Console NISSAN TIIDA 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3280 of 3787

![NISSAN TIIDA 2011 Service Service Manual CONTROL LINKAGEMT-59

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

b. Pull the release button (1) of select cable (2) and then remove it from control shaft select lever (3).

5. Mo NISSAN TIIDA 2011 Service Service Manual CONTROL LINKAGEMT-59

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

b. Pull the release button (1) of select cable (2) and then remove it from control shaft select lever (3).

5. Mo](/img/5/57396/w960_57396-3279.png)

CONTROL LINKAGEMT-59

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

b. Pull the release button (1) of select cable (2) and then remove it from control shaft select lever (3).

5. Move shift selector to neutral position.

6. Remove shift selector handle.

7. Remove center console assembly. Refer to IP-12, "

Removal and

Installation".

8. Remove M/T shift selector assembly bolts.

9. Remove exhaust front tube, cent er muffler and heat plate. Refer

to EX-10, "

Removal and Installation".

10. Remove cable support bracket.

11. Remove select cable and shift selector cable from cable bracket.

12. Remove M/T shift selector assembly from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Self tapping bolts are used to attach cables to the clutch housing.

• Securely assemble each cable and lever of control shaft.

• Be careful about the installation direction, and push shift selector handle onto shift selector.

CAUTION:

Do not reuse shift selector handle.

• Make sure that the front/rear claws (1) of M/T shift selector assem- bly are in contact with flange of the floor (2).

• When shift selector is selected to 1st-2nd side and 5th-6th side, confirm shift lever returns to neutral position smoothly.

• When shift selector is shifted to each position, make sure there is

no binding or disconnection in each boot.

• Move stopper (1) to lock position when installing the shift cable onto the control shaft shift lever.

