Console NISSAN TIIDA 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 618 of 3787

BL-108

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

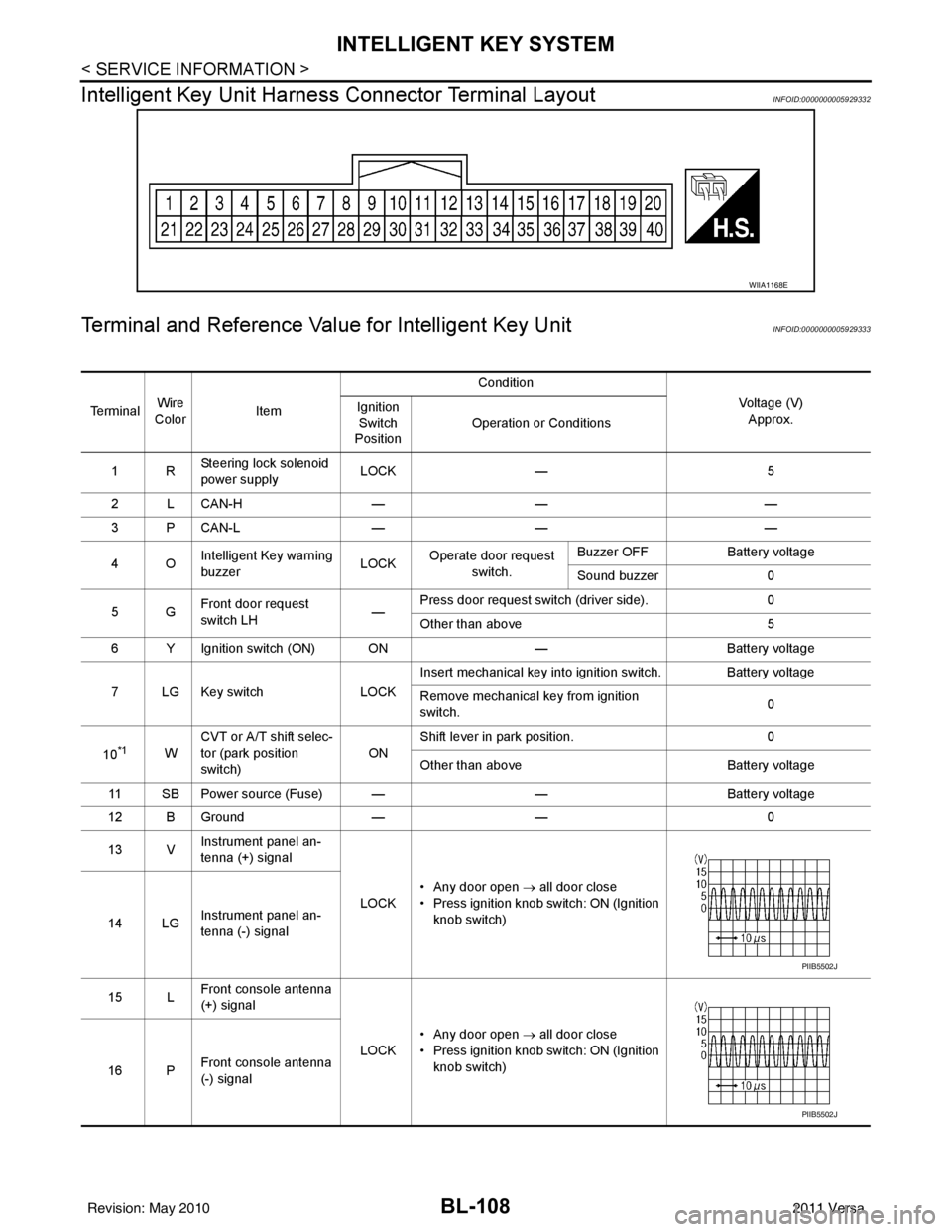

Intelligent Key Unit Harnes s Connector Terminal Layout

INFOID:0000000005929332

Terminal and Reference Value for Intelligent Key UnitINFOID:0000000005929333

WIIA1168E

Te r m i n a lWire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

1R Steering lock solenoid

power supply LOCK

— 5

2 L CAN-H —— —

3 P CAN-L —— —

4O Intelligent Key warning

buzzer LOCK

Operate door request

switch. Buzzer OFF

Battery voltage

Sound buzzer 0

5G Front door request

switch LH —Press door request switch (driver side).

