filter NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3169 of 3787

![NISSAN TIIDA 2011 Service Repair Manual OIL PUMPLU-21

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL PUMP

ComponentINFOID:0000000005928703

Removal and InstallationINFOID:0000000005928704

REMOVAL

1. Remove the timing ch NISSAN TIIDA 2011 Service Repair Manual OIL PUMPLU-21

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL PUMP

ComponentINFOID:0000000005928703

Removal and InstallationINFOID:0000000005928704

REMOVAL

1. Remove the timing ch](/img/5/57396/w960_57396-3168.png)

OIL PUMPLU-21

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

OIL PUMP

ComponentINFOID:0000000005928703

Removal and InstallationINFOID:0000000005928704

REMOVAL

1. Remove the timing chain and oil pump drive chain. Refer to

EM-160, "Removal and Installation".

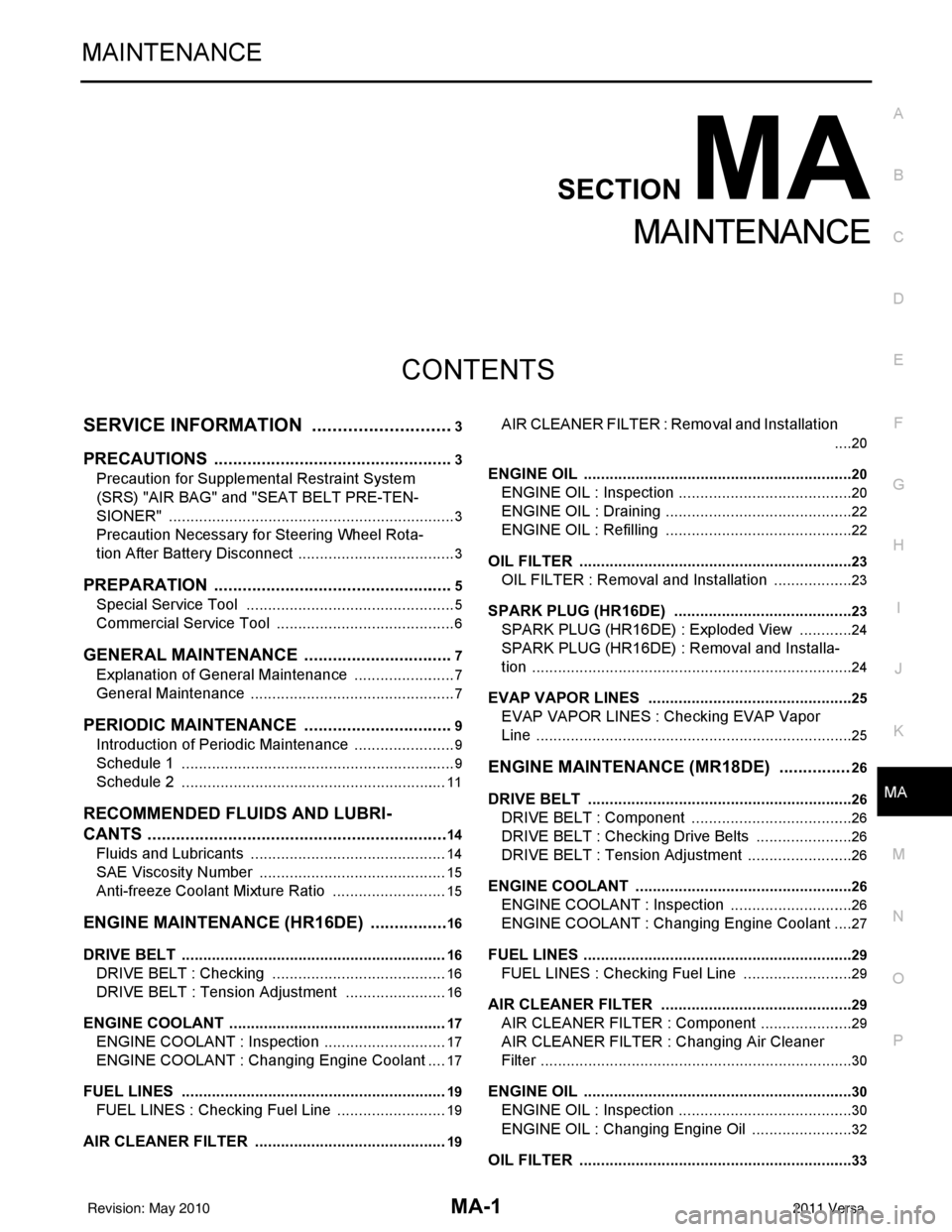

1. Oil level gauge2. Oil level gauge guide3. Rear oil seal

4. O-ring 5. Oil pan (upper)6. Oil pump drive chain

7. Crankshaft sprocket 8. Oil pump sprocket9. Timing chain tensioner (for oil pump)

10. Oil pump 11. Drain plug12. Drain plug washer

13. Oil pan (lower) 14. Oil filter15. Connector bolt

16. O-ring A. Refer to LU-21

Oil pan side

PBIC4482E

Revision: May 2010 2011 Versa

Page 3171 of 3787

![NISSAN TIIDA 2011 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005928705

