remove engine NISSAN TIIDA 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 279 of 3787

AT-262

< SERVICE INFORMATION >

DISASSEMBLY

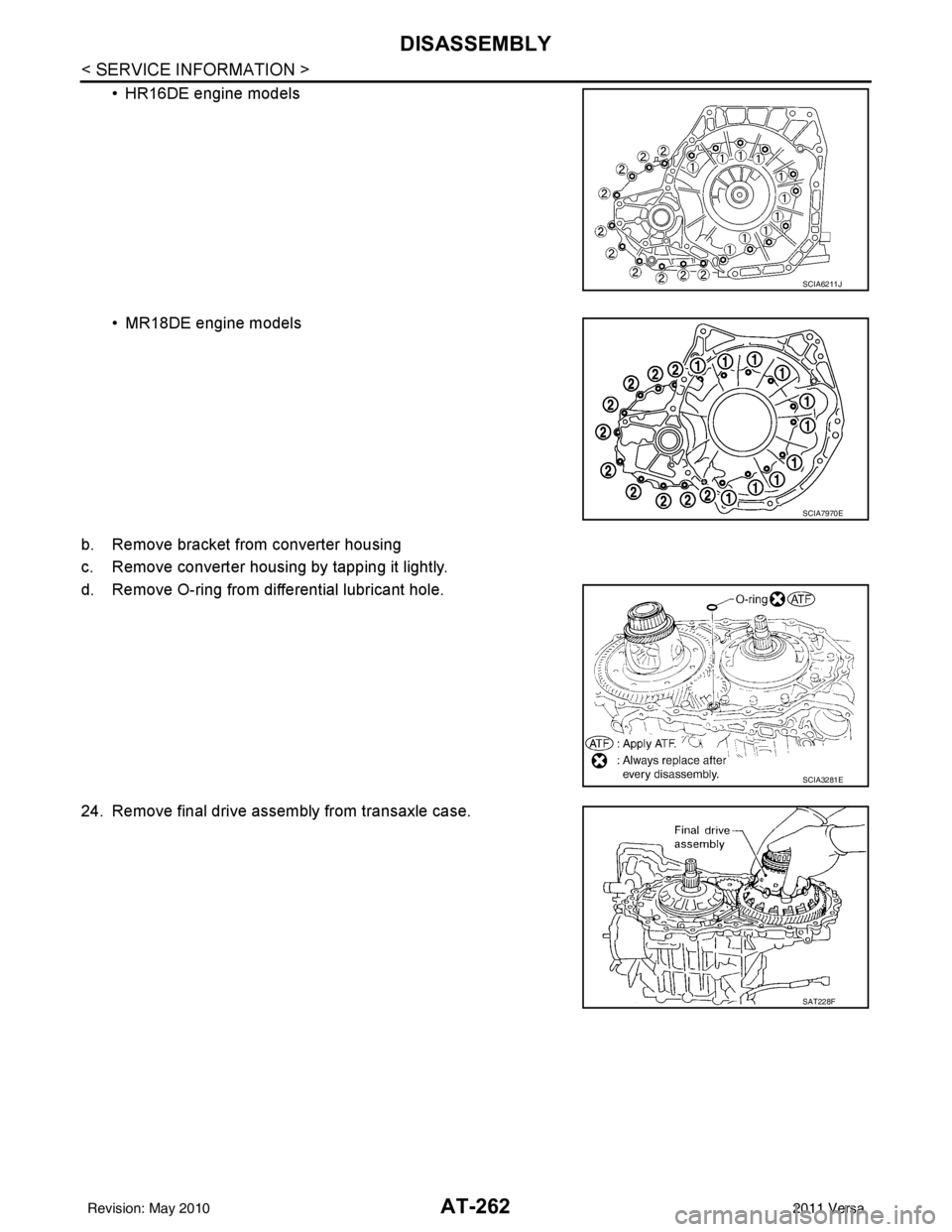

• HR16DE engine models

• MR18DE engine models

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

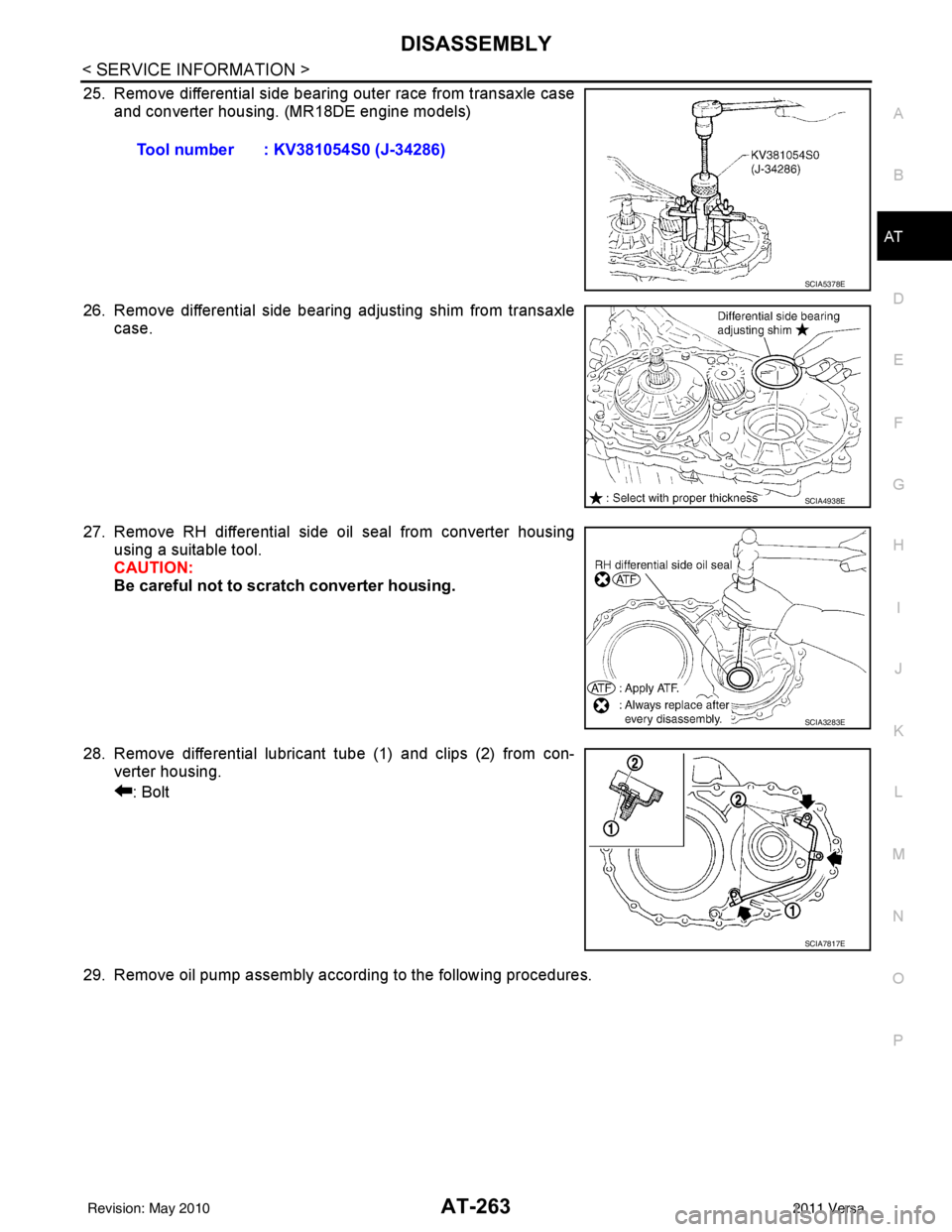

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case.

SCIA6211J

SCIA7970E

SCIA3281E

SAT228F

Revision: May 2010 2011 Versa

Page 280 of 3787

DISASSEMBLYAT-263

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

25. Remove differential side bearing outer race from transaxle case and converter housing. (MR18DE engine models)

26. Remove differential side bearing adjusting shim from transaxle case.

27. Remove RH differential side oil seal from converter housing using a suitable tool.

CAUTION:

Be careful not to scratch converter housing.

