Console NISSAN TIIDA 2011 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2828 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

68370-4B000: 15 x 25 mm (0.59 x 0.98 in) pad/ 68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000005929590

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

Revision: May 2010 2011 Versa

Page 2829 of 3787

IP-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 2833 of 3787

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

Removal and Installation

INFOID:0000000005929593

CAUTION:

• Disconnect both the negative and positive battery terminals, then wait at least three minutes.

• Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

• Be careful not to scratch pad and other parts.

INSTRUMENT PANEL ASSEMBLY

Removal

1. Disconnect both the negative and positive battery terminals, then wait at least three minutes.

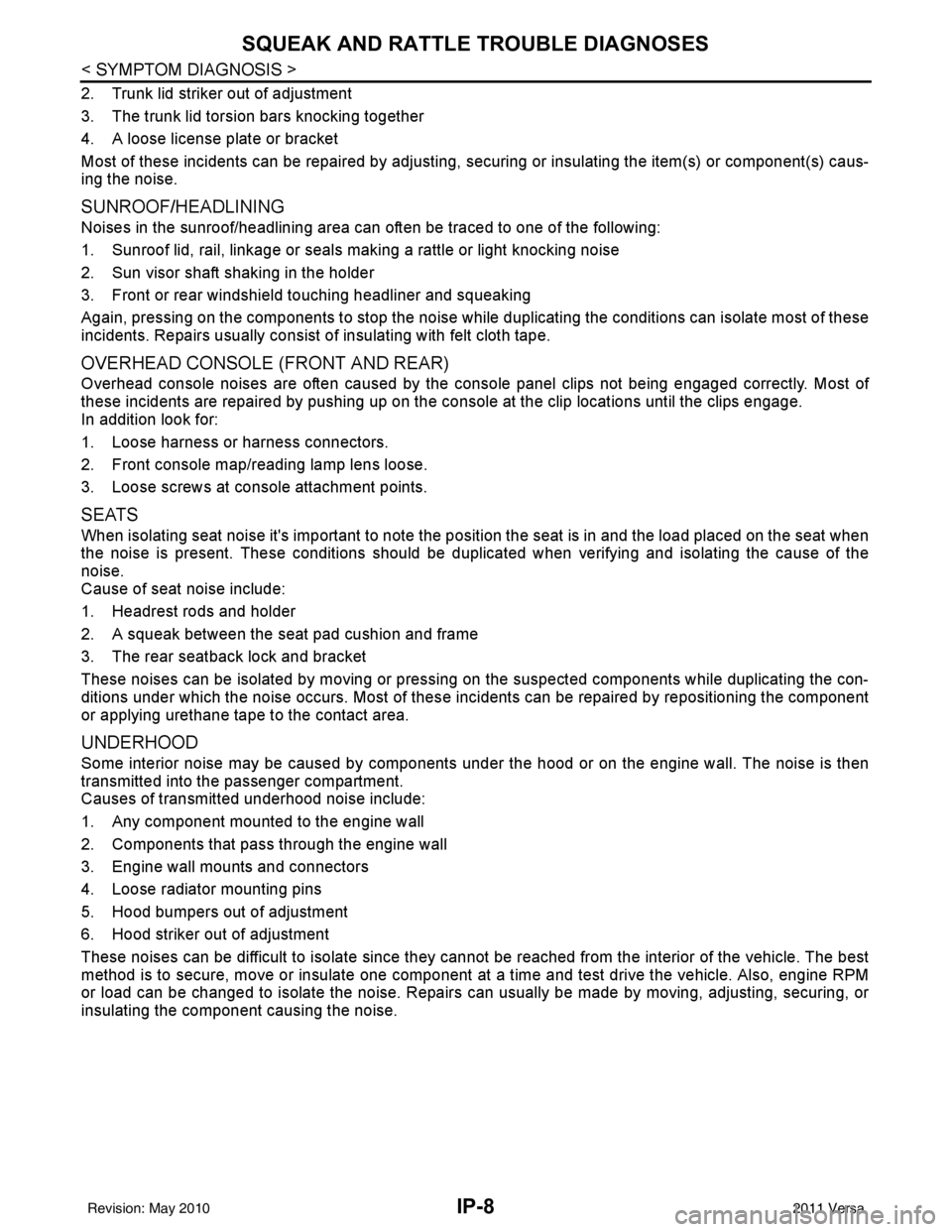

2. Pull instrument finisher E backward by approximately 30

degrees while disengaging the metal clips and pawl.