ENGINE OIL P NISSAN TIIDA 2011 Service Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005928705

ENGINE OIL P](/img/5/57396/w960_57396-3170.png)

SERVICE DATA AND SPECIFICATIONS (SDS)LU-23

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000005928705

ENGINE OIL PRESSURE

Unit: kPa (bar, kg/cm2, psi)

ENGINE OIL CAPACITY

Unit: (US qt, Imp qt)

Engine speed

Approximate discharge oil pressure

Idle speed 60 (0.60, 0.61, 9)

2,000 rpm 200 (2.0, 2.0, 29)

Drain and refillWith oil filter change Approximately 4.1 (4 3/8, 3 5/8)

Without oil filter change

Approximately 3.9 (4 1/8, 3 3/8)

Dry engine (engine overhaul) Approximately 4.9 (5 1/8, 4 3/8)

Revision: May 2010 2011 Versa

Page 3172 of 3787

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K

M

SECTION MA

A

B

MA

N

O P

CONTENTS

MAINTENANCE

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

PREPARATION ...................................................5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

GENERAL MAINTENANCE ........................... .....7

Explanation of General Maintenance .................. ......7

General Maintenance ................................................7

PERIODIC MAINTENANCE ................................9

Introduction of Periodic Maintenance .................. ......9

Schedule 1 ................................................................9

Schedule 2 ..............................................................11

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

14

Fluids and Lubricants .......................................... ....14

SAE Viscosity Number ............................................15

Anti-freeze Coolant Mixture Ratio ...........................15

ENGINE MAINTENANCE (HR16DE) .................16

DRIVE BELT .......................................................... ....16

DRIVE BELT : Checking .........................................16

DRIVE BELT : Tension Adjustment ........................16

ENGINE COOLANT ............................................... ....17

ENGINE COOLANT : Inspection .............................17

ENGINE COOLANT : Changing Engine Coolant ....17

FUEL LINES .......................................................... ....19

FUEL LINES : Checking Fuel Line ..........................19

AIR CLEANER FILTER ......................................... ....19

AIR CLEANER FILTER : Removal and Installation

....

20

ENGINE OIL ........................................................... ....20

ENGINE OIL : Inspection .........................................20

ENGINE OIL : Draining ............................................22

ENGINE OIL : Refilling ............................................22

OIL FILTER ............................................................ ....23

OIL FILTER : Removal and Installation ...................23

SPARK PLUG (HR16DE) ...................................... ....23

SPARK PLUG (HR16DE) : Exploded View .............24

SPARK PLUG (HR16DE) : Removal and Installa-

tion ....................................................................... ....

24

EVAP VAPOR LINES ............................................ ....25

EVAP VAPOR LINES : Checking EVAP Vapor

Line ..........................................................................

25

ENGINE MAINTENANCE (MR18DE) ...............26

DRIVE BELT .......................................................... ....26

DRIVE BELT : Component ......................................26

DRIVE BELT : Checking Drive Belts .......................26

DRIVE BELT : Tension Adjustment .........................26

ENGINE COOLANT ............................................... ....26

ENGINE COOLANT : Inspection .............................26

ENGINE COOLANT : Changing Engine Coolant ....27

FUEL LINES ........................................................... ....29

FUEL LINES : Checking Fuel Line ..........................29

AIR CLEANER FILTER ......................................... ....29

AIR CLEANER FILTER : Component ......................29

AIR CLEANER FILTER : Changing Air Cleaner

Filter .........................................................................

30

ENGINE OIL ........................................................... ....30

ENGINE OIL : Inspection .........................................30

ENGINE OIL : Changing Engine Oil ........................32

OIL FILTER ............................................................ ....33

Revision: May 2010 2011 Versa

Page 3173 of 3787

MA-2

OIL FILTER : Removal and Installation ..................33

SPARK PLUG ........................................................ ...34

SPARK PLUG : Component ...................................34

SPARK PLUG : Removal and Installation ..............35

EVAP VAPOR LINES ............................................. ...36

EVAP VAPOR LINES : Checking EVAP Vapor

Line .........................................................................

36

CHASSIS AND BODY MAINTENANCE ............37

EXHAUST SYSTEM ............................................... ...37

EXHAUST SYSTEM : Checking Exhaust System

HR16DE .............................................................. ...

37

EXHAUST SYSTEM : Checking Exhaust System

MR18DE .............................................................. ...

37

CVT FLUID ............................................................. ...37

CVT FLUID : Checking CVT Fluid ..........................37

CVT FLUID : Changing CVT Fluid ..........................38

CLUTCH FLUID ..................................................... ...39

CLUTCH FLUID : Air Bleeding Procedure ..............39

M/T OIL ................................................................... ...40

M/T OIL : Draining (RS5F91R) ...............................40

M/T OIL : Refilling (RS5F91R) ................................41

M/T OIL : Inspection (RS5F91R) ............................41

M/T OIL : Changing M/T Oil (RS6F94R) .................41

M/T OIL : Checking M/T Oil (RS6FF94R) ...............42

A/T FLUID .............................................................. ...42

A/T FLUID : Checking A/T Fluid .............................42

A/T FLUID : Changing A/T Fluid .............................43

WHEELS ................................................................. ...43

WHEELS : Adjustment ............................................43

BRAKE FLUID LEVEL AND LEAKS ..................... ...45

BRAKE FLUID LEVEL AND LEAKS : On Board In-

spection ...................................................................