28. Remove differential lubricant tube (1) and clips (2) from con- verter housing.

: Bolt

29. Remove oil pump assembly according to the following procedures. Tool number : KV381054S0 (J-34286)

SCIA5378E

SCIA4938E

SCIA3283E

SCIA7817E

Revision: May 2010

2011 Versa

Page 287 of 3787

AT-270

< SERVICE INFORMATION >

DISASSEMBLY

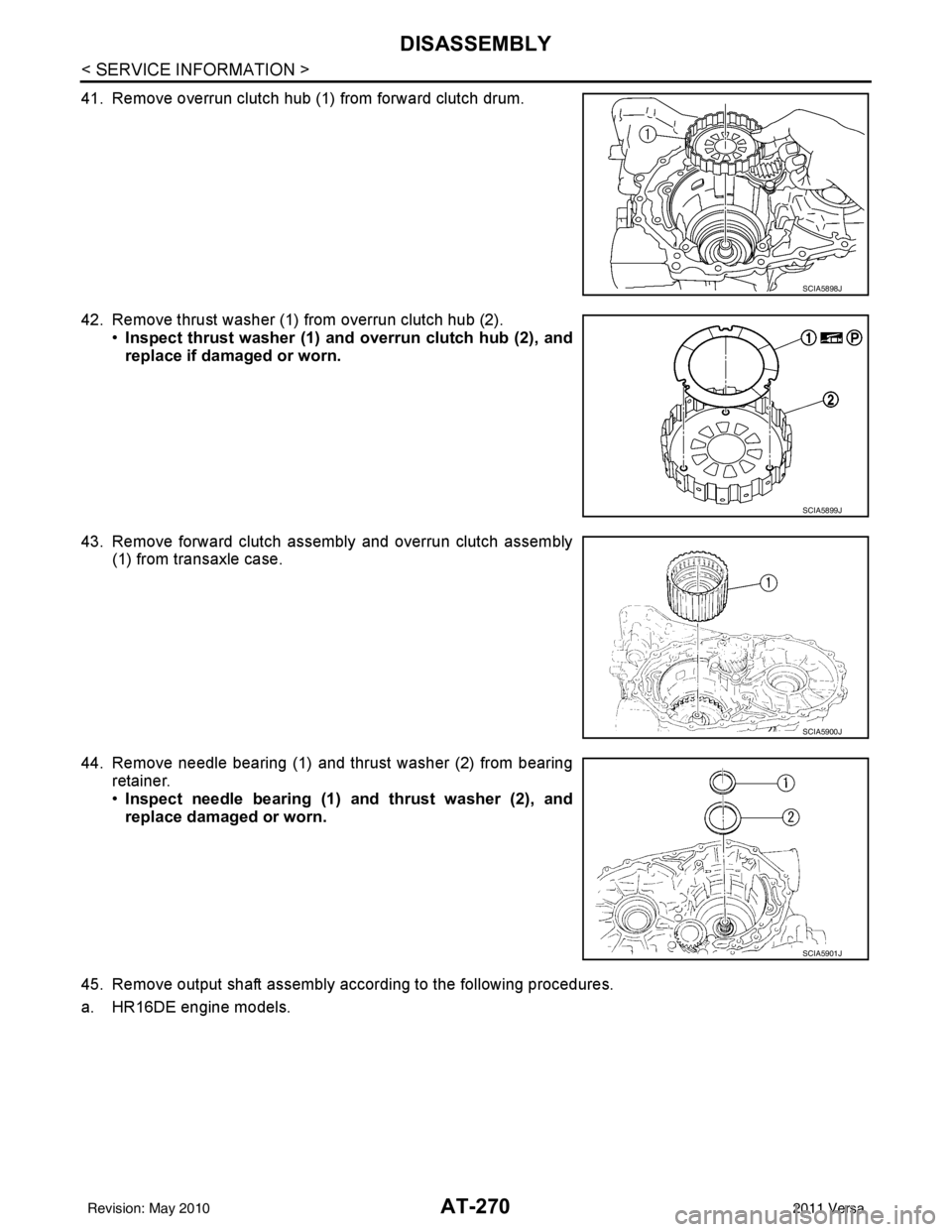

41. Remove overrun clutch hub (1) from forward clutch drum.

42. Remove thrust washer (1) from overrun clutch hub (2).•Inspect thrust washer (1) and overrun clutch hub (2), and

replace if damaged or worn.

43. Remove forward clutch assembly and overrun clutch assembly (1) from transaxle case.

44. Remove needle bearing (1) and thrust washer (2) from bearing retainer.

•Inspect needle bearing (1) and thrust washer (2), and

replace damaged or worn.

45. Remove output shaft assembly according to the following procedures.

a. HR16DE engine models.

SCIA5898J

SCIA5899J

SCIA5900J

SCIA5901J

Revision: May 2010 2011 Versa

Page 288 of 3787

DISASSEMBLYAT-271

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

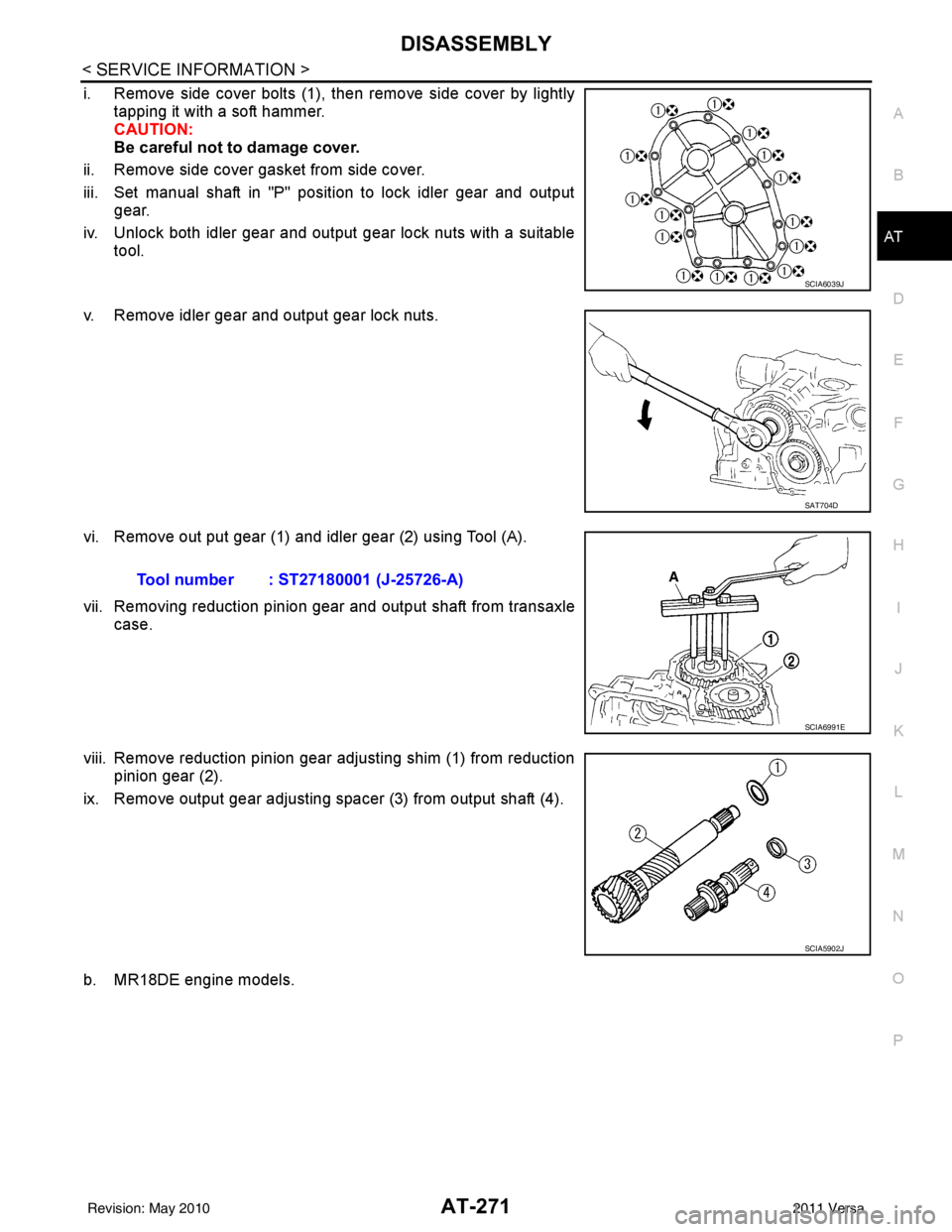

i. Remove side cover bolts (1), then remove side cover by lightly tapping it with a soft hammer.

