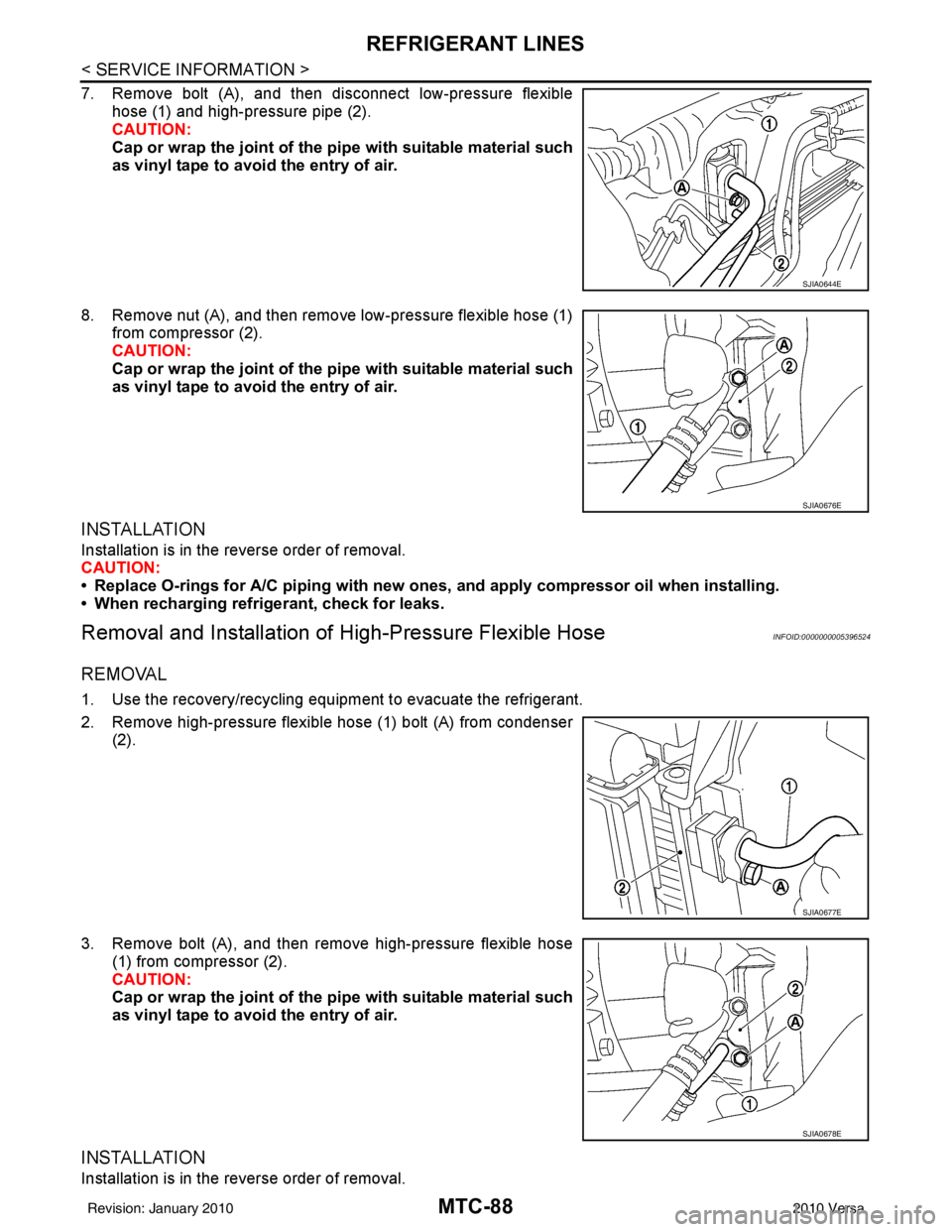

1. Check the clearance around the entire periphery of the clutch disc (1) and pulley (2) using a suitable tool (A).

• Measure the clearance for the type 1 compressor as shown.