WCIA0606E

SCIA7630E

PCIB1510E

SCIA7846E

Revision: May 2010 2011 Versa

Page 3375 of 3787

A/C UNIT ASSEMBLYMTC-59

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

A/C UNIT ASSEMBLY

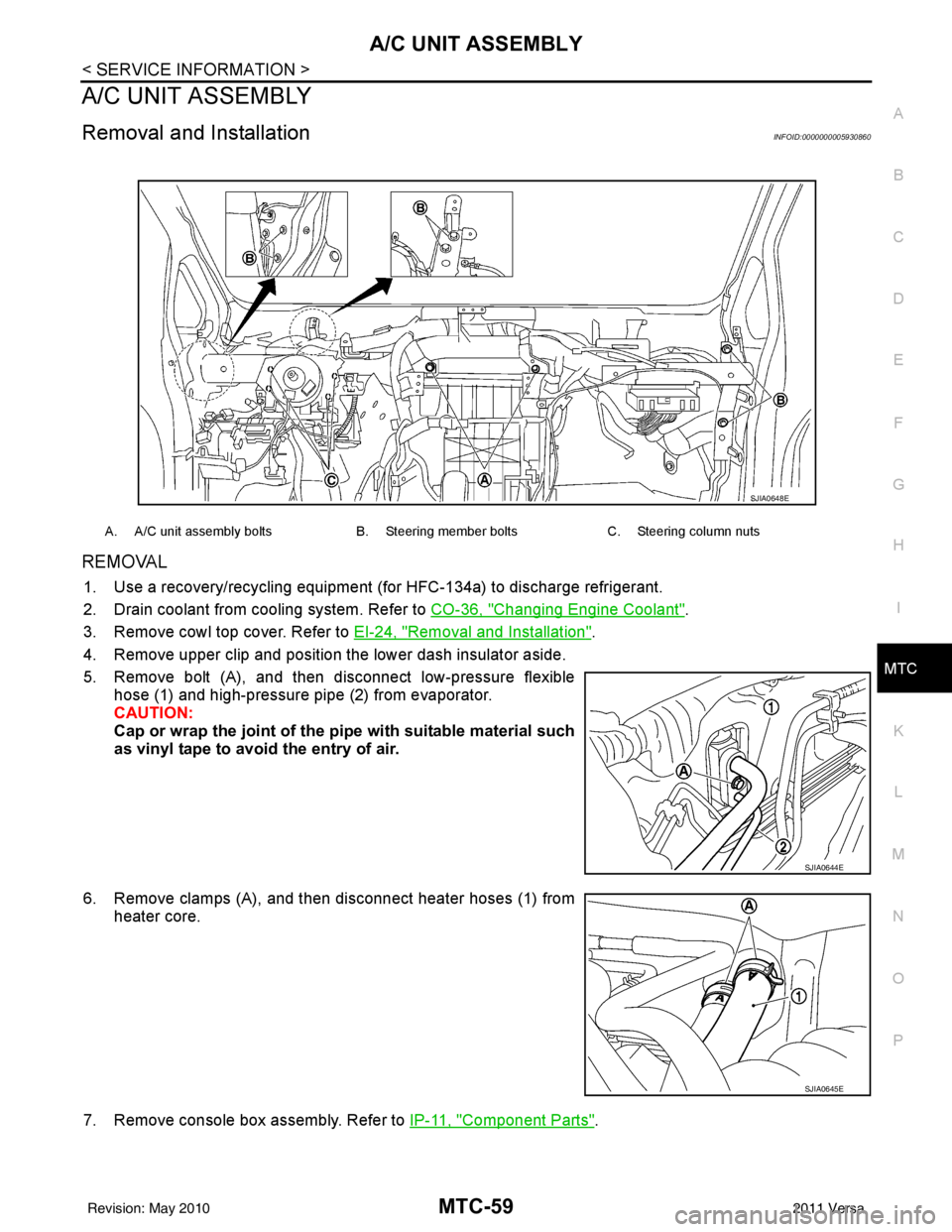

Removal and InstallationINFOID:0000000005930860

REMOVAL

1. Use a recovery/recycling equipment (f or HFC-134a) to discharge refrigerant.

2. Drain coolant from cooling system. Refer to CO-36, "

Changing Engine Coolant".

3. Remove cowl top cover. Refer to EI-24, "

Removal and Installation".

4. Remove upper clip and position the lower dash insulator aside.

5. Remove bolt (A), and then disconnect low-pressure flexible hose (1) and high-pressure pipe (2) from evaporator.

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

6. Remove clamps (A), and then disconnect heater hoses (1) from heater core.

7. Remove console box assembly. Refer to IP-11, "

Component Parts".