: Metal clip

: Pawl

3. Remove cluster lid C. : Metal clip

: Pawl

a. Remove the upper screws from cluster lid C.

b. Pull cluster lid C backward while disengaging the metal clips and pawl.

c. Disconnect harness connector, and then remove cluster lid C.

4. Remove audio unit. Refer to AV-29, "

Removal and Installation" (Audio without Navigation) or AV-73,

"Removal and Installation" (Audio with Navigation).

5. Remove front pillar garnish. Refer to EI-41

.

1. Instrument upper mask 2. Instrument upper panel assembly 3. Instrument side panel (LH)

4. Combination meter 5. Instrument finisher E 6. Cluster lid A

7. Instrument side mask (LH) 8. Instrument panel & pad 9. Side ventilator assembly (LH)

10. Instrument side finisher 11. Instrument lower finisher 12. Steering column cover upper

13. Fuse block lid 14. Steering column cover lower 15. Steering lock escutcheon

16. Instrument lower cover (LH) 17. Console rear finisher (with armrest) 18. Console body assembly (with arm- rest)

19. Center console 20. Console mask cover (with armrest) 21. Console mask

22. A/T console finisher / M/T console boot / CVT console finisher 23. Console rear finisher (without armrest) 24. Console body assembly (without

armrest)

25. Rear cup holder (without armrest) 26. Instrument lower cover (RH) 27. Instrument finisher D