2. If specified clearance is not obt ained, replace compressor clutch.

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation of Low-Pressure Flexible HoseINFOID:0000000005396523

REMOVAL

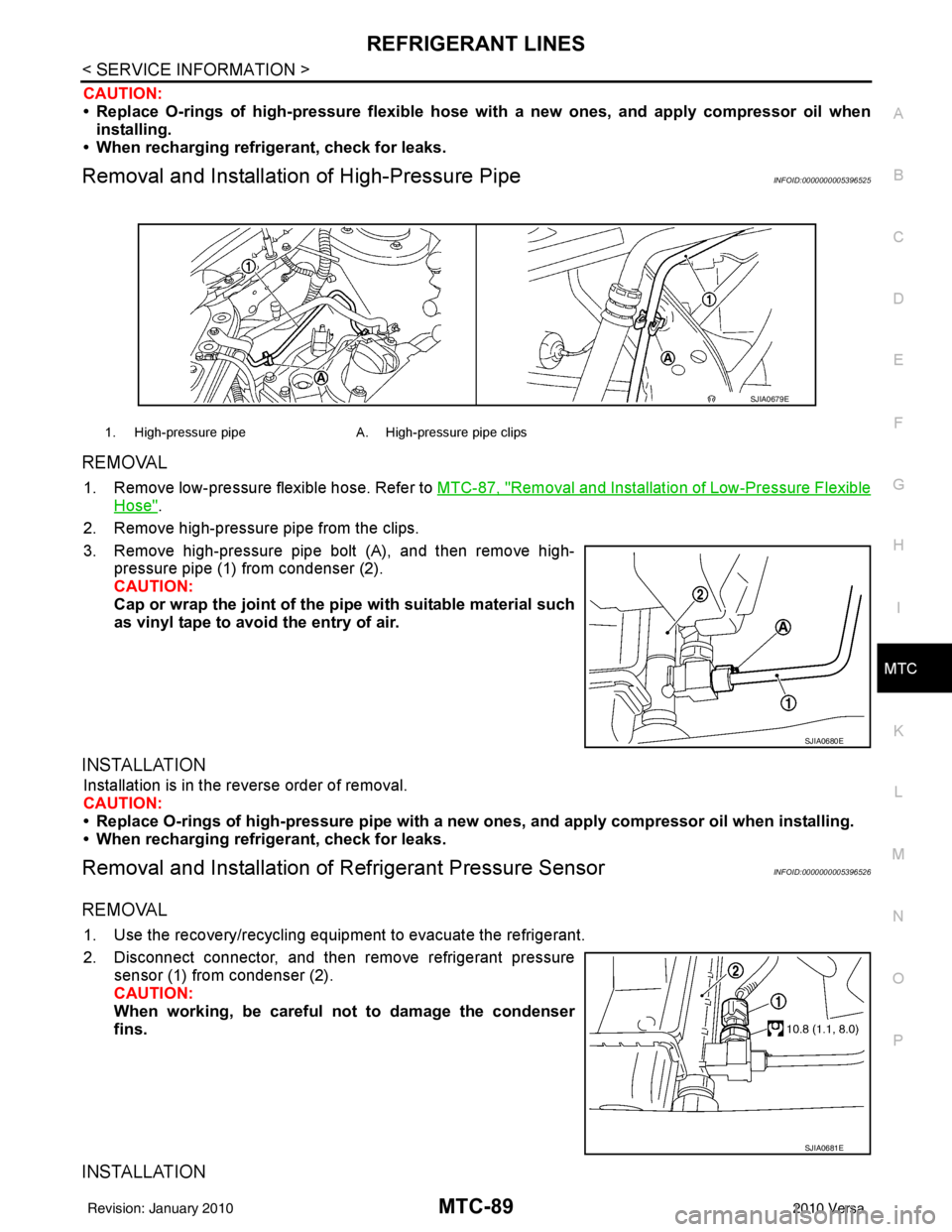

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove engine cover (MR18DE only).