A. A/C unit assembly boltsB. Steering member boltsC. Steering column nuts

SJIA0648E

SJIA0644E

SJIA0645E

Revision: May 2010 2011 Versa

Page 3383 of 3787

BLOWER FAN RESISTORMTC-67

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

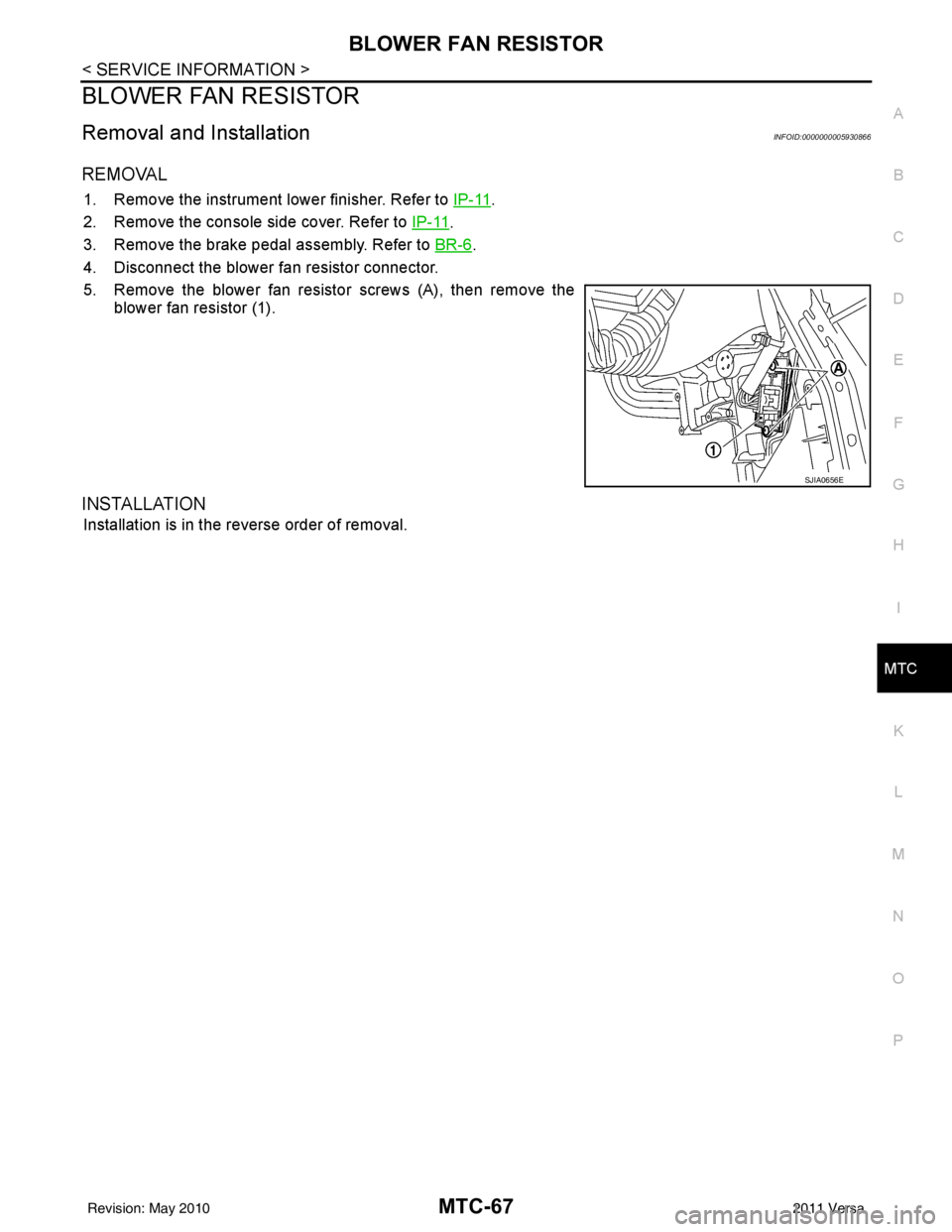

BLOWER FAN RESISTOR

Removal and InstallationINFOID:0000000005930866

REMOVAL

1. Remove the instrument lower finisher. Refer to IP-11.

2. Remove the console side cover. Refer to IP-11

.

3. Remove the brake pedal assembly. Refer to BR-6

.

4. Disconnect the blower fan resistor connector.

5. Remove the blower fan resistor screws (A), then remove the blower fan resistor (1).

INSTALLATION

Installation is in the reverse order of removal.

