Front NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2638 of 3745

FL-8

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

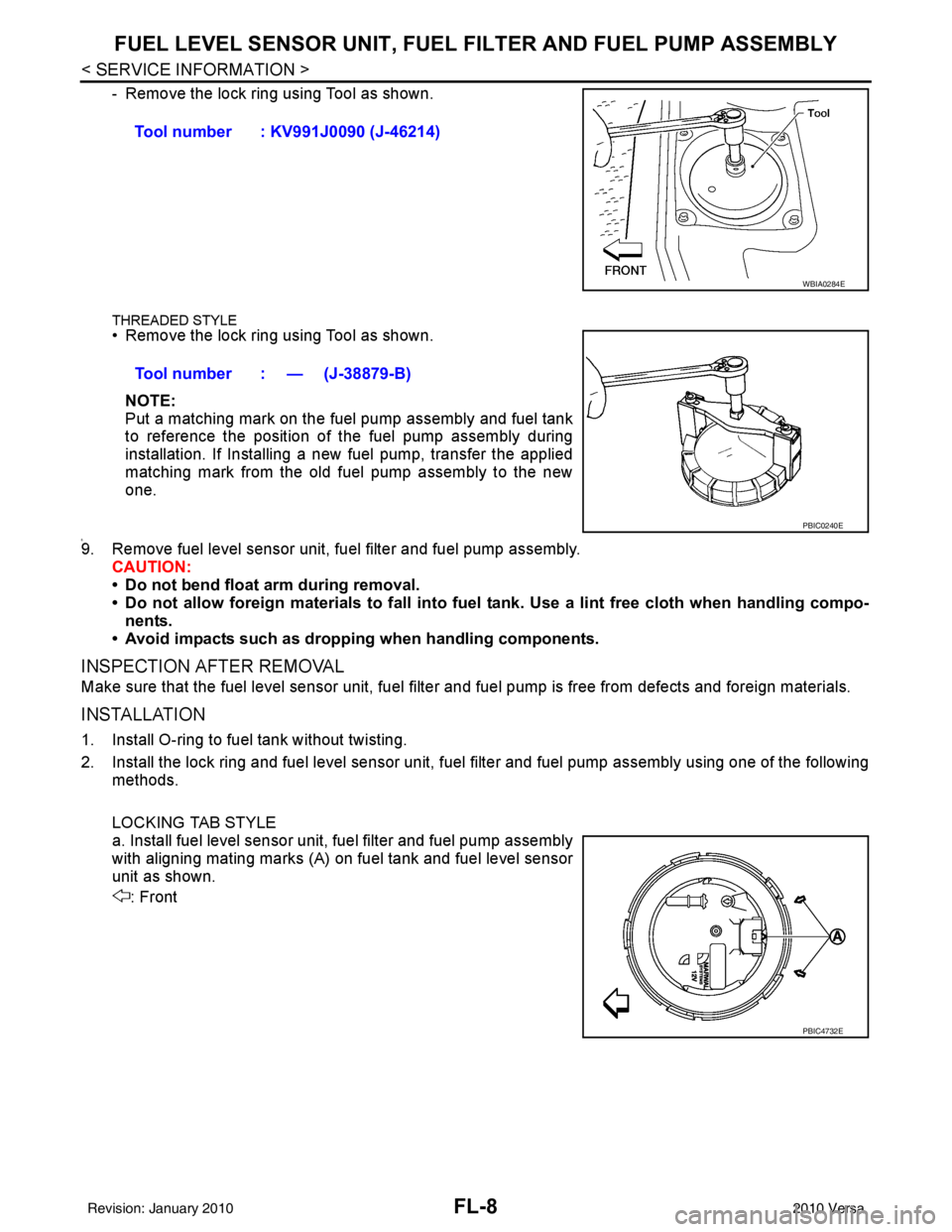

- Remove the lock ring using Tool as shown.

THREADED STYLE• Remove the lock ring using Tool as shown.

NOTE:

Put a matching mark on the fuel pump assembly and fuel tank

to reference the position of the fuel pump assembly during

installation. If Installing a new fuel pump, transfer the applied

matching mark from the old fuel pump assembly to the new

one.

8.9. Remove fuel level sensor unit, fuel filter and fuel pump assembly. CAUTION:

• Do not bend float arm during removal.

• Do not allow foreign materials to fall into fuel tank. Use a lint free cloth when handling compo-

nents.

• Avoid impacts such as dropping when handling components.

INSPECTION AFTER REMOVAL

Make sure that the fuel level sensor unit, fuel filter and fuel pump is free from defects and foreign materials.

INSTALLATION

1. Install O-ring to fuel tank without twisting.

2. Install the lock ring and fuel level sensor unit, fuel filter and fuel pump assembly using one of the following

methods.