45

BRAKE FLUID LEVEL AND LEAKS : Drain and

Refill ........................................................................

45

BRAKE LINES AND CABLES ............................... ...46

BRAKE LINES AND CABLES : Checking Brake

Line and Cables ................................................... ...

46

DISC BRAKE .......................................................... ...46

DISC BRAKE : On Board Inspection ......................46

DRUM BRAKE ....................................................... ...46

DRUM BRAKE : Inspection .....................................46

AXLE AND SUSPENSION PARTS ........................ ...47

AXLE AND SUSPENSION PARTS : Axle and

Suspension Parts ................................................. ...

47

DRIVE SHAFT ........................................................ ...48

DRIVE SHAFT : Drive Shaft ...................................48

LOCKS, HINGES AND HOOD LATCH .................. ...48

LOCKS, HINGES AND HOOD LATCH : Lubricat-

ing Locks, Hinges and Hood Latch .........................

49

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS ................................... ...

49

SEAT BELT, BUCKLES, RETRACTORS, AN-

CHORS AND ADJUSTERS : Checking Seat

Belts, Buckles, Retractors, Anchors and Adjusters

...

49

Revision: May 2010 2011 Versa

Page 3176 of 3787

PREPARATIONMA-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

PREPARATION

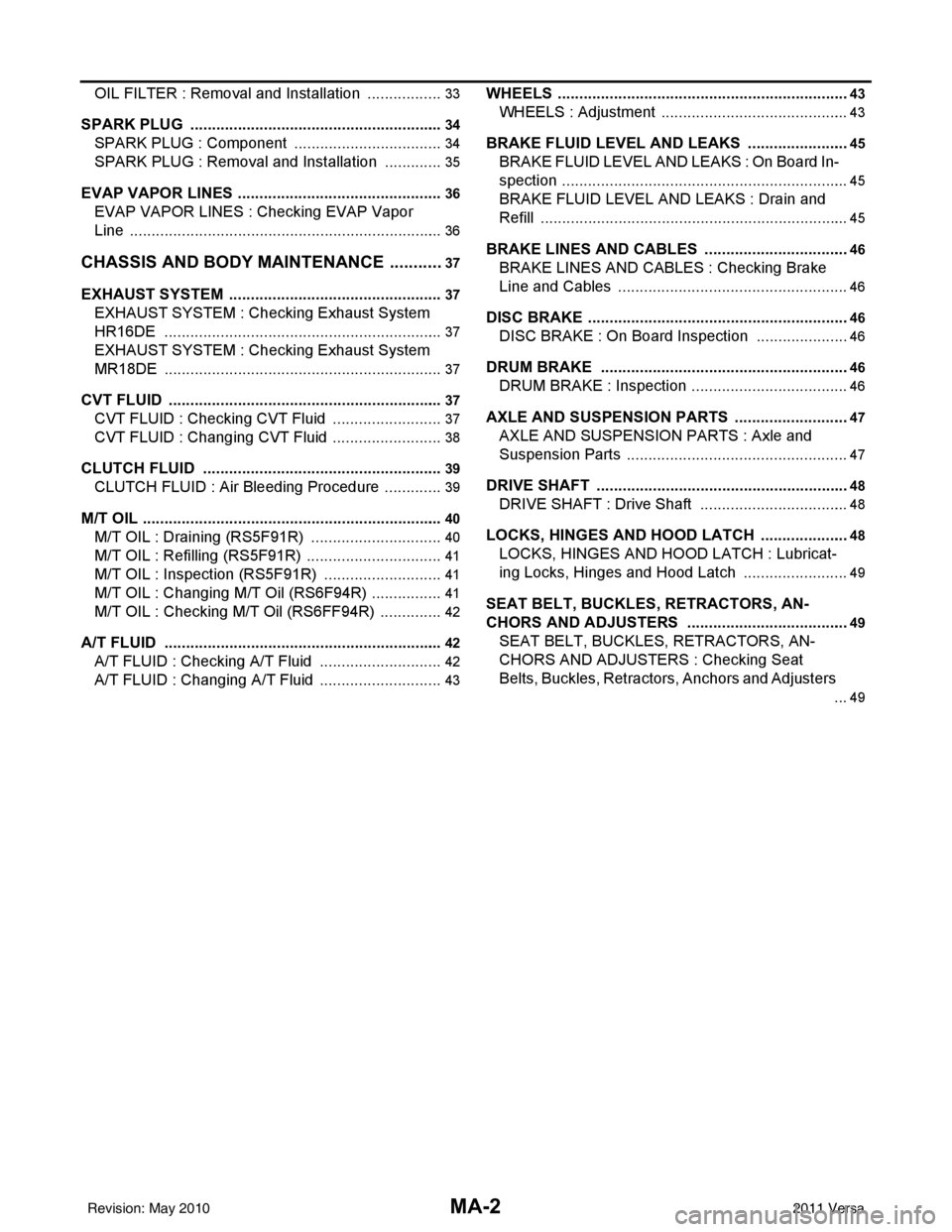

Special Service ToolINFOID:0000000006413333

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

KV10115801

(—)

