filter NISSAN TIIDA 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 211 of 3787

AT-194

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 3.

NG >> Repair or replace accelerator pedal position sensor.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Torque converter relief valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Torque converter. Refer to AT-257, "

Disassembly" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

5.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

A/T Does Not Hold Lock-up ConditionINFOID:0000000005928259

SYMPTOM:

A/T does not hold lock-up condi tion for more than 30 seconds on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

Revision: May 2010 2011 Versa

Page 212 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-195

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

4.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Torque converter clutch control valve

- Torque converter clutch solenoid valve

- Pilot valve

- Pilot filter

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Lock-up Is Not ReleasedINFOID:0000000005928260

SYMPTOM:

Lock-up is not released when accelerator peda l is released on “Cruise Test — Part 1”.

DIAGNOSTIC PROCEDURE

1. CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfuncti oning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 1" .

OK or NG

Revision: May 2010 2011 Versa

Page 299 of 3787

AT-282

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

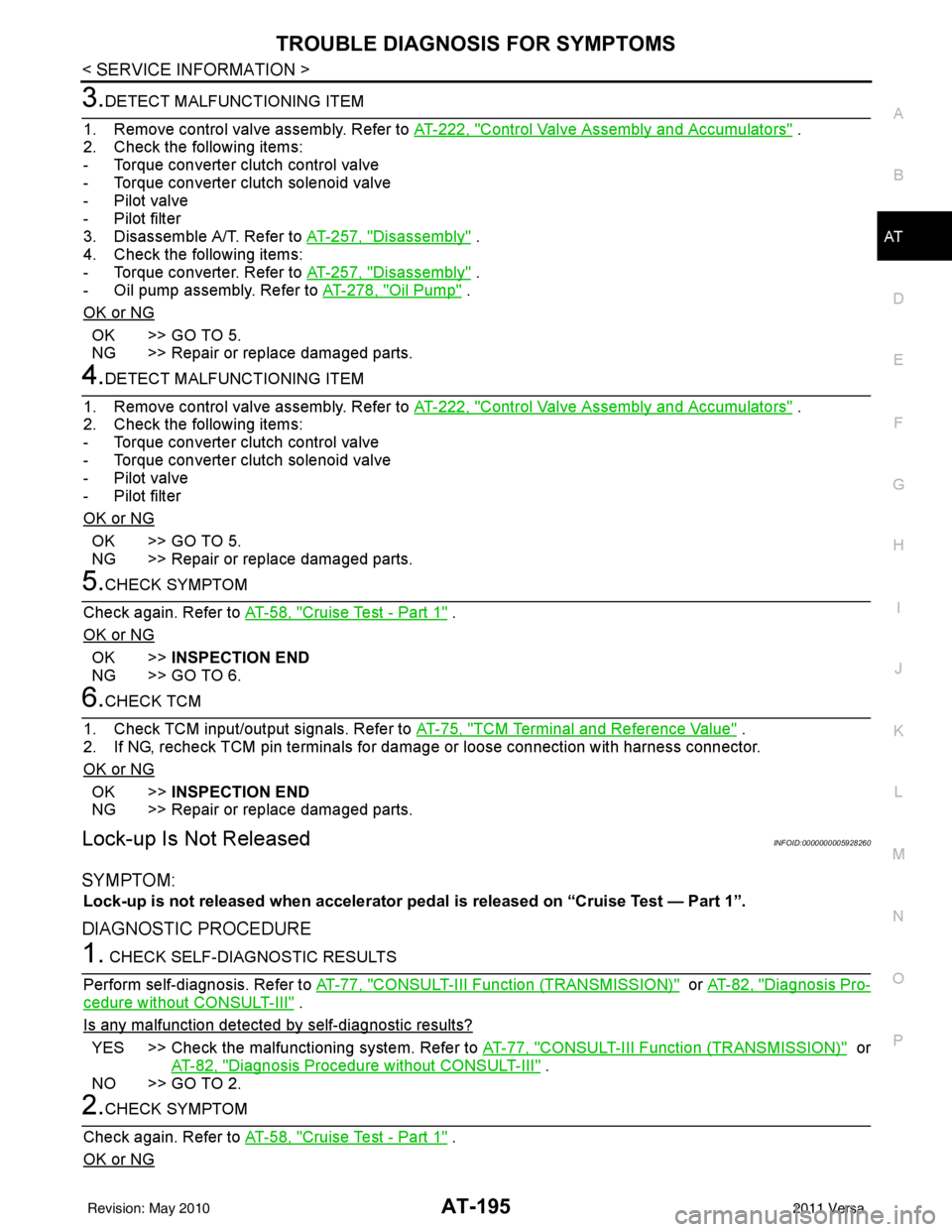

DISASSEMBLY

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3).

1. Pilot filter2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure

holding spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring18. Oil strainer