0

Other than above 5

6 Y Ignition switch (ON) ON —Battery voltage

7 LG Key switch LOCKInsert mechanical key into ignition switch. Battery voltage

Remove mechanical key from ignition

switch.

0

10

*1W CVT or A/T shift selec-

tor (park position

switch)

ONShift lever in park position.

0

Other than above Battery voltage

11 SB Power source (Fuse) — —Battery voltage

12 B Ground —— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

PIIB5502J

PIIB5502J

Revision: May 2010

2011 Versa

Page 628 of 3787

![NISSAN TIIDA 2011 Service User Guide BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

BD/TR REQ SWIndicates [ON/OFF] condition of back door request switch.

IGN NISSAN TIIDA 2011 Service User Guide BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

BD/TR REQ SWIndicates [ON/OFF] condition of back door request switch.

IGN](/img/5/57396/w960_57396-627.png)

BL-118

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

*: Select “SELECTION FROM MENU”.

ACTIVE TEST

* : Sedan

WORK SUPPORT

BD/TR REQ SWIndicates [ON/OFF] condition of back door request switch.

IGN SW Indicates [ON/OFF] condition of ignition switch in ON position.

ACC SW Indicates [ON/OFF] condition of ignition switch in ACC position.

STOP LAMP SW Indicates [ON/OFF] condition of stop lamp switch.

P RANGE SW Indicates [ON/OFF] condition of shift lever park position.

BD OPEN SW Indicates [ON/OFF] condition of back door open switch.

DOOR LOCK SIG* Indicates [ON/OFF] condition of door lock signal from Intelligent Key button.

DOOR UNLOCK SIG* Indicates [ON/OFF] condition of door unlock signal from Intelligent Key button

KEYLESS PANIC* Indicates [ON/OFF] condition of panic signal from Intelligent Key button

DOOR SW DR* Indicates [OPEN/CLOSE] condition of front door sw

itch driver side from BCM via CAN communica-

tion line.

DOOR SW AS* Indicates [OPEN/CLOSE] condition of front door switch passenger side from BCM via CAN commu-

nication line.

DOOR SW RR* Indicates [OPEN/CLOSE] condition of rear door switch RH from BCM via CAN communication line.

DOOR SW RL* Indicates [OPEN/CLOSE] condition of rear door switch LH from BCM via CAN communication line.

VEHICLE SPEED* Indicates [km/h] condition of vehicle speed.

Monitor item

Content

Te s t i t e mD e s c r i p t i o n

DOOR LOCK/UNLOCK This test is able to check door lock/unlock operation.

• The all door lock actuators are unlocked when “ALL UNLK” on CONSULT-III screen is touched.

• The all door lock actuators are locked when “LOCK” on CONSULT-III screen is touched.

ANTENNA This test is able to check Intelligent Key antenna operation.

When the following conditions are met, hazard warning lamps flash.

• Inside key antenna (front console) detects Intelligent Key, when “ROOM ANT1” on CONSULT-

III screen is touched.

• Inside key antenna (instrument panel and rear floor) detects Intelligent Key, when “ROOM

ANT2” on CONSULT-III screen is touched.

• Outside key antenna (driver side) detects Intelligent Key, when “DR ANT” on CONSULT-III screen is touched.

• Outside key antenna (passenger side) detects Intelligent Key, when “AS ANT” on CONSULT-III screen is touched.

• Outside key antenna (rear bumper) detects Intelligent Key, when “BK DR ANT” on CONSULT- III screen is touched.

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation.