Oil filter wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

KV991J0070

(J-45695)

Coolant Refill Tool Refilling engine cooling system

—

(J-48891)

Spark plug socket Removing and installing spark plug

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT375

WBIA0539E

LMA053

ALBIA0672GB

S-NT564

Revision: May 2010

2011 Versa

Page 3180 of 3787

PERIODIC MAINTENANCEMA-9

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

PERIODIC MAINTENANCE

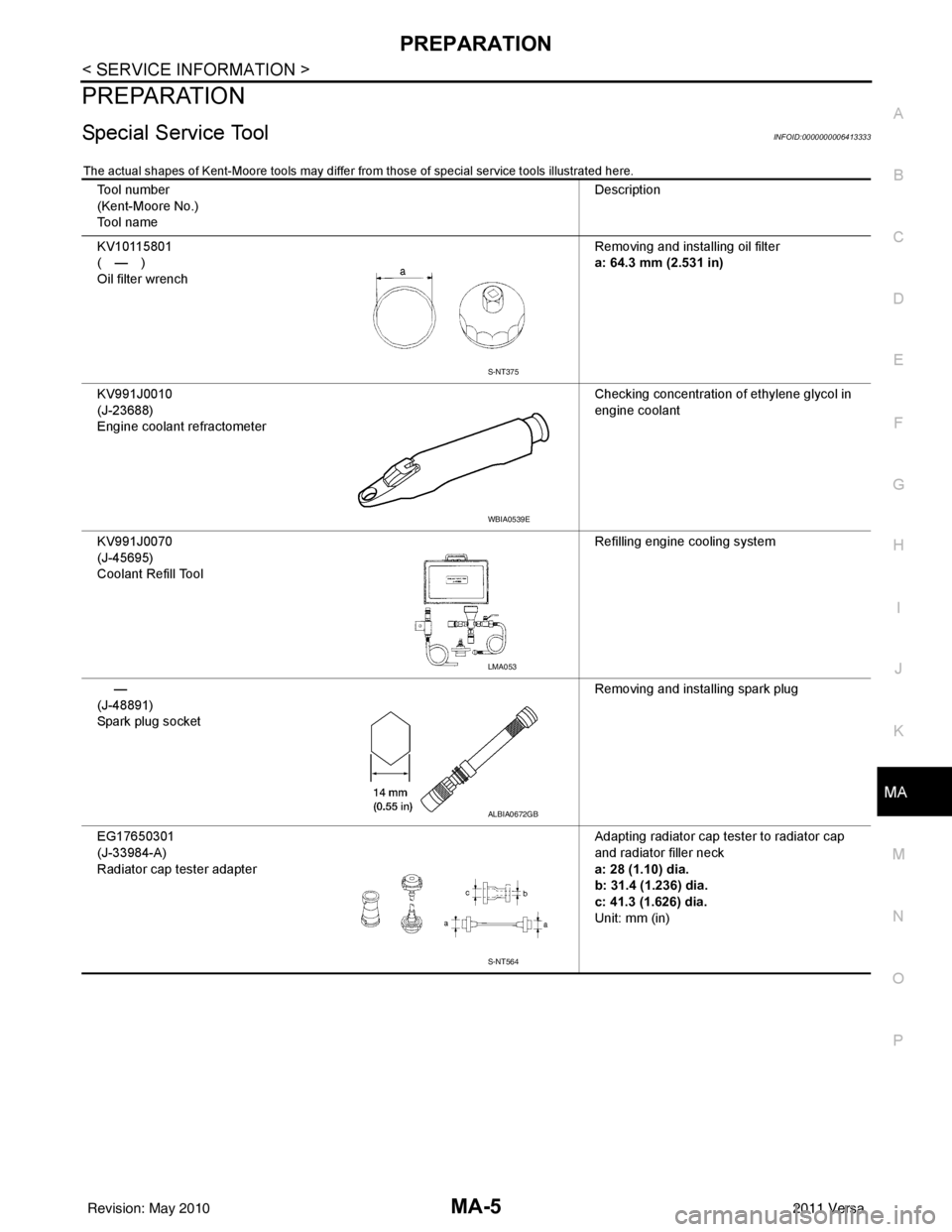

Introduction of Periodic MaintenanceINFOID:0000000005931131

Two different maintenance schedules are provi ded, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000005931132

Emission Control System Maintenance

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-9

Chassis and Body

Maintenance

MA-9

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to your driving habits.