28. Controller 29. Cluster lid C 30. Audio unit

31. Glove box assembly 32. Side ventilator assembly (RH) 33. Instrument side mask (RH)

34. Passenger air bag module assembly 35. Instrument side panel (RH) Pawl

Clip Metal clip

WIIA1224E

WIIA1225E

Revision: May 2010 2011 Versa

Page 2835 of 3787

IP-14

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

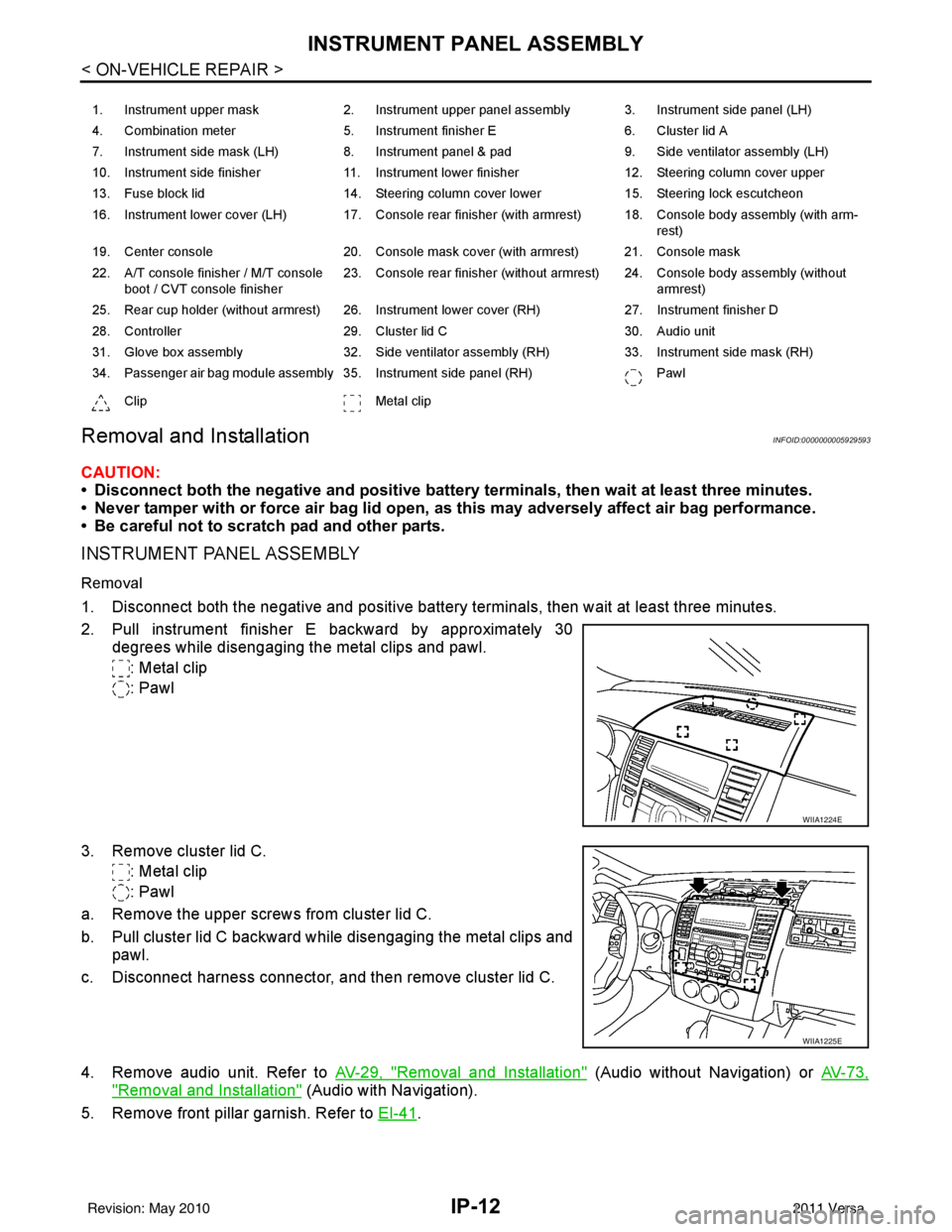

10. Remove steering lock escutcheon.

11. Remove the steering column cover screws, then disengage pawls and remove the steering column cov-

ers.

12. Remove cluster lid A.

a. Remove screws from instrument upper panel right side.

b. Lift the instrument upper panel up, disengage metal clips. : Metal clip

: Clip

c. Pull backward and disengage clips.

d. Remove cluster lid A.

13. Remove combination meter. Refer to COMBINATION METER procedure.

14. Disengage pawls and remove fuse block lid.

15. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

16. Remove glove box. Refer to GLOVE BOX ASSEMBLY procedure.

17. Remove side ventilator assembly (RH). : Metal clip

: Pawl

a. Insert a suitable tool into the top gap of the side ventilator assembly, then starting from center console side, disengage the

clips and pawl of instrument panel pad.