CAUTION:

Be careful not to damage cover.

ii. Remove side cover gasket from side cover.

iii. Set manual shaft in "P" position to lock idler gear and output gear.

iv. Unlock both idler gear and output gear lock nuts with a suitable tool.

v. Remove idler gear and output gear lock nuts.

vi. Remove out put gear (1) and idler gear (2) using Tool (A).

vii. Removing reduction pinion gear and output shaft from transaxle case.

viii. Remove reduction pinion gear adjusting shim (1) from reduction pinion gear (2).

ix. Remove output gear adjusting spacer (3) from output shaft (4).

b. MR18DE engine models.

SCIA6039J

SAT704D

Tool number : ST27180001 (J-25726-A)

SCIA6991E

SCIA5902J

Revision: May 2010 2011 Versa

Page 340 of 3787

REPAIR FOR COMPONENT PARTSAT-323

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

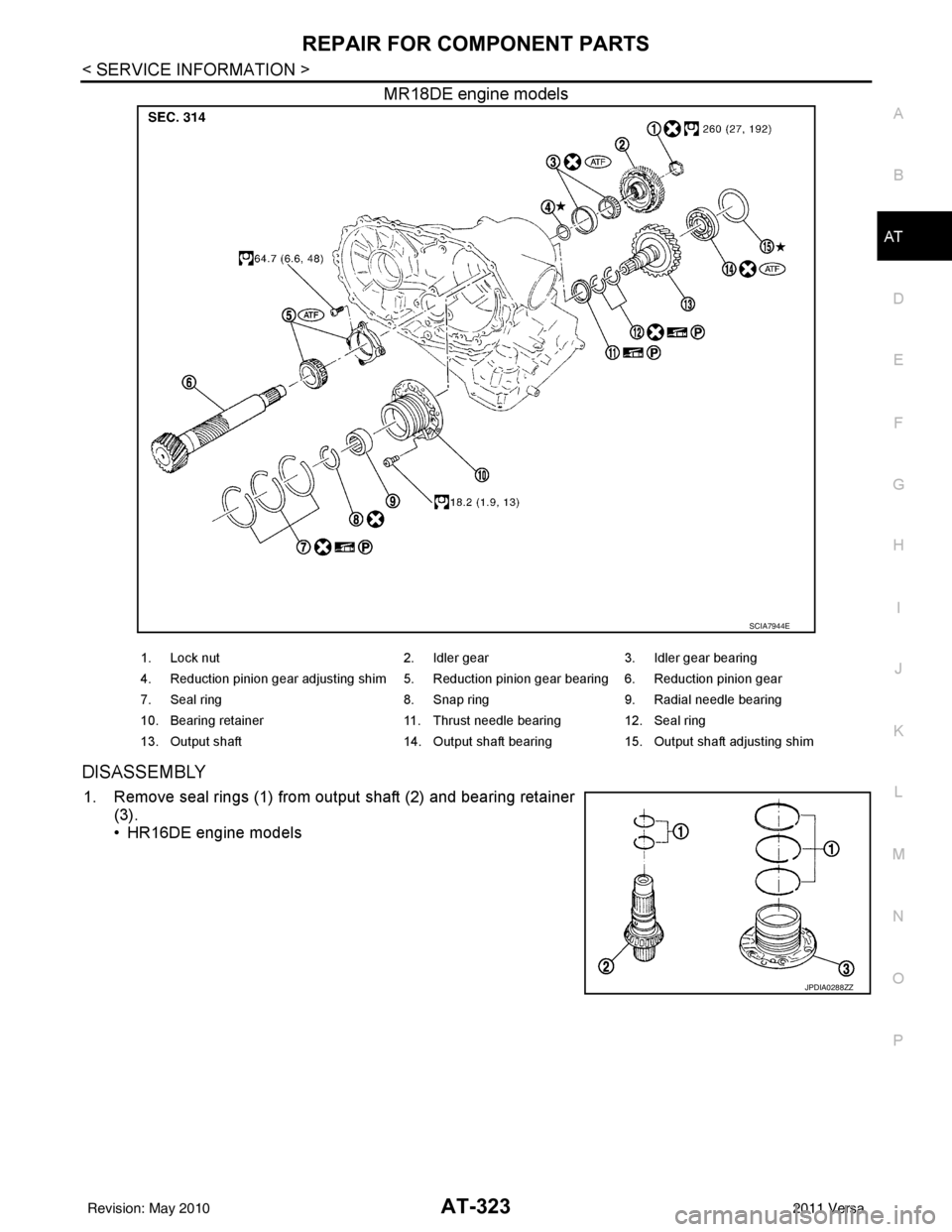

MR18DE engine models

DISASSEMBLY

1. Remove seal rings (1) from output shaft (2) and bearing retainer (3).

• HR16DE engine models

SCIA7944E

1. Lock nut 2. Idler gear3. Idler gear bearing

4. Reduction pinion gear adjusting shim 5. Reduction pinion gear bearing 6. Reduction pinion gear

7. Seal ring 8. Snap ring9. Radial needle bearing