SCIA8407J

SCIA7058E

Revision: May 2010 2011 Versa

Page 301 of 3787

AT-284

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

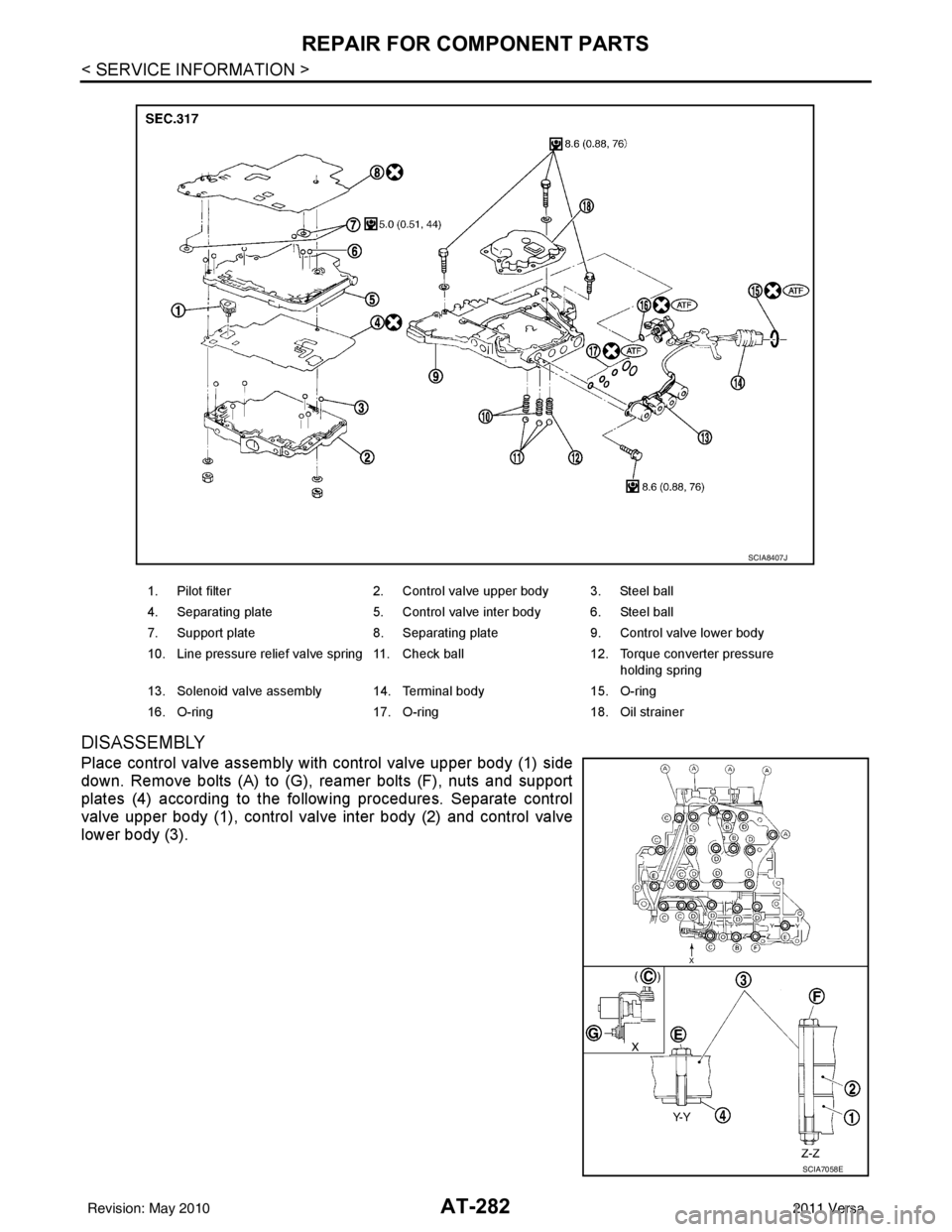

5. Remove control valve lower body (1) from control valve interbody (2).

(3): Control valve upper body

6. Turn over control valve lower body (1).

7. Remove bolts (E), support plates (2) and separating plate (3) from control valve lower body (1).

8. Remove check balls (1), line pressure relief valve springs (2) and torque converter pressure holding spring (3) from control

valve lower body (4).

CAUTION:

Be careful not to lose check ba lls (1), line pressure relief

valve springs (2) and torque converter pressure holding

spring (3).