3. Remove cowl top cover. Refer to EI-22, "

Removal and Installation".

4. Remove lower dash insulator.

5. Remove ground wire harness (1).

6. Remove bolt (A) and nut (B) from low-pressure flexible hose (2) bracket.Clutch disc to pulley

clearance (B)

: 0.3 - 0.6 mm (0.012 - 0.024 in)

AWIIA1251ZZ

SJIA0675E

Revision: January 20102010 Versa

Page 3367 of 3745

MTC-88

< SERVICE INFORMATION >

REFRIGERANT LINES

7. Remove bolt (A), and then disconnect low-pressure flexiblehose (1) and high-pressure pipe (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

8. Remove nut (A), and then remove low-pressure flexible hose (1) from compressor (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of High-Pressure Flexible HoseINFOID:0000000005396524

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Remove high-pressure flexible hose (1) bolt (A) from condenser (2).

3. Remove bolt (A), and then remove high-pressure flexible hose (1) from compressor (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

SJIA0644E

SJIA0676E

SJIA0677E

SJIA0678E

Revision: January 20102010 Versa

Page 3368 of 3745

REFRIGERANT LINESMTC-89

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

CAUTION:

• Replace O-rings of high-pressure flexible hose with a new ones, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of High-Pressure PipeINFOID:0000000005396525

REMOVAL

1. Remove low-pressure flexible hose. Refer to MTC-87, "Removal and Installation of Low-Pressure Flexible

Hose".

2. Remove high-pressure pipe from the clips.

3. Remove high-pressure pipe bolt (A), and then remove high- pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure pipe with a new ones, and apply compr essor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Refrigerant Pressure SensorINFOID:0000000005396526

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

1. High-pressure pipe A. High-pressure pipe clips

SJIA0679E

SJIA0680E

SJIA0681E

Revision: January 20102010 Versa

Page 3369 of 3745

MTC-90

< SERVICE INFORMATION >

REFRIGERANT LINES

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of refrigerant pressure sensor with a new one, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000005396527