PIIB3969E

PIIB2880E

LIIA2544E

PIIB3977E

Revision: May 2010 2011 Versa

Page 2842 of 3787

INSTRUMENT PANEL ASSEMBLYIP-21

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

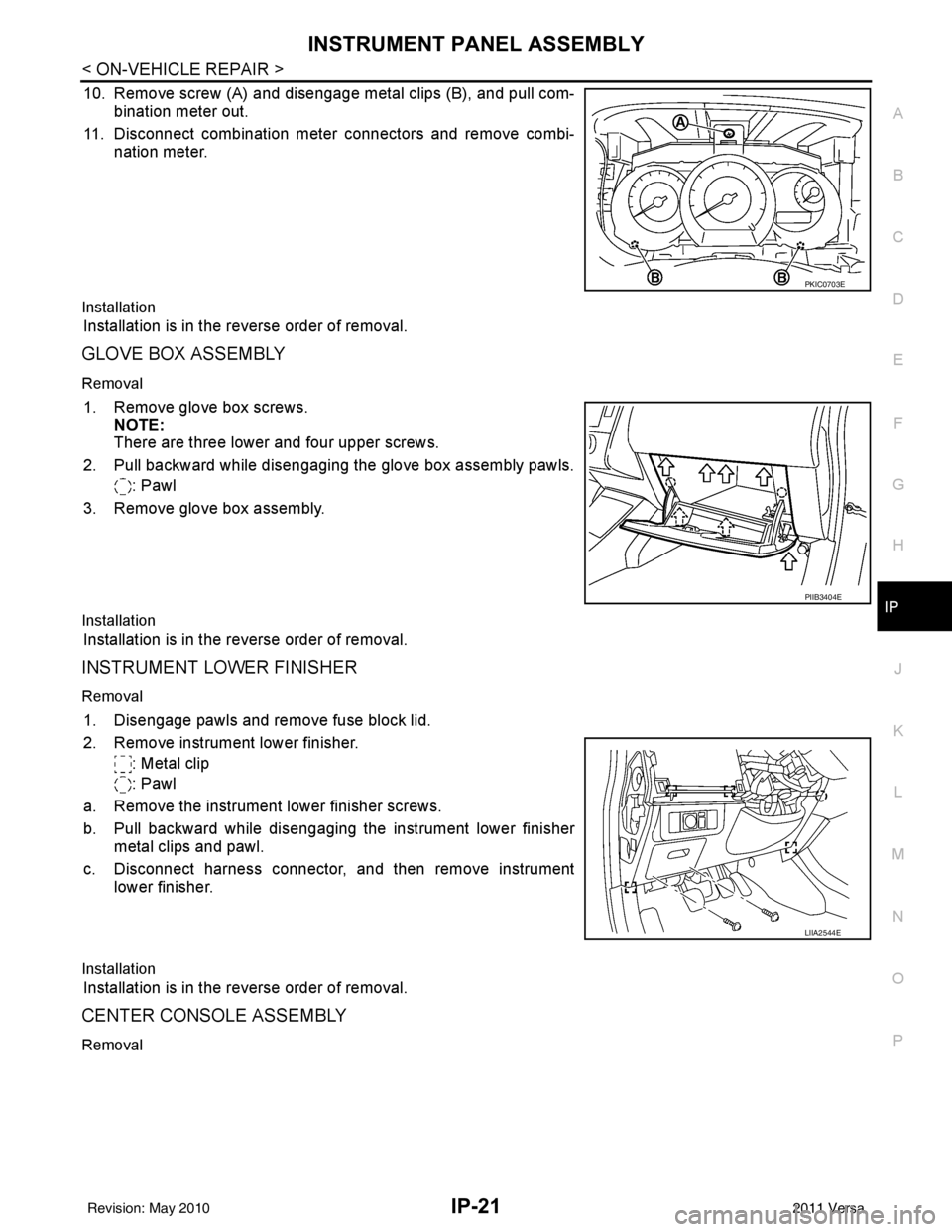

10. Remove screw (A) and disengage metal clips (B), and pull com- bination meter out.

11. Disconnect combination meter connectors and remove combi- nation meter.

Installation

Installation is in the reverse order of removal.

GLOVE BOX ASSEMBLY

Removal

1. Remove glove box screws.NOTE:

There are three lower and four upper screws.

2. Pull backward while disengaging the glove box assembly pawls. : Pawl

3. Remove glove box assembly.

Installation

Installation is in the reverse order of removal.

INSTRUMENT LOWER FINISHER

Removal

1. Disengage pawls and remove fuse block lid.

2. Remove instrument lower finisher. : Metal clip

: Pawl

a. Remove the instrument lower finisher screws.

b. Pull backward while disengaging the instrument lower finisher metal clips and pawl.

c. Disconnect harness connector, and then remove instrument lower finisher.

Installation

Installation is in the reverse order of removal.