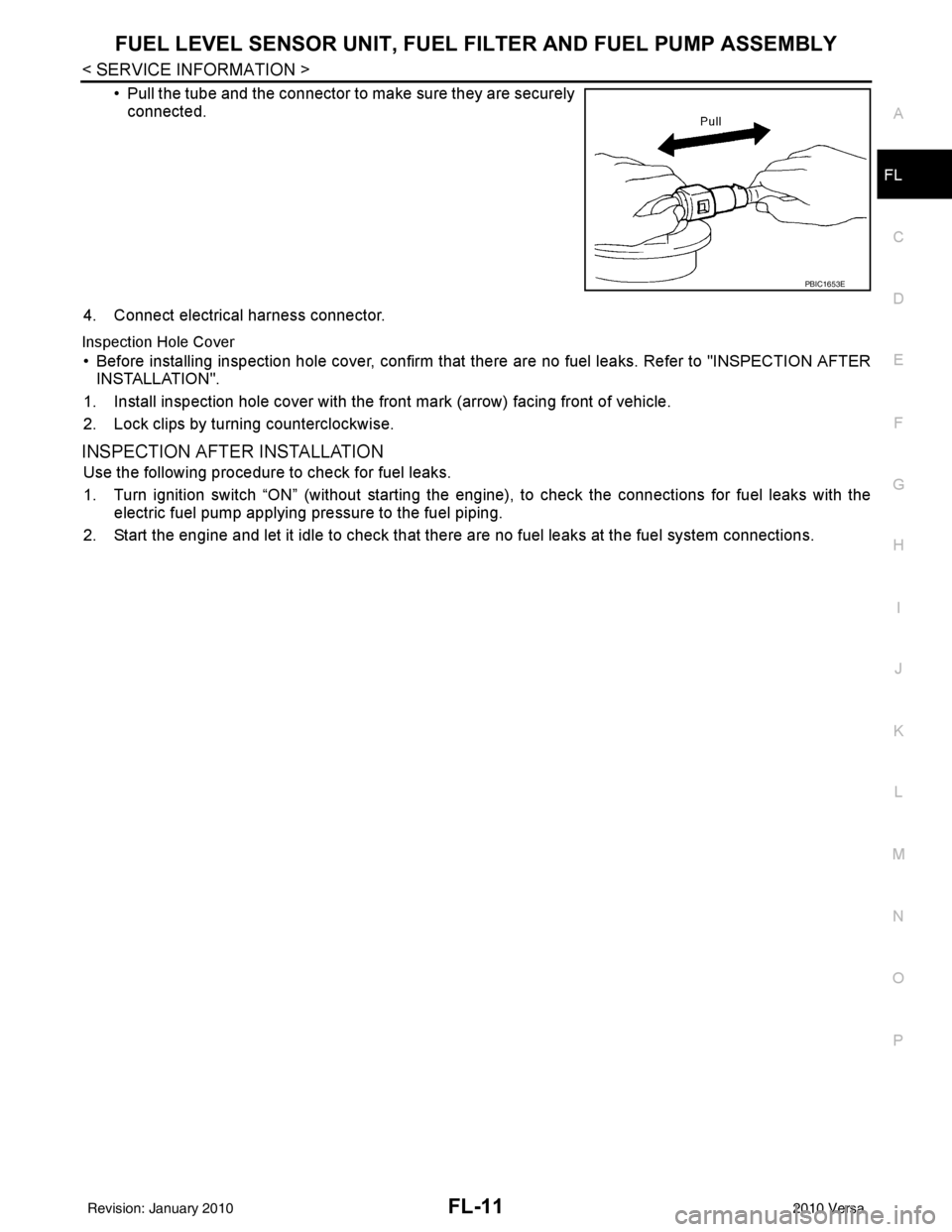

LOCKING TAB STYLE

a. Install fuel level sensor unit, fuel filter and fuel pump assembly

with aligning mating marks (A) on fuel tank and fuel level sensor

unit as shown.

: FrontTool number : KV991J0090 (J-46214)

WBIA0284E

Tool number : — (J-38879-B)

PBIC0240E

PBIC4732E

Revision: January 20102010 Versa

Page 2641 of 3745

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLYFL-11

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

• Pull the tube and the connector to make sure they are securely

connected.

4. Connect electrical harness connector.

Inspection Hole Cover

• Before installing inspection hole cover, confirm that there are no fuel leaks. Refer to "INSPECTION AFTER INSTALLATION".

1. Install inspection hole cover with the front mark (arrow) facing front of vehicle.

2. Lock clips by turning counterclockwise.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (without starting the engi ne), to check the connections for fuel leaks with the

electric fuel pump applying pressure to the fuel piping.

2. Start the engine and let it idle to check that ther e are no fuel leaks at the fuel system connections.

PBIC1653E

Revision: January 20102010 Versa

Page 2642 of 3745

FL-12

< SERVICE INFORMATION >

FUEL TANK

FUEL TANK

ComponentINFOID:0000000006055187

Removal and InstallationINFOID:0000000006055188

REMOVAL

WARNING:

Be sure to read “General Precautions” when working on the fuel system. Refer to FL-5, "

General Pre-

caution".

1. Drain fuel from fuel tank if necessary. Refer to FL-6, "

Removal and Installation".

CAUTION:

• Because fuel tank becomes unstable when installing/removing, fuel should be drained if the

level exceeds specification FL-6, "

Removal and Installation".

• Situate vehicle on a flat and solid surface.

2. Open fuel door and unscrew the fuel filler cap to release the pressure inside the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to EC-496, "

Inspection" (HR16DE), EC-582, "Fuel

Pressure Check" (MR18DE).

4. Remove rear seat bottom. Refer to SE-16, "

Removal and Installation" (60:40 Split - Hatchback), SE-22,

"Removal and Installation" (60:40 Split - Sedan), or SE-26, "Removal and Installation" (Fixed).

