Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2594 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EX-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713806

The Supplemental Res NISSAN TIIDA 2010 Service Repair Manual EX-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713806

The Supplemental Res](/img/5/57397/w960_57397-2593.png)

EX-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713806

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005399808

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2598 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

ON-VEHICLE REPAIR

EXHAUST SYSTEM

ComponentINFOID:0000000005399812

Removal and InstallationINFOID:0000000005399813

WARNING:

• Perform the procedure w NISSAN TIIDA 2010 Service Repair Manual EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

ON-VEHICLE REPAIR

EXHAUST SYSTEM

ComponentINFOID:0000000005399812

Removal and InstallationINFOID:0000000005399813

WARNING:

• Perform the procedure w](/img/5/57397/w960_57397-2597.png)

EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

ON-VEHICLE REPAIR

EXHAUST SYSTEM

ComponentINFOID:0000000005399812

Removal and InstallationINFOID:0000000005399813

WARNING:

• Perform the procedure with the exhaust system fu

lly cooled down because the system will be hot

just after the engine is turned off.

• Be careful not to cut your ha nd on heat insulator edges.

CAUTION:

• Use genuine NISSAN exhaust system parts or equivalent, which are specially designed for heat resistance, corrosion resistance and shape.

REMOVAL

Remove exhaust system components using power tools.

• Remove heated oxygen sensor using Tool as needed.

CAUTION:

1. Main muffler 2. Mounting rubber3. Ring gasket

4. Center muffler 5. Mounting rubber6. Spring

7. Seal bearing 8. Heated oxygen sensor 2 9. Exhaust front tube

10. Seal bearing 11. Stud bolt12. Spring

13. Ground cable (If equipped)

AWBIA0881GB

Tool number : KV10114400 (J-38365)

Revision: January 20102010 Versa

Page 2599 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EXHAUST SYSTEMEX-7

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

Be careful not to damage heated oxygen sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

NISSAN TIIDA 2010 Service Repair Manual EXHAUST SYSTEMEX-7

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

Be careful not to damage heated oxygen sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:](/img/5/57397/w960_57397-2598.png)

EXHAUST SYSTEMEX-7

< ON-VEHICLE REPAIR > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

Be careful not to damage heated oxygen sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bearings with new ones

when installing.

• Before installing a new heated oxygen sensor, clean and apply an ti-seize lubricant to exhaust sys-

tem threads using suitable tool.

• Discard any heated oxygen sensor which has been dr opped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a co ncrete floor; install a new one.

• Do not over-tighten the heated oxygen sensor. Doing so may damage the heated oxygen sensor,

resulting in the MIL coming on.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

• Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

• When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left

directions.

NOTE:

If ground cable was removed, it is not necessary to reinstall it.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in the direction shown.

• Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4). • Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side

in the direction shown.

• Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten bolt (4). • Be careful that the stud bolt does not interfere with the flanged

area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

INSPECTION AFTER INSTALLATION

• With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

• Check to ensure that brackets and mounting rubbers are installed properly and free from undue stress. Improper installation could result in excessive noise and vibration. Oxygen sensor thread cleaner : — (J-43897-18)

Oxygen sensor thread cleaner : — (J-43897-12)

PBIC3797E

PBIC3798E

Revision: January 20102010 Versa

Page 2600 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EX-8

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713807

Th NISSAN TIIDA 2010 Service Repair Manual EX-8

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713807

Th](/img/5/57397/w960_57397-2599.png)

EX-8

< SERVICE INFORMATION >[MR18DE]

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005713807

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005399815

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2603 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

EXHAUST SYSTEM

Checking Exhaust SystemINFOID:0000000005399818

Check exhaust pipes, muffler and mounting for imprope NISSAN TIIDA 2010 Service Repair Manual EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

EXHAUST SYSTEM

Checking Exhaust SystemINFOID:0000000005399818

Check exhaust pipes, muffler and mounting for imprope](/img/5/57397/w960_57397-2602.png)

EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

EXHAUST SYSTEM

Checking Exhaust SystemINFOID:0000000005399818

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration.

• If necessary, repair or replace damaged parts.

ComponentINFOID:0000000005399819

Removal and InstallationINFOID:0000000005399820

WARNING:

• Perform the procedure with the exhaust system fully cooled down because the system will be hot

just after the engine is turned off.