CENTER CONSOLE ASSEMBLY

Removal

PKIC0703E

PIIB3404E

LIIA2544E

Revision: May 2010 2011 Versa

Page 2843 of 3787

IP-22

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

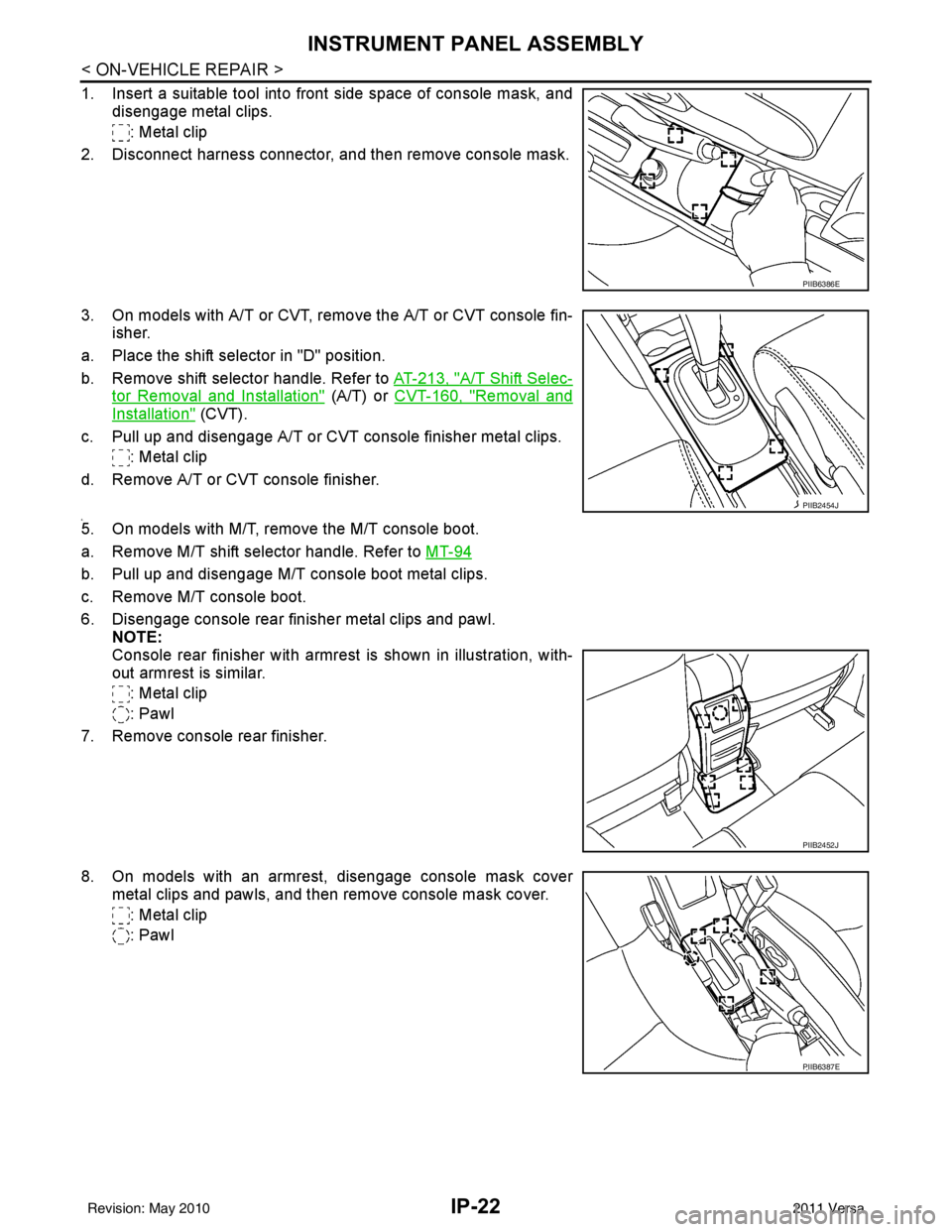

1. Insert a suitable tool into front side space of console mask, anddisengage metal clips.

: Metal clip

2. Disconnect harness connector, and then remove console mask.

3. On models with A/T or CVT, remo ve the A/T or CVT console fin-

isher.

a. Place the shift selector in "D" position.

b. Remove shift selector handle. Refer to AT-213, "

A/T Shift Selec-

tor Removal and Installation" (A/T) or CVT-160, "Removal and

Installation" (CVT).

c. Pull up and disengage A/T or CVT console finisher metal clips. : Metal clip

d. Remove A/T or CVT console finisher.

4.5. On models with M/T, remove the M/T console boot.

a. Remove M/T shift selector handle. Refer to MT-94

b. Pull up and disengage M/T console boot metal clips.

c. Remove M/T console boot.

6. Disengage console rear finisher metal clips and pawl.

NOTE:

Console rear finisher with armrest is shown in illustration, with-

out armrest is similar.

