Block NISSAN TIIDA 2011 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1038 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refi NISSAN TIIDA 2011 Service Workshop Manual CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refi](/img/5/57396/w960_57396-1037.png)

CO-38

< SERVICE INFORMATION >[MR18DE]

ENGINE COOLANT

10. Place the coolant container (with the refill hose insert

ed) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed. Refer to CO-40, "Component".

2. Install radiator drain plug. •If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-203, "

Disas-

sembly and Assembly".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-40, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system.

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

Revision: May 2010 2011 Versa

Page 1048 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su NISSAN TIIDA 2011 Service Workshop Manual CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su](/img/5/57396/w960_57396-1047.png)

CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making sure rubber ring (1) groove fits securely

to thermostat flange (A).

CAUTION:

Replace the rubber ring with a new one.

- Install thermostat (1) into the thermostat housing (2) with jiggle valve (A) facing upwards.

• Use the following procedure to install the thermostat housing.

- Securely insert the rubber ring into the mating groove of thermostat housing and install it. CAUTION:

Replace the rubber ring with a new one.

- Install the thermostat housing to the cylinder block without displacing the gasket from the gasket position.

InspectionINFOID:0000000006413349

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

PBIC3315J

PBIC3548J

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Revision: May 2010 2011 Versa

Page 1070 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN TIIDA 2011 Service Workshop Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57396/w960_57396-1069.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005928732

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: May 2010 2011 Versa

Page 1212 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual CVT SHIFT LOCK SYSTEMCVT-157

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Check voltage between CVT shift selector harness connector terminal 5 and ground.

OK or NG

OK >> GO NISSAN TIIDA 2011 Service Workshop Manual CVT SHIFT LOCK SYSTEMCVT-157

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Check voltage between CVT shift selector harness connector terminal 5 and ground.

OK or NG

OK >> GO](/img/5/57396/w960_57396-1211.png)

CVT SHIFT LOCK SYSTEMCVT-157

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Check voltage between CVT shift selector harness connector terminal 5 and ground.

OK or NG

OK >> GO TO 9.

NG >> GO TO 6.

6.CHECK STOP LAMP SWITCH

1. Turn ignition switch OFF.

2. Disconnect stop lamp switch harness connector.

3. Check continuity between stop lamp switch terminals 3 and 4.

Check stop lamp switch after adjusting brake pedal. Refer to

BR-6

.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.DETECT MALFUNCTIONING ITEM

Check the following. If any items are damaged, repair or replace damaged parts.

• Harness for short or open between ignition switch and stop lamp switch harness connector

• Harness for short or open between stop lamp switch harness connector and CVT shift selector harness con-

nector

• 10A fuse [No.3, located in the fuse block (J/B)]

• Ignition switch, Refer to PG-4

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

8.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect CVT shift selector harness connector.

3. Check continuity between CVT shift selector harness connector terminal 6 and ground.

4. Connect CVT shift selector harness connector.

OK or NG

OK >> Replace shift lock solenoid and park position switch assembly. Refer to CVT-163, "

CVT Shift Selector Disas-

sembly and Assembly".

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect CVT shift selector harness connector. Voltage:

Brake pedal depressed: Battery voltage

Brake pedal released: 0V

SCIA7935E

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

AWDIA0419ZZ

Continuity should exist.

