NISSAN TIIDA 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 3321 of 3745

MTC-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

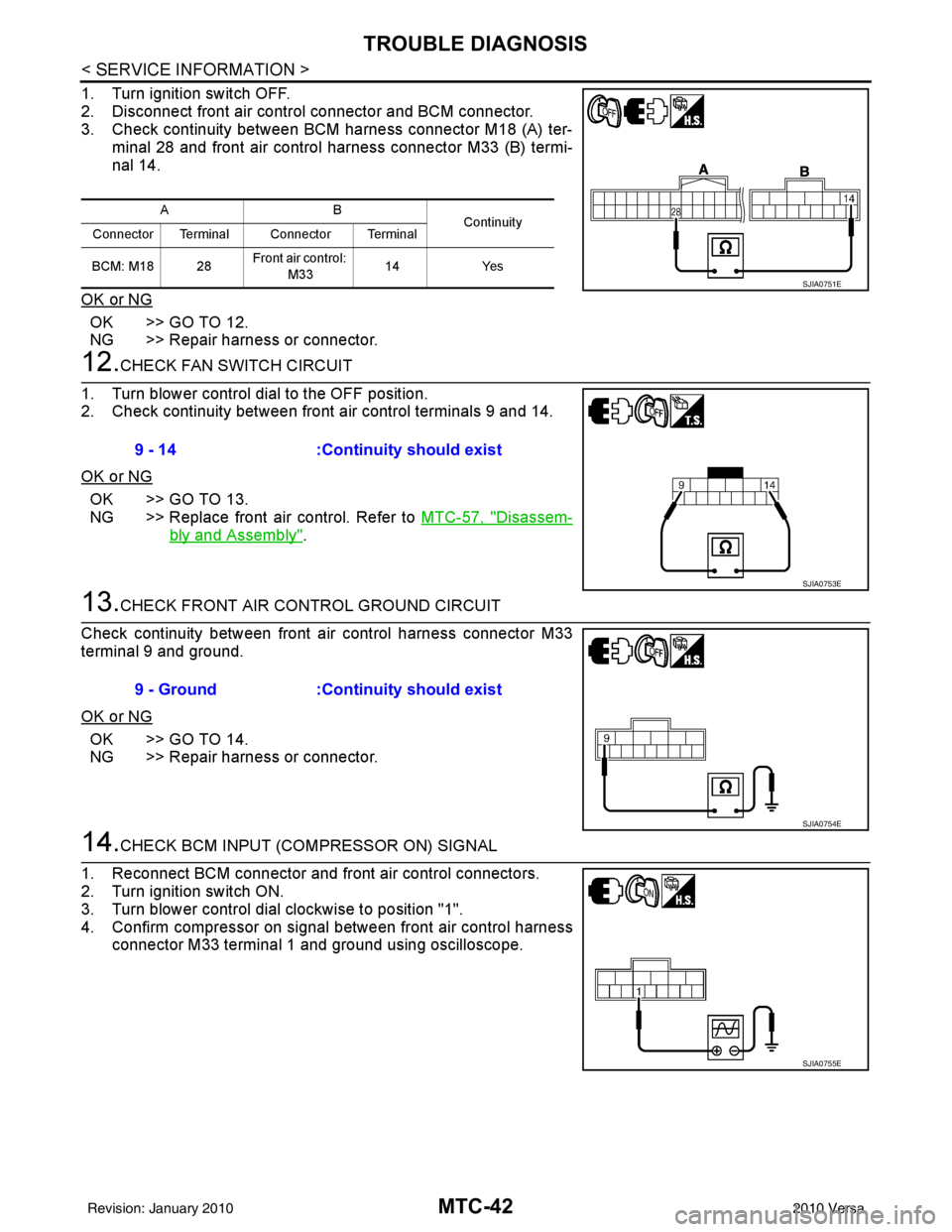

1. Turn ignition switch OFF.

2. Disconnect front air control connector and BCM connector.

3. Check continuity between BCM harness connector M18 (A) ter-minal 28 and front air control harness connector M33 (B) termi-

nal 14.

OK or NG

OK >> GO TO 12.

NG >> Repair harness or connector.

12.CHECK FAN SWITCH CIRCUIT

1. Turn blower control dial to the OFF position.

2. Check continuity between front air control terminals 9 and 14.

OK or NG

OK >> GO TO 13.

NG >> Replace front air control. Refer to MTC-57, "

Disassem-

bly and Assembly".

13.CHECK FRONT AIR CONTROL GROUND CIRCUIT

Check continuity between front air control harness connector M33

terminal 9 and ground.

OK or NG

OK >> GO TO 14.

NG >> Repair harness or connector.

14.CHECK BCM INPUT (COMPRESSOR ON) SIGNAL

1. Reconnect BCM connector and front air control connectors.

2. Turn ignition switch ON.

3. Turn blower control dial clockwise to position "1".

4. Confirm compressor on signal between front air control harness connector M33 terminal 1 and ground using oscilloscope.

AB Continuity

Connector Terminal Connector Terminal

BCM: M18 28 Front air control:

M33 14

Yes

SJIA0751E

9 - 14 :Continuity should exist

SJIA0753E

9 - Ground :Continuity should exist

SJIA0754E

SJIA0755E

Revision: January 20102010 Versa

Page 3322 of 3745

TROUBLE DIAGNOSISMTC-43

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

OK or NG

OK >> GO TO 15.

