Time NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2226 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-932

< SERVICE INFORMATION >[MR18DE]

DTC P1572 ASCD BRAKE SWITCH

DTC Confirmation Procedure

INFOID:0000000006342132

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

• If DTC Confirmation Proce NISSAN TIIDA 2011 Service Repair Manual EC-932

< SERVICE INFORMATION >[MR18DE]

DTC P1572 ASCD BRAKE SWITCH

DTC Confirmation Procedure

INFOID:0000000006342132

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

• If DTC Confirmation Proce](/img/5/57396/w960_57396-2225.png)

EC-932

< SERVICE INFORMATION >[MR18DE]

DTC P1572 ASCD BRAKE SWITCH

DTC Confirmation Procedure

INFOID:0000000006342132

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

• Procedure for malfunction B is not described here. It takes extremely long time to complete procedure for

malfunction B. By performing procedure for malfunction A, the incident that causes malfunction B can be

detected.

TESTING CONDITION:

Steps 3 and 6 may be conducted with the drive wheels li fted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-III

1. Start engine.

2. Press MAIN switch and make sure that CRUISE indicator lights up.

3. Drive the vehicle for at least 5 consecutive seconds under the following condition.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to EC-934, "

Diagnosis Procedure".

If 1st trip DTC is not detec ted, go to the following step.

6. Drive the vehicle for at least 5 consecutive seconds under the following condition.

7. Check 1st trip DTC.

8. If 1st trip DTC is detected, go to EC-934, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III” above.

Vehicle speed More than 30 km/h (19 MPH)

Shift lever Suitable position

Vehicle speed More than 30 km/h (19 MPH)

Shift lever Suitable position

Driving location Depress the brake pedal for more than 5

seconds so as not to come off from the

above-mentioned vehicle speed.

Revision: May 2010

2011 Versa

Page 2238 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-944

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

DTC P1805 BRAKE SWITCH

DescriptionINFOID:0000000006342149

Brake switch signal is applied to the ECM through the stop lamp switch when the NISSAN TIIDA 2011 Service Repair Manual EC-944

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

DTC P1805 BRAKE SWITCH

DescriptionINFOID:0000000006342149

Brake switch signal is applied to the ECM through the stop lamp switch when the](/img/5/57396/w960_57396-2237.png)

EC-944

< SERVICE INFORMATION >[MR18DE]

DTC P1805 BRAKE SWITCH

DTC P1805 BRAKE SWITCH

DescriptionINFOID:0000000006342149

Brake switch signal is applied to the ECM through the stop lamp switch when the brake pedal is depressed.

This signal is used mainly to decrease the engine speed when the vehicle is driving.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000006342150

Specification data are reference values.

On Board Diagn

osis LogicINFOID:0000000006342151

The MIL will not light up for this self-diagnosis.

FA I L - S A F E M O D E

When the malfunction is detected, the ECM enters in fail-safe mode.

DTC Confirmation ProcedureINFOID:0000000006342152

1. Turn ignition switch ON.

2. Fully depress the brake pedal for at least 5 seconds.

3. Erase the DTC.

4. Check 1st trip DTC.

5. If 1st trip DTC is detected, go to EC-946, "

Diagnosis Procedure".

Monitor item Condition Specification

BRAKE SW • Ignition switch: ON Brake pedal: Fully released

OFF

Brake pedal: Slightly depressed ON

DTC No. Trouble diagnosis nameDTC detecting condition Possible cause

P1805

1805 Brake switch A brake switch signal is not sent to ECM for

extremely long time while the vehicle is driv-

ing. • Harness or connectors

(Stop lamp switch circuit is open or shorted.)

• Stop lamp switch

Engine operation condition in fail-fail safe mode

ECM controls the electric throttle control actuator by regulating the throttle opening to a small range.

Therefore, acceleration will be poor.