5. Turn the three retainers 90 ° in a clockwise direction and remove the fuel pump inspection hole cover.

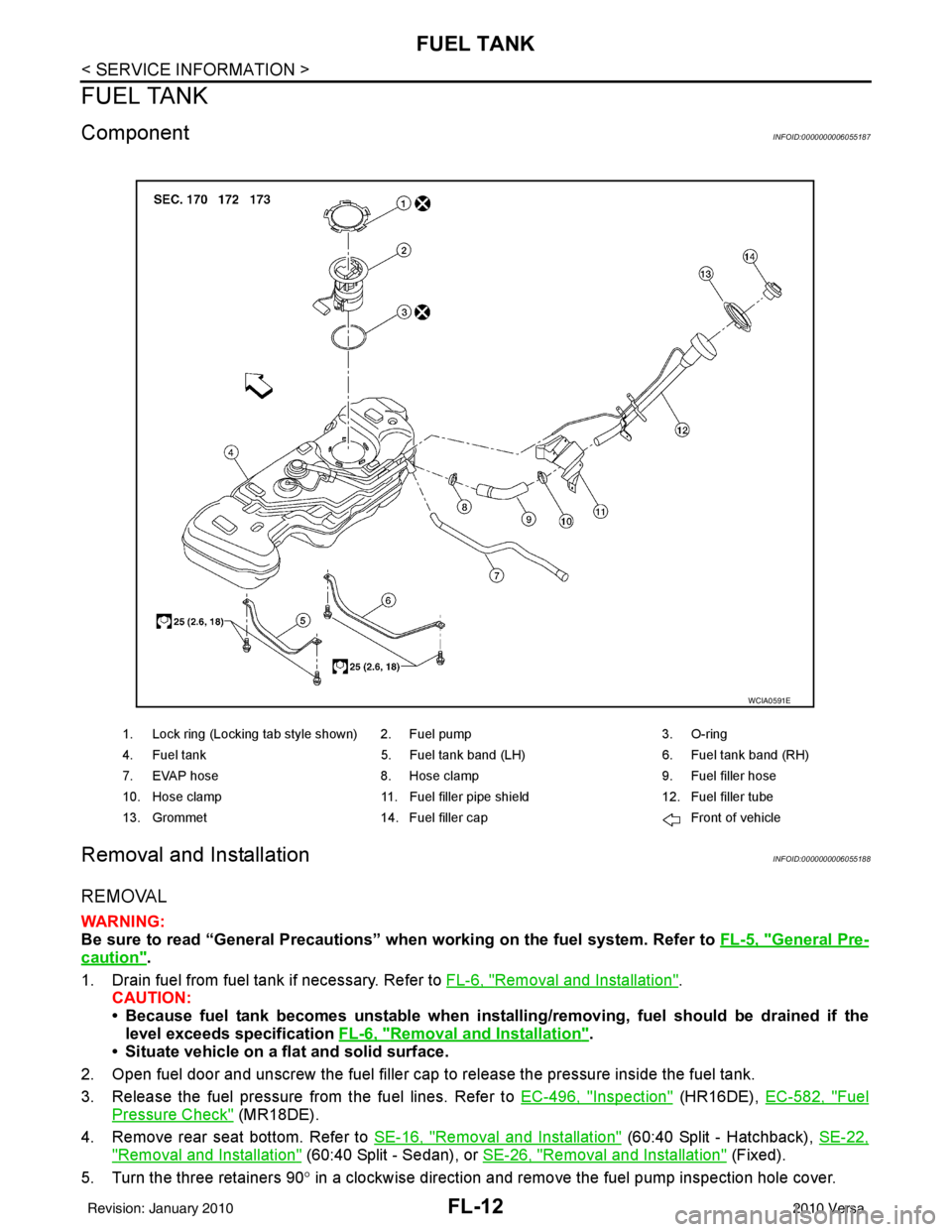

1. Lock ring (Locking tab style shown) 2. Fuel pump 3. O-ring

4. Fuel tank 5. Fuel tank band (LH) 6. Fuel tank band (RH)

7. EVAP hose 8. Hose clamp 9. Fuel filler hose

10. Hose clamp 11. Fuel filler pipe shield 12. Fuel filler tube

13. Grommet 14. Fuel filler cap Front of vehicle

WCIA0591E

Revision: January 20102010 Versa

Page 2643 of 3745

FUEL TANKFL-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

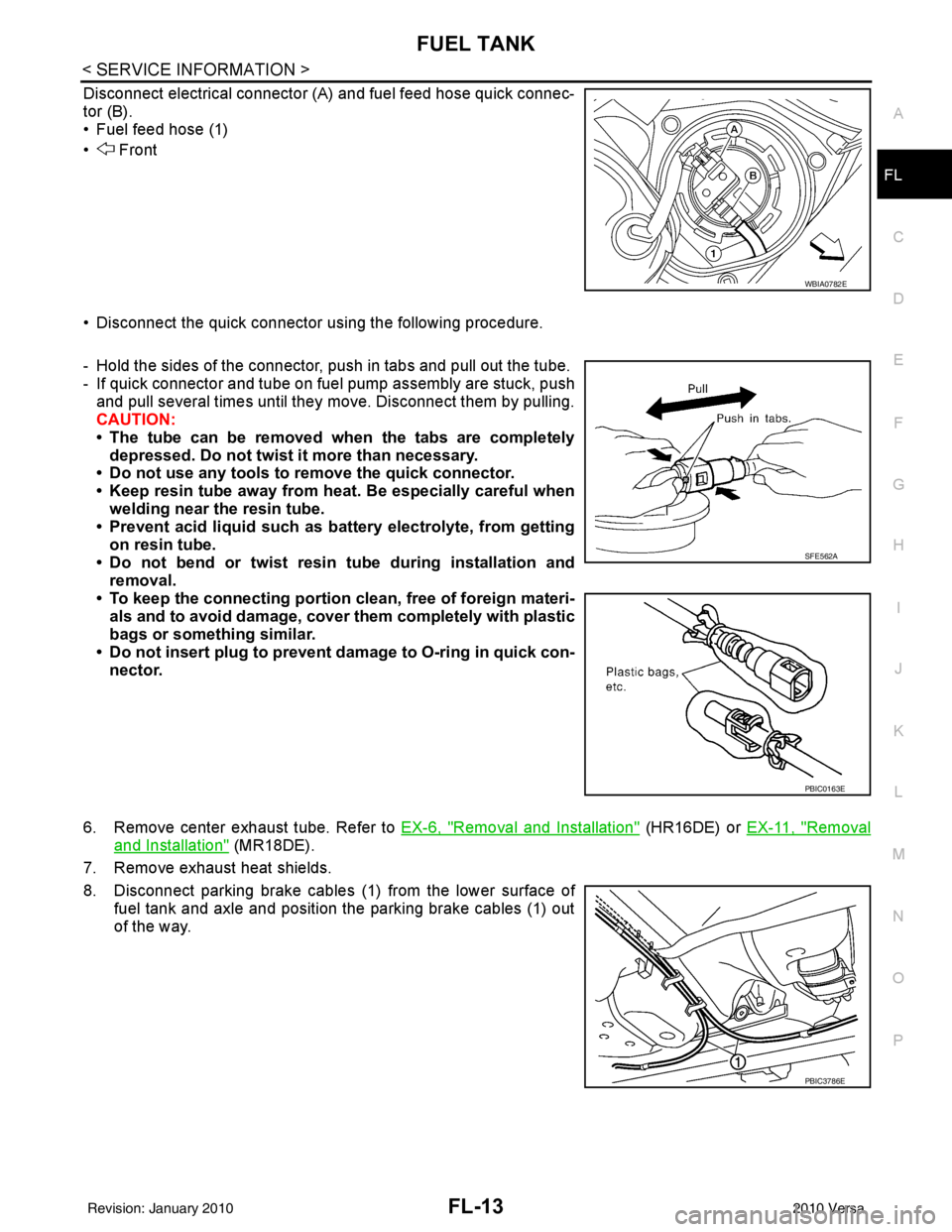

Disconnect electrical connector (A

) and fuel feed hose quick connec-

tor (B).

• Fuel feed hose (1)

• Front

• Disconnect the quick connector using the following procedure.

- Hold the sides of the connector, push in tabs and pull out the tube.

- If quick connector and tube on fuel pump assembly are stuck, push and pull several times until they move. Disconnect them by pulling.

CAUTION:

• The tube can be removed when the tabs are completely depressed. Do not twist it more than necessary.

• Do not use any tools to remove the quick connector.

• Keep resin tube away from heat. Be especially careful when welding near the resin tube.

• Prevent acid liquid such as ba ttery electrolyte, from getting

on resin tube.

• Do not bend or twist resin tube during installation and removal.

• To keep the connecting portion clean, free of foreign materi- als and to avoid damage, cover them completely with plastic

bags or something similar.

• Do not insert plug to prevent damage to O-ring in quick con-

nector.

6. Remove center exhaust tube. Refer to EX-6, "

Removal and Installation" (HR16DE) or EX-11, "Removal

and Installation" (MR18DE).

7. Remove exhaust heat shields.

8. Disconnect parking brake cables (1) from the lower surface of

fuel tank and axle and position the parking brake cables (1) out

of the way.

WBIA0782E

SFE562A

PBIC0163E

PBIC3786E

Revision: January 20102010 Versa

Page 2645 of 3745

FUEL TANKFL-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

EVAP Canister

1. Check the connection for damage or any foreign materials.

2. Align the connector with the tube, then insert the c

onnector straight into the tube until a “click” sound is

heard.

3. After connecting, make sure that the connection is secure. • Pull the tube and the connector to make sure they are securely connected.