NG >> GO TO 17.

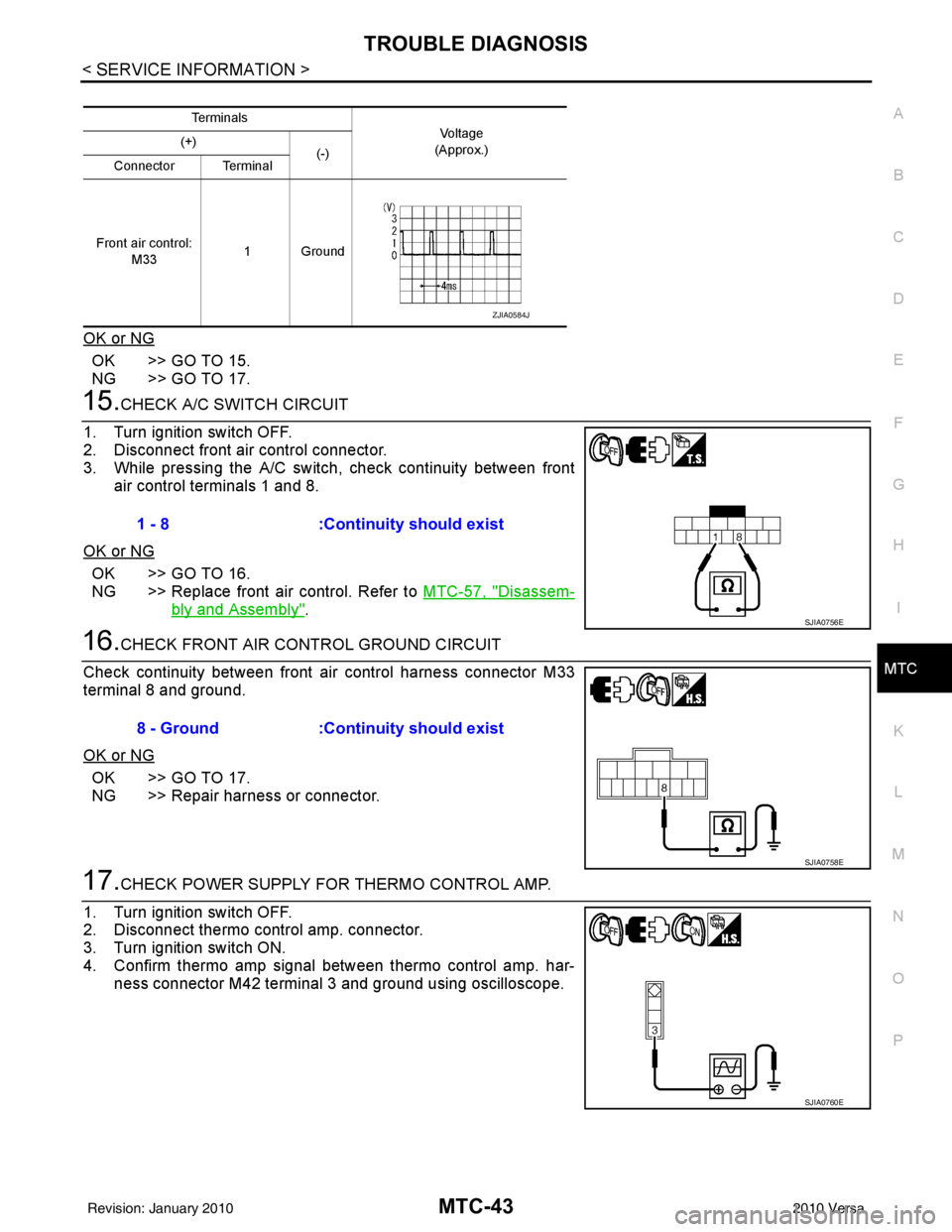

15.CHECK A/C SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. While pressing the A/C switch, check continuity between front air control terminals 1 and 8.

OK or NG

OK >> GO TO 16.

NG >> Replace front air control. Refer to MTC-57, "

Disassem-

bly and Assembly".

16.CHECK FRONT AIR CONTROL GROUND CIRCUIT

Check continuity between front air control harness connector M33

terminal 8 and ground.

OK or NG

OK >> GO TO 17.

NG >> Repair harness or connector.

17.CHECK POWER SUPPLY FOR THERMO CONTROL AMP.

1. Turn ignition switch OFF.

2. Disconnect thermo control amp. connector.

3. Turn ignition switch ON.

4. Confirm thermo amp signal between thermo control amp. har- ness connector M42 terminal 3 and ground using oscilloscope.

Te r m i n a l s

Voltag e

(Approx.)

(+)

(-)

Connector Terminal

Front air control: M33 1Ground

ZJIA0584J

1 - 8

:Continuity should exist

SJIA0756E

8 - Ground :Continuity should exist

SJIA0758E

SJIA0760E

Revision: January 20102010 Versa

Page 3323 of 3745

MTC-44

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

OK or NG

OK >> • GO TO 18 (with CVT).• GO TO 19 (without CVT).

NG >> GO TO 21.