Emission Control Sys-

tem Maintenance

MA-11Chassis and Body

Maintenance

MA-11

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference Section -

Page or - Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.5

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belt NOTE (1) MA-16

(HR)

MA-26

(MR)

Air cleaner filter NOTE (2) [R]EM-13

(HR)

EM-136

(MR)

EVAP vapor lines I*MA-25

(HR)

MA-36

(MR)

Fuel lines I*FL-5

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) CO-11

(HR)

CO-36

(MR)

Engine oil R R R R R R R R LU-8

(HR)

LU-18

(MR)

Engine oil filter (Use

genuine oil filter or

equivalent) RRRRRRRR

LU-9

(HR)

LU-20

(MR)

Spark plugs (Iridium/

platinum - tipped

type) Replace every 105,000 miles (168,000 km)

EM-17

(HR)

EM-151

(MR)

Intake and exhaust

valve clearance* NOTE (5) EM-114

(HR)

EM-230

(MR)

Revision: May 2010 2011 Versa

Page 3181 of 3787

![NISSAN TIIDA 2011 Service Repair Manual MA-10

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 NISSAN TIIDA 2011 Service Repair Manual MA-10

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48](/img/5/57396/w960_57396-3180.png)

MA-10

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

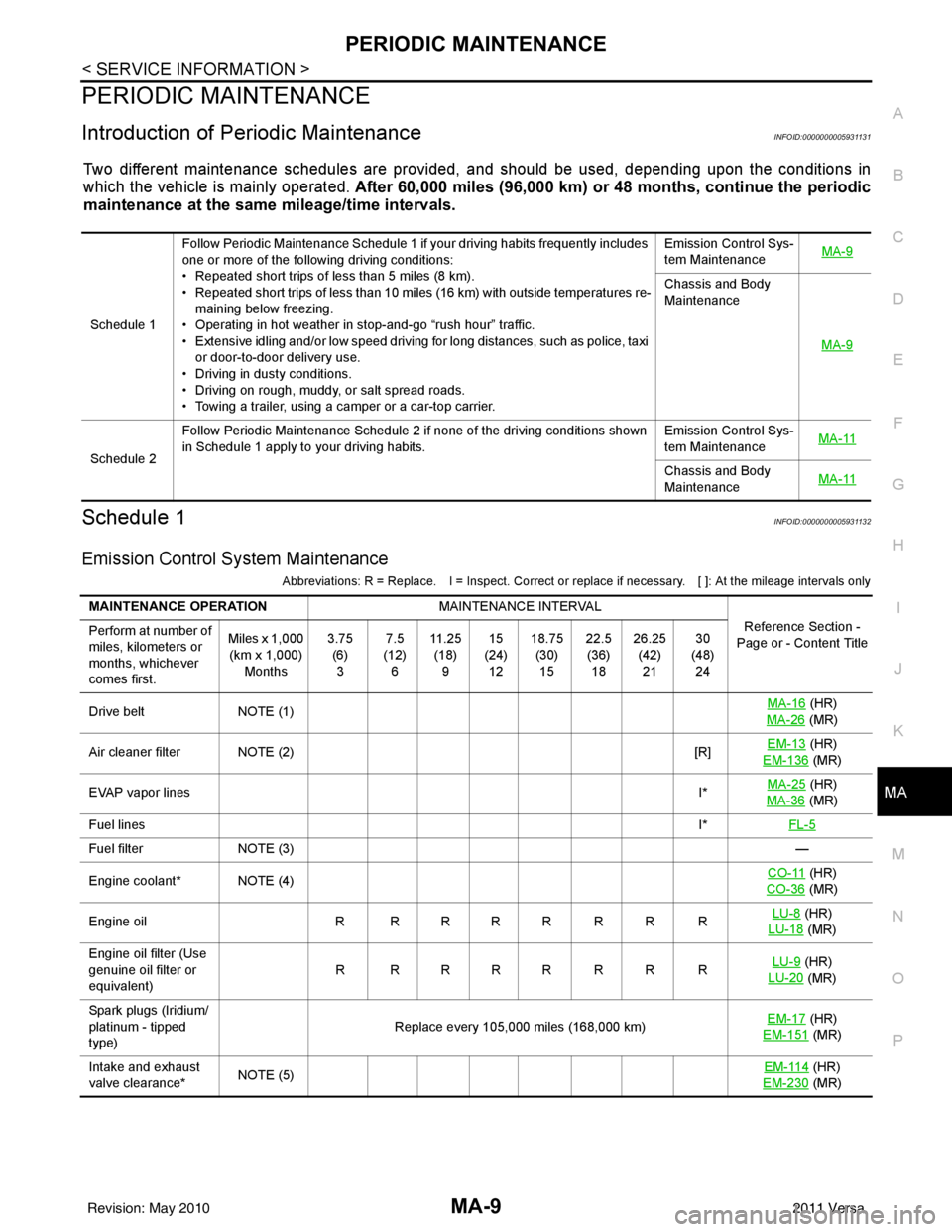

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts i f found

damaged.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to the FL section.

(4) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months. Use only Genuine NISSAN long life Antifreeze/Coolant (blue) or equivalent with proper mixture ratio of 50% an ti-

freeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life

expectancy of the factory fill coolant.

(5) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and inter vals are

required.

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary.