SJIA0656E

Revision: May 2010 2011 Versa

Page 3388 of 3787

MTC-72

< SERVICE INFORMATION >

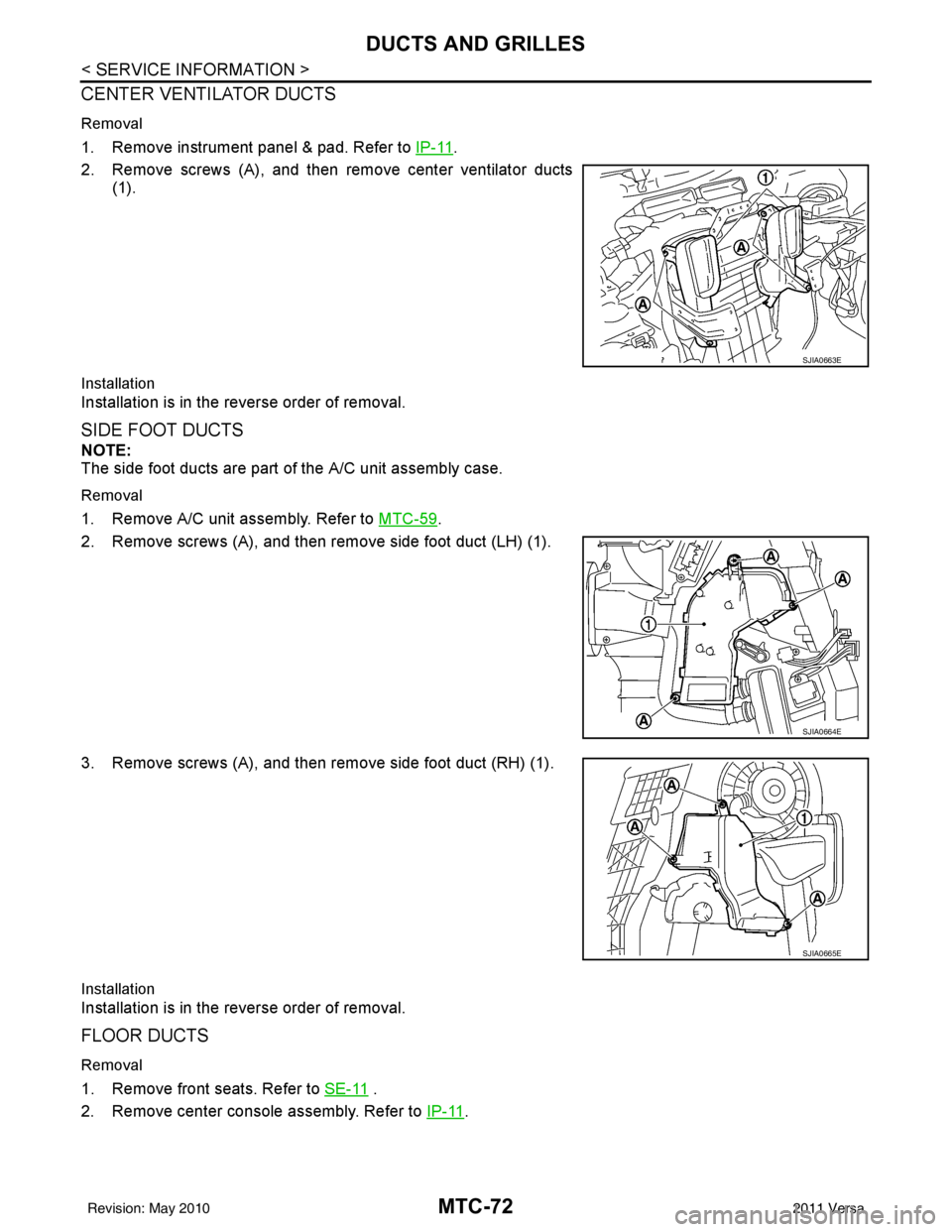

DUCTS AND GRILLES

CENTER VENTILATOR DUCTS

Removal

1. Remove instrument panel & pad. Refer to IP-11.

2. Remove screws (A), and then remove center ventilator ducts (1).

Installation

Installation is in the reverse order of removal.

SIDE FOOT DUCTS

NOTE:

The side foot ducts are part of the A/C unit assembly case.

Removal

1. Remove A/C unit assembly. Refer to MTC-59.

2. Remove screws (A), and then remove side foot duct (LH) (1).

3. Remove screws (A), and then remove side foot duct (RH) (1).

Installation

Installation is in the reverse order of removal.

FLOOR DUCTS

Removal

1. Remove front seats. Refer to SE-11 .

2. Remove center console assembly. Refer to IP-11

.