REMOVAL

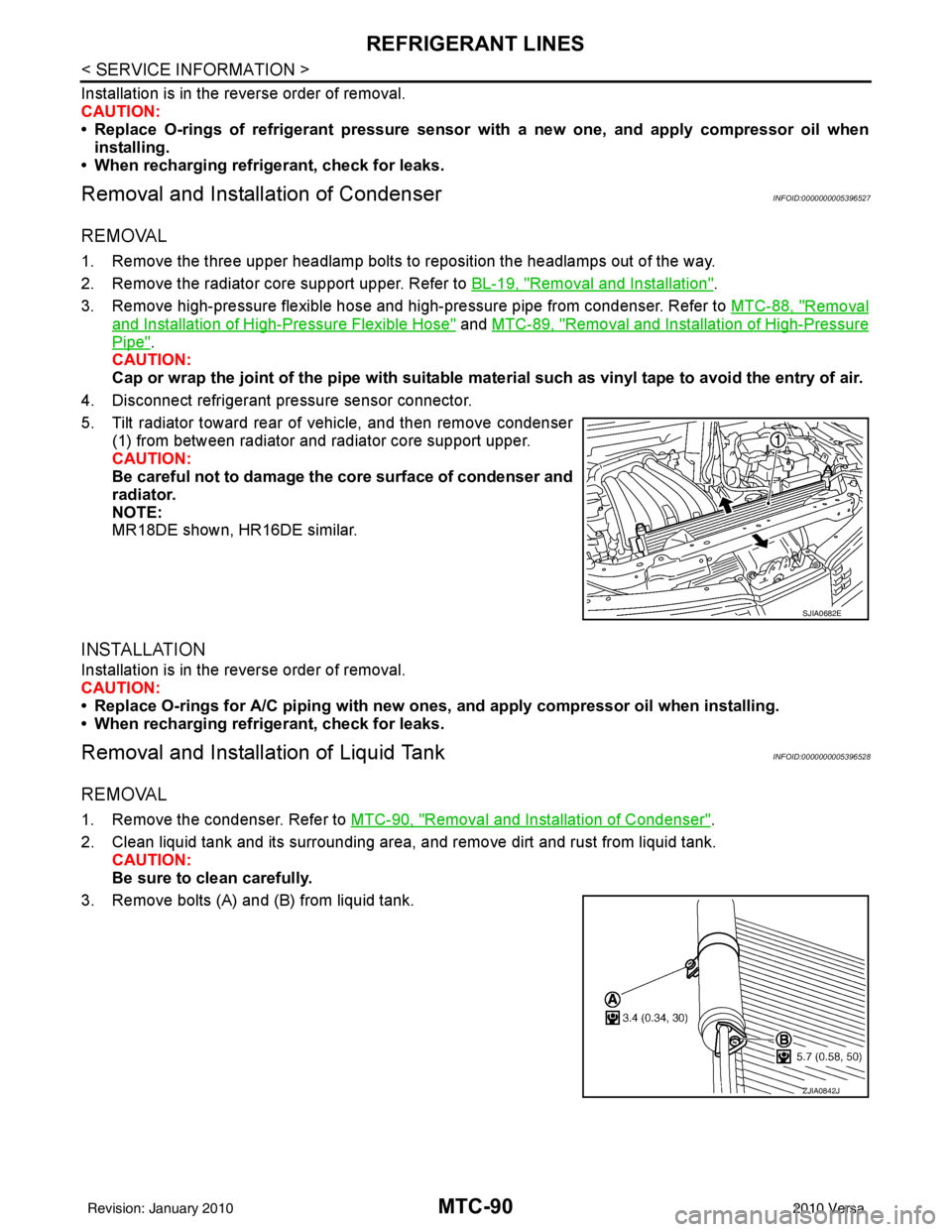

1. Remove the three upper headlamp bolts to reposition the headlamps out of the way.

2. Remove the radiator core support upper. Refer to BL-19, "

Removal and Installation".

3. Remove high-pressure flexible hose and high-pressure pipe from condenser. Refer to MTC-88, "

Removal

and Installation of High-Pressure Flexible Hose" and MTC-89, "Removal and Installation of High-Pressure

Pipe".

CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

4. Disconnect refrigerant pressure sensor connector.

5. Tilt radiator toward rear of vehicle, and then remove condenser (1) from between radiator and radiator core support upper.

CAUTION:

Be careful not to damage the core surface of condenser and

radiator.

NOTE:

MR18DE shown, HR16DE similar.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings for A/C piping with new ones, and apply compressor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Liquid TankINFOID:0000000005396528