9. Remove control valve inter body from control valve upper body.

10. Remove pilot filter (1) from control valve upper body (2).

11. Remove separating plate from control valve upper body (2).

SCIA7181E

SCIA7009E

SCIA6491J

SCIA4977E

SCIA7011E

Revision: May 2010 2011 Versa

Page 304 of 3787

REPAIR FOR COMPONENT PARTSAT-287

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

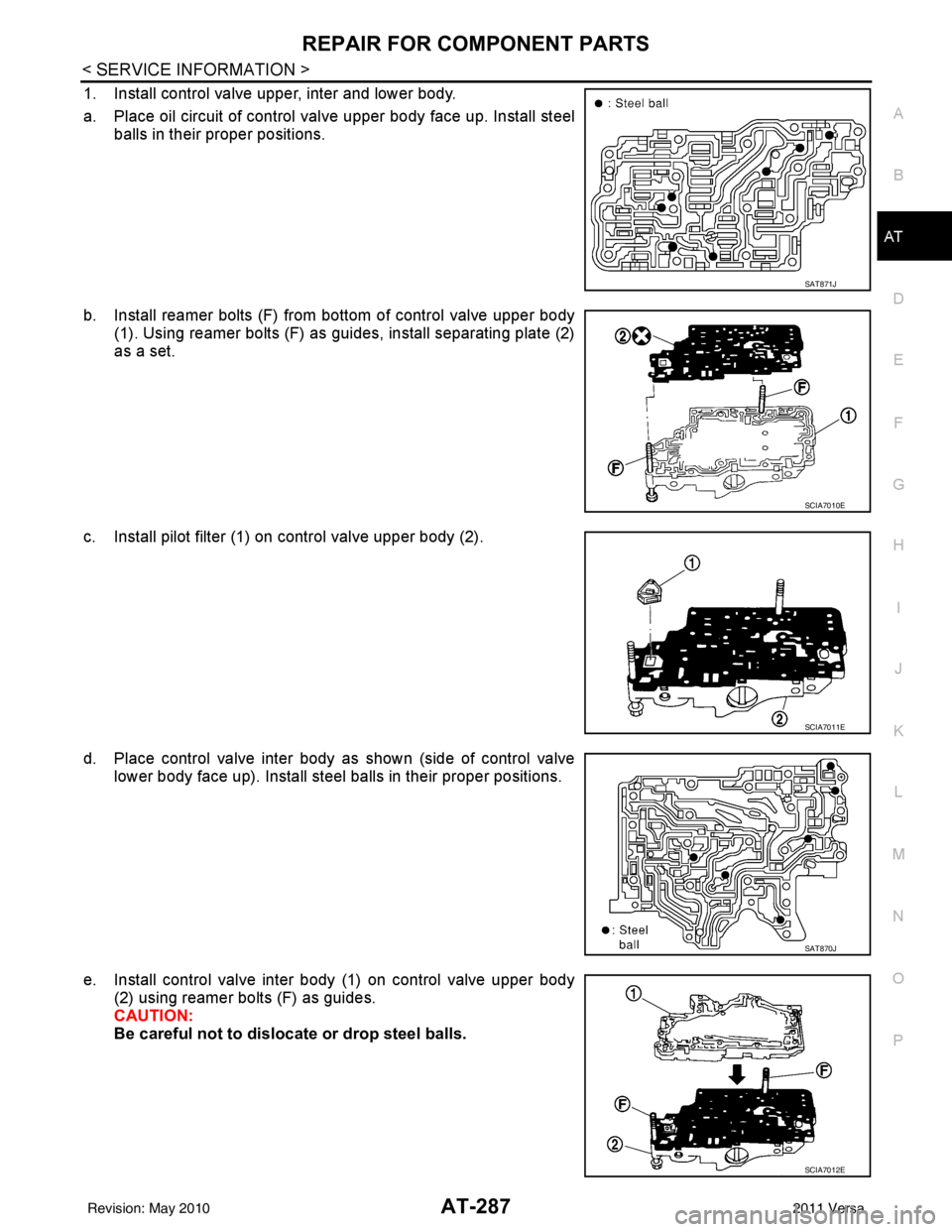

1. Install control valve upper, inter and lower body.

a. Place oil circuit of control valve upper body face up. Install steel balls in their proper positions.

b. Install reamer bolts (F) from bottom of control valve upper body (1). Using reamer bolts (F) as guides, install separating plate (2)

as a set.

c. Install pilot filter (1) on control valve upper body (2).

d. Place control valve inter body as shown (side of control valve lower body face up). Install steel balls in their proper positions.

e. Install control valve inter body (1) on control valve upper body (2) using reamer bolts (F) as guides.

CAUTION:

Be careful not to dislocate or drop steel balls.