SJIA0663E

SJIA0664E

SJIA0665E

Revision: May 2010 2011 Versa

Page 3417 of 3787

PARKING BRAKE CONTROLPB-5

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

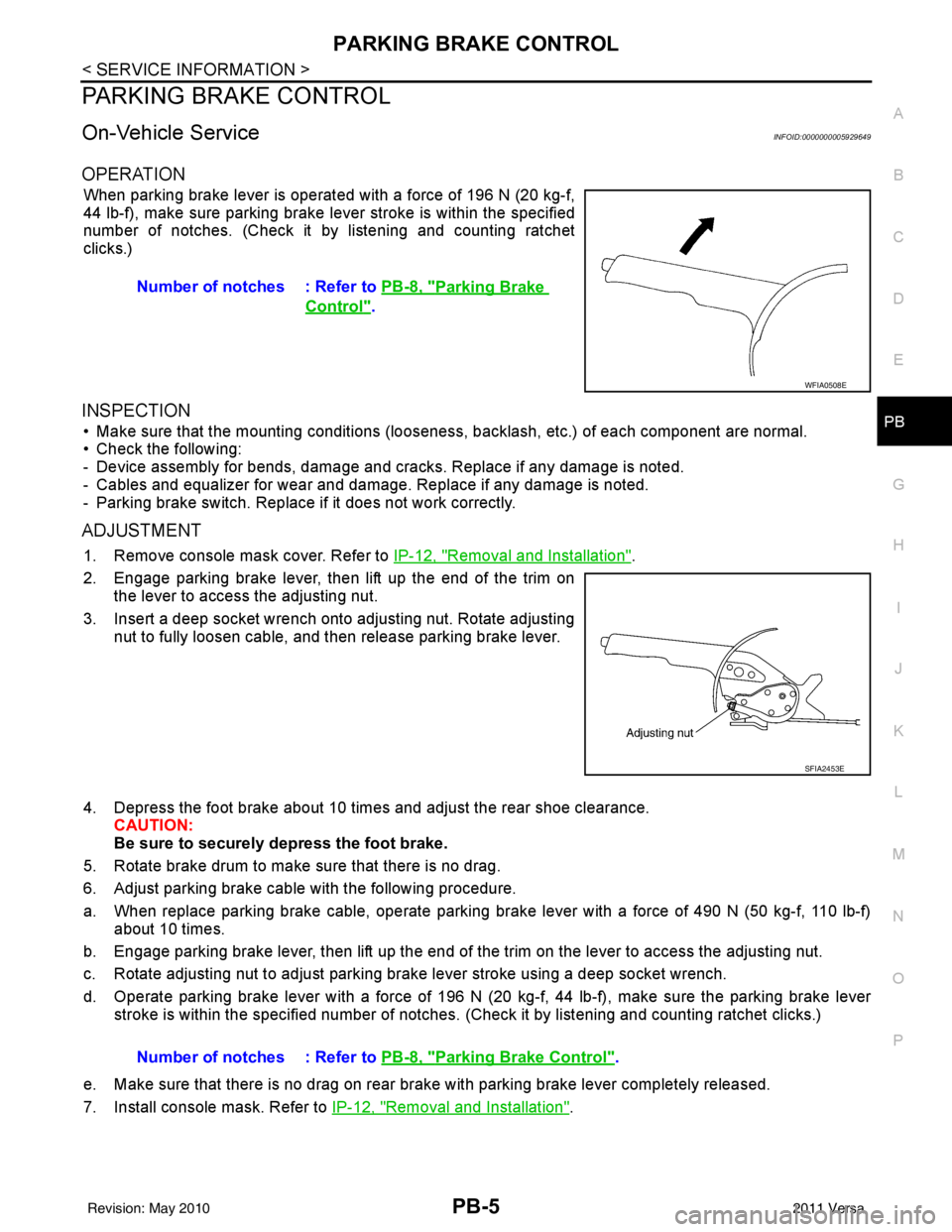

PARKING BRAKE CONTROL

On-Vehicle ServiceINFOID:0000000005929649

OPERATION

When parking brake lever is operated with a force of 196 N (20 kg-f,

44 lb-f), make sure parking brake le ver stroke is within the specified

number of notches. (Check it by listening and counting ratchet

clicks.)

INSPECTION

• Make sure that the mounting conditions (looseness, backlash, etc.) of each component are normal.

• Check the following:

- Device assembly for bends, damage and cracks. Replace if any damage is noted.

- Cables and equalizer for wear and damage. Replace if any damage is noted.

- Parking brake switch. Replace if it does not work correctly.

ADJUSTMENT

1. Remove console mask cover. Refer to IP-12, "Removal and Installation".

2. Engage parking brake lever, then lift up the end of the trim on the lever to access the adjusting nut.

3. Insert a deep socket wrench onto adjusting nut. Rotate adjusting nut to fully loosen cable, and then release parking brake lever.

4. Depress the foot brake about 10 ti mes and adjust the rear shoe clearance.

CAUTION:

Be sure to securely depress the foot brake.

5. Rotate brake drum to make sure that there is no drag.

6. Adjust parking brake cable with the following procedure.

a. When replace parking brake cable, operate parking br ake lever with a force of 490 N (50 kg-f, 110 lb-f)

about 10 times.

b. Engage parking brake lever, then lift up the end of the trim on the lever to access the adjusting nut.

c. Rotate adjusting nut to adjust parking brake lever stroke using a deep socket wrench.

d. Operate parking brake lever with a force of 196 N (20 kg-f, 44 lb-f), make sure the parking brake lever

stroke is within the specified number of notches. (Check it by listening and counting ratchet clicks.)

e. Make sure that there is no drag on rear brake with parking brake lever completely released.

7. Install console mask. Refer to IP-12, "

Removal and Installation".

Number of notches : Refer to

PB-8, "

Parking Brake

Control".

WFIA0508E

SFIA2453E

Number of notches : Refer to PB-8, "Parking Brake Control".