SCIA7936E

Revision: May 2010 2011 Versa

Page 1243 of 3787

DI-4

< SERVICE INFORMATION >

COMBINATION METERS

COMBINATION METERS

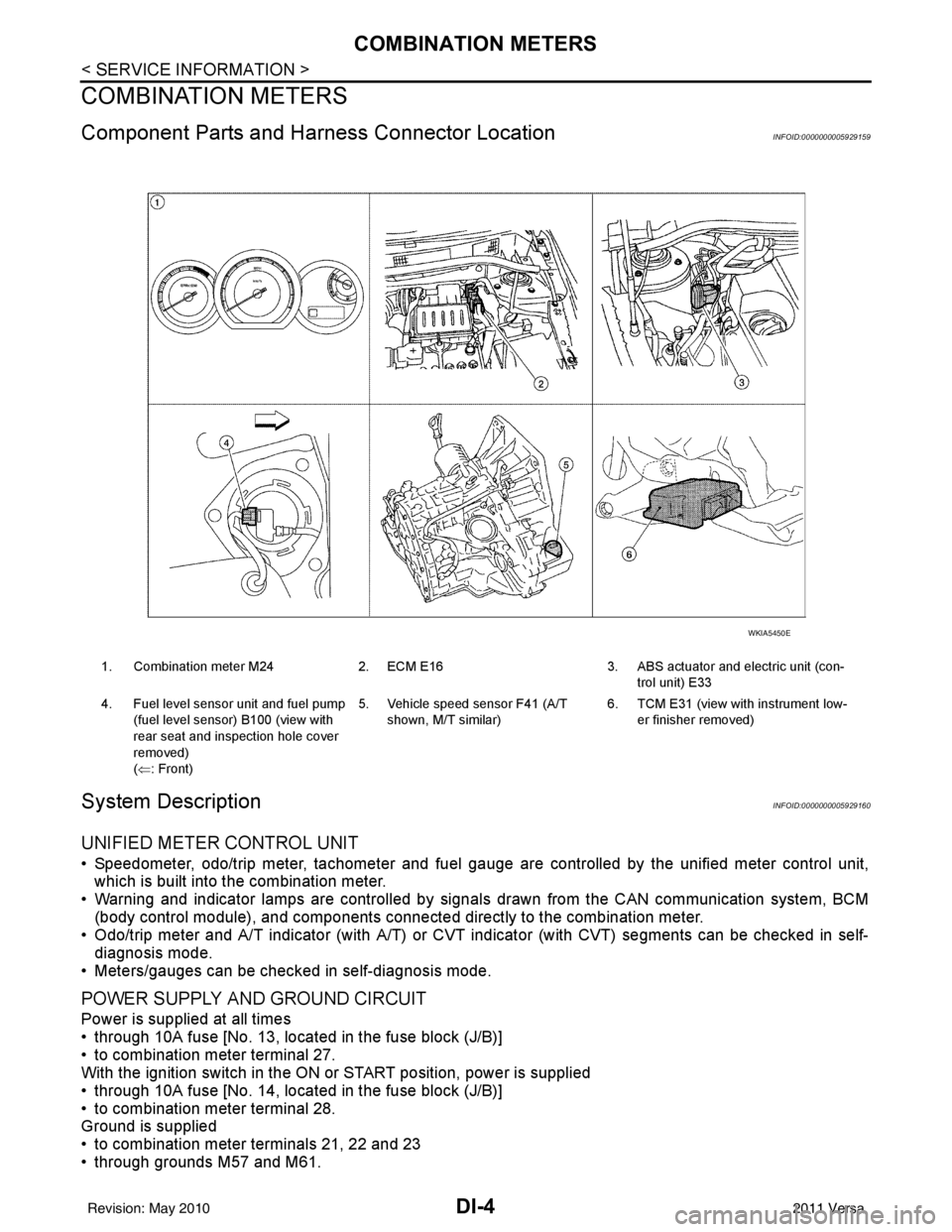

Component Parts and Harness Connector LocationINFOID:0000000005929159

System DescriptionINFOID:0000000005929160

UNIFIED METER CONTROL UNIT

• Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signals drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