: Metal clip

: Pawl

7. Remove console rear finisher.

8. On models with an armrest, disengage console mask cover metal clips and pawls, and then remove console mask cover.

: Metal clip

: Pawl

PIIB6386E

PIIB2454J

PIIB2452J

PIIB6387E

Revision: May 2010 2011 Versa

Page 2844 of 3787

INSTRUMENT PANEL ASSEMBLYIP-23

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

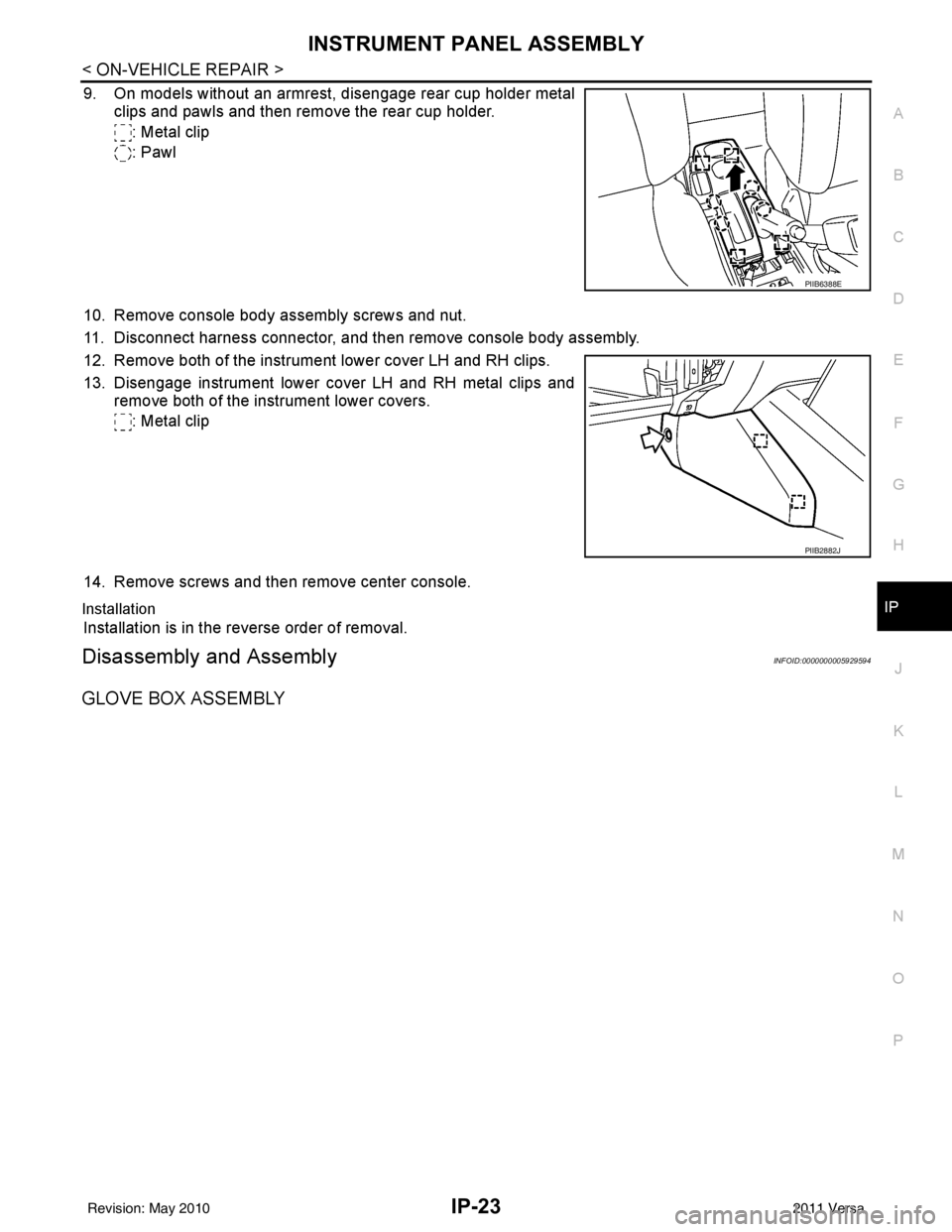

9. On models without an armrest, disengage rear cup holder metal

clips and pawls and then remove the rear cup holder.

: Metal clip

: Pawl

10. Remove console body assembly screws and nut.

11. Disconnect harness connector, and then remove console body assembly.

12. Remove both of the instrument lower cover LH and RH clips.

13. Disengage instrument lower cover LH and RH metal clips and remove both of the instrument lower covers.

: Metal clip

14. Remove screws and then remove center console.

Installation

Installation is in the reverse order of removal.