Vehicle condition Driving condition

Engine: Idling Normal

Accelerating Poor acceleration

Revision: May 2010 2011 Versa

Page 2298 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-1004

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

ASCD INDICATOR

Component DescriptionINFOID:0000000006342224

ASCD indicator lamp illuminates to indicate ASCD

operation status. Lamp has two indi NISSAN TIIDA 2011 Service Repair Manual EC-1004

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

ASCD INDICATOR

Component DescriptionINFOID:0000000006342224

ASCD indicator lamp illuminates to indicate ASCD

operation status. Lamp has two indi](/img/5/57396/w960_57396-2297.png)

EC-1004

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

ASCD INDICATOR

Component DescriptionINFOID:0000000006342224

ASCD indicator lamp illuminates to indicate ASCD

operation status. Lamp has two indicators, CRUISE and

SET, and is integrated in combination meter.

CRUISE indicator illuminates when MAIN switch on ASCD st eering switch is turned ON to indicate that ASCD

system is ready for operation.

SET indicator illuminates when following conditions are met.

• CRUISE indicator is illuminated.

• SET/COAST switch on ASCD steering switch is turned ON while vehicle speed is within the range of ASCD setting.

SET indicator remains lit during ASCD control.

Refer to EC-523

for the ASCD function.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000006342225

Specification data are reference value.

Monitor item Condition Specification

CRUISE LAMP • Ignition switch: ON MAIN switch: Pressed at 1st time

→ 2nd

ON

→ OFF

SET LAMP • MAIN switch: ON

• Vehicle: Between 40 km/h (25

MPH) and 144 km/h (89 MPH) ASCD: Operating

ON

ASCD: Not operating OFF

Revision: May 2010 2011 Versa

Page 2300 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-1006

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

OK or NG

OK >>

INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC UXXXX is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses f NISSAN TIIDA 2011 Service Repair Manual EC-1006

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

OK or NG

OK >>

INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC UXXXX is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses f](/img/5/57396/w960_57396-2299.png)

EC-1006

< SERVICE INFORMATION >[MR18DE]

ASCD INDICATOR

OK or NG

OK >>

INSPECTION END

NG >> GO TO 2.

2.CHECK DTC

Check that DTC UXXXX is not displayed.

Ye s o r N o

Yes >> Perform trouble diagnoses for DTC UXXXX.

No >> GO TO 3.

3.CHECK COMBINATION METER OPERATION

Does combination meter operate normally?

Ye s o r N o

Ye s > > G O T O 4 .

No >> Check combination meter circuit. Refer to DI-4

.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

ASCD Indicator ConditionSpecification

CRUISE LAMP • Ignition switch: ONMAIN switch: Pressed at 1st

time

→ 2nd ON

→ OFF

SET LAMP •MAIN switch: ON

• Vehicle: Between 40 km/h (25

MPH) and 144 km/h (89

MPH) ASCD: Operating

ON

ASCD: Not operating OFF

Revision: May 2010 2011 Versa

Page 2303 of 3787

![NISSAN TIIDA 2011 Service Repair Manual FUEL INJECTOREC-1009

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTOR

Component DescriptionINFOID:0000000006342230

The fuel injector is a small, precise solenoid valve. W NISSAN TIIDA 2011 Service Repair Manual FUEL INJECTOREC-1009

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTOR

Component DescriptionINFOID:0000000006342230

The fuel injector is a small, precise solenoid valve. W](/img/5/57396/w960_57396-2302.png)

FUEL INJECTOREC-1009

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTOR

Component DescriptionINFOID:0000000006342230

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

CONSULT-III Reference Val

ue in Data Monitor ModeINFOID:0000000006342231

Specification data are reference values.

PBIA9664J

Monitor item Condition Specification

B/FUEL SCHDL See EC-624

.

INJ PULSE-B1 • Engine: After warming up

• Air conditioner switch: OFF

• Shift lever: P or N (A/T, CVT),

Neutral (M/T)

•No load Idle

2.0 - 3.0 msec

2,000 rpm 1.9 - 2.9 msec

Revision: May 2010 2011 Versa

Page 2321 of 3787

![NISSAN TIIDA 2011 Service Repair Manual IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release NISSAN TIIDA 2011 Service Repair Manual IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release](/img/5/57396/w960_57396-2320.png)

IGNITION SIGNALEC-1027

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

7. Remove fuel pump fuse (1) in IPDM E/R (2) to release fuel pres-

sure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pres-

sure applies again during the following procedure.