SMA211A

1. Main muffler 2. Mounting rubber3. Ring gasket

4. Center muffler 5. Mounting rubber6. Spring

7. Seal bearing 8. Heated oxygen sensor 29. Exhaust front tube

10. Seal bearing 11. Stud bolt12. Spring

13. Ground cable ( If equipped )

AWBIA0746GB

Revision: January 20102010 Versa

Page 2604 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EX-12

< SERVICE INFORMATION >[MR18DE]

EXHAUST SYSTEM

• Be careful not to cut your ha

nd on heat insulator edges.

CAUTION:

• Use genuine NISSAN exhaust system parts or equivalent, which are special NISSAN TIIDA 2010 Service Repair Manual EX-12

< SERVICE INFORMATION >[MR18DE]

EXHAUST SYSTEM

• Be careful not to cut your ha

nd on heat insulator edges.

CAUTION:

• Use genuine NISSAN exhaust system parts or equivalent, which are special](/img/5/57397/w960_57397-2603.png)

EX-12

< SERVICE INFORMATION >[MR18DE]

EXHAUST SYSTEM

• Be careful not to cut your ha

nd on heat insulator edges.

CAUTION:

• Use genuine NISSAN exhaust system parts or equivalent, which are specially designed for heat resistance, corrosion resistance and shape.

REMOVAL

Remove exhaust system components using power tools.

• Remove heated oxygen sensor using Tool as needed.

CAUTION:

Be careful not to damage heated oxygen sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bear ings with new ones when installing.

• Before installing a new heated oxygen sensor, clean and apply anti-seize lubricant to exhaust sys-

tem threads using suitable tool.

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a co ncrete floor; install a new one.

• Do not over-tighten the heated oxygen sensor. Doing so may damage the heated oxygen sensor,

resulting in the MIL coming on.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

• Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

• When installing each mounting rubb er, avoid twisting or unusual extension in up/down and right/left

directions.

NOTE:

If ground cable was removed, it is not necessary to reinstall it.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in the direction shown.

• Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4). • Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side in the direction shown.

• Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten bolt (4). • Be careful that the stud bolt does not interfere with the flanged

area ( ).

• Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.Tool number : KV10114400 (J-38365)

Oxygen sensor thread cleaner : — (J-43897-18)

Oxygen sensor thread cleaner : — (J-43897-12)

PBIC3797E

PBIC3798E

Revision: January 20102010 Versa

Page 2606 of 3745

FAX-1

DRIVELINE/AXLE

CEF

G H

I

J

K L

M

SECTION FA X

A

B

FA X

N

O P

CONTENTS

FRONT AXLE

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

General Precautions .................................................3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ................................ ......5