10. Bearing retainer 11. Thrust needle bearing 12. Seal ring

13. Output shaft 14. Output shaft bearing15. Output shaft adjusting shim

JPDIA0288ZZ

Revision: May 2010 2011 Versa

Page 341 of 3787

AT-324

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

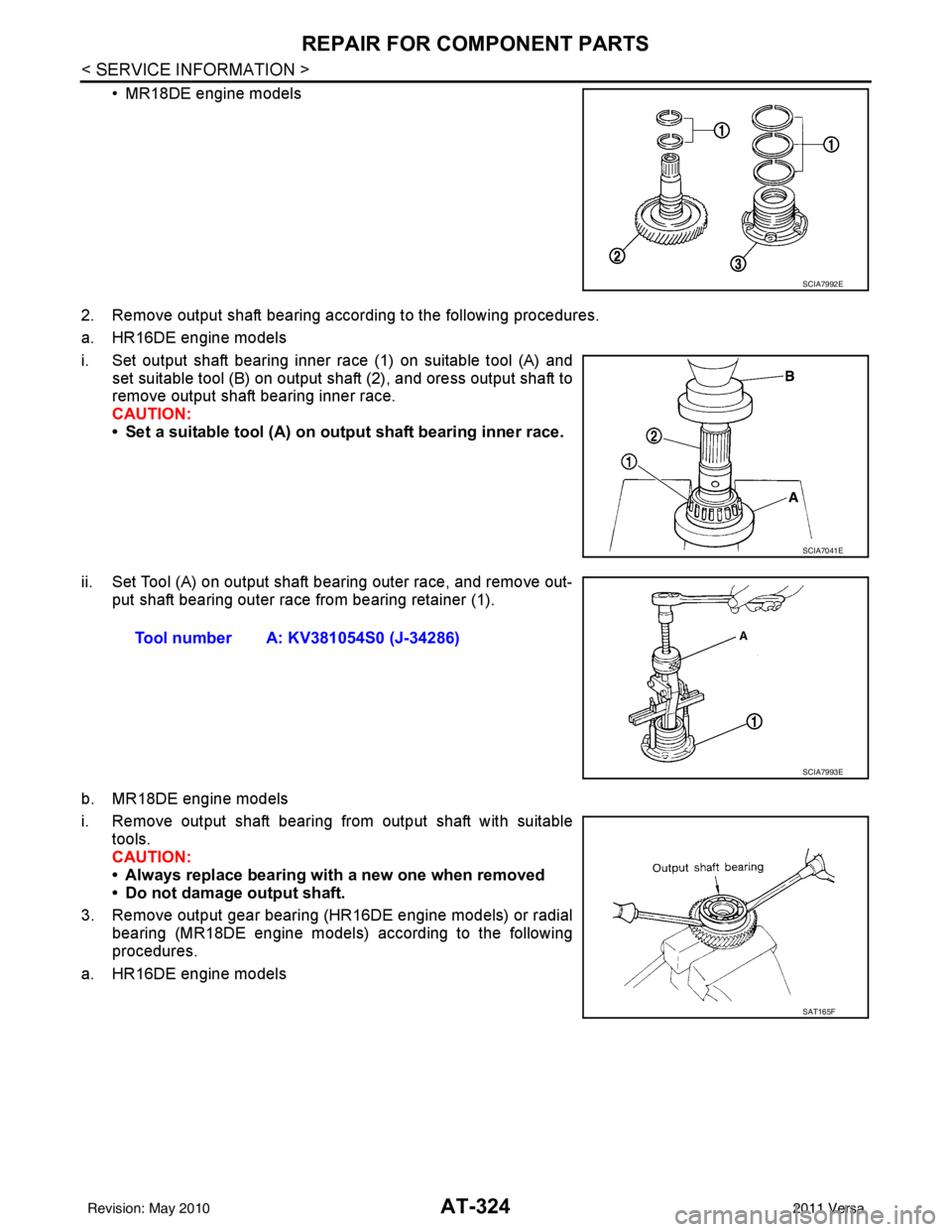

• MR18DE engine models

2. Remove output shaft bearing according to the following procedures.

a. HR16DE engine models

i. Set output shaft bearing inner race (1) on suitable tool (A) and set suitable tool (B) on output shaft (2), and oress output shaft to

remove output shaft bearing inner race.

CAUTION:

• Set a suitable tool (A) on output shaft bearing inner race.

ii. Set Tool (A) on output shaft bearing outer race, and remove out- put shaft bearing outer race from bearing retainer (1).

b. MR18DE engine models

i. Remove output shaft bearing from output shaft with suitable tools.

CAUTION:

• Always replace bearing with a new one when removed

• Do not damage output shaft.

3. Remove output gear bearing (HR16DE engine models) or radial bearing (MR18DE engine models) according to the following

procedures.

a. HR16DE engine models

SCIA7992E

SCIA7041E

Tool number A: KV381054S0 (J-34286)