(⇐: Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

WKIA5450E

Revision: May 2010 2011 Versa

Page 1252 of 3787

COMBINATION METERSDI-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

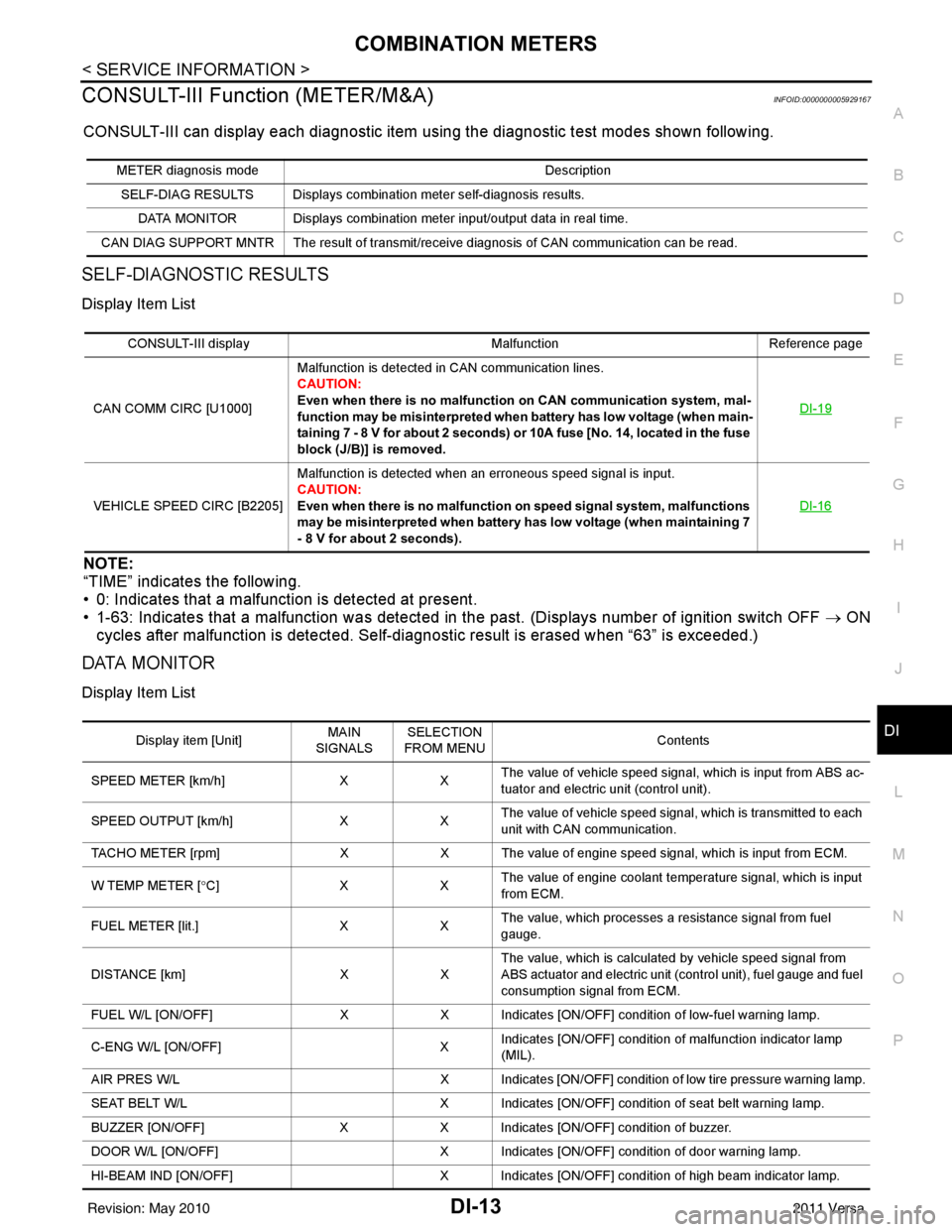

CONSULT-III Function (METER/M&A)INFOID:0000000005929167

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

NOTE:

“TIME” indicates the following.

• 0: Indicates that a malfunction is detected at present.

• 1-63: Indicates that a malfunction was detected in the past. (Displays number of ignition switch OFF → ON

cycles after malfunction is detected. Self-di agnostic result is erased when “63” is exceeded.)

DATA MONITOR

Display Item List

METER diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results. DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

CONSULT-III display MalfunctionReference page

CAN COMM CIRC [U1000] Malfunction is detected in CAN communication lines.