REMOVAL

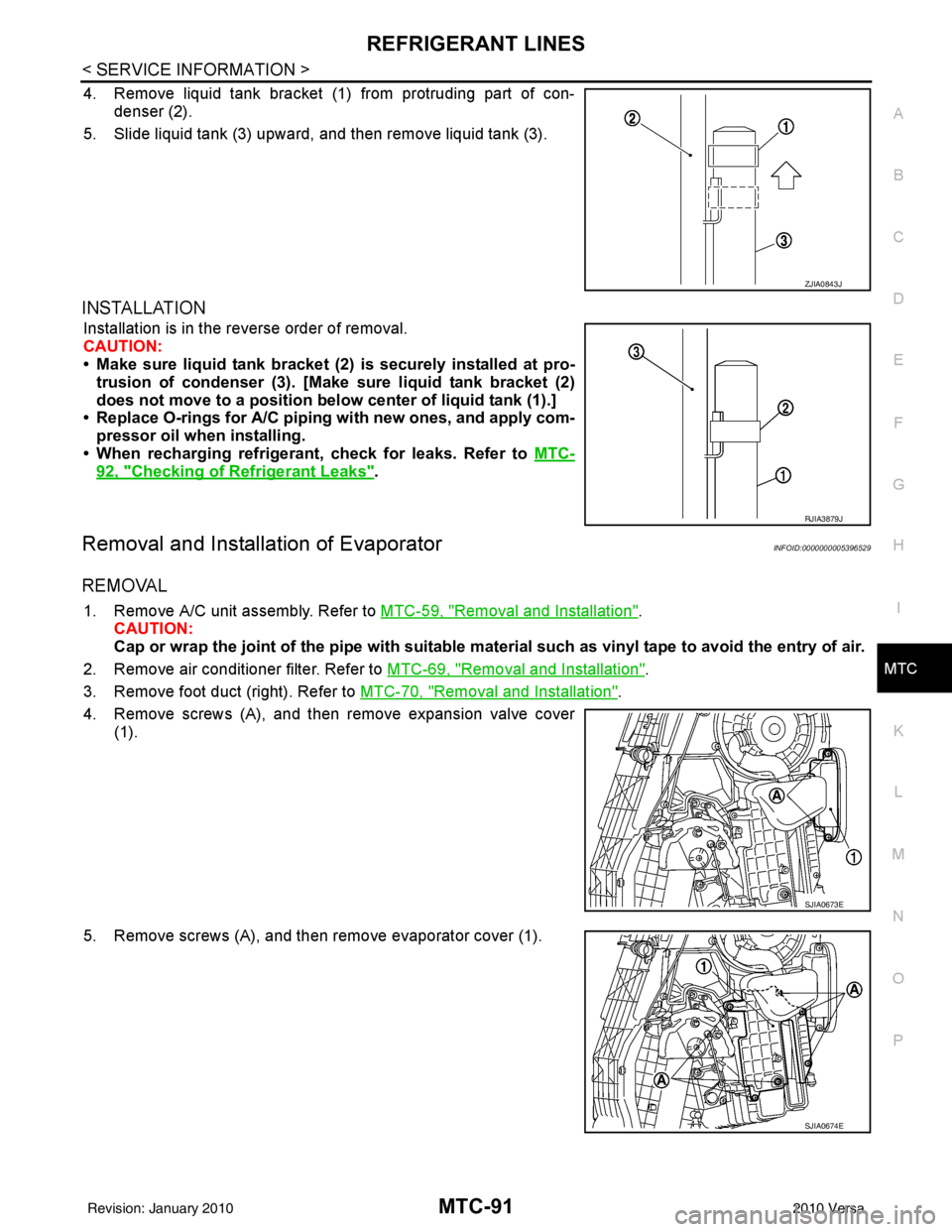

1. Remove the condenser. Refer to MTC-90, "Removal and Installation of Condenser".

2. Clean liquid tank and its surrounding area, and remove dirt and rust from liquid tank. CAUTION:

Be sure to clean carefully.

3. Remove bolts (A) and (B) from liquid tank.

SJIA0682E

ZJIA0842J

Revision: January 20102010 Versa

Page 3370 of 3745

REFRIGERANT LINESMTC-91

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

4. Remove liquid tank bracket (1 ) from protruding part of con-

denser (2).

5. Slide liquid tank (3) upward, and then remove liquid tank (3).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Make sure liquid tank bracket (2) is securely installed at pro- trusion of condenser (3). [Make sure liquid tank bracket (2)

does not move to a position belo w center of liquid tank (1).]

• Replace O-rings for A/C piping with new ones, and apply com-

pressor oil when installing.

• When recharging refrigerant, check for leaks. Refer to MTC-

92, "Checking of Refrigerant Leaks".

Removal and Installation of EvaporatorINFOID:0000000005396529

REMOVAL

1. Remove A/C unit assembly. Refer to MTC-59, "Removal and Installation".

CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

2. Remove air conditioner filter. Refer to MTC-69, "

Removal and Installation".

3. Remove foot duct (right). Refer to MTC-70, "

Removal and Installation".

4. Remove screws (A), and then remove expansion valve cover (1).

5. Remove screws (A), and then remove evaporator cover (1).

ZJIA0843J

RJIA3879J

SJIA0673E

SJIA0674E

Revision: January 20102010 Versa