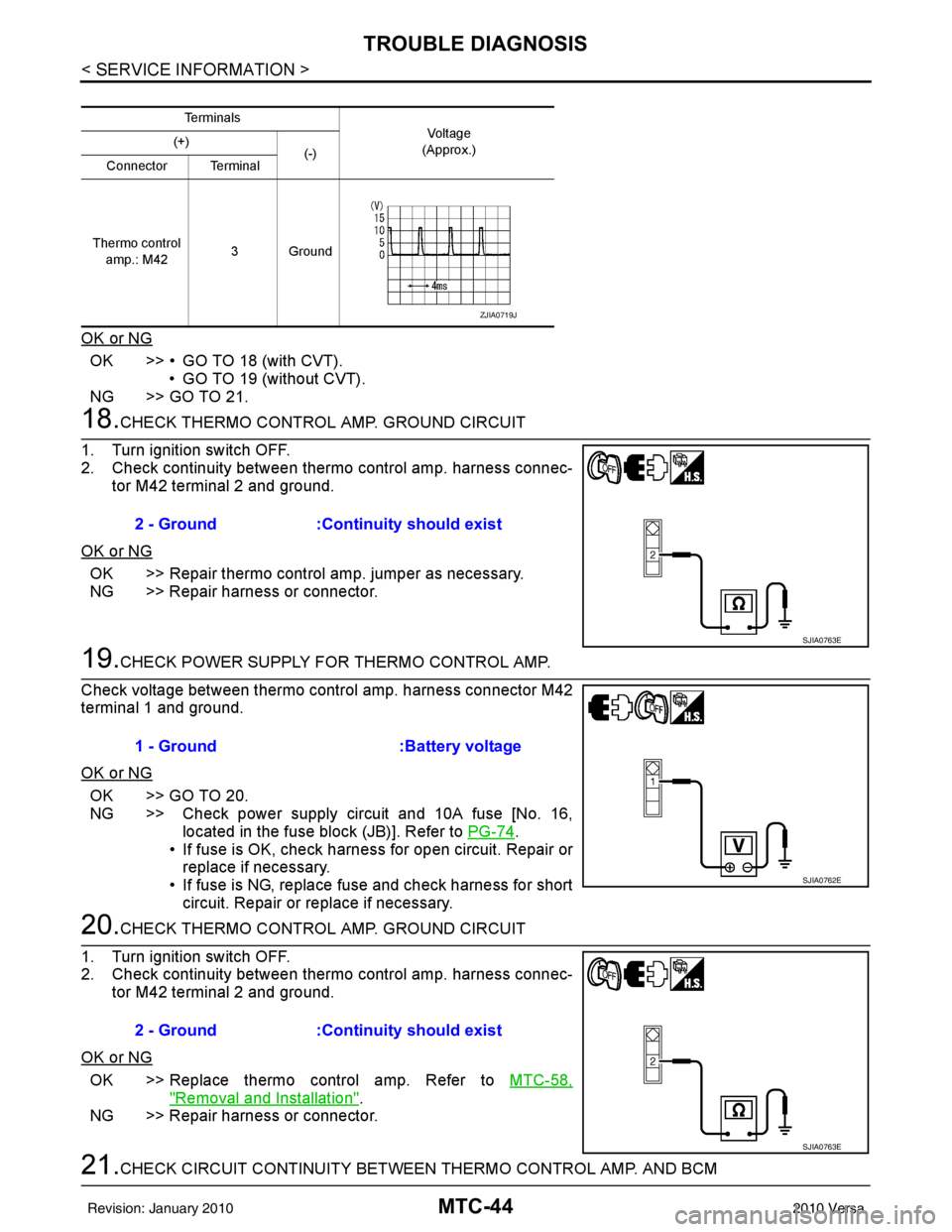

18.CHECK THERMO CONTROL AMP. GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between thermo control amp. harness connec- tor M42 terminal 2 and ground.

OK or NG

OK >> Repair thermo control amp. jumper as necessary.

NG >> Repair harness or connector.

19.CHECK POWER SUPPLY FOR THERMO CONTROL AMP.

Check voltage between thermo control amp. harness connector M42

terminal 1 and ground.

OK or NG

OK >> GO TO 20.

NG >> Check power supply circuit and 10A fuse [No. 16, located in the fuse block (JB)]. Refer to PG-74

.

• If fuse is OK, check harness for open circuit. Repair or

replace if necessary.

• If fuse is NG, replace fuse and check harness for short circuit. Repair or replace if necessary.

20.CHECK THERMO CONTROL AMP. GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between thermo control amp. harness connec- tor M42 terminal 2 and ground.

OK or NG

OK >> Replace thermo control amp. Refer to MTC-58,

"Removal and Installation".

NG >> Repair harness or connector.

21.CHECK CIRCUIT CONTINUITY BETWEEN THERMO CONTROL AMP. AND BCM

Te r m i n a l s

Vo l ta g e

(Approx.)