- : Vehicle front

8. Start engine.

9. After engine stalls, crank it two or three times to release all fuel pressure.

10. Turn ignition switch OFF.

11. Remove all ignition coil harness connectors to avoid the electri- cal discharge from the ignition coils.

12. Remove ignition coil and spark plug of the cylinder to be checked.

13. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

14. Connect spark plug and harness connector to ignition coil.

15. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

16. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• Do not approach to the spark plug and the ignition coilwithin 50 cm. Be careful not to get an electrical shock

while checking, because the el ectrical discharge voltage

becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

17. If NG, replace ignition coil with power transistor.

CONDENSER-2

1. Turn ignition switch OFF.

2. Disconnect condenser-2 harness connector.

3. Check resistance between condenser-2 terminals 1 and 2.

4. If NG, replace condenser-2.

Removal and InstallationINFOID:0000000006342246

IGNITION COIL WITH POWER TRANSISTOR

Refer to MA-34.

Spark should be generated.

PBIB2958E

PBIB2325E

Resistance: Above 1 M

Ω [at 25 °C (77° F)]

PBIB0794E

Revision: May 2010 2011 Versa

Page 2333 of 3787

PRECAUTIONSEI-3

< PRECAUTION >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929545

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005929546

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 2334 of 3787

EI-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

PrecautionINFOID:0000000005929547

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

- Water-soluble stains:

Dip a cloth in warm water, and squeeze tightly. After wiping the stain, wipe with a soft dry cloth.

- Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the

stain with the cloth. Next, dip the soft cloth in fr esh water, and then squeeze it tightly. Then clean off the

detergent completely. Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.

• When performing procedures that require removal of the cowl top, cover the lower end of the windshield with a suitable protection

material.

PIIB3706J

Revision: May 2010 2011 Versa

Page 2339 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSISEI-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 2402 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EM-12

< SYMPTOM DIAGNOSIS >[HR16DE]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000005930923

1. Locate the area wher NISSAN TIIDA 2011 Service Repair Manual EM-12

< SYMPTOM DIAGNOSIS >[HR16DE]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000005930923

1. Locate the area wher](/img/5/57396/w960_57396-2401.png)

EM-12

< SYMPTOM DIAGNOSIS >[HR16DE]