Intelligent Key warning buzzer sounds when “ON” on CONSULT-III screen is touched.

INSIDE BUZZER This test is able to check Intelligent Key warning chime (Instrument panel) operation.

• Take away warning chime sounds when “TAKE OUT” on CONSULT-III screen is touched.

• Ignition switch warning chime sounds when “KNOB” on CONSULT-III screen is touched.

• Ignition key warning chime sounds when “KEY” on CONSULT-III screen is touched.

INDICATOR This test is able to check warning lamp operation.

• “KEY” Warning lamp (Green) illuminates when “BLUE ON” on CONSULT-III screen is touched.

• “KEY” Warning lamp (Red) illuminates when

“RED ON” on CONSULT-III screen is touched.

• “LOCK” Warning lamp illuminates when “KNOB ON” on CONSULT-III screen is touched.

• “KEY” Warning lamp (Green) flashes when “BLUE IND” on CONSULT-III screen is touched.

• “KEY” Warning lamp (RED) flashes when “RED IND” on CONSULT-III screen is touched.

• “P-SHIFT” Warning lamp flashes when “KNOB IND” on CONSULT-III screen is touched.

Revision: May 2010 2011 Versa

Page 657 of 3787

INTELLIGENT KEY SYSTEMBL-147

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

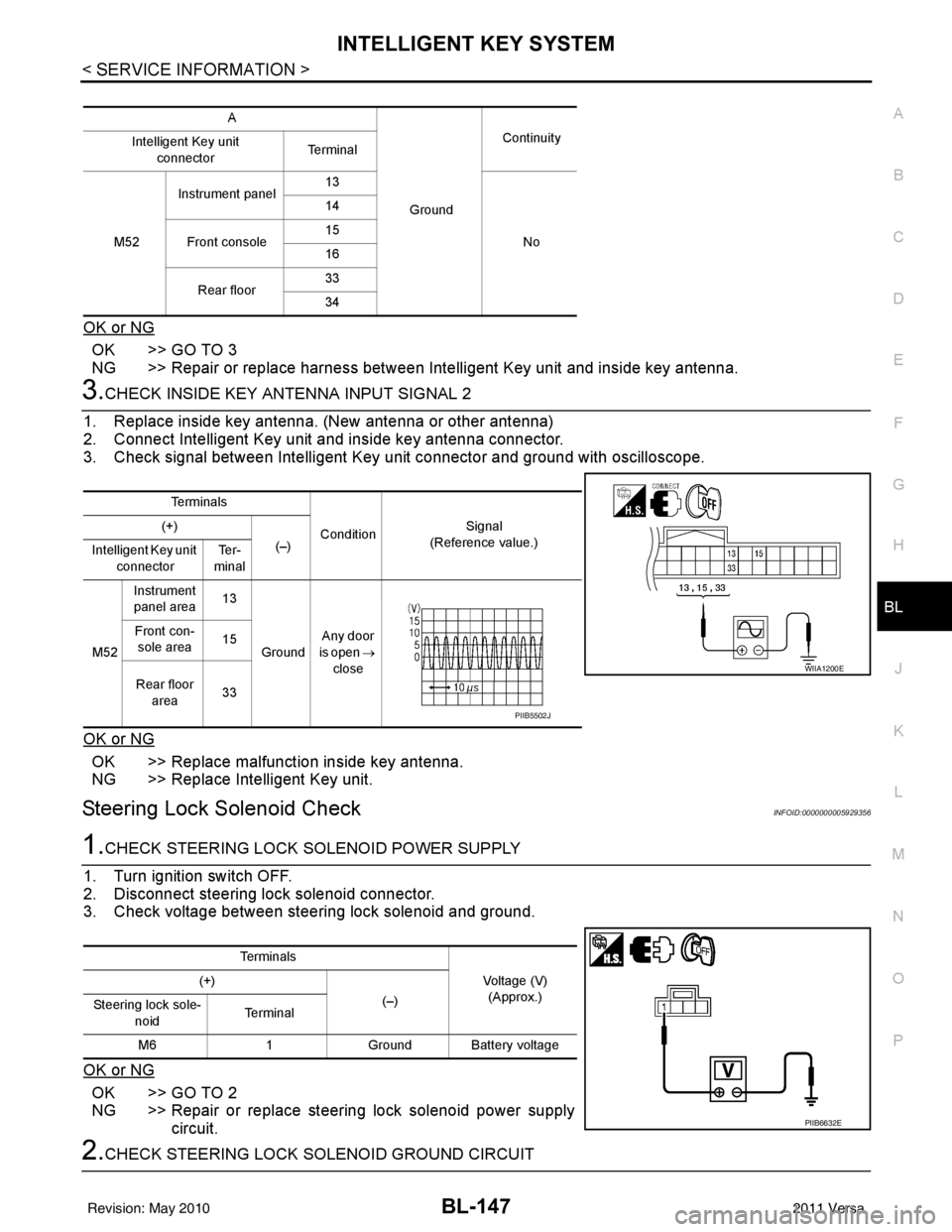

OK or NG

OK >> GO TO 3