SCIA7993E

SAT165F

Revision: May 2010 2011 Versa

Page 342 of 3787

REPAIR FOR COMPONENT PARTSAT-325

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

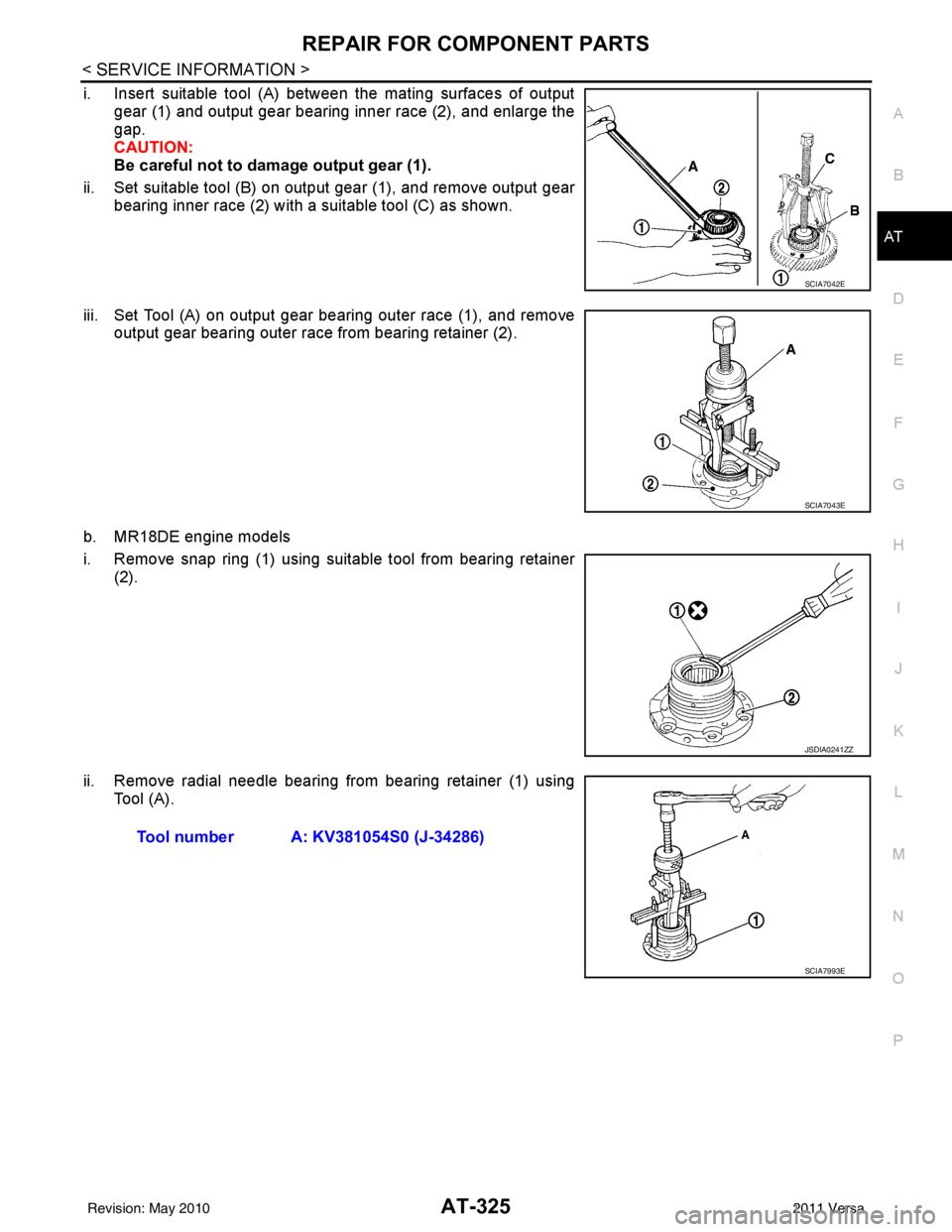

i. Insert suitable tool (A) between the mating surfaces of output gear (1) and output gear bearing inner race (2), and enlarge the

gap.

CAUTION:

Be careful not to damage output gear (1).

ii. Set suitable tool (B) on output gear (1), and remove output gear bearing inner race (2) with a suitable tool (C) as shown.

iii. Set Tool (A) on output gear bearing outer race (1), and remove output gear bearing outer race from bearing retainer (2).

b. MR18DE engine models

i. Remove snap ring (1) using suit able tool from bearing retainer

(2).

ii. Remove radial needle bearing from bearing retainer (1) using Tool (A).

SCIA7042E

SCIA7043E

JSDIA0241ZZ

Tool number A: KV381054S0 (J-34286)