FRONT WHEEL HUB AND KNUCKLE .............6

On-Vehicle Inspection and Service ..................... .....6

Removal and Installation ..........................................6

FRONT DRIVE SHAFT ......................................9

On-Vehicle Inspection and Service ..........................9

Removal and Installation (Left Side) .........................9

Removal and Installation (Right Side) .....................10

Disassembly and Assembly (Left Side) ...................13

Disassembly and Assembly (Right Side) .................18

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

25

Wheel Bearing .........................................................25

Drive Shaft ...............................................................25

Dynamic Damper .....................................................25

Boot Bands ..............................................................25

Revision: January 20102010 Versa

Page 2607 of 3745

FAX-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714408

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005397119

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2610 of 3745

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGFAX-5

< SERVICE INFORMATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

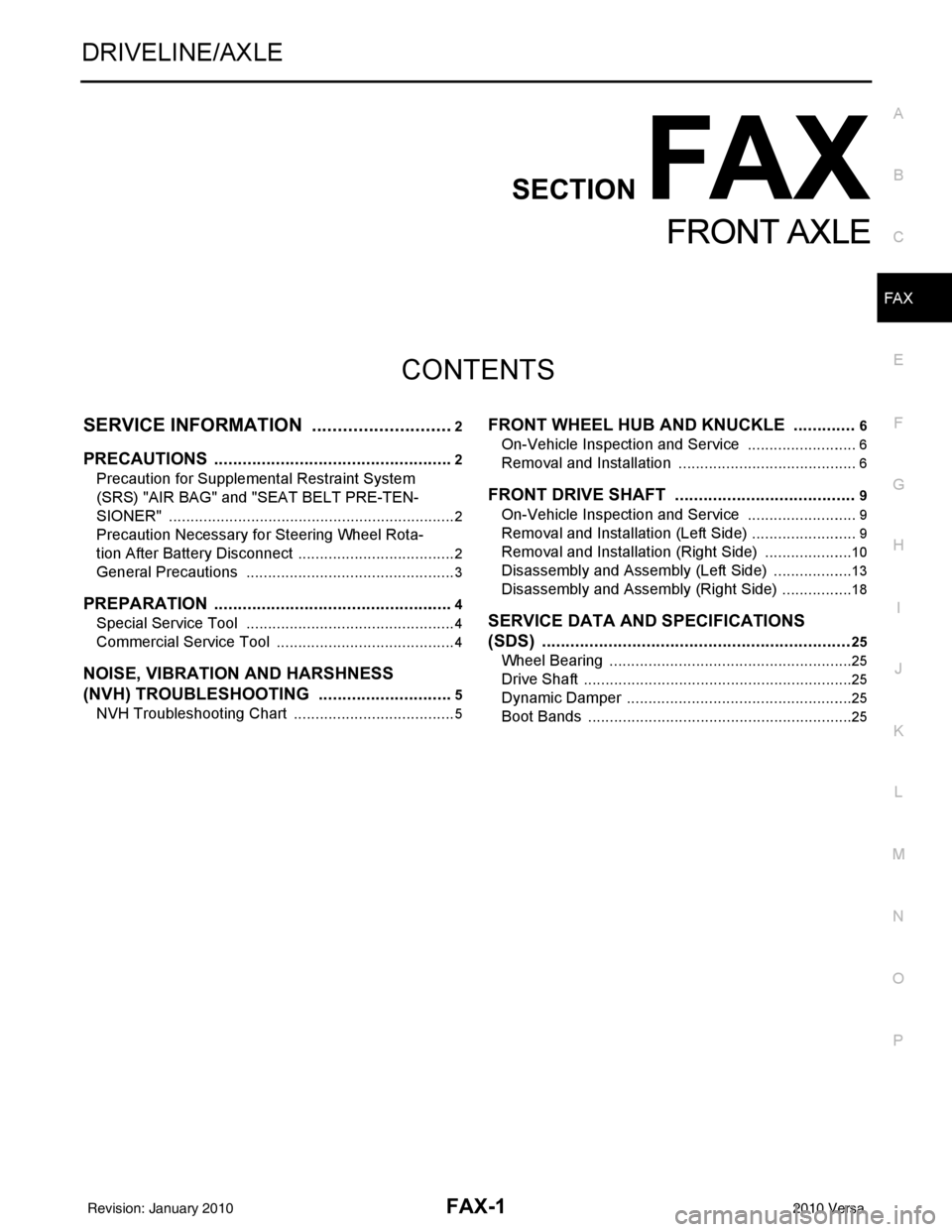

NVH Troubleshooting ChartINFOID:0000000005397123

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

—

—

—

FAX-6—

FAX-6

FSU-6, "

NVH Troubleshooting Chart

"

Refer to FRONT AXLE in this chart.

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

Refer to DRIVE SHAFT in this chart. BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

FRONT SUSPENSION

FRONT AXLE

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKES

STEERING

SymptomDRIVE

SHAFT

Noise

××××××× ××

Shake × × ××××× ××

FRONT

AXLE Noise

×××× ×××××

Shake ×××× ×××××

Vibration ×××××××

Shimmy ×××××××

Shudder × × ×× ××

Poor quality ride or handling ×××××

Revision: January 20102010 Versa

Page 2611 of 3745

FAX-6

< SERVICE INFORMATION >

FRONT WHEEL HUB AND KNUCKLE

FRONT WHEEL HUB AND KNUCKLE

On-Vehicle Inspection and ServiceINFOID:0000000005397124

• Check the axle and suspension parts for excessive play, wear, or damage.

• Shake each front wheel to check for excessive play as shown.

FRONT WHEEL BEARING INSPECTION

• Move wheel hub and bearing assembly in the axial direction by hand. Make sure the axial end play is within

specification.

• Check that the wheel hub bearing operates smoothly.

• Replace the wheel hub assembly if the axial end play exceeds specification, or if the wheel bearing does not turn smoothly. Refer to RAX-6, "

Removal and Installation" .