NG >> Repair or replace harness between Intelligent Key unit and inside key antenna.

3.CHECK INSIDE KEY ANTENNA INPUT SIGNAL 2

1. Replace inside key antenna. (New antenna or other antenna)

2. Connect Intelligent Key unit and inside key antenna connector.

3. Check signal between Intelligent Key unit connector and ground with oscilloscope.

OK or NG

OK >> Replace malfunction inside key antenna.

NG >> Replace Intelligent Key unit.

Steering Lock Solenoid CheckINFOID:0000000005929356

1.CHECK STEERING LOCK SOLENOID POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect steering lock solenoid connector.

3. Check voltage between steering lock solenoid and ground.

OK or NG

OK >> GO TO 2

NG >> Repair or replace steering lock solenoid power supply circuit.

2.CHECK STEERING LOCK SOLENOID GROUND CIRCUIT

A

GroundContinuity

Intelligent Key unit

connector Te r m i n a l

M52 Instrument panel

13

No

14

Front console 15

16

Rear floor 33

34

Te r m i n a l s

ConditionSignal

(Reference value.)

(+)

(–)

Intelligent Key unit

connector Te r -

minal

M52 Instrument

panel area 13

Ground Any door

is open →

close

Front con-

sole area 15

Rear floor area 33

WIIA1200E

PIIB5502J

Te r m i n a l s

Voltage (V)(Approx.)

(+)

(–)