(+)

(-)

Connector Terminal

Thermo control amp.: M42 3Ground

ZJIA0719J

2 - Ground

:Continuity should exist

SJIA0763E

1 - Ground :Battery voltage

SJIA0762E

2 - Ground:Continuity should exist

SJIA0763E

Revision: January 20102010 Versa

Page 3324 of 3745

TROUBLE DIAGNOSISMTC-45

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

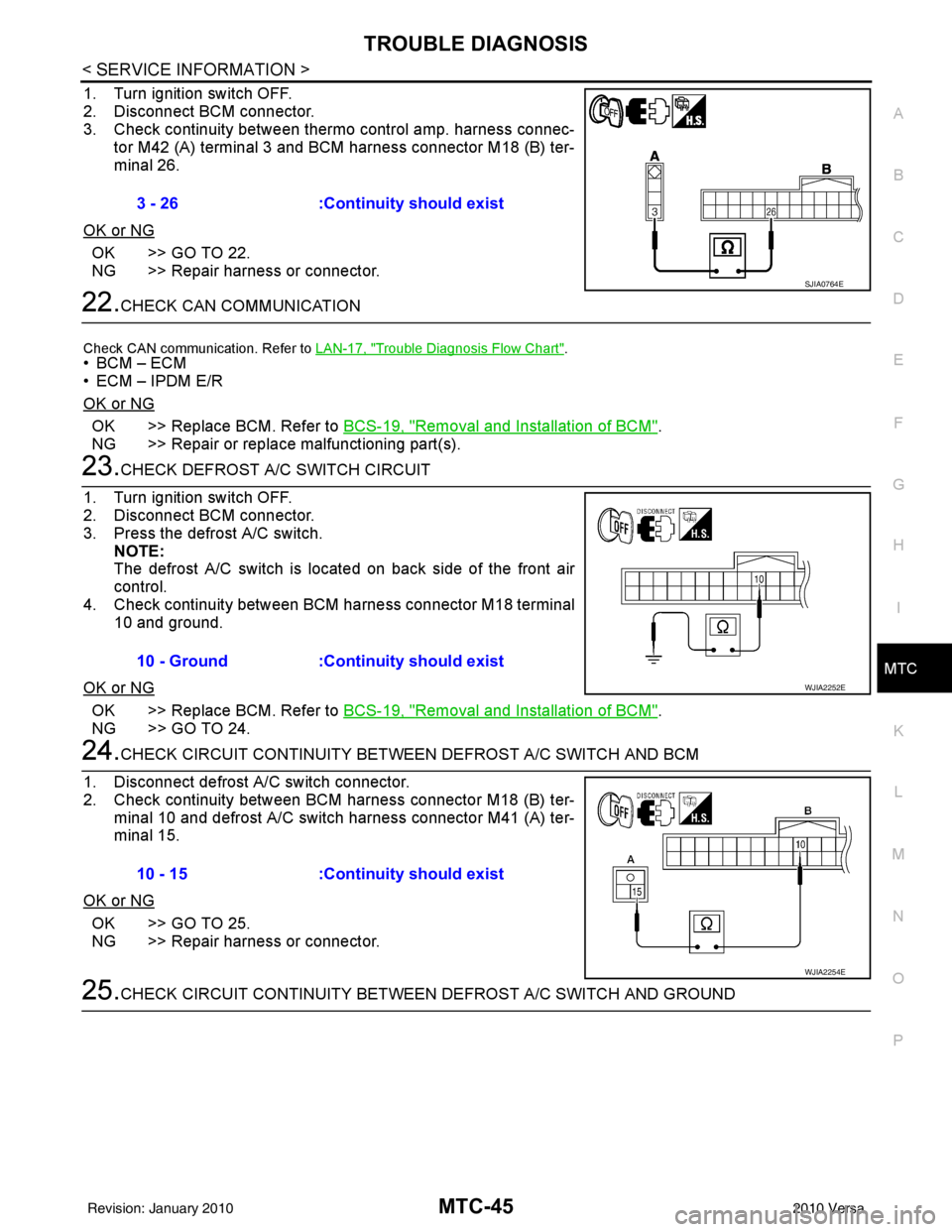

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between thermo control amp. harness connec- tor M42 (A) terminal 3 and BCM harness connector M18 (B) ter-

minal 26.

OK or NG

OK >> GO TO 22.

NG >> Repair harness or connector.

22.CHECK CAN COMMUNICATION

Check CAN communication. Refer to LAN-17, "Trouble Diagnosis Flow Chart".

•BCM – ECM

• ECM – IPDM E/R

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> Repair or replace malfunctioning part(s).

23.CHECK DEFROST A/C SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Press the defrost A/C switch. NOTE:

The defrost A/C switch is located on back side of the front air

control.

4. Check continuity between BCM harness connector M18 terminal 10 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> GO TO 24.

24.CHECK CIRCUIT CONTINUITY BETWEE N DEFROST A/C SWITCH AND BCM

1. Disconnect defrost A/C switch connector.

2. Check continuity between BCM harness connector M18 (B) ter- minal 10 and defrost A/C switch harness connector M41 (A) ter-

minal 15.

OK or NG

OK >> GO TO 25.

NG >> Repair harness or connector.