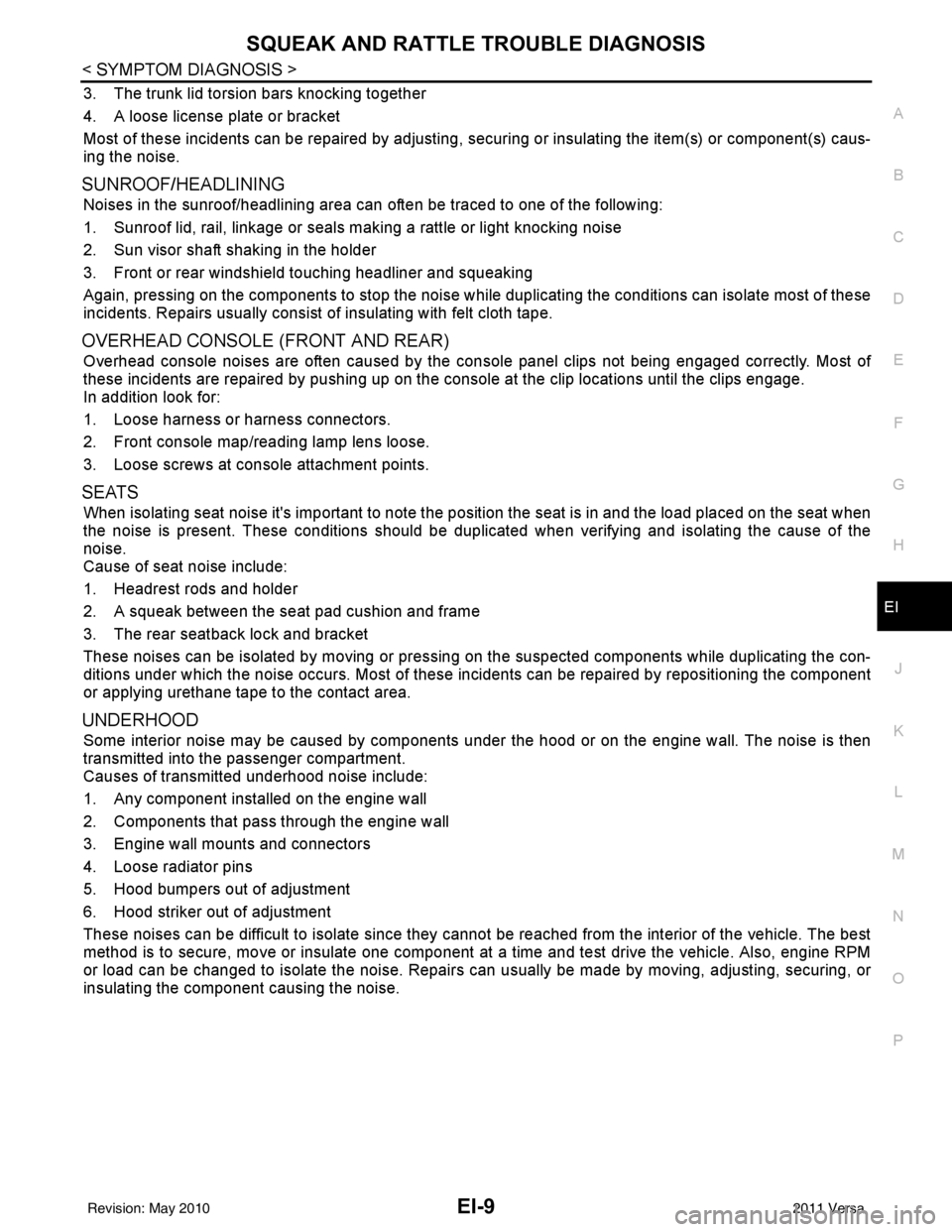

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

Use the Chart Below to Help You Find the Cause of the Symptom

INFOID:0000000005930923

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely related B: Related C: Sometimes related —: Not relatedLocation

of noise Typ e of

noise Operating condition of engine

Source of noise Check item Refer-

ence page

Before

warm- up After

warm- up When

start- ing When

idling When

racing While

driving

Top of en-

gine

Rocker

cover

Cylinder

head Ticking or

clicking

CA—AB— Tappet

noiseValve clearance

EM-19

Rattle C A — A B C Camshaft

bearing

noiseCamshaft journal oil

clearance

Camshaft runout

EM-112EM-112

Crank-

shaft pul-

ley

Cylinder

block

(Side of

engine)

Oil panSlap or

knock

—A—BB—

Piston pin

noisePiston to piston pin oil

clearance

Connecting rod small

end clearance

EM-116

EM-119

Slap or

rap

A——BBA

Piston

slap noisePiston to cylinder bore

clearance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsion EM-116EM-116

EM-116

EM-119

Knock A B C B B B

Connect-

ing rod

bearing

noiseConnecting rod small

end clearance

Connecting rod bearing

oil clearance

EM-116EM-119

Knock A B — A B C

Main bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runout EM-120EM-116

Front of

engine

Front cov-

erTapping or

ticking

AA—BBB Timing

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operation

EM-57

Front of

engineSqueak-

ing or fizz-

ing

AB—B—C Drive belt

(Sticking

or slip-

ping)Drive belt deflection

E M - 111

Creaking A B A B A B Drive belt

(Slipping)Idler pulley bearing op-

eration

Squall

Creak AB—BAB Water

pump

noise

Water pump operation

CO-21

Revision: May 2010 2011 Versa