Disassembly and AssemblyINFOID:0000000005929594

GLOVE BOX ASSEMBLY

PIIB6388E

PIIB2882J

Revision: May 2010 2011 Versa

Page 2845 of 3787

IP-24

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

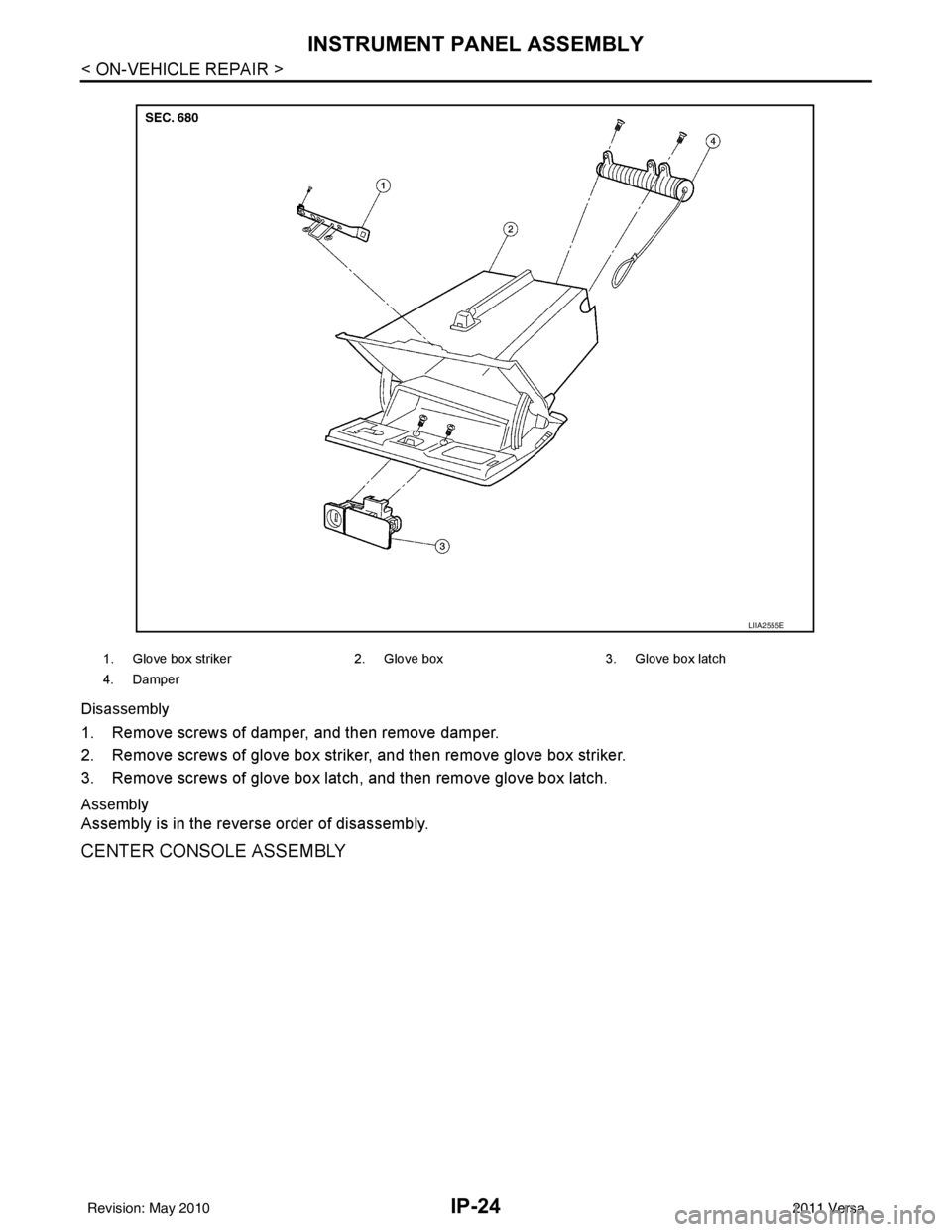

Disassembly

1. Remove screws of damper, and then remove damper.

2. Remove screws of glove box striker, and then remove glove box striker.

3. Remove screws of glove box latch, and then remove glove box latch.

Assembly

Assembly is in the reverse order of disassembly.