SAT871J

SCIA7010E

SCIA7011E

SAT870J

SCIA7012E

Revision: May 2010 2011 Versa

Page 863 of 3787

BR-16

< SERVICE INFORMATION >

BRAKE MASTER CYLINDER

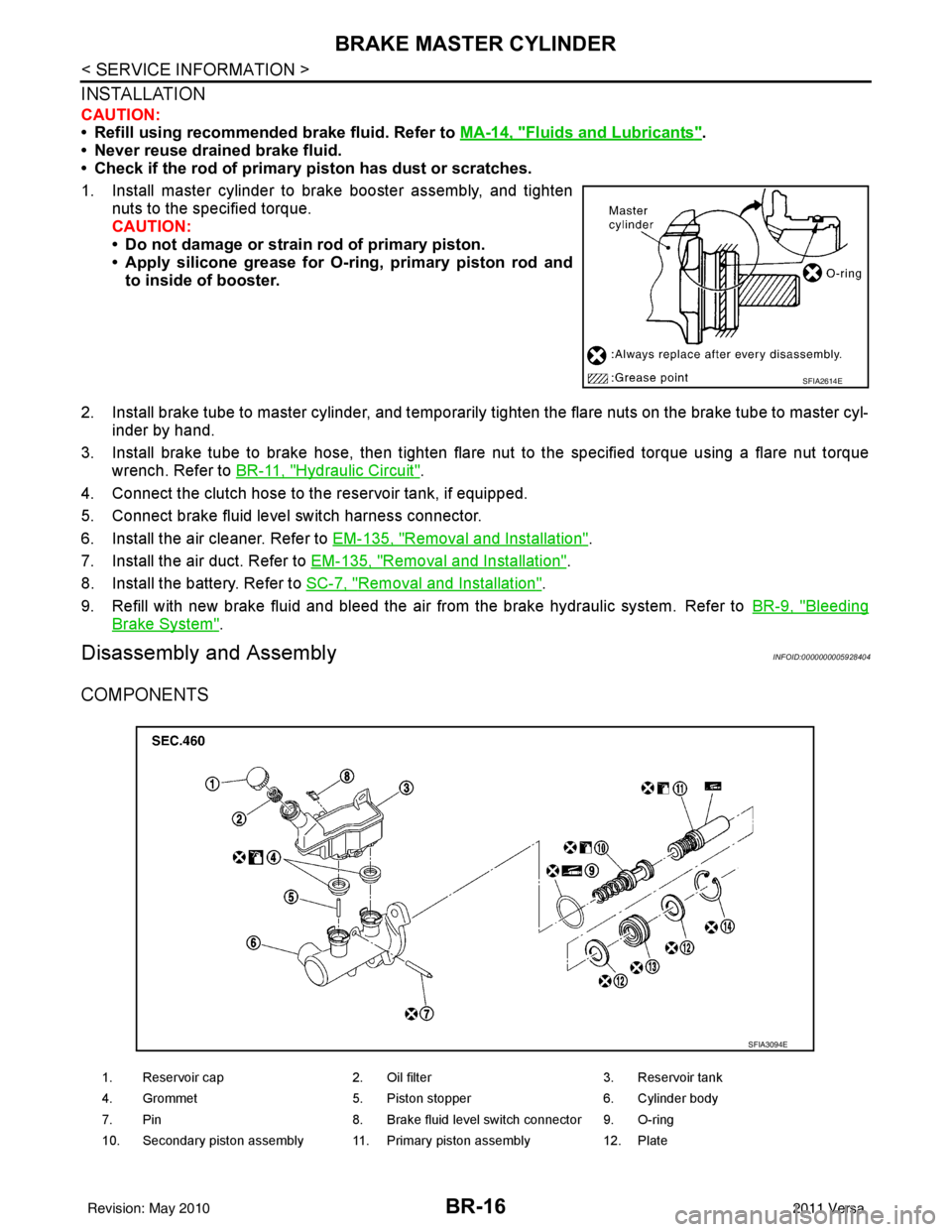

INSTALLATION

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Check if the rod of primary piston has dust or scratches.

1. Install master cylinder to brake booster assembly, and tighten nuts to the specified torque.

CAUTION:

• Do not damage or strain rod of primary piston.

• Apply silicone grease for O-ring, primary piston rod andto inside of booster.

2. Install brake tube to master cylinder, and temporarily tighten the flare nuts on the brake tube to master cyl- inder by hand.

3. Install brake tube to brake hose, then tighten flare nut to the specified torque using a flare nut torque

wrench. Refer to BR-11, "

Hydraulic Circuit".

4. Connect the clutch hose to the reservoir tank, if equipped.

5. Connect brake fluid level switch harness connector.

6. Install the air cleaner. Refer to EM-135, "

Removal and Installation".

7. Install the air duct. Refer to EM-135, "

Removal and Installation".

8. Install the battery. Refer to SC-7, "

Removal and Installation".

9. Refill with new brake fluid and bleed the air from the brake hydraulic system. Refer toBR-9, "

Bleeding

Brake System".

Disassembly and AssemblyINFOID:0000000005928404

COMPONENTS

SFIA2614E

1. Reservoir cap2. Oil filter 3. Reservoir tank

4. Grommet 5. Piston stopper 6. Cylinder body

7. Pin 8. Brake fluid level switch connector 9. O-ring

10. Secondary piston assembly 11. Primary piston assembly 12. Plate

SFIA3094E

Revision: May 2010 2011 Versa

Page 1072 of 3787

![NISSAN TIIDA 2011 Service User Guide CVT FLUIDCVT-17

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the coole NISSAN TIIDA 2011 Service User Guide CVT FLUIDCVT-17

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the coole](/img/5/57396/w960_57396-1071.png)

CVT FLUIDCVT-17

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

3. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

• Wear safety glasses and rubber gloves when spraying theTransmission Cooler Cleaner.

• Spray Transmission Cooler Cleaner only with adequate

ventilation.

• Avoid contact with eyes and skin.