CAUTION:

Even when there is no malfuncti

on on CAN communication system, mal-

function may be misinterpreted when battery has low voltage (when main-

taining 7 - 8 V for about 2 seconds) or 10A fuse [No. 14, located in the fuse

block (J/B)] is removed. DI-19

VEHICLE SPEED CIRC [B2205]

Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction

on speed signal system, malfunctions

may be misinterpreted when battery has low voltage (when maintaining 7

- 8 V for about 2 seconds). DI-16

Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

SPEED METER [km/h] XXThe value of vehicle speed signa

l, which is input from ABS ac-

tuator and electric unit (control unit).

SPEED OUTPUT [km/h] XXThe value of vehicle speed signal, which is transmitted to each

unit with CAN communication.

TACHO METER [rpm] XX The value of engine speed signal, which is input from ECM.

W TEMP METER [ °C] X XThe value of engine coolant temperature signal, which is input

from ECM.

FUEL METER [lit.] XXThe value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] XXThe value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption signal from ECM.

FUEL W/L [ON/OFF] XX Indicates [ON/OFF] condition of low-fuel warning lamp.

C-ENG W/L [ON/OFF] XIndicates [ON/OFF] condition of malfunction indicator lamp

(MIL).

AIR PRES W/L X Indicates [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L X Indicates [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] XX Indicates [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Indicates [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Indicates [ON/OFF] condition of high beam indicator lamp.

Revision: May 2010 2011 Versa

Page 1283 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual DI-44

< SERVICE INFORMATION >

WARNING CHIME

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to NISSAN TIIDA 2011 Service Workshop Manual DI-44

< SERVICE INFORMATION >

WARNING CHIME

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to](/img/5/57396/w960_57396-1282.png)

DI-44

< SERVICE INFORMATION >

WARNING CHIME

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

IGNITION KEY WARNING CHIME (WITHOUT INTELLIGENT KEY)

With the key inserted into the key switch, and the ignition switch in the OFF or ACC position, when driver's

door is opened, the warning chime will sound.

• BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter with CAN communication line.

• When combination meter receives key warning signal, it sounds warning chime.

IGNITION KEY WARNING CHIME (WITH INTELLIGENT KEY)

When Mechanical Key Is Used

With the key inserted into the key switch, and the igniti on switch in the LOCK or ACC position, when driver's

door is opened, the warning chime will sound.

• BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter with

CAN communication line.

• When combination meter receives key warning signal, it sounds warning chime.

When Intelligent Key Is Carried With The Driver

Refer to BL-88, "System Description".

LIGHT WARNING CHIME

The warning chime sounds, when driver's door is opened (door switch ON) with lighting switch ON and the

ignition switch is in any position other than ON or START.

NOTE:

BCM detected lighting switch in the 1st or 2nd position, refer to LT-64, "

Combination Switch Reading Func-

tion".

• BCM detects headlamps are illuminated, and sends light warning signal to combination meter with CAN

communication lines.

WKIA5463E

WKIA5464E

Revision: May 2010 2011 Versa

Page 1290 of 3787

WARNING CHIMEDI-51

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

OK >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NG >> Replace front door switch LH.