Revision: May 2010 2011 Versa

Page 3418 of 3787

PB-6

< SERVICE INFORMATION >

PARKING BRAKE CONTROL

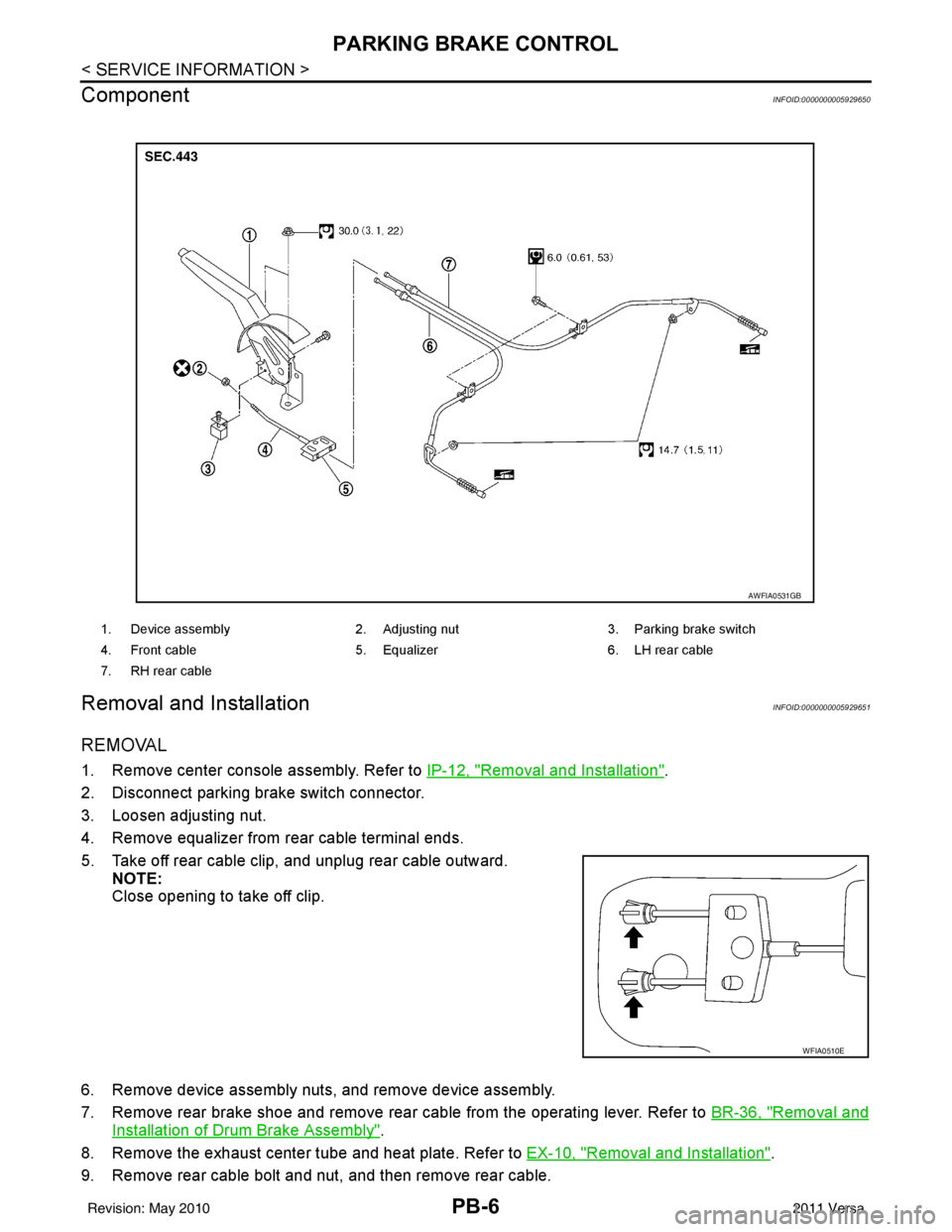

Component

INFOID:0000000005929650

Removal and InstallationINFOID:0000000005929651

REMOVAL

1. Remove center console assembly. Refer to IP-12, "Removal and Installation".

2. Disconnect parking brake switch connector.

3. Loosen adjusting nut.

4. Remove equalizer from rear cable terminal ends.

5. Take off rear cable clip, and unplug rear cable outward. NOTE:

Close opening to take off clip.

6. Remove device assembly nuts, and remove device assembly.

7. Remove rear brake shoe and remove rear cable from the operating lever. Refer to BR-36, "

Removal and

Installation of Drum Brake Assembly".

8. Remove the exhaust center tube and heat plate. Refer to EX-10, "

Removal and Installation".