• Do not breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until CVT fluid flows out of t he cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 490 to 883 kPa (5 to 9 kg/cm

2,

71 to 128 psi) through the cooler outlet hose to force any

remaining CVT fluid into the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform "CVT FLUID COOLER INSPECTION PROCEDURE".

CVT FLUID COOLER INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1 mm (0.040 in) in size or metal powder is found in the coffee filter, this is normal. If normal

debris is found, the CVT fluid cooler/radiator can be re-used and

the procedure is ended.

SCIA4421E

SCIA4424E

SCIA4425E

SCIA2967E

Revision: May 2010 2011 Versa

Page 1073 of 3787

![NISSAN TIIDA 2011 Service User Guide CVT-18

< SERVICE INFORMATION >[RE0F08B]

CVT FLUID

b. If one or more pieces of debris are found that are over 1 mm

(0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter, NISSAN TIIDA 2011 Service User Guide CVT-18

< SERVICE INFORMATION >[RE0F08B]

CVT FLUID

b. If one or more pieces of debris are found that are over 1 mm

(0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter,](/img/5/57396/w960_57396-1072.png)

CVT-18

< SERVICE INFORMATION >[RE0F08B]

CVT FLUID

b. If one or more pieces of debris are found that are over 1 mm

(0.040 in) in size and/or peeled clutch facing material is found in

the coffee filter, the fluid cooler is not serviceable. The radiator/

fluid cooler must be replac ed and the inspection procedure is

ended.

CVT FLUID COOLER FINAL INSPECTION

After performing all procedures, ensure that all remaining oil is cleaned from all components.

SCIA7031E

Revision: May 2010 2011 Versa

Page 1096 of 3787

![NISSAN TIIDA 2011 Service User Guide TROUBLE DIAGNOSISCVT-41

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Road TestINFOID:0000000005928754

DESCRIPTION

• The purpose of the test is to determine overall performance NISSAN TIIDA 2011 Service User Guide TROUBLE DIAGNOSISCVT-41

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Road TestINFOID:0000000005928754

DESCRIPTION

• The purpose of the test is to determine overall performance](/img/5/57396/w960_57396-1095.png)

TROUBLE DIAGNOSISCVT-41

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Road TestINFOID:0000000005928754

DESCRIPTION

• The purpose of the test is to determine overall performance of CVT and analyze causes of problems.

• The road test consists of the following three parts:

1. “Check Before Engine Is Started” CVT-42

.

2. “Check at Idle”CVT-42

.

3. “Cruise Test”CVT-43

.

• Before road test, familiarize yourself with all test procedures and items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot items which check out No Good after road test.

Judgement Possible cause

Idle speed Low for all positions

(“P”, “R”, “N”, “D”, “L”)

Possible causes include malfunctions in the pressure supply system and low oil pump output.

For example

• Oil pump wear

• Pressure regulator valve or plug sticking or spring fatigue

• Oil strainer

⇒ oil pump ⇒ pressure regulator valve passage oil leak

• Engine idle speed too low

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

High Possible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

• Accelerator pedal position signal malfunction

• CVT fluid temperature sensor malfunction

• Line pressure solenoid) malfunction (sticking in OFF state, filter clog, cut line)

• Pressure regulator valve or plug sticking

Stall speed Line pressure does

not rise higher than

the line pressure for

idle.

Possible causes include a sensor malfunction or malfunction in the pressure adjustment func-

tion.

For example

• Accelerator pedal position signal malfunction

•TCM malfunction

• Line pressure solenoid) malfunction (shorting, sticking in ON state)

• Pressure regulator valve or plug sticking

The pressure rises,

but does not enter the

standard position. Possible causes include malfunctions in the pressure supply system and malfunction in the pres-

sure adjustment function.

For example

• Accelerator pedal position signal malfunction

• Line pressure solenoid) malfunction (sticking, filter clog)

• Pressure regulator valve or plug sticking

Only low for a specific

position Possible causes include an oil pressure leak in a passage or device related to the position after

the pressure is distributed by the manual valve.