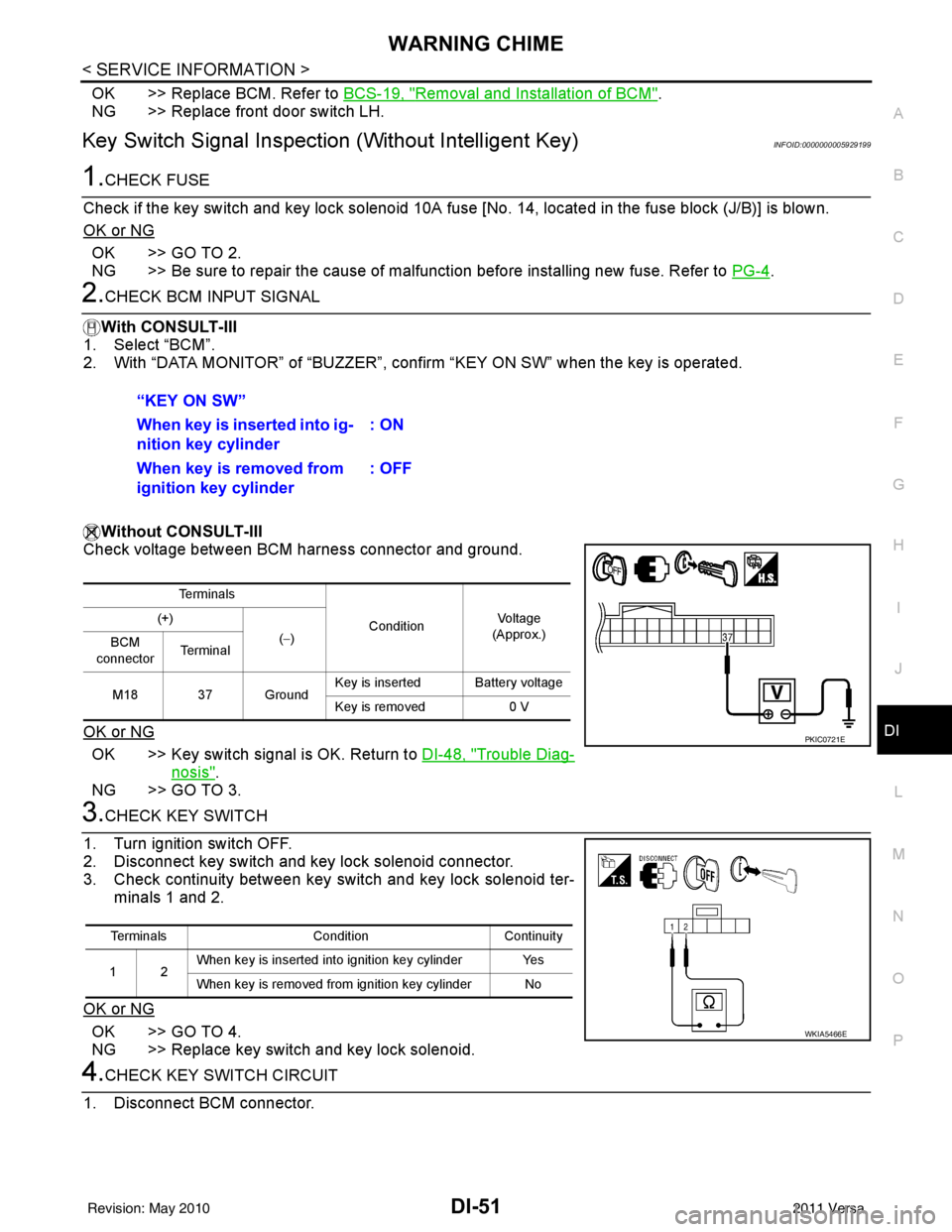

Key Switch Signal Inspection (Without Intelligent Key)INFOID:0000000005929199

1.CHECK FUSE

Check if the key switch and key lock solenoid 10A fuse [No. 14, located in the fuse block (J/B)] is blown.

OK or NG

OK >> GO TO 2.

NG >> Be sure to repair the cause of malfunction before installing new fuse. Refer to PG-4

.

2.CHECK BCM INPUT SIGNAL

With CONSULT-III

1. Select “BCM”.

2. With “DATA MONITOR” of “BUZZER”, confirm “KEY ON SW” when the key is operated.

Without CONSULT-III

Check voltage between BCM harness connector and ground.

OK or NG

OK >> Key switch signal is OK. Return to DI-48, "Trouble Diag-

nosis".

NG >> GO TO 3.

3.CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and key lock solenoid connector.

3. Check continuity between key switch and key lock solenoid ter- minals 1 and 2.

OK or NG

OK >> GO TO 4.

NG >> Replace key switch and key lock solenoid.

4.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector. “KEY ON SW”

When key is inserted into ig-

nition key cylinder

: ON

When key is removed from

ignition key cylinder : OFF

Te r m i n a l s

ConditionVoltag e

(Approx.)