Steering lock sole-

noid Te r m i n a l

M6 1Ground Battery voltage

PIIB6632E

Revision: May 2010 2011 Versa

Page 691 of 3787

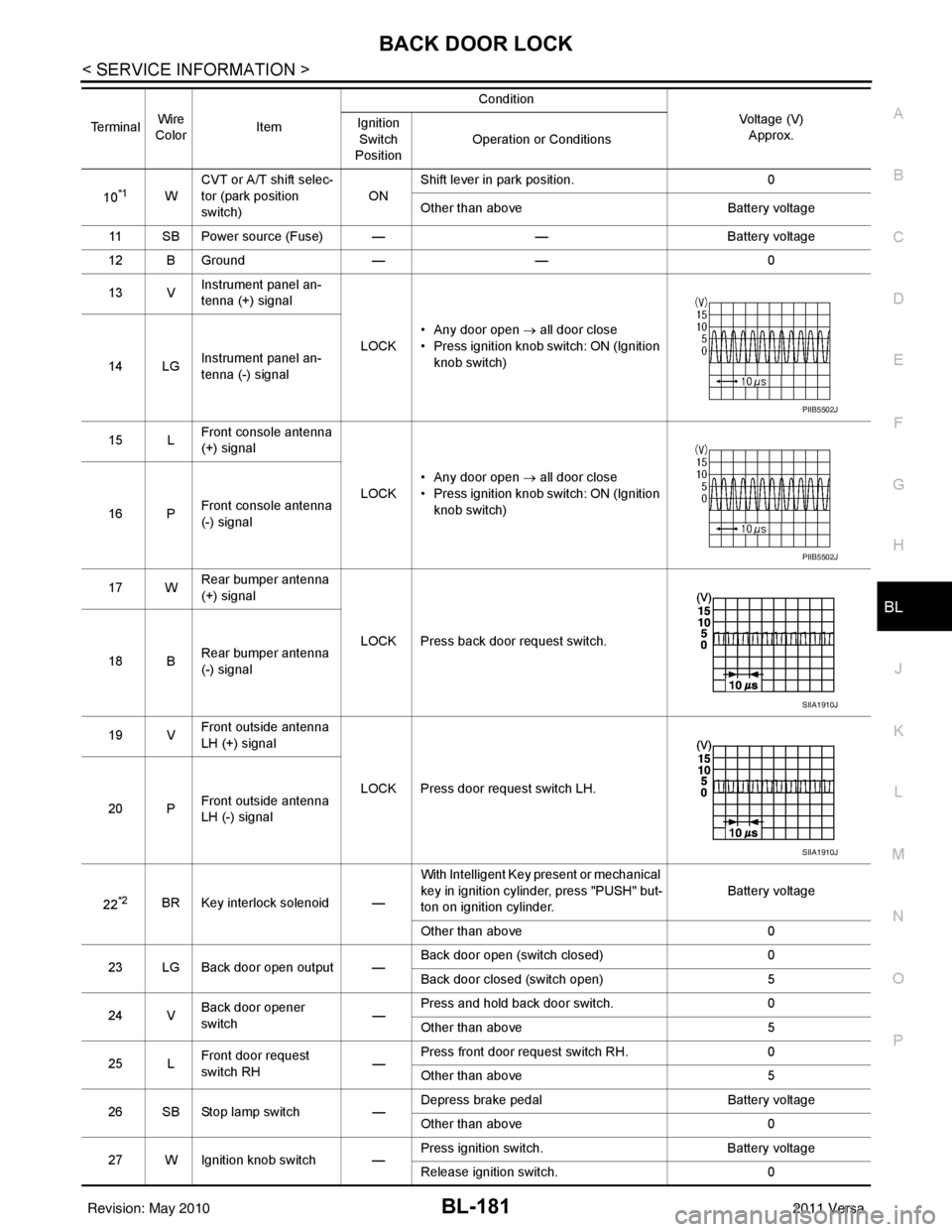

BACK DOOR LOCKBL-181

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

10*1W CVT or A/T shift selec-

tor (park position

switch)

ONShift lever in park position.

0

Other than above Battery voltage

11 SB Power source (Fus e) — —Battery voltage

12 B Ground —— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2BR Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH

—Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: May 2010

2011 Versa

Page 716 of 3787

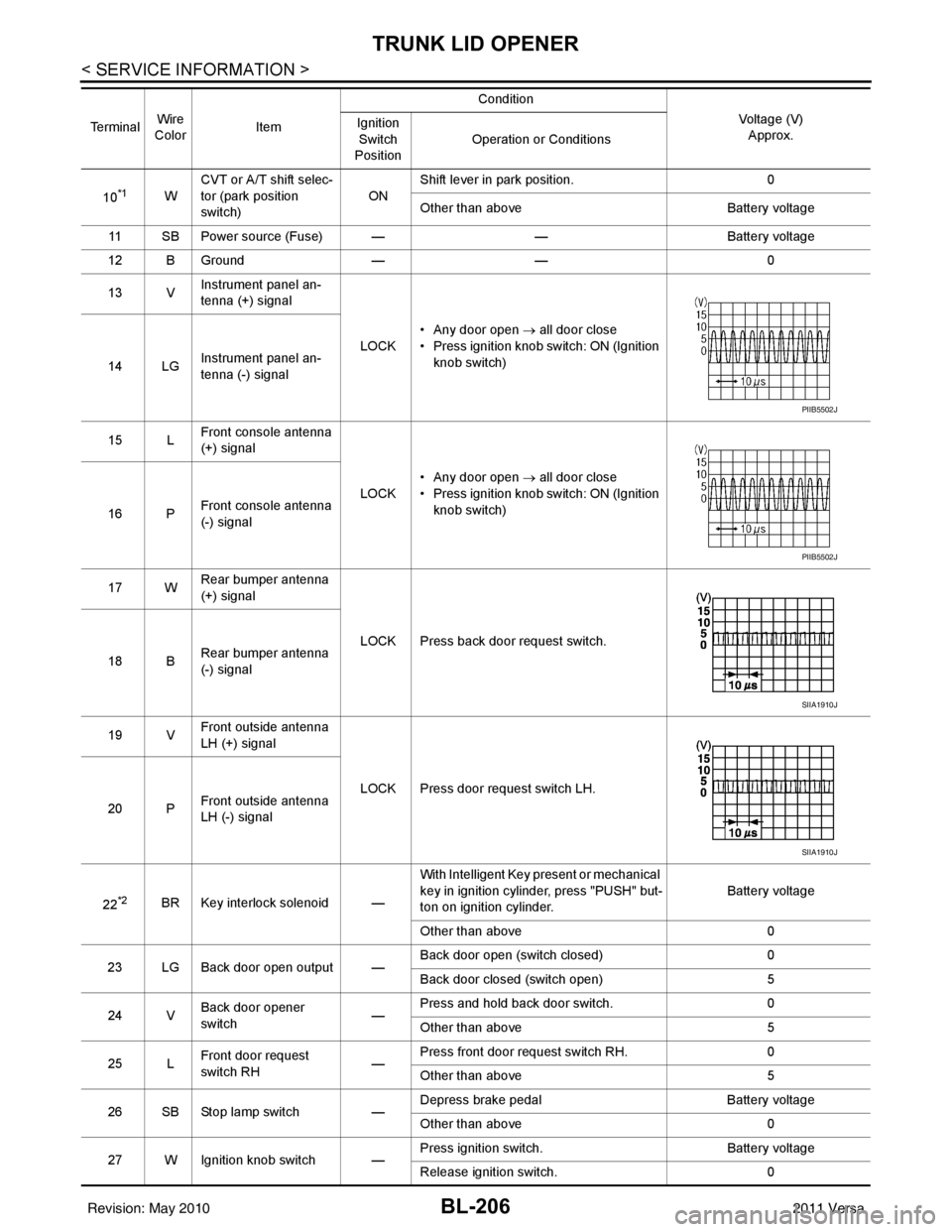

BL-206

< SERVICE INFORMATION >

TRUNK LID OPENER

10*1WCVT or A/T shift selec-

tor (park position

switch)

ONShift lever in park position.

0

Other than above Battery voltage

11 SB Power source (Fuse) — —Battery voltage

12 B Ground —— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2BR Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH

—Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

Te r m i n a l

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: May 2010

2011 Versa

Page 741 of 3787

VEHICLE SECURITY (THEFT WARNING) SYSTEMBL-231

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

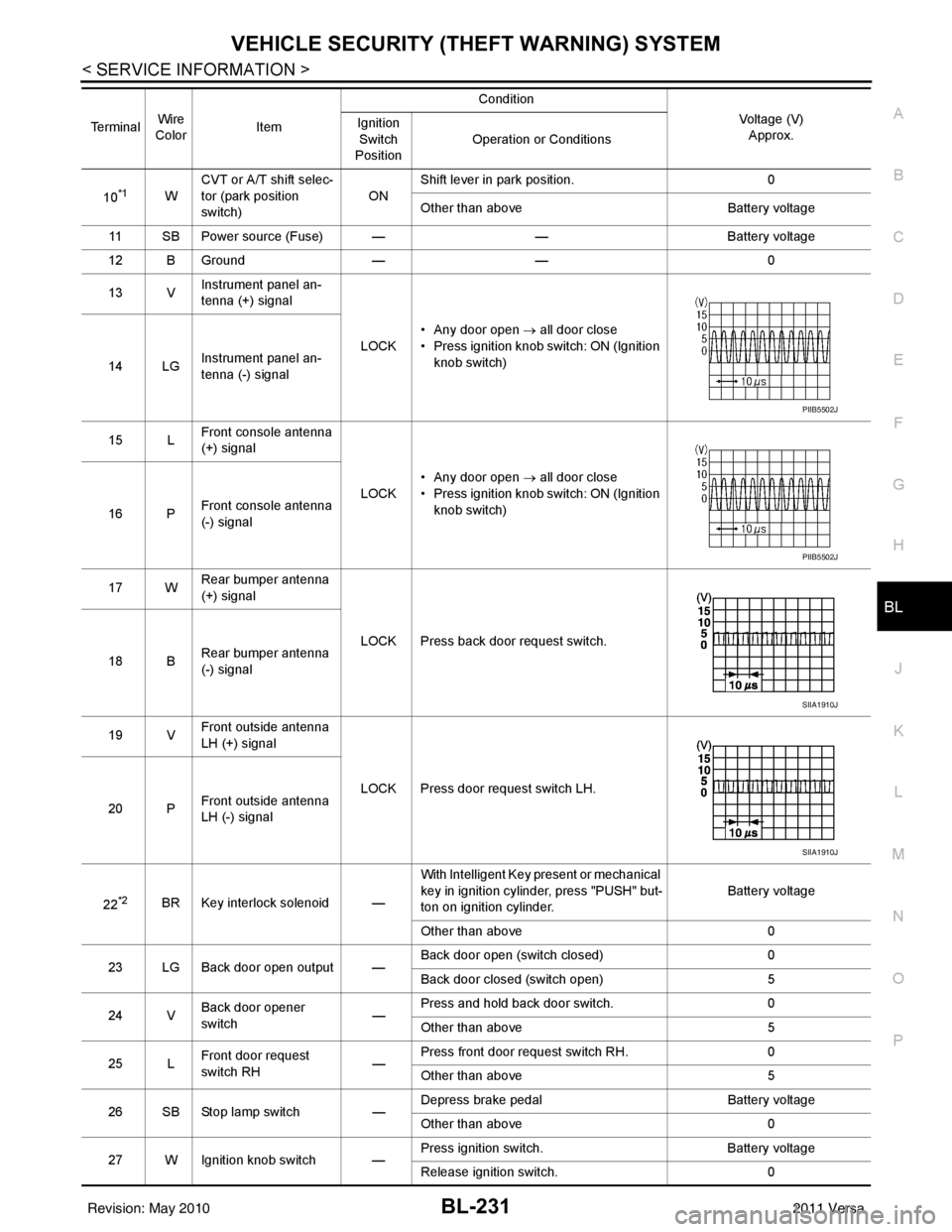

10*1W CVT or A/T shift selec-

tor (park position

switch)

ONShift lever in park position.

0

Other than above Battery voltage

11 SB Power source (Fus e) — —Battery voltage

12 B Ground —— 0

13 V Instrument panel an-

tenna (+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

14 LG Instrument panel an-

tenna (-) signal

15 L Front console antenna

(+) signal

LOCK• Any door open

→ all door close

• Press ignition knob switch: ON (Ignition knob switch)

16 P Front console antenna

(-) signal

17 W Rear bumper antenna

(+) signal

LOCK Press back door request switch.

18 B Rear bumper antenna

(-) signal

19 V Front outside antenna

LH (+) signal

LOCK Press door request switch LH.

20 P Front outside antenna

LH (-) signal

22

*2BR Key interlock solenoid — With Intelligent Key present or mechanical

key in ignition cylinder, press "PUSH" but-

ton on ignition cylinder.

Battery voltage

Other than above 0

23 LG Back door open output — Back door open (switch closed)

0

Back door closed (switch open) 5

24 V Back door opener

switch —Press and hold back door switch.