SAT786A

SAT496G

Revision: May 2010

2011 Versa

Page 1298 of 3787

EC-4

DTC Logic ..............................................................249

Wiring Diagram ......................................................250

Diagnosis Procedure .............................................250

Component Inspection ...........................................252

P0222, P0223 TP SENSOR .............................253

Description ........................................................... ..253

DTC Logic ..............................................................253

Wiring Diagram ......................................................254

Diagnosis Procedure .............................................254

Component Inspection ...........................................256

Special Repair Requirement ..................................256

P0300, P0301, P0302, P0303, P0304 MIS-

FIRE ................................................................ .

257

DTC Logic ............................................................ ..257

Diagnosis Procedure .............................................258

P0327, P0328 KS .............................................263

Description ........................................................... ..263

DTC Logic ..............................................................263

Wiring Diagram ......................................................264

Diagnosis Procedure .............................................264

Component Inspection ...........................................265

P0335 CKP SENSOR (POS) ...........................267

Description ........................................................... ..267

DTC Logic ..............................................................267

Wiring Diagram ......................................................268

Diagnosis Procedure .............................................269

Component Inspection ...........................................271

P0340 CMP SENSOR (PHASE) ......................272

Description ........................................................... ..272

DTC Logic ..............................................................272

Wiring Diagram ......................................................274

Diagnosis Procedure .............................................274

Component Inspection ...........................................276

P0420 THREE WAY CATALYST FUNCTION .277

DTC Logic ..............................................................277

Component Function Check ..................................278

Diagnosis Procedure .............................................279

P0441 EVAP CONTROL SYSTEM ..................282

DTC Logic ............................................................ ..282

Component Function Check ..................................283

Diagnosis Procedure .............................................284

Component Inspection (Drain filter) .......................287

P0442 EVAP CONTROL SYSTEM ..................288

DTC Logic ............................................................ ..288

Diagnosis Procedure .............................................289

Component Inspection (Fuel filler cap) ..................293

Component Inspection (Drain filter) .......................293

P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE .......................

295

Description ........................................................... ..295

DTC Logic ..............................................................295

Wiring Diagram ......................................................297

Diagnosis Procedure ............................................ .297

Component Inspection ..........................................300

P0444, P0445 EVAP CANISTER PURGE

VOLUME CONTROL SOLENOID VALVE .......

301

Description ........................................................... .301

DTC Logic .............................................................301

Wiring Diagram .....................................................302

Diagnosis Procedure .............................................302

Component Inspection ..........................................304

P0447 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

305

Description ........................................................... .305

DTC Logic .............................................................305

Wiring Diagram .....................................................306

Diagnosis Procedure .............................................306

Component Inspection ..........................................308

P0448 EVAP CANISTER VENT CONTROL

VALVE ..............................................................

310

Description ........................................................... .310

DTC Logic .............................................................310

Wiring Diagram .....................................................312

Diagnosis Procedure .............................................312

Component Inspection ..........................................314

P0451 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

316

Description ........................................................... .316

DTC Logic .............................................................316

Diagnosis Procedure .............................................316

Component Inspection ..........................................318

P0452 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

319

Description ........................................................... .319

DTC Logic .............................................................319

Wiring Diagram .....................................................321

Diagnosis Procedure .............................................321

Component Inspection ..........................................324

P0453 EVAP CONTROL SYSTEM PRES-

SURE SENSOR ................................................

326

Description ........................................................... .326

DTC Logic .............................................................326

Wiring Diagram .....................................................328

Diagnosis Procedure .............................................328

Component Inspection ..........................................332

P0455 EVAP CONTROL SYSTEM ..................333

DTC Logic .............................................................333

Diagnosis Procedure .............................................334

Component Inspection (Fuel filler cap) .................337

Component Inspection (Drain filter) ......................338

P0456 EVAP CONTROL SYSTEM ..................339

DTC Logic .............................................................339

Component Function Check .................................341

Diagnosis Procedure .............................................341

Revision: May 2010 2011 Versa