(+)

(−)

BCM

connector Te r m i n a l

M18 37 Ground Key is inserted Battery voltage

Key is removed

0 V

PKIC0721E

Terminals ConditionContinuity

12 When key is inserted into ignition key cylinder Yes

When key is removed from ignition key cylinder No

WKIA5466E

Revision: May 2010

2011 Versa

Page 1557 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual P0327, P0328 KSEC-263

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0327, P0328 KS

DescriptionINFOID:0000000005929934

The knock sensor is attached to the cylinder block.

It senses NISSAN TIIDA 2011 Service Workshop Manual P0327, P0328 KSEC-263

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0327, P0328 KS

DescriptionINFOID:0000000005929934

The knock sensor is attached to the cylinder block.

It senses](/img/5/57396/w960_57396-1556.png)

P0327, P0328 KSEC-263

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

P0327, P0328 KS

DescriptionINFOID:0000000005929934

The knock sensor is attached to the cylinder block.

It senses engine knocking using a piezoelectric element. A

knocking vibration from the cylinder blo ck is sensed as vibrational pressure. This pressure is converted into a

voltage signal and sent to the ECM.

DTC LogicINFOID:0000000005929935

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Go to EC-264, "Diagnosis Procedure".

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detected conditionPossible cause

P0327 Knock sensor circuit low

input An excessively low voltage from the sensor is

sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor

P0328 Knock sensor circuit high

input An excessively high voltage from the sensor is

sent to ECM.

Revision: May 2010

2011 Versa

Page 1576 of 3787

![NISSAN TIIDA 2011 Service Workshop Manual EC-282

< COMPONENT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

P0441 EVAP CONTROL SYSTEM

DTC LogicINFOID:0000000005929952

DTC DETECTION LOGIC

NOTE:

If DTC P0441 is displayed with other DTC such

as NISSAN TIIDA 2011 Service Workshop Manual EC-282

< COMPONENT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

P0441 EVAP CONTROL SYSTEM

DTC LogicINFOID:0000000005929952

DTC DETECTION LOGIC

NOTE:

If DTC P0441 is displayed with other DTC such

as](/img/5/57396/w960_57396-1575.png)

EC-282

< COMPONENT DIAGNOSIS >[HR16DE]

P0441 EVAP CONTROL SYSTEM

P0441 EVAP CONTROL SYSTEM

DTC LogicINFOID:0000000005929952

DTC DETECTION LOGIC

NOTE:

If DTC P0441 is displayed with other DTC such

as P2122, P2123, P2127, P2128 or P2138, first perform

trouble diagnosis for other DTC.

In this evaporative emission (EVAP) control system, purge flow occurs during non-closed throttle conditions.

Purge volume is related to air intake volume. Under normal purge conditions (non-closed throttle), the EVAP

canister purge volume control solenoid valve is open to admit purge flow. Purge flow exposes the EVAP con-

trol system pressure sensor to intake manifold vacuum.

Under normal conditions (non-closed throttle), sensor output voltage indicates if pressure drop and purge flow

are adequate. If not, a ma lfunction is determined.

DTC CONFIRMATION PROCEDURE

1.INSPECTION START

Do you have CONSULT-III?

Do you have CONSULT-III?

YES >> GO TO 2.

NO >> GO TO 6.

2.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PBIB1026E

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0441 EVAP control system in-

correct purge flow EVAP control system does not operate properly,

EVAP control system has a leak between intake

manifold and EVAP control system pressure sen-

sor. • EVAP canister purge volume control so-

lenoid valve stuck closed

• EVAP control system pressure sensor and the circuit

• Loose, disconnected or improper con-

nection of rubber tube

• Blocked rubber tube

• Cracked EVAP canister

• EVAP canister purge volume control so- lenoid valve circuit

• Accelerator pedal position sensor

• Blocked purge port

• EVAP canister vent control valve

• Drain filter

Revision: May 2010 2011 Versa