9. Remove rear cable bolt and nut, and then remove rear cable.

1. Device assembly 2. Adjusting nut3. Parking brake switch

4. Front cable 5. Equalizer6. LH rear cable

7. RH rear cable

AWFIA0531GB

WFIA0510E

Revision: May 2010 2011 Versa

Page 3470 of 3787

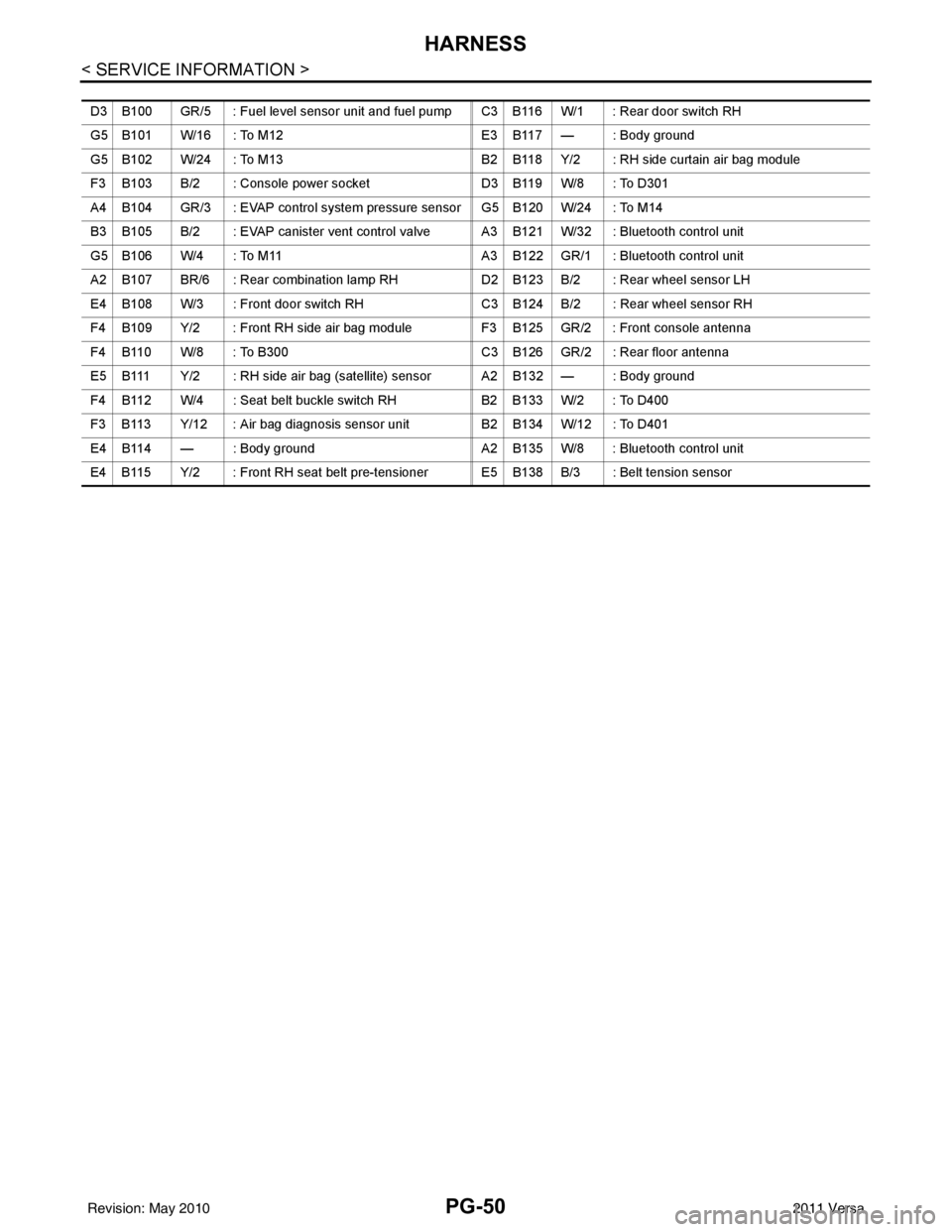

PG-50

< SERVICE INFORMATION >

HARNESS

D3 B100 GR/5 : Fuel level sensor unit and fuel pump C3 B116 W/1 : Rear door switch RH

G5 B101 W/16 : To M12E3 B117 — : Body ground

G5 B102 W/24 : To M13 B2 B118 Y/2 : RH side curtain air bag module

F3 B103 B/2 : Console power socket D3 B119 W/8 : To D301

A4 B104 GR/3 : EVAP control system pressure sensor G5 B120 W/24 : To M14

B3 B105 B/2 : EVAP canister vent control valve A3 B121 W/32 : Bluetooth control unit