SCIA7993E

Revision: May 2010 2011 Versa

Page 349 of 3787

AT-332

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

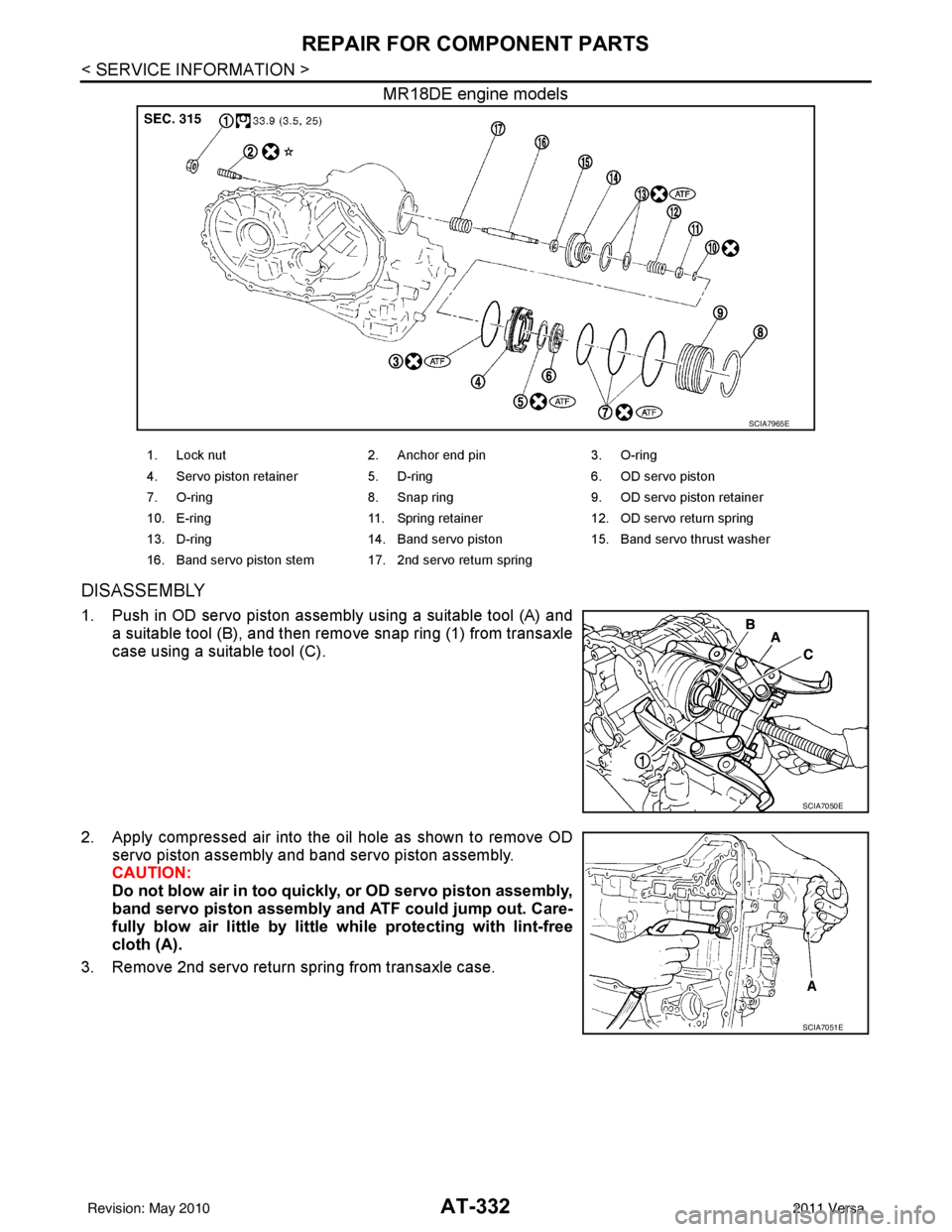

MR18DE engine models

DISASSEMBLY

1. Push in OD servo piston assembly using a suitable tool (A) anda suitable tool (B), and then remove snap ring (1) from transaxle

case using a suitable tool (C).

2. Apply compressed air into the oil hole as shown to remove OD servo piston assembly and band servo piston assembly.

CAUTION:

Do not blow air in too quickly, or OD servo piston assembly,

band servo piston assembly and ATF could jump out. Care-

fully blow air little by little while protecting with lint-free

cloth (A).