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Section -

Page or - Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x

1,000

(km x

1,000)

Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belt NOTE

(1) I*EM-13

(HR)

EM-132

(MR)

Air cleaner filter NOTE

(2) [R]

EM-16

(HR)

EM-135

(MR)

EVAP vapor lines I*MA-25

(HR)

MA-36

(MR)

Fuel lines I*MA-19

, MA-29

Fuel filter NOTE

(3) —

Engine coolant* NOTE

(4) CO-11

(HR)

CO-36

(MR)

Engine oil R R R R R R R R LU-8

(HR)

LU-18

(MR)

Engine oil filter (Use

genuine oil filter or

equivalent) R R R R RRRR

LU-9

(HR)

LU-20

(MR)

Spark plugs (Iridium/

platinum - tipped type) Replace every 105,000 miles (168,000 km) EM-17

(HR)

EM-151

(MR)

Intake and exhaust

valve clearance* NOTE

(5) EM-114

(HR)

EM-230

(MR)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Section -

Page or -

Content Title

Perform at number of

miles, kilometers or

months, whichever

comes first. Miles x

1,000

(km x

1,000)

Months 3.75

(6)3 7.5

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Brake lines & cables IIMA-46

Brake pads, rotors,

drums & linings IIII MA-46

MA-46

Revision: May 2010

2011 Versa

Page 3183 of 3787

![NISSAN TIIDA 2011 Service Repair Manual MA-12

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 NISSAN TIIDA 2011 Service Repair Manual MA-12

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48](/img/5/57396/w960_57396-3182.png)

MA-12

< SERVICE INFORMATION >

PERIODIC MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belt if found

damaged or if the auto belt tensioner reading reaches the maximum limit.

(2) Maintenance-free item. For service procedures, refer to the FL section.

(3) First replacement interval is 105,000 miles (168,000 km) or 84 months. After first replacement, replace every 75,000 miles (120,000

km) or 60 months. Use only Genuine NISSAN long life Antifreeze/Coolant (blue) or equivalent with proper mixture ratio of 50% an ti-

freeze and 50% demineralized or distilled water. Mixing any other type of coolant or the use of non-distilled water will reduce the life

expectancy of the factory fill coolant.

(4) Periodic maintenance is not required. However, if valve noise increases, inspect valve clearance.

Maintenance items and intervals with “*” are recommended by NISSAN for reliab le vehicle operation. The owner need not perform such

maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

Chassis and Body Maintenance

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. .

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Ti- tle

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x

1,000

(km x

1,000)

Months 7.5

(12) 6 15

(24) 12 22.5

(36) 18 30

(48) 24 37.5

(60) 30 45

(72) 36 52.5

(84) 42 60

(96) 48

Drive belt NOTE (1) I*EM-13

(HR)

EM-132

(MR)

Air cleaner filter [R][R]EM-16

(HR)

EM-136

(MR)

EVAP vapor lines I*I*MA-25

(HR)

MA-36

(MR)

Fuel lines I*I*FL-5

Fuel filter NOTE (2) —

Engine coolant* NOTE (3) CO-11

(HR)

CO-36

(MR)

Engine oil RR R RRRRR LU-8

(HR)

LU-18

(MR)

Engine oil filter (Use genuine

oil filter or equivalent.) RR R RRRRR LU-9

(HR)

LU-20

(MR)

Spark plugs (Iridium/plati-

num - tipped type) Replace every 105,000 miles (168,000 km) EM-17

(HR)

EM-151

(MR)

Intake and exhaust valve

clearance* NOTE (4)

EM-114

(HR)

EM-230

(MR)

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

B ra ke lin e s & cab le s IIII MA-46

Brake pads, rotors, drums & lin-

ings IIII

MA-46

MA-46

Manual transaxle oil or automatic

transaxle fluid IIIIMT-11

(RS5F91R)

MT-54

(RS6F94R)

AT- 1 7

(A/T)

C VT flu id NO TE (1) IIII CVT-15

(RE0F08B)