CENTER CONSOLE ASSEMBLY

1. Glove box striker2. Glove box 3. Glove box latch

4. Damper

LIIA2555E

Revision: May 2010 2011 Versa

Page 2846 of 3787

INSTRUMENT PANEL ASSEMBLYIP-25

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

IP

N

O P

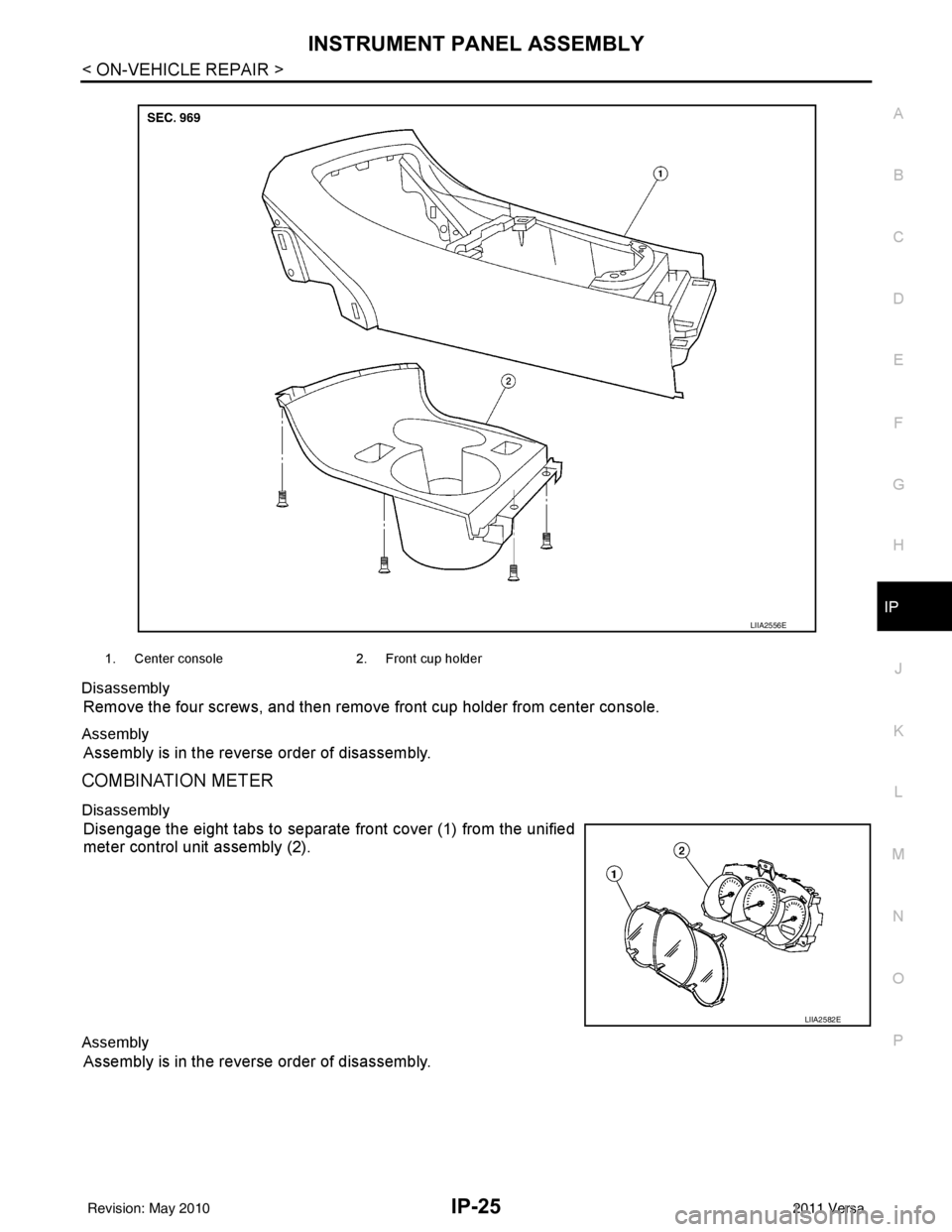

Disassembly

Remove the four screws, and then remove

front cup holder from center console.

Assembly

Assembly is in the reverse order of disassembly.

COMBINATION METER

Disassembly

Disengage the eight tabs to separate front cover (1) from the unified

meter control unit assembly (2).

Assembly

Assembly is in the reverse order of disassembly.

1. Center console 2. Front cup holder

LIIA2556E

LIIA2582E

Revision: May 2010 2011 Versa

Page 3235 of 3787

![NISSAN TIIDA 2011 Service Owners Guide MT-14

< SERVICE INFORMATION >[RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000005929667

Removal and InstallationINFOID:0000000005929668

REMOVAL

1. Remove the battery. Refer to

SC- NISSAN TIIDA 2011 Service Owners Guide MT-14

< SERVICE INFORMATION >[RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000005929667

Removal and InstallationINFOID:0000000005929668

REMOVAL

1. Remove the battery. Refer to

SC-](/img/5/57396/w960_57396-3234.png)

MT-14

< SERVICE INFORMATION >[RS5F91R]

CONTROL LINKAGE

CONTROL LINKAGE

Exploded ViewINFOID:0000000005929667

Removal and InstallationINFOID:0000000005929668

REMOVAL

1. Remove the battery. Refer to

SC-7, "Removal and Installation".

2. Remove the air duct and air cleaner case. Refer to EM-25, "

Removal and Installation" .

3. Press the release button (1) of select cable and shift selector

cable, and then remove select cable and shift selector cable

from select lever of control shaft (2).

4. Move shift selector to neutral position.

5. Remove shift selector handle.

6. Remove center console assembly. Refer to IP-12, "

Removal and

Installation".

7. Remove M/T shift selector assembly bolts.

8. Remove exhaust front tube, center muffler and heat plate. Refer to EX-5, "

Removal and Installation".

9. Remove cable support bracket.

10. Remove select cable and shift select or cable from cable mounting bracket.

11. Remove M/T shift selector assembly from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

1. Shift selector handle 2. Shift selector lever 3. M/T shift selector assembly

4. Select cable 5. Shift selector cable6. Clutch housing

7. Cable mounting bracket 8. Bracket

A: Black color B: White color

PCIB1508E

SCIA7077E

Revision: May 2010 2011 Versa