3. Remove 2nd servo return spring from transaxle case.

SCIA7965E

1. Lock nut 2. Anchor end pin 3. O-ring

4. Servo piston retainer 5. D-ring 6. OD servo piston

7. O-ring 8. Snap ring 9. OD servo piston retainer

10. E-ring 11. Spring retainer 12. OD servo return spring

13. D-ring 14. Band servo piston 15. Band servo thrust washer

16. Band servo piston stem 17. 2nd servo return spring

SCIA7050E

SCIA7051E

Revision: May 2010 2011 Versa

Page 351 of 3787

AT-334

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

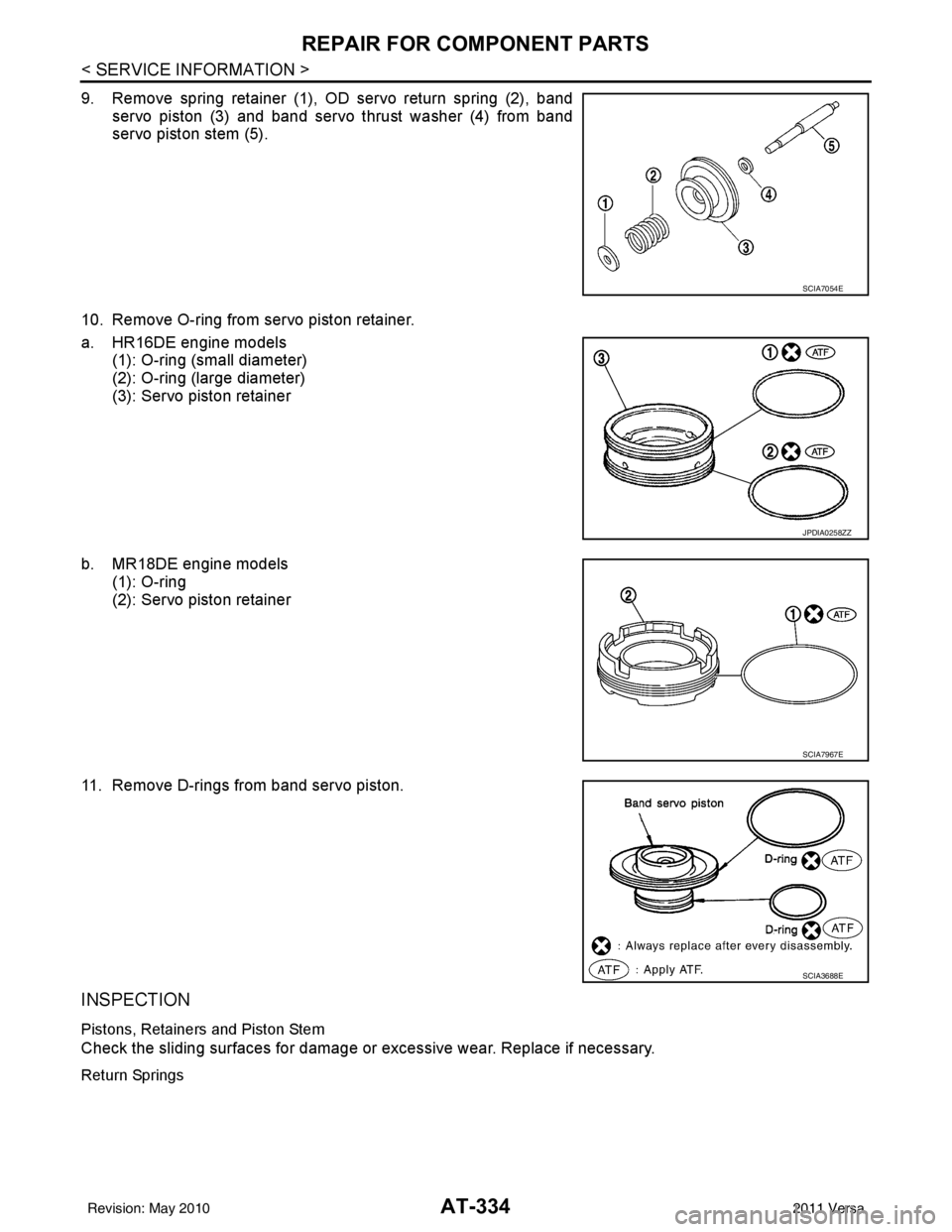

9. Remove spring retainer (1), OD servo return spring (2), bandservo piston (3) and band servo thrust washer (4) from band

servo piston stem (5).