Steering gear & linkage, axle &

suspension parts II

PS-15

, MA-47

Tire rotation NOTE (2) WT-7

Revision: May 2010 2011 Versa

Page 3185 of 3787

MA-14

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

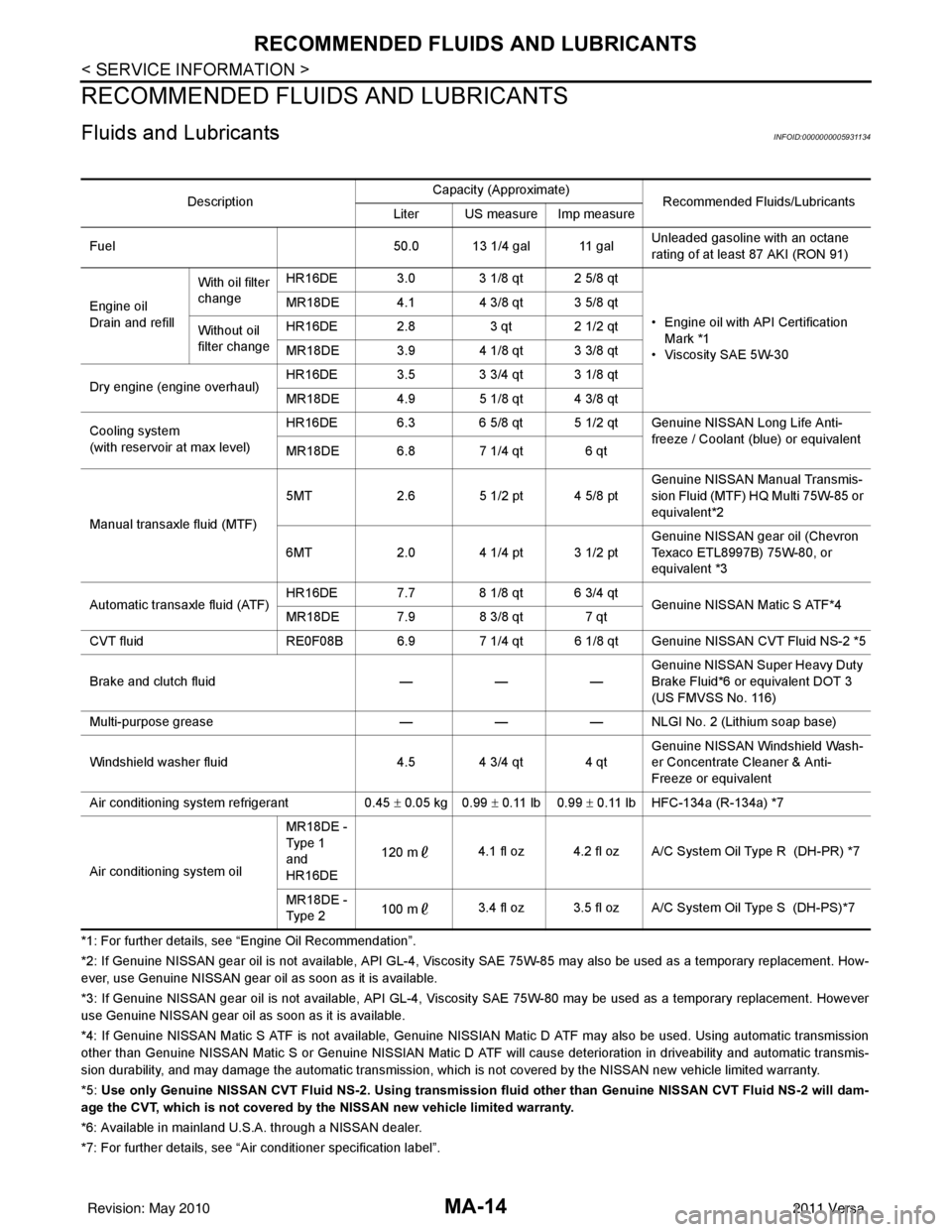

Fluids and LubricantsINFOID:0000000005931134

*1: For further details, see “Engine Oil Recommendation”.

*2: If Genuine NISSAN gear oil is not available, API GL-4, Viscosity SAE 75W-85 may also be used as a temporary replacement. How-

ever, use Genuine NISSAN gear oil as soon as it is available.

*3: If Genuine NISSAN ge ar oil is not available, API GL-4, Viscosity SAE 75W-80 may be used as a temporary replacement. However

use Genuine NISSAN gear oil as soon as it is available.

*4: If Genuine NISSAN Matic S ATF is not available, Genuine NISSIAN Matic D ATF may also be used. Using automatic transmission

other than Genuine NISSAN Matic S or Genuine NISSIAN Matic D ATF will cause deteri oration in driveability and automatic transmis-

sion durability, and may damage the automatic transmission, which is not covered by th e NISSAN new vehicle limited warranty.

*5: Use only Genuine NISSAN CVT Fluid NS-2. Using transmission fluid other than Genuine NISSAN CVT Fluid NS-2 will dam-

age the CVT, which is not covered by the NISSAN new vehicle limited warranty.

*6: Available in mainland U.S.A. through a NISSAN dealer.

*7: For further details, see “Air conditioner specification label”. Description

Capacity (Approximate)

Recommended Fluids/Lubricants

Liter US measure Imp measure

Fuel 50.0 13 1/4 gal 11 galUnleaded gasoline with an octane

rating of at least 87 AKI (RON 91)

Engine oil

Drain and refill With oil filter

change

HR16DE 3.0 3 1/8 qt 2 5/8 qt

• Engine oil with API Certification Mark *1

• Viscosity SAE 5W-30

MR18DE 4.1 4 3/8 qt 3 5/8 qt

Without oil

filter change HR16DE 2.8

3 qt 2 1/2 qt

MR18DE 3.9 4 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE 3.5 3 3/4 qt 3 1/8 qt

MR18DE 4.9 5 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE 6.3 6 5/8 qt 5 1/2 qt Genuine NISSAN Long Life Anti-

freeze / Coolant (blue) or equivalent

MR18DE 6.8 7 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT

2.6 5 1/2 pt 4 5/8 pt Genuine NISSAN Manual Transmis-

sion Fluid (MTF) HQ Multi 75W-85 or

equivalent*2

6MT 2.0 4 1/4 pt 3 1/2 pt Genuine NISSAN gear oil (Chevron

Texaco ETL8997B) 75W-80, or

equivalent *3

Automatic transaxle fluid (ATF) HR16DE 7.7 8 1/8 qt 6 3/4 qt

Genuine NISSAN Matic S ATF*4

MR18DE 7.9 8 3/8 qt 7 qt

CVT fluid RE0F08B 6.9 7 1/4 qt 6 1/8 qt Genuine NISSAN CVT Fluid NS-2 *5

Brake and clutch fluid ———Genuine NISSAN Super Heavy Duty

Brake Fluid*6 or equivalent DOT 3

(US FMVSS No. 116)