CAUTION:

The wheel hub assembly does not requ ire maintenance. If any of the following symptoms are noted,

replace the wheel hub assembly.

• Growling noise is emitted from the wheel hub bearing during operation.

• Wheel hub bearing drags or turns roughly.

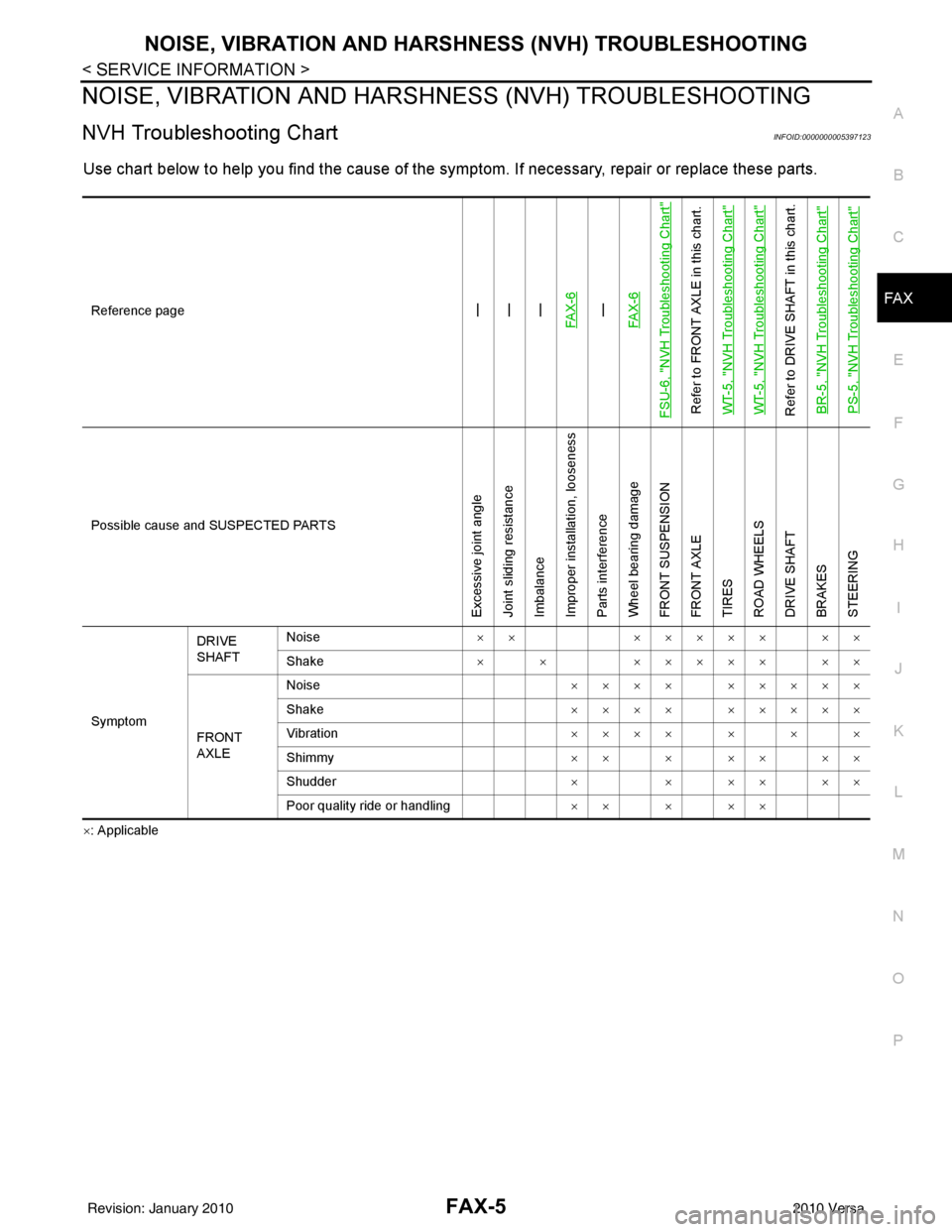

Removal and InstallationINFOID:0000000005397125

COMPONENT

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-7, "Adjustment" .

SMA525A

Axial end play : 0.05 mm (0.002 in) or less

1. Drive shaft2. Steering knuckle3. Splash guard

4. Wheel hub and bearing assembly 5. Cotter pin

WDIA0366E

Revision: January 20102010 Versa