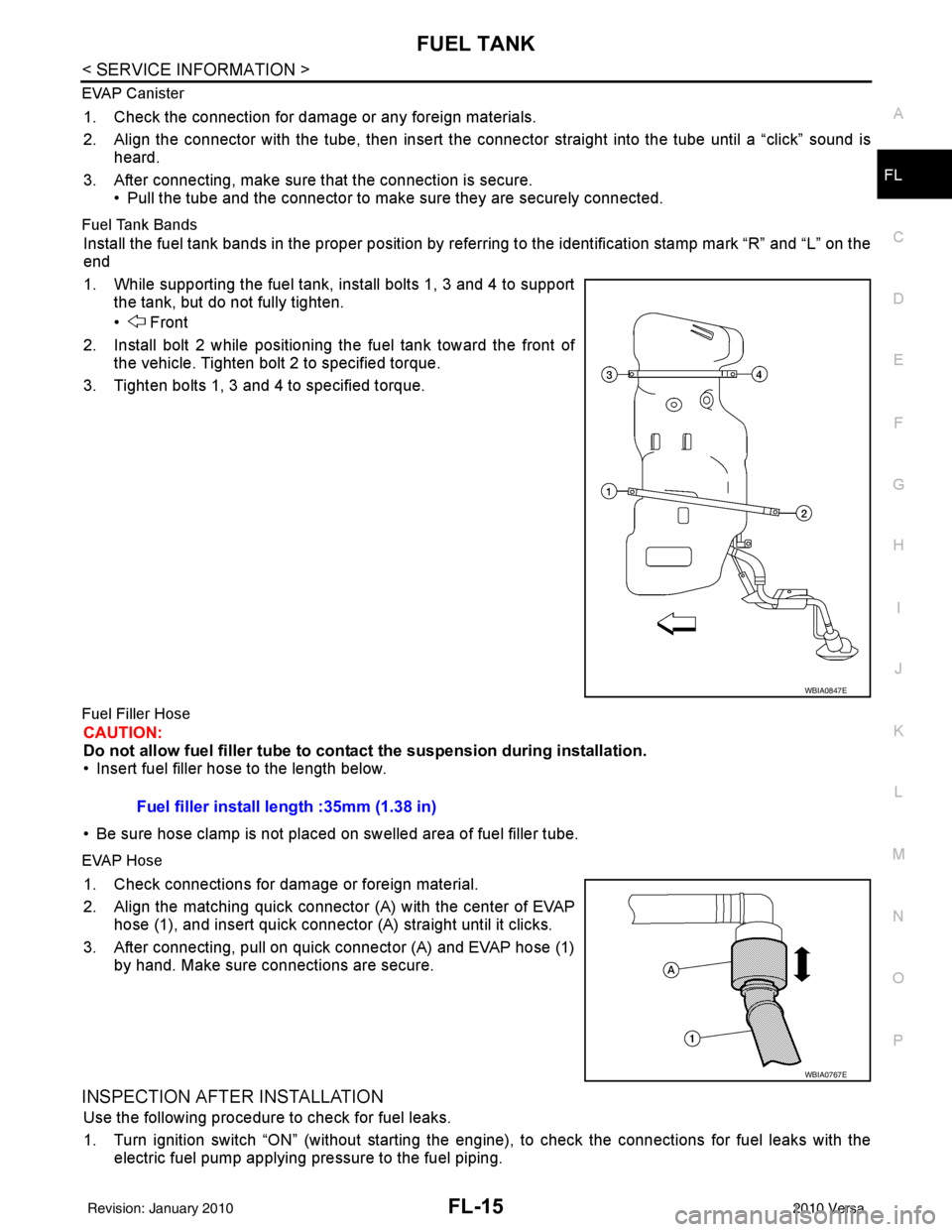

Fuel Tank Bands

Install the fuel tank bands in the proper position by referring to the identification stamp mark “R” and “L” on the

end

1. While supporting the fuel tank, install bolts 1, 3 and 4 to supportthe tank, but do not fully tighten.

• Front

2. Install bolt 2 while positioning the fuel tank toward the front of the vehicle. Tighten bolt 2 to specified torque.

3. Tighten bolts 1, 3 and 4 to specified torque.

Fuel Filler Hose

CAUTION:

Do not allow fuel filler tube to cont act the suspension during installation.

• Insert fuel filler hose to the length below.

• Be sure hose clamp is not placed on swelled area of fuel filler tube.

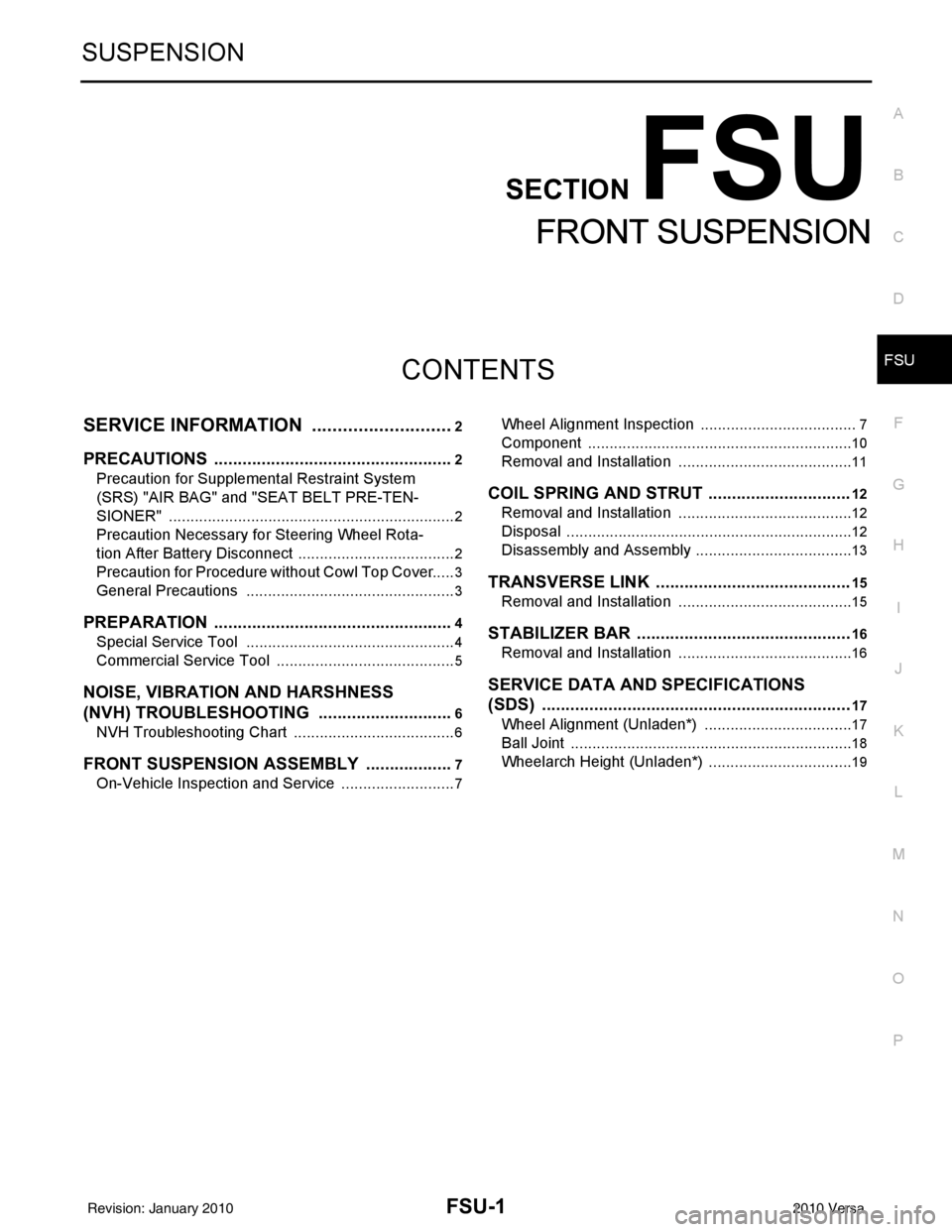

EVAP Hose

1. Check connections for damage or foreign material.

2. Align the matching quick connector (A) with the center of EVAP

hose (1), and insert quick connector (A) straight until it clicks.

3. After connecting, pull on quick connector (A) and EVAP hose (1) by hand. Make sure connections are secure.

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (without starting the engi ne), to check the connections for fuel leaks with the

electric fuel pump applying pressure to the fuel piping.

WBIA0847E

Fuel filler install length :35mm (1.38 in)

WBIA0767E

Revision: January 20102010 Versa

Page 2648 of 3745

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Procedure without Cowl Top Cover ......3

General Precautions .................................................3

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

6

NVH Troubleshooting Chart ................................ ......6

FRONT SUSPENSION ASSEMBLY ...................7

On-Vehicle Inspection and Service ..................... ......7

Wheel Alignment Inspection .....................................7

Component .......................................................... ....10

Removal and Installation .........................................11

COIL SPRING AND STRUT ..............................12

Removal and Installation .........................................12

Disposal ...................................................................12

Disassembly and Assembly .....................................13

TRANSVERSE LINK .........................................15

Removal and Installation .........................................15

STABILIZER BAR .............................................16

Removal and Installation .........................................16

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Wheel Alignment (Unladen*) ...................................17

Ball Joint ..................................................................18

Wheelarch Height (Unladen*) ..................................19

Revision: January 20102010 Versa

Page 2649 of 3745

FSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005397054

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005397055

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2653 of 3745

FSU-6

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

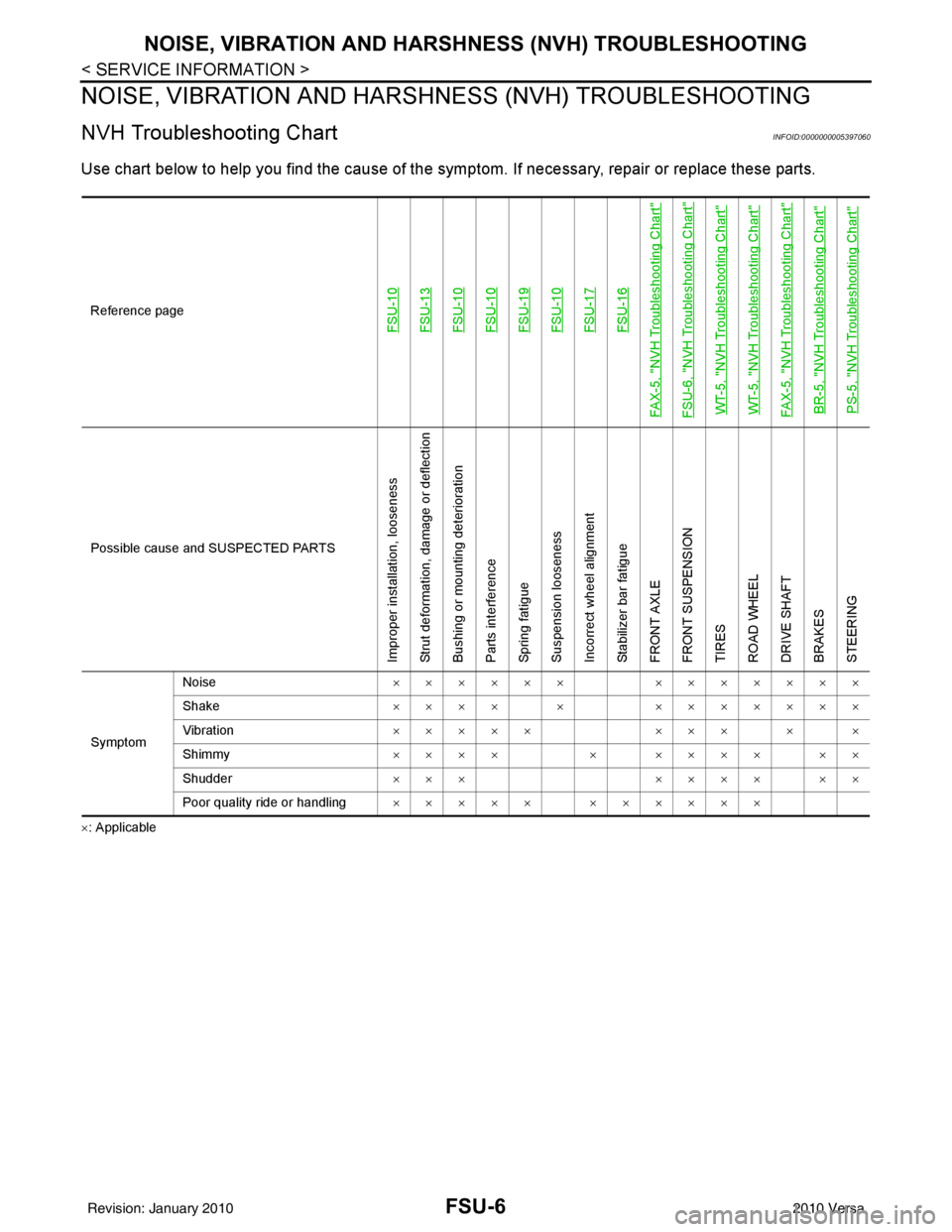

NVH Troubleshooting ChartINFOID:0000000005397060

Use chart below to help you find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference page

FSU-10FSU-13FSU-10FSU-10FSU-19FSU-10FSU-17FSU-16

FAX-5, "

NVH Troubleshooting Chart

"

FSU-6, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

WT-5, "

NVH Troubleshooting Chart

"

FAX-5, "

NVH Troubleshooting Chart

"

BR-5, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause an

d SUSPECTED PARTS

Improper installation, looseness

Strut deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

FRONT AXLE

FRONT SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomNoise

×××××× ×××××××

Shake ×××× × ×××××××

Vibration ××××× ××× × ×

Shimmy ×××× × ×××× ××

Shudder ××× ×××× ××

Poor quality ride or handling ××××× ××××××

Revision: January 20102010 Versa

Page 2654 of 3745

FRONT SUSPENSION ASSEMBLYFSU-7

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000005397061

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

INSPECTION OF LOWER BALL JOINT END PLAY

1. Set front wheels in a straight-ahead position. Do not depress brake pedal.

2. Place an iron bar or similar tool between transverse link and steering knuckle.

3. Measure axial end play by prying it up and down.

CAUTION:

Be careful not to damage ball joint boot. Do not damage the installation position by applying

excessive force.

STRUT INSPECTION

Check for oil leakage, damage and replace as necessary.

Wheel Alignment InspectionINFOID:0000000005397062

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-6, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FAX-6, "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the suspension member for any damage.

8. Check the vehicle height. Refer to FSU-19, "

Wheelarch Height (Unladen*)" .

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is re commended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated. • Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific a lignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-17, "Wheel

Alignment (Unladen*)" .

1. When displaying the alignment settings, many alignm ent machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.Axial end play : 0 mm (0 in)

Revision: January 20102010 Versa

Page 2655 of 3745

FSU-8

< SERVICE INFORMATION >

FRONT SUSPENSION ASSEMBLY

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER, CASTER AND KINGPIN INCLINATION ANGLES INSPECTION

• Camber, caster, kingpin inclination angles cannot be adjusted.

• Before inspection, mount front wheels onto turning radius gauge. Mount rear wheels onto a stand that has

same height so vehicle will remain horizontal.

Using a CCK Gauge

Install the CCK gauge attachment [SST: KV991040S0] with the following procedure on wheel, then measure

wheel alignment.

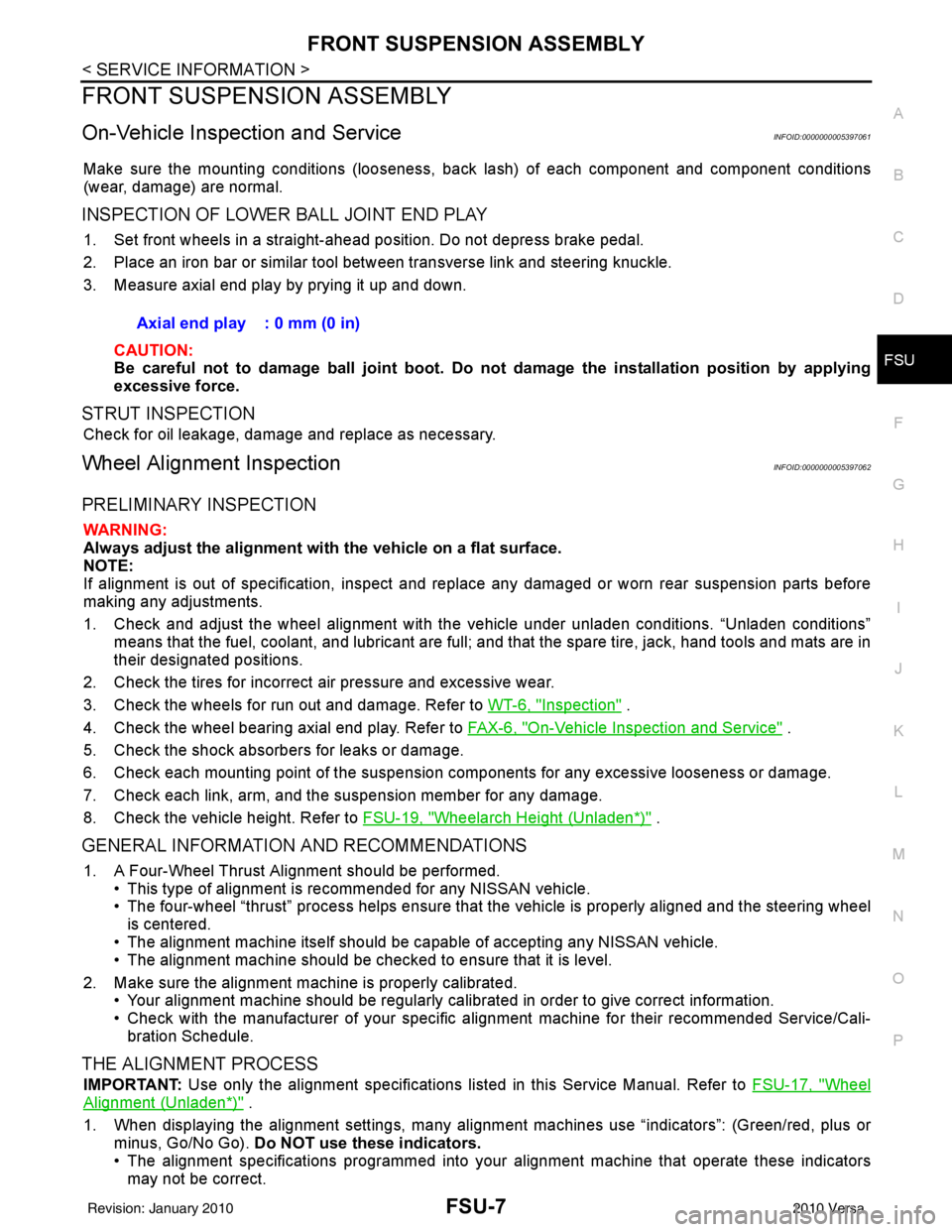

1. Remove three wheel nuts, and install the guide bolts to hub bolt.

2. Screw the adapter into the plate unt il it contacts the plate tightly.

3. Screw the center plate into the plate.

4. Insert the plate assembly on the guide bolt. Put the spring in, and then evenly screw the three guide bolt nuts. When fastening

the guide nuts, do not completely compress the spring.

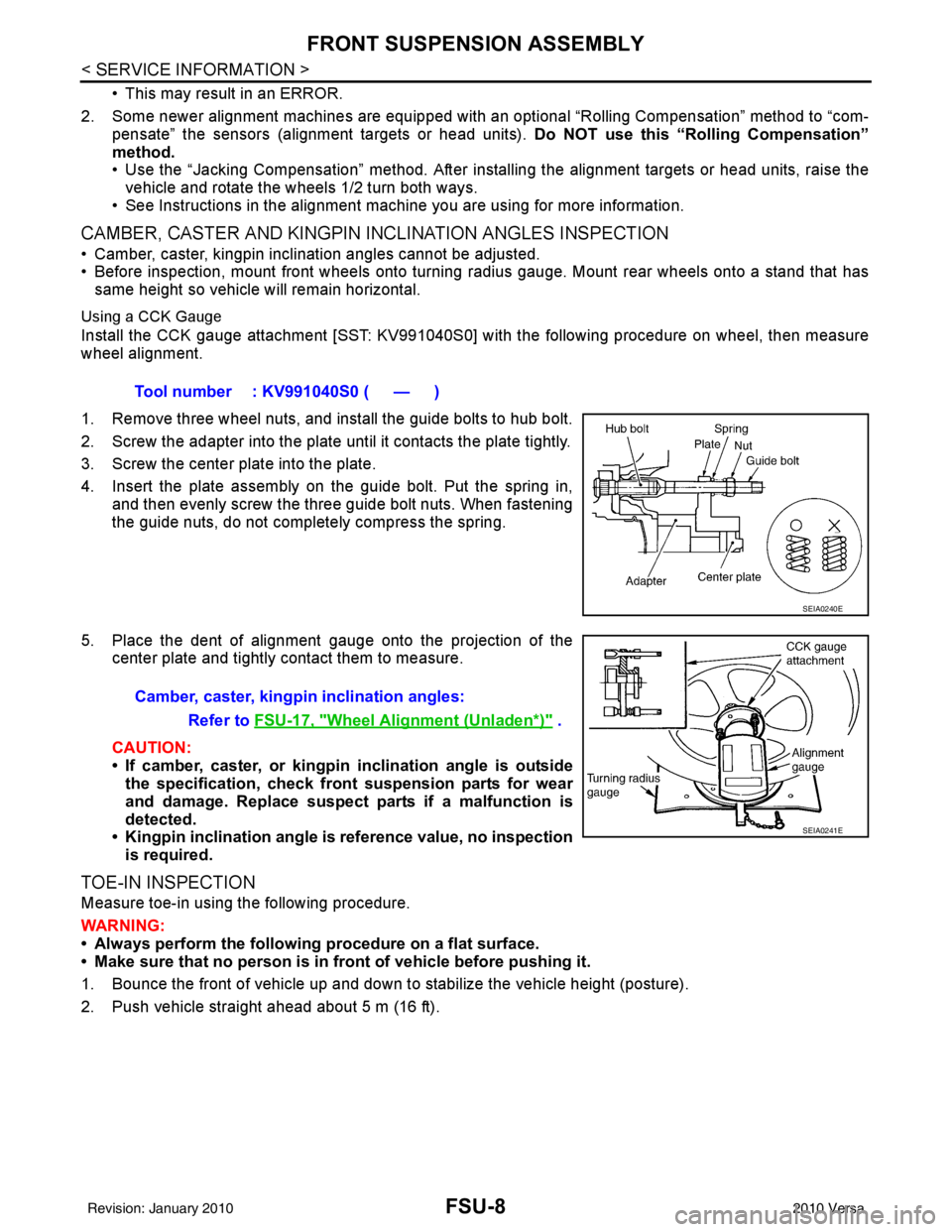

5. Place the dent of alignment gauge onto the projection of the center plate and tightly contact them to measure.

CAUTION:

• If camber, caster, or kingpin inclination angle is outside

the specification, check front suspension parts for wear

and damage. Replace suspect parts if a malfunction is

detected.

• Kingpin inclination angle is reference value, no inspection

is required.

TOE-IN INSPECTION

Measure toe-in using the following procedure.

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fr ont of vehicle before pushing it.

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push vehicle straight ahead about 5 m (16 ft). Tool number : KV991040S0 ( — )

SEIA0240E

Camber, caster, kingpi

n inclination angles:

Refer to FSU-17, "

Wheel Alignment (Unladen*)" .

SEIA0241E

Revision: January 20102010 Versa