Multi-purpose grease ——— NLGI No. 2 (Lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt 4 qtGenuine NISSAN Windshield Wash-

er Concentrate Cleaner & Anti-

Freeze or equivalent

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb HFC-134a (R-134a) *7

Air conditioning system oil MR18DE -

Typ e 1

and

HR16DE

120 m

4.1 fl oz 4.2 fl oz A/C System Oil Type R (DH-PR) *7

MR18DE -

Typ e 2 100 m

3.4 fl oz 3.5 fl oz A/C System Oil Type S (DH-PS)*7

Revision: May 2010

2011 Versa

Page 3190 of 3787

ENGINE MAINTENANCE (HR16DE)MA-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

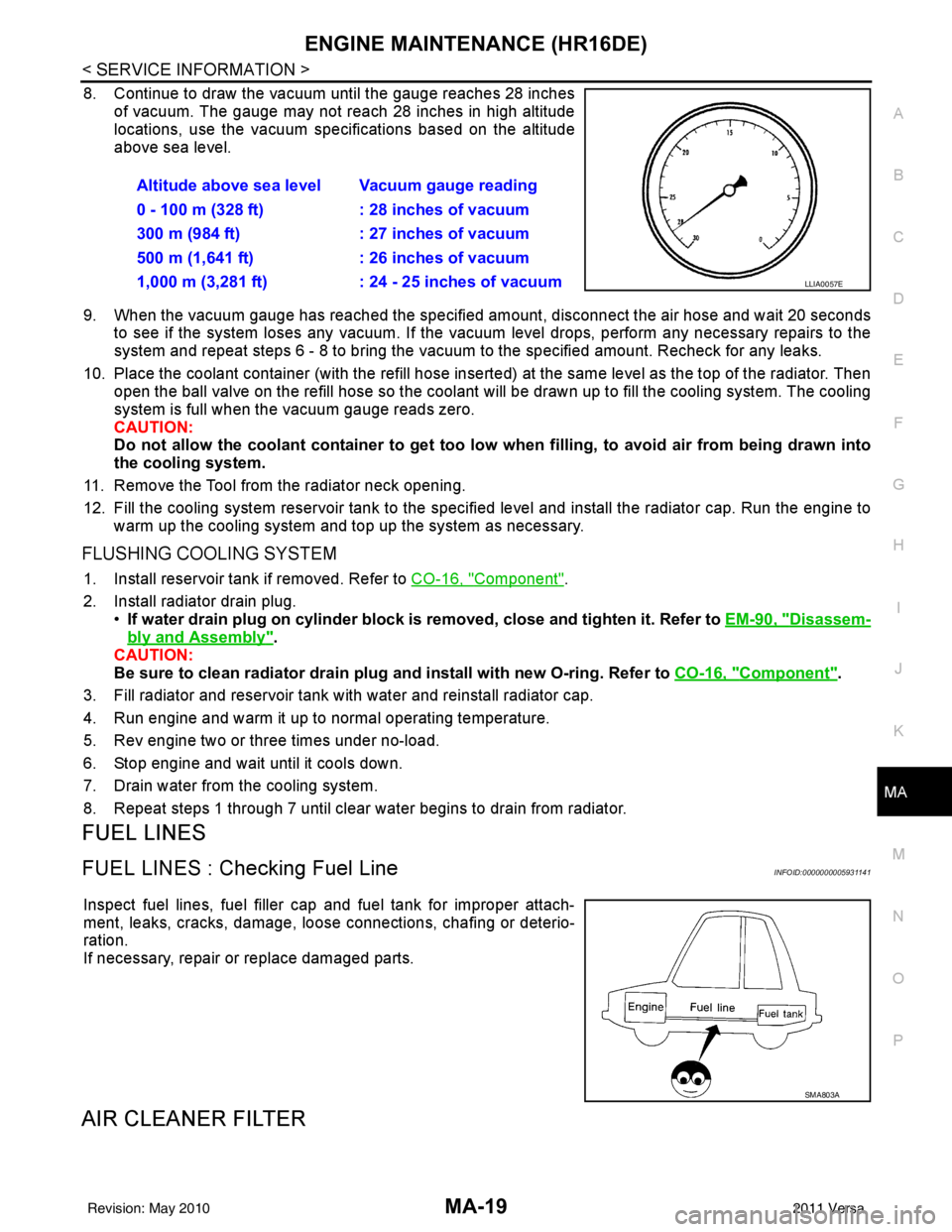

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-16, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-90, "

Disassem-

bly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

FUEL LINES

FUEL LINES : Checking Fuel LineINFOID:0000000005931141

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loos e connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

SMA803A

Revision: May 2010 2011 Versa