25.CHECK CIRCUIT CONTINUITY BETWEE N DEFROST A/C SWITCH AND GROUND

3 - 26

:Continuity should exist

SJIA0764E

10 - Ground :Continuity should exist

WJIA2252E

10 - 15:Continuity should exist

WJIA2254E

Revision: January 20102010 Versa

Page 3325 of 3745

MTC-46

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

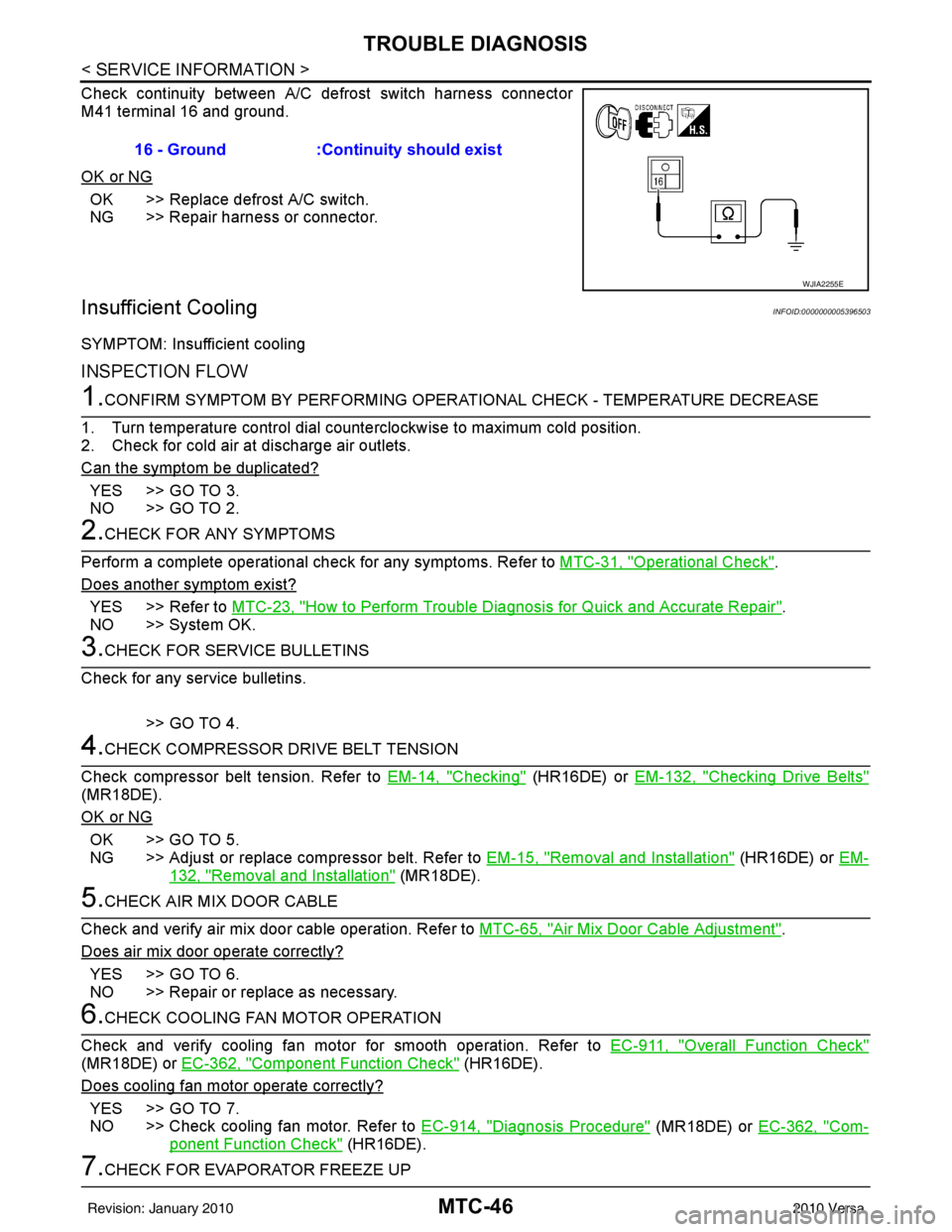

Check continuity between A/C defrost switch harness connector

M41 terminal 16 and ground.

OK or NG

OK >> Replace defrost A/C switch.

NG >> Repair harness or connector.

Insufficient CoolingINFOID:0000000005396503

SYMPTOM: Insufficient cooling

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - TEMPERATURE DECREASE

1. Turn temperature control dial counterclockwise to maximum cold position.

2. Check for cold air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check".

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COMPRESSOR DRIVE BELT TENSION

Check compressor belt tension. Refer to EM-14, "

Checking" (HR16DE) or EM-132, "Checking Drive Belts"

(MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Adjust or replace compressor belt. Refer to EM-15, "

Removal and Installation" (HR16DE) or EM-

132, "Removal and Installation" (MR18DE).

5.CHECK AIR MIX DOOR CABLE

Check and verify air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment".

Does air mix door operate correctly?

YES >> GO TO 6.

NO >> Repair or replace as necessary.

6.CHECK COOLING FAN MOTOR OPERATION

Check and verify cooling fan motor for smooth operation. Refer to EC-911, "

Overall Function Check"

(MR18DE) or EC-362, "Component Function Check" (HR16DE).

Does cooling fan motor operate correctly?

YES >> GO TO 7.

NO >> Check cooling fan motor. Refer to EC-914, "

Diagnosis Procedure" (MR18DE) or EC-362, "Com-

ponent Function Check" (HR16DE).

7.CHECK FOR EVAPORATOR FREEZE UP16 - Ground :Continuity should exist

WJIA2255E

Revision: January 20102010 Versa

Page 3326 of 3745

TROUBLE DIAGNOSISMTC-47

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Start engine and run A/C. Check for evaporator freeze up.

Does evaporator freeze up?

YES >> Perform diagnostic work flow. Refer to "DIAGNOSTIC WORK FLOW".

NO >> GO TO 8.

8.CHECK REFRIGERANT PRESSURE

Check refrigerant pressure with manifold gauge connected. Refer to "PERFORMANCE CHART".

OK or NG

OK >> GO TO 9.