G5 B106 W/4 : To M11 A3 B122 GR/1 : Bluetooth control unit

A2 B107 BR/6 : Rear combination lamp RH D2 B123 B/2 : Rear wheel sensor LH

E4 B108 W/3 : Front door switch RH C3 B124 B/2 : Rear wheel sensor RH

F4 B109 Y/2 : Front RH side air bag module F3 B125 GR/2 : Front console antenna

F4 B110 W/8 : To B300 C3 B126 GR/2 : Rear floor antenna

E5 B111 Y/2 : RH side air bag (satellite) sensor A2 B132 — : Body ground

F4 B112 W/4 : Seat belt buckle switch RH B2 B133 W/2 : To D400

F3 B113 Y/12 : Air bag diagnosis sensor unit B2 B134 W/12 : To D401

E4 B114 — : Body ground A2 B135 W/8 : Bluetooth control unit

E4 B115 Y/2 : Front RH seat belt pre-tensioner E5 B138 B/3 : Belt tension sensor

Revision: May 2010 2011 Versa

Page 3471 of 3787

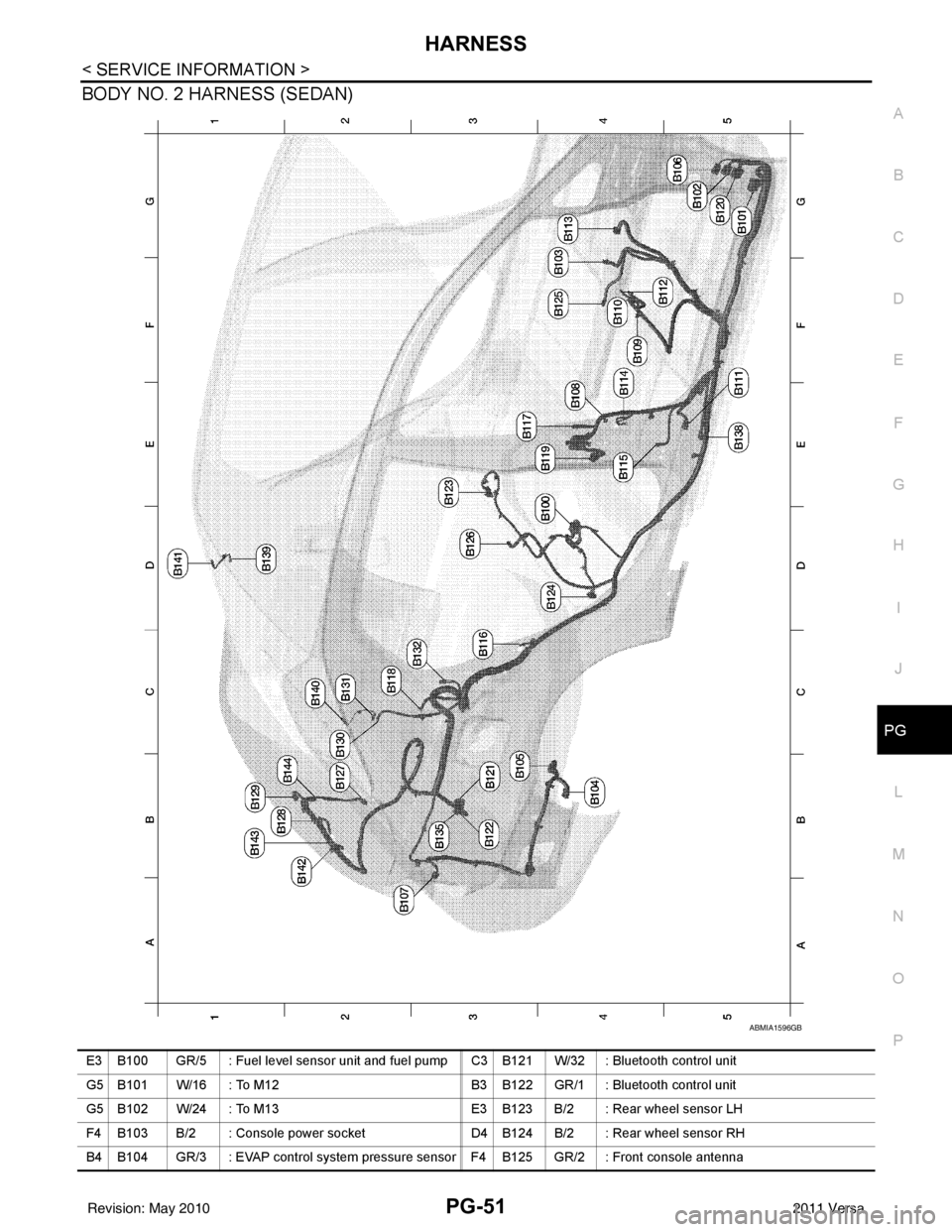

HARNESSPG-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

BODY NO. 2 HARNESS (SEDAN)

ABMIA1596GB

E3 B100 GR/5 : Fuel level sensor unit and fuel pump C3 B121 W/32 : Bluetooth control unit

G5 B101 W/16 : To M12 B3 B122 GR/1 : Bluetooth control unit

G5 B102 W/24 : To M13 E3 B123 B/2 : Rear wheel sensor LH

F4 B103 B/2 : Console power socket D4 B124 B/2 : Rear wheel sensor RH

B4 B104 GR/3 : EVAP control system pressure sensor F4 B125 GR/2 : Front console antenna

Revision: May 2010 2011 Versa

Page 3530 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

The following materials, not available through NISSAN Parts Department, can also be used to repair squeaks

and rattles.

UHMW(TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929522

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: May 2010 2011 Versa

Page 3531 of 3787

RF-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa