engine NISSAN TIIDA 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: TIIDA, Model: NISSAN TIIDA 2010Pages: 3745, PDF Size: 73.67 MB

Page 2279 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-1014

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

FUEL PUMP

DescriptionINFOID:0000000005532910

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery v NISSAN TIIDA 2010 Service Repair Manual EC-1014

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

FUEL PUMP

DescriptionINFOID:0000000005532910

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery v](/img/5/57397/w960_57397-2278.png)

EC-1014

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

FUEL PUMP

DescriptionINFOID:0000000005532910

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal

from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engine is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition switch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The ECM does not directly drive the fuel

pump. It controls the ON/OFF fuel pump relay, which in turn controls the fuel pump.

COMPONENT DESCRIPTION

A turbine type design fuel pump is used in the fuel tank.

• Fuel level sensor unit and fuel pump (1)

• Fuel pressure regulator (2)

• Fuel level sensor (3)

• Fuel tank temperature sensor (4)

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005532911

Specification data are reference values.

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON Operates for 1 second

Engine running and cranking Operates

Engine: Stopped Stops in 1.5 seconds

Except as shown above St ops

BBIA0704E

Monitor itemCondition Specification

FUEL PUMP RLY • For 1 second after turning ignition switch ON

• Engine running or cranking

ON

• Except above conditions OFF

Revision: January 20102010 Versa

Page 2281 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-1016

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

Diagnosis Procedure

INFOID:0000000005532913

1.CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose (1) with two fingers.

- Illus NISSAN TIIDA 2010 Service Repair Manual EC-1016

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

Diagnosis Procedure

INFOID:0000000005532913

1.CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose (1) with two fingers.

- Illus](/img/5/57397/w960_57397-2280.png)

EC-1016

< SERVICE INFORMATION >[MR18DE]

FUEL PUMP

Diagnosis Procedure

INFOID:0000000005532913

1.CHECK OVERALL FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose (1) with two fingers.

- Illustration shows the view with intake air duct removed.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

4. Check voltage between ECM terminal 23 and ground with CON- SULT-III or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector E46.

3. Turn ignition switch ON.

4. Check voltage between IPDM E/R terminal 47 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 11.

TERMI- NAL NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

23 GR Fuel pump relay [Ignition switch: ON]

• For 1 second after turning ignition switch ON

[Engine is running]

0 - 1.0 V

[Ignition switch: ON]

• More than 1 second after turning ignition switch ON BATTERY VOLTAGE

(11 - 14 V)

Fuel pressure pulsation should be felt on the fuel feed

hose for 1 second after ignition switch is turned ON.

BBIA0712E

Voltage: Battery voltage

PBIA9573J

Voltage: Battery voltage

PBIB3319E

Revision: January 20102010 Versa

Page 2286 of 3745

![NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1021

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TER-

MI-

NAL

NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

32 P ECM relay

(Self shut-off) [Engine is running NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1021

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TER-

MI-

NAL

NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

32 P ECM relay

(Self shut-off) [Engine is running](/img/5/57397/w960_57397-2285.png)

IGNITION SIGNALEC-1021

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

TER-

MI-

NAL

NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

32 P ECM relay

(Self shut-off) [Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF 0 - 1.0 V

[Ignition switch: OFF]

• More than a few seconds after turning igni- tion switch OFF BATTERY VOLTAGE

(11 - 14 V)

105 G Power supply for ECM [Ignition switch: ON] BATTERY VOLTAGE

(11 - 14 V)

Revision: January 20102010 Versa

Page 2288 of 3745

![NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1023

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureIN NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1023

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureIN](/img/5/57397/w960_57397-2287.png)

IGNITION SIGNALEC-1023

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000005532918

1.CHECK ENGINE START

Turn ignition switch OFF, and restart engine.

Is engine running?

Ye s o r N o

Yes (With CONSULT-III)>>GO TO 2.

Yes (Without CONSULT-III)>>GO TO 3.

No >> GO TO 4.

2.CHECK OVERALL FUNCTION

With CONSULT-III

1. Perform “POWER BALANCE” in “A CTIVE TEST” mode with CONSULT-III.

2. Make sure that each circuit produces a momentary engine speed drop.

OK or NG

OK >> INSPECTION END

NG >> GO TO 10.

3.CHECK OVERALL FUNCTION

Without CONSULT-III

1. Let engine idle.

2. Read the voltage signal between ECM terminals 17, 18, 21, 22 and ground with an oscilloscope.

3. Verify that the oscilloscope screen shows the signal wave as shown below.

NOTE:

The pulse cycle changes depending on rpm at idle.

OK or NG

TER- MI-

NAL

NO. WIRE

COLOR ITEM

CONDITION DATA (DC Voltage)

17

18

21

22 R

LG

G

SB Ignition signal No. 1

Ignition signal No. 2

Ignition signal No. 4

Ignition signal No. 3 [Engine is running]

•

Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm

at idle 0 - 0.3 V

[Engine is running]

• Warm-up condition

• Engine speed: 2,500 rpm 0.2 - 0.5 V

PBIA9265J

PBIA9266J

PBIA9567J

PBIA9265J

Revision: January 20102010 Versa

Page 2292 of 3745

![NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release NISSAN TIIDA 2010 Service Repair Manual IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release](/img/5/57397/w960_57397-2291.png)

IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri- cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coilwithin 50 cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals 1 and 2.

4. If NG, replace condenser-2.

Removal and InstallationINFOID:0000000005532920

IGNITION COIL WITH POWER TRANSISTOR

Refer to EM-149.

Spark should be generated.

PBIB2958E

PBIB2325E

Resistance: Above 1 M

Ω [at 25 °C (77° F)]

PBIB0794E

Revision: January 20102010 Versa

Page 2295 of 3745

![NISSAN TIIDA 2010 Service Repair Manual EC-1030

< SERVICE INFORMATION >[MR18DE]

REFRIGERANT PRESSURE SENSOR

Diagnosis Procedure

INFOID:0000000005532923

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to n NISSAN TIIDA 2010 Service Repair Manual EC-1030

< SERVICE INFORMATION >[MR18DE]

REFRIGERANT PRESSURE SENSOR

Diagnosis Procedure

INFOID:0000000005532923

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to n](/img/5/57397/w960_57397-2294.png)

EC-1030

< SERVICE INFORMATION >[MR18DE]

REFRIGERANT PRESSURE SENSOR

Diagnosis Procedure

INFOID:0000000005532923

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower fan switch ON.

3. Check voltage between ECM terminal 41 and ground with CON- SULT-III or tester.

OK or NG

OK >> INSPECTION END

NG >> GO TO 2.

2.CHECK GROUND CONNECTIONS

1. Turn A/C switch and blower fan switch OFF.

2. Stop engine and turn ignition switch OFF.

3. Loosen and retighten ground screw on the body. Refer to EC-638, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

TERMI- NAL NO. WIRE

COLOR ITEM

CONDITIONDATA (DC Voltage)

41 GR Refrigerant pressure sensor [Engine is running]

•

Warm-up condition

• Both A/C switch and blower fan switch: ON

(Compressor operates) 1.0 - 4.0 V

48 BR Sensor ground

(Refrigerant pressure sensor) [Engine is running]

•

Warm-up condition

• Idle speed Approximately 0 V

74 W Sensor power supply

(Refrigerant pressure sensor) [Ignition switch: ON]

Approximately 5 V

Voltage: 1.0 - 4.0 V

PBIA9574J

:Vehicle front

1. Body ground E24 2. Engine ground F9 3. Engine ground F16

4. Body ground E15

BBIA0698E

Revision: January 20102010 Versa

Page 2300 of 3745

![NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)EC-1035

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000005532926

Idle Speed and NISSAN TIIDA 2010 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)EC-1035

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000005532926

Idle Speed and](/img/5/57397/w960_57397-2299.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EC-1035

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel PressureINFOID:0000000005532926

Idle Speed and Ignition TimingINFOID:0000000005532927

*: Under the following conditions:

• Air conditioner switch: OFF

• Electric load: OFF (Lights, heater fan & rear window defogger)

• Steering wheel: Kept in straight-ahead position

Calculated Load ValueINFOID:0000000005532928

Mass Air Flow SensorINFOID:0000000005532929

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorINFOID:0000000005532930

Engine Coolant Temperature SensorINFOID:0000000005532931

Fuel pressure at idle

Approximately 350 kPa (3.57 kg/cm2, 51 psi)

Target idle speedA/T No load* (in P or N position)

700 ± 50 rpm

CVT No load* (In P or N position)

M/T No load* (in Neutral position)

Air conditioner: ON A/T In P or N position

850 rpm or more

CVT In P or N position

M/T In Neutral position

Ignition timing A/T In P or N position

13 ± 5 ° BTDC

CVT In P or N position

M/T In Neutral position

Calculated load value (Using CONSULT-III or GST)

At idle 10 - 35 %

At 2,500 rpm 10 - 35 %

Supply voltageBattery voltage (11 - 14 V )

Output voltage at idle 1.0 - 1.3* V

Mass air flow (Using CONSULT-III or GST) 1.0 - 4.0 g·m/sec at idle*

2.0 - 10.0 g·m/sec at 2,500 rpm*

Temperature [ °C ( °F)] Resistance (k Ω)

25 (77) 1.800 - 2.200

Temperature [°C ( °F)] Resistance (k Ω)

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Revision: January 20102010 Versa