NG >> Perform diagnostic work flow. Refer to "DIAGNOSTIC WORK FLOW".

9.CHECK AIR DUCTS

Check ducts for air leaks.

OK or NG

OK >> If the symptom still exists, perform a complete operational check. Refer to MTC-31, "Operational

Check". If other symptoms exist, refer to MTC-23, "How to Perform Trouble Diagnosis for Quick

and Accurate Repair".

NG >> Repair air leaks.

DIAGNOSTIC WORK FLOW

Revision: January 20102010 Versa

Page 3327 of 3745

MTC-48

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

*1MTC-93, "Checking System for

Leaks Using the Fluorescent Leak

Detector"

*2MTC-79, "Removal and Installation of

Compressor - HR16DE" or MTC-81,

"Removal and Installation of Com-

pressor - MR18DE"

*3 "PERFORMANCE CHART"

*4 "TROUBLE DIAGNOSIS FOR AB- NORMAL PRESSURE" *5

MTC-33, "

Air Mix Door"

AWIIA0999GB

Revision: January 20102010 Versa

Page 3328 of 3745

TROUBLE DIAGNOSISMTC-49

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

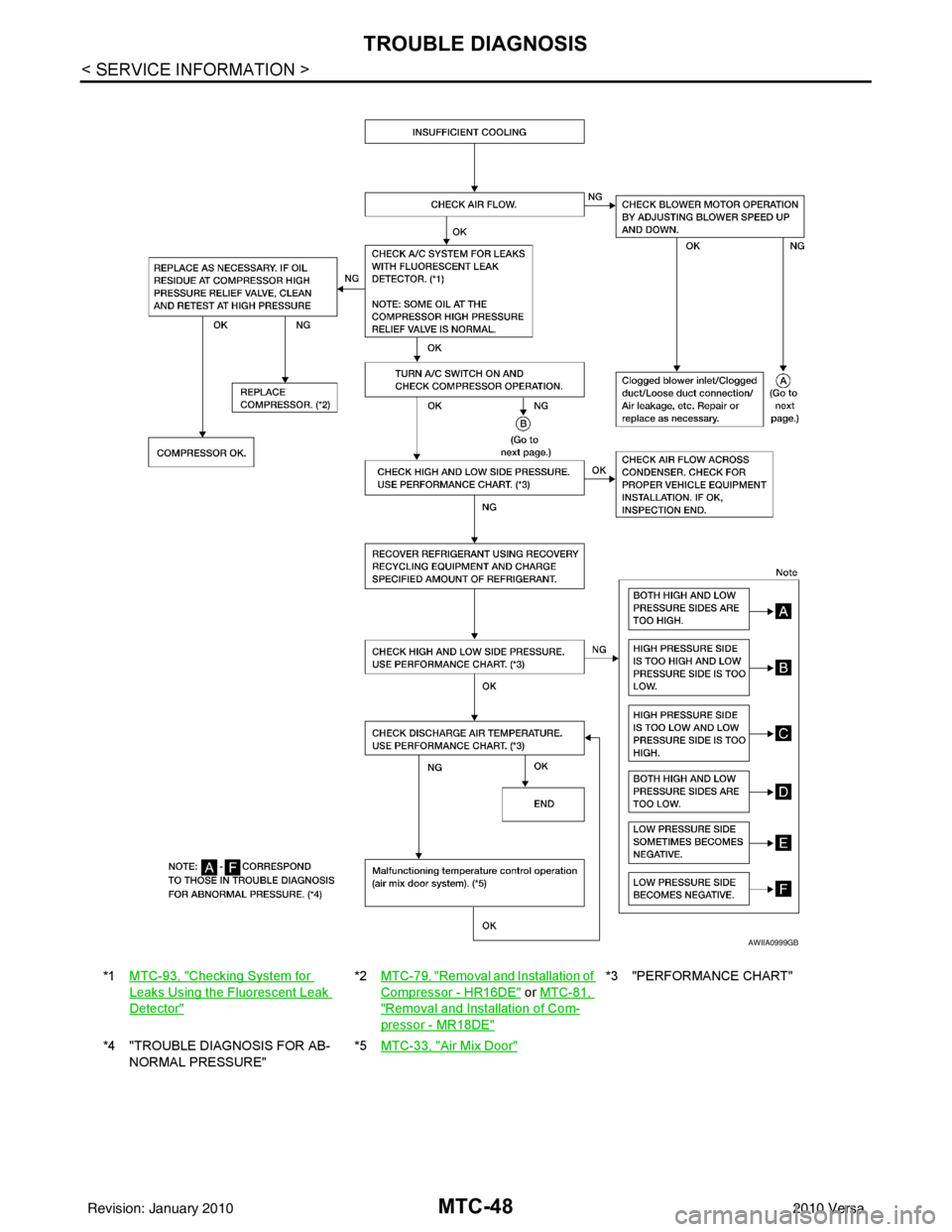

PERFORMANCE CHART

Test Condition

*1 MTC-63, "Removal and Installation"*2MTC-34, "Front Blower Motor Circuit"*3 MTC-79, "Removal and Installation of

Compressor - HR16DE" or MTC-81,

"Removal and Installation of Com-

pressor - MR18DE"

*4 EM-14, "Checking" (HR16DE) EM-

132, "Checking Drive Belts"

(MR18DE) *5

MTC-79, "