0

Other than above 5

25 L Front door request

switch RH

—Press front door request switch RH.

0

Other than above 5

26 SB Stop lamp switch —Depress brake pedal

Battery voltage

Other than above 0

27 W Ignition knob switch — Press ignition switch.

Battery voltage

Release ignition switch. 0

Terminal

Wire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch

Position Operation or Conditions

PIIB5502J

PIIB5502J

SIIA1910J

SIIA1910J

Revision: May 2010

2011 Versa

Page 1216 of 3787

![NISSAN TIIDA 2011 Service User Guide SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the NISSAN TIIDA 2011 Service User Guide SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the](/img/5/57396/w960_57396-1215.png)

SHIFT CONTROL SYSTEMCVT-161

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

REMOVAL

CAUTION:

Make sure that parking brake is applie d before removal and installation.

1. Place the shift selector in the “N” position.

2. Remove the center console assembly. Refer to IP-11

.

3. Disconnect the CVT shift selector harness connector (1).

4. Remove the key interlock cable from the CVT shift selector assembly. Refer to CVT-166, "

Removal and Installation".

5. Remove the bolts (A) from the CVT shift selector assembly (1).

6. Remove exhaust front tube, center muffler and heat plates. Refer to EM-141

.

1. Shift selector handle 2. CVT shift selector assembly 3. Lock plate

4. Bracket 5. Control cable6. Bracket

7. Lock plate 8. Bracket9. Transaxle assembly

A. Floor

WCIA0639E

SCIA6965E

WCIA0609E

Revision: May 2010 2011 Versa

Page 1221 of 3787

![NISSAN TIIDA 2011 Service User Guide CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005928967

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal NISSAN TIIDA 2011 Service User Guide CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005928967

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal](/img/5/57396/w960_57396-1220.png)

CVT-166

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

Removal and InstallationINFOID:0000000005928967

COMPONENTS

REMOVAL

Refer to the figure for key interlock cable removal procedure.

CAUTION:

Make sure that parking brake is applied before removal/installation.

1. Place the shift selector in the "N" position.

2. Remove the center console assembly. Refer to

IP-11

.

3. Slide the slider (A) toward the casing cap (B) while pressing tabs (C) on the slider to separate the slider (A) from the adjust holder

(D).

4. Remove the casing cap (B) from the cable bracket on the CVT shift selector assembly.

5. Remove the key interlock cable from the key interlock rod (E).

1. Key interlock cable 2. Key cylinder 3. CVT shift selector assembly

A. Lock plate B. HolderC. Clip

D. Slider E. Key interlock rod F. Adjust holder

G. C a s i n g c a p

WCIA0621E

SCIA6975E

Revision: May 2010 2011 Versa

Page 1223 of 3787

![NISSAN TIIDA 2011 Service User Guide CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C) NISSAN TIIDA 2011 Service User Guide CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C)](/img/5/57396/w960_57396-1222.png)

CVT-168

< SERVICE INFORMATION >[RE0F08B]

KEY INTERLOCK CABLE

8. Slide the slider (A) toward the key interlock rod (D) while press-

ing the pull lock (B) down to securely connect the adjust holder

(C) with the key interlock rod (D).

CAUTION:

• Do not press tabs when holding slider (A).

• Do not apply any side to side force to key interlock rod (D)when sliding slider (A).

9. Secure the key interlock cable (1) with the clip (A).

10. Install steering column cover (upper and lower) and instrument lower finisher. Refer to IP-11

.

11. Install the center console assembly. Refer to IP-11

.

12. Install the shift selector handle. Refer to CVT-163, "

Shift Selec-

tor Handle Removal and Installation".

13. Check shift lock system. Refer to CVT-153, "

Description".

SCIA6978E

SCIA6973E

Revision: May 2010 2011 Versa

Page 2338 of 3787

EI-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929551

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

Revision: May 2010 2011 Versa