Page 2304 of 3745

PRECAUTIONSEI-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005714352

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005396814

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: January 20102010 Versa

Page 2306 of 3745

PREPARATIONEI-5

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

PREPARATION

PREPARATION

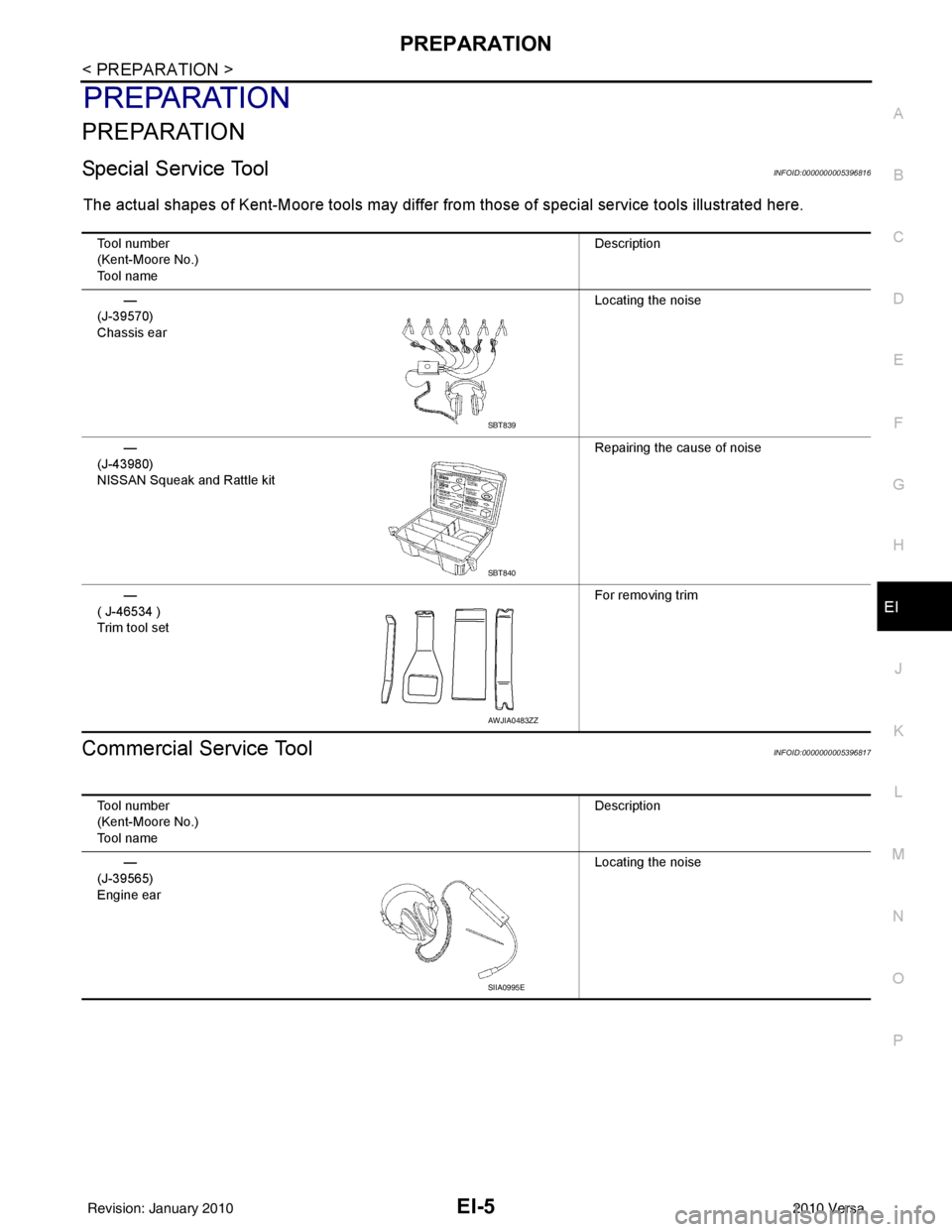

Special Service ToolINFOID:0000000005396816

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000005396817

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-39570)

Chassis ear Locating the noise

—

(J-43980)

NISSAN Squeak and Rattle kit Repairing the cause of noise

—

( J-46534 )

Trim tool set For removing trim

SBT839

SBT840

AWJIA0483ZZ

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39565)

Engine ear Locating the noise

SIIA0995E

Revision: January 20102010 Versa

Page 2308 of 3745

SQUEAK AND RATTLE TROUBLE DIAGNOSISEI-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

• Close a door.

• Tap or push/pull around the area where the noise appears to be coming from.

• Rev the engine.

• Use a floor jack to recreate vehicle “twist”.

• At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T and CVT models).

• Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear: J-39565 and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by: • Removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners

can be broken or lost during the repair , resulting in the creation of new noise.

• Tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessi ve force, otherwise the noise will be elimi-

nated only temporarily.

• Feeling for a vibration with your hand by touching t he component(s) that you suspect is (are) causing

the noise.

• Placing a piece of paper between components that you suspect are causing the noise.

• Looking for loose components and contact marks.

Refer to EI-8, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the component, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts

Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSA N Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 x 135 mm (3.94 x 5.31 in)/76884-71L01: 60 x 85 mm (2.36 x 3.35 in)/76884-71L02: 15 x 25

mm (0.59 x 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 x 50 mm (1.97 x 1.97 in)/73982-50Y00: 10 mm (0.39 in) thick, 50 x 50

mm (1.97 x 1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 x 50 mm (1.18 x 1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/ 68239-13E00: 5 mm (0.20 in) wide tape roll

Revision: January 20102010 Versa