Removal and Installation of

Compressor - HR16DE" or MTC-81,

"Removal and Installation of Com-

pressor - MR18DE"

AWIIA1000GB

Revision: January 20102010 Versa

Page 3329 of 3745

MTC-50

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

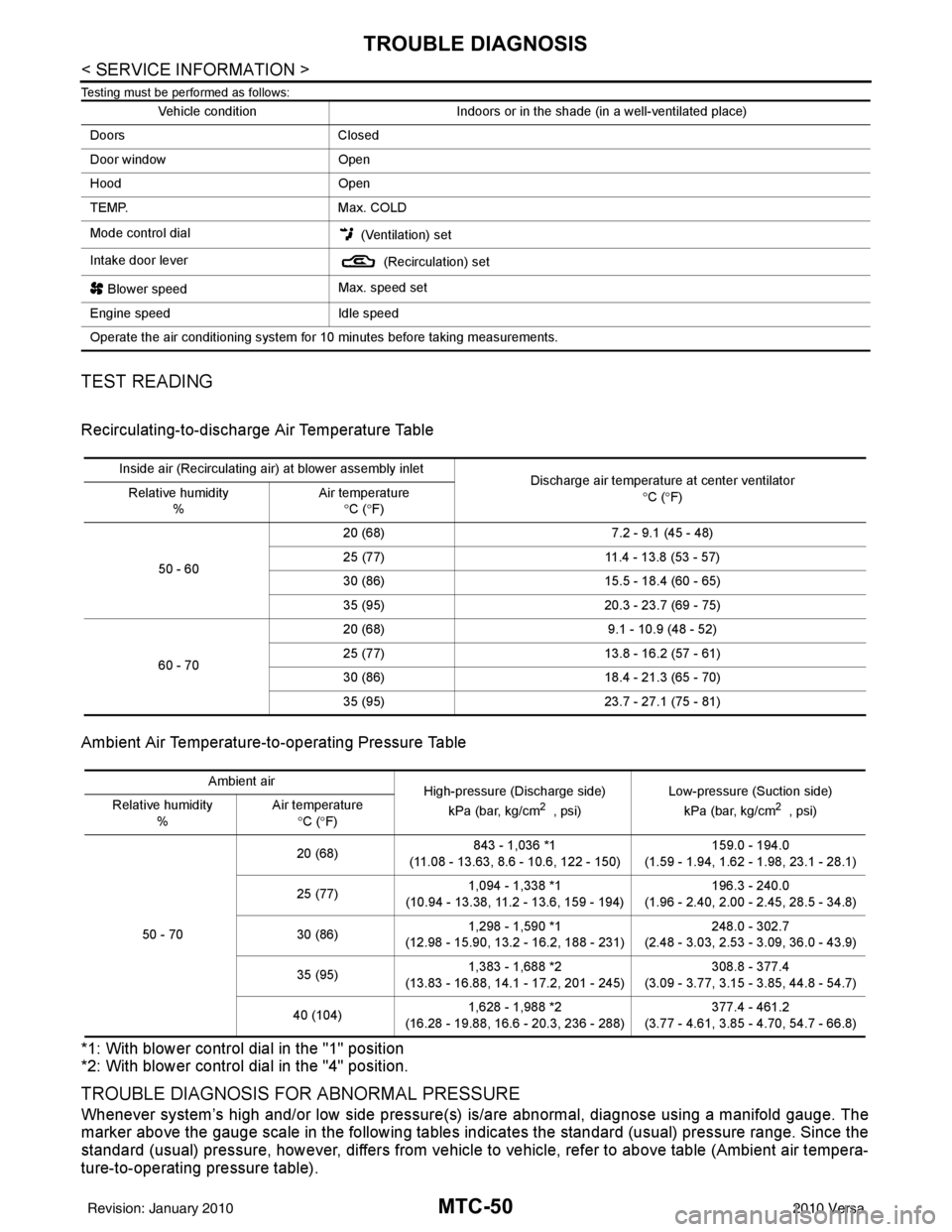

Testing must be performed as follows:

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

*1: With blower control dial in the "1" position

*2: With blower control dial in the "4" position.

TROUBLE DIAGNOSIS FOR ABNORMAL PRESSURE

Whenever system’s high and/or low side pressure(s) is/are abnormal, diagnose using a manifold gauge. The

marker above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the

standard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air tempera-

ture-to-operating pressure table).

Vehicle condition Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode control dial (Ventilation) set

Intake door lever (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

7.2 - 9.1 (45 - 48)

25 (77) 11.4 - 13.8 (53 - 57)

30 (86) 15.5 - 18.4 (60 - 65)

35 (95) 20.3 - 23.7 (69 - 75)

60 - 70 20 (68)

9.1 - 10.9 (48 - 52)

25 (77) 13.8 - 16.2 (57 - 61)

30 (86) 18.4 - 21.3 (65 - 70)

35 (95) 23.7 - 27.1 (75 - 81)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2 , psi) Low-pressure (Suction side)

kPa (bar, kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

843 - 1,036 *1

(11.08 - 13.63, 8.6 - 10.6, 122 - 150) 159.0 - 194.0

(1.59 - 1.94, 1.62 - 1.98, 23.1 - 28.1)

25 (77) 1,094 - 1,338 *1

(10.94 - 13.38, 11.2 - 13.6, 159 - 194) 196.3 - 240.0

(1.96 - 2.40, 2.00 - 2.45, 28.5 - 34.8)