10. Remove O-ring from servo piston retainer.

a. HR16DE engine models (1): O-ring (small diameter)

(2): O-ring (large diameter)

(3): Servo piston retainer

b. MR18DE engine models (1): O-ring

(2): Servo piston retainer

11. Remove D-rings from band servo piston.

INSPECTION

Pistons, Retainers and Piston Stem

Check the sliding surfaces for damage or excessive wear. Replace if necessary.

Return Springs

SCIA7054E

JPDIA0258ZZ

SCIA7967E

SCIA3688E

Revision: May 2010 2011 Versa

Page 356 of 3787

REPAIR FOR COMPONENT PARTSAT-339

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

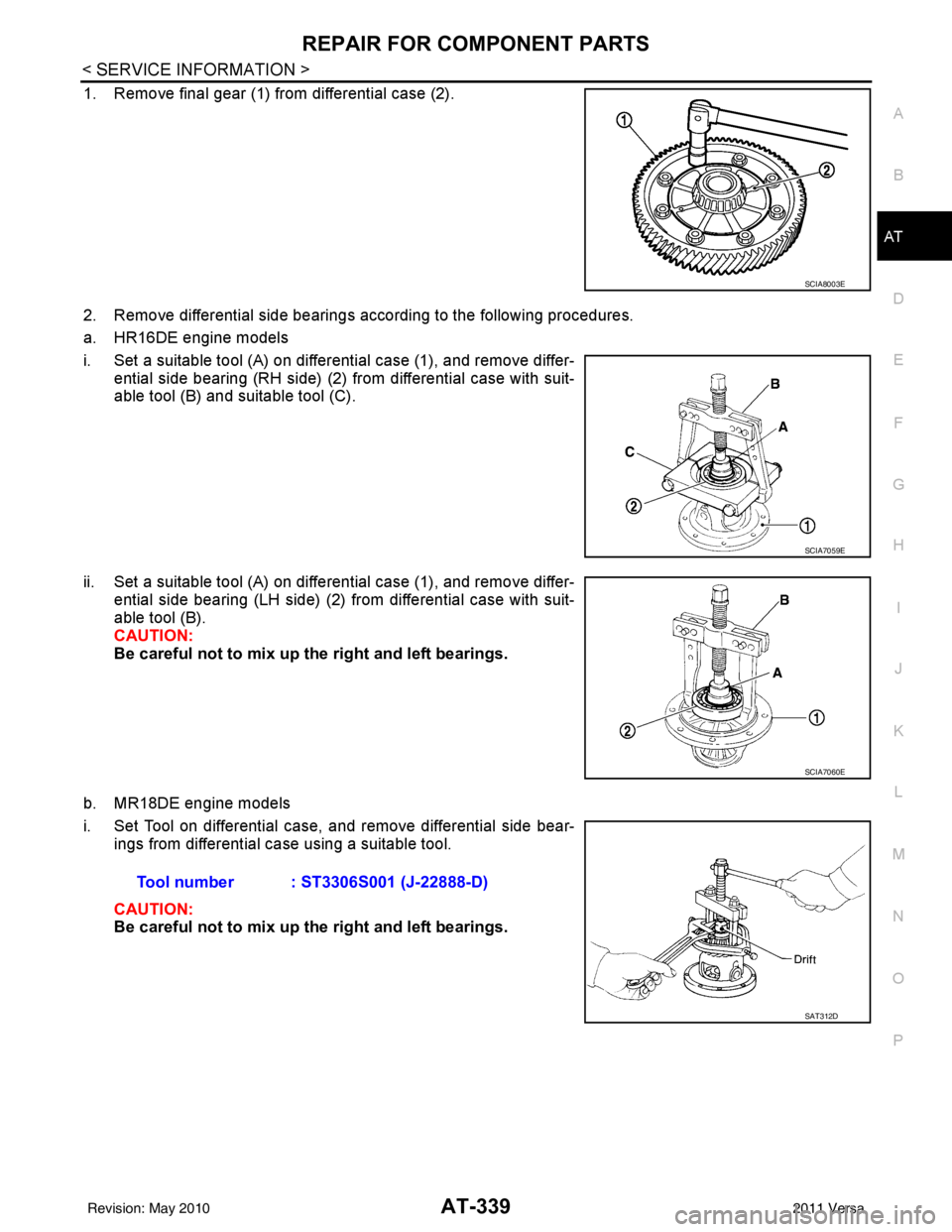

1. Remove final gear (1) from differential case (2).

2. Remove differential side bearings according to the following procedures.

a. HR16DE engine models

i. Set a suitable tool (A) on differential case (1), and remove differ- ential side bearing (RH side) (2) from differential case with suit-

able tool (B) and suitable tool (C).

ii. Set a suitable tool (A) on differential case (1), and remove differ- ential side bearing (LH side) (2) from differential case with suit-

able tool (B).

CAUTION:

Be careful not to mix up the right and left bearings.

b. MR18DE engine models

i. Set Tool on differential case, and remove differential side bear- ings from differential case using a suitable tool.

CAUTION:

Be careful not to mix up the right and left bearings.

SCIA8003E

SCIA7059E

SCIA7060E

Tool number : ST3306S001 (J-22888-D)

SAT312D

Revision: May 2010 2011 Versa