30 (86) 1,298 - 1,590 *1

(12.98 - 15.90, 13.2 - 16.2, 188 - 231) 248.0 - 302.7

(2.48 - 3.03, 2.53 - 3.09, 36.0 - 43.9)

35 (95) 1,383 - 1,688 *2

(13.83 - 16.88, 14.1 - 17.2, 201 - 245) 308.8 - 377.4

(3.09 - 3.77, 3.15 - 3.85, 44.8 - 54.7)

40 (104) 1,628 - 1,988 *2

(16.28 - 19.88, 16.6 - 20.3, 236 - 288) 377.4 - 461.2

(3.77 - 4.61, 3.85 - 4.70, 54.7 - 66.8)

Revision: January 20102010 Versa

Page 3330 of 3745

TROUBLE DIAGNOSISMTC-51

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

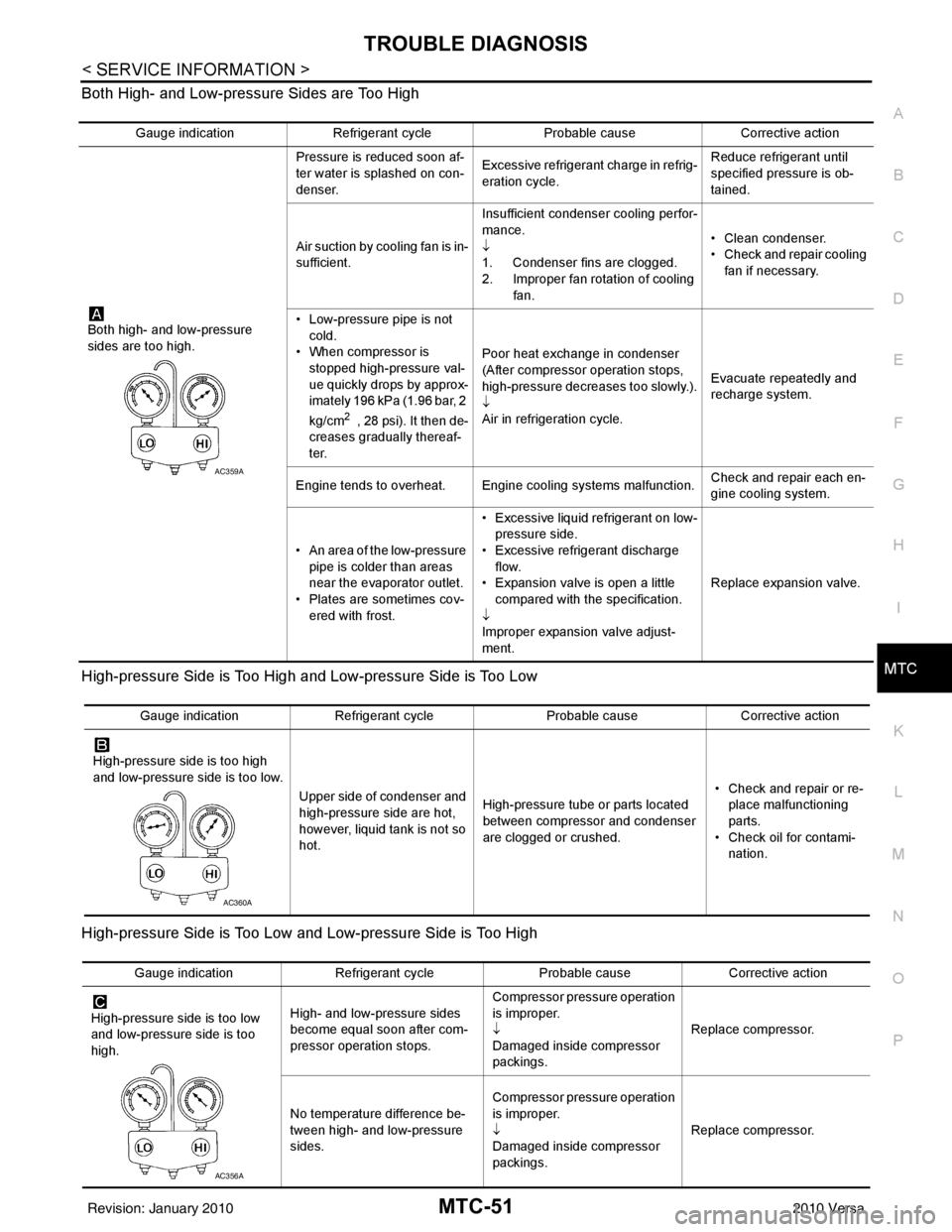

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication

Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in refrig-

eration cycle. Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. • Clean condenser.

• Check and repair cooling

fan if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2 , 28 psi). It then de-

creases gradually thereaf-

ter. Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.

Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction. Check and repair each en-

gine cooling system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant on low-

pressure side.

• Excessive refrigerant discharge flow.

• Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment. Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycle Probable causeCorrective action

High-pressure side is too high

and low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. • Check and repair or re-

place malfunctioning

parts.

• Check oil for contami- nation.

AC360A

Gauge indication Refrigerant cycle Probable causeCorrective action

High-pressure side is too low

and low-pressure side is too

high. High- and low-pressure sides

become equal soon after com-

pressor operation stops. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Revision: January 20102010 Versa