Engine front side NISSAN TIIDA 2011 Service Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 3179 of 3787

MA-8

< SERVICE INFORMATION >

GENERAL MAINTENANCE

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. MA-49

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Clutch pedal Make sure the pedal operates smoothly and check that it has the proper free play. CL-6

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to keep

floor mats away from the pedal. BR-6

and

BR-20

Parking brake Check that the lever has the proper travel and make sure that the vehicle is held

securely on a fairly steep hill when only the parking brake is applied. PB-5

Automatic transaxle

“Park” mechanismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the se-

lector lever in the “P” position without applying any brakes. —

CVT P (Park) position

mechanism On a fairly steep hill check that the vehicle is held securely with the selector lever

in the “P” position without applying any brakes.

—

Item

Reference page

ItemReference page

Windshield wash-

er fluid Check that there is adequate fluid in the tank.

—

Engine coolant

level Check the coolant level when the engine is cold. CO-11

(HR)

CO-36

(MR)

Radiator and hos-

es Check the front of the radiator and clean off any dirt, insects, leaves, etc., that may

have accumulated. Make sure the radiator hoses have no cracks, deformation, de-

terioration or loose connections.

—

Brake and clutch

fluid levels Make sure that the brake and clutch fluid levels are between the “MAX” and “MIN”

lines on the reservoirs.

BR-9

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require frequent

checks of the battery fluid level. —

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. EM-13

(HR)

EM-132

(MR)

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot and turning

off the engine. MA-20

(HR)

MA-30

(MR)

CVT and Automat-

ic transaxle fluid

level Check the level on the dipstick after putting the selector lever in “P” with the engine

idling.

MA-37

MA-42

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the exhaust

seems unusual or there is a smell of exhaust fumes, immediately locate the trouble

and correct it. MA-37, "EXHAUST SYS-

TEM : Checking Exhaust

System HR16DE", MA-37,

"EXHAUST SYSTEM :

Checking Exhaust System

MR18DE"

Underbody

The underbody is frequently exposed to corrosive substances such as those used

on icy roads or to control dust. It is very important to remove these substances, oth-

erwise rust will form on the floor pan, frame, fuel lines and around the exhaust sys-

tem. At the end of winter, the underbody should be thoroughly flushed with plain

water, being careful to clean those areas where mud and dirt can easily accumu-

late. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle has

been parked for a while. Water dripping from the air conditioner after use is normal.

If you should notice any leaks or gasoline fumes are evident, check for the cause

and correct it immediately. —

Revision: May 2010

2011 Versa

Page 3186 of 3787

RECOMMENDED FLUIDS AND LUBRICANTSMA-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

SAE Viscosity NumberINFOID:0000000005931135

NISSAN recommends the use of an energy conser ving oil in order to improve fuel economy.

Select only engine oils that meet the American Petroleum Institute (API) certification and International Lubrica-

tion Standardization and Approval Committee (ILSAC) ce rtification and SAE viscosity standard. These oils

have the API certification mark on the front of the container. Oils which do not have the specified quality label

should not be used as they could cause engine damage.

Anti-freeze Coolant Mixture RatioINFOID:0000000005931136

The engine cooling system is filled at the factory wit h a high-quality, long life, year-round, anti-freeze coolant

solution. The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system

additives are not necessary.

CAUTION:

• When adding or replacing coolant, be sure to u se only Genuine NISSAN Long Life AntiFreeze / Cool-

ant (blue) or equivalent with the proper mixture ratio of 50% an ti-freeze and 50% demineralized or

distilled water.

• Mixing any other type of coolant or the use of non-distilled water will reduce the life expectancy of

the factory-fi ll coolant.

SAIA1514E

1. API certification mark 2. API service symbol

For outside temperatures down to :Genuine NISSAN Anti-freeze /

Coolant (blue) or equivalent Demineralized water or distilled

water

° C °F

-35 -3050% 50%

Revision: May 2010 2011 Versa

Page 3189 of 3787

MA-18

< SERVICE INFORMATION >

ENGINE MAINTENANCE (HR16DE)

1. Open radiator drain plug (1) at the bottom of radiator, and thenremove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-90

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing. Refer to CO-16, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be complete ly empty of coolant and water.

• Apply sealant to the threads of the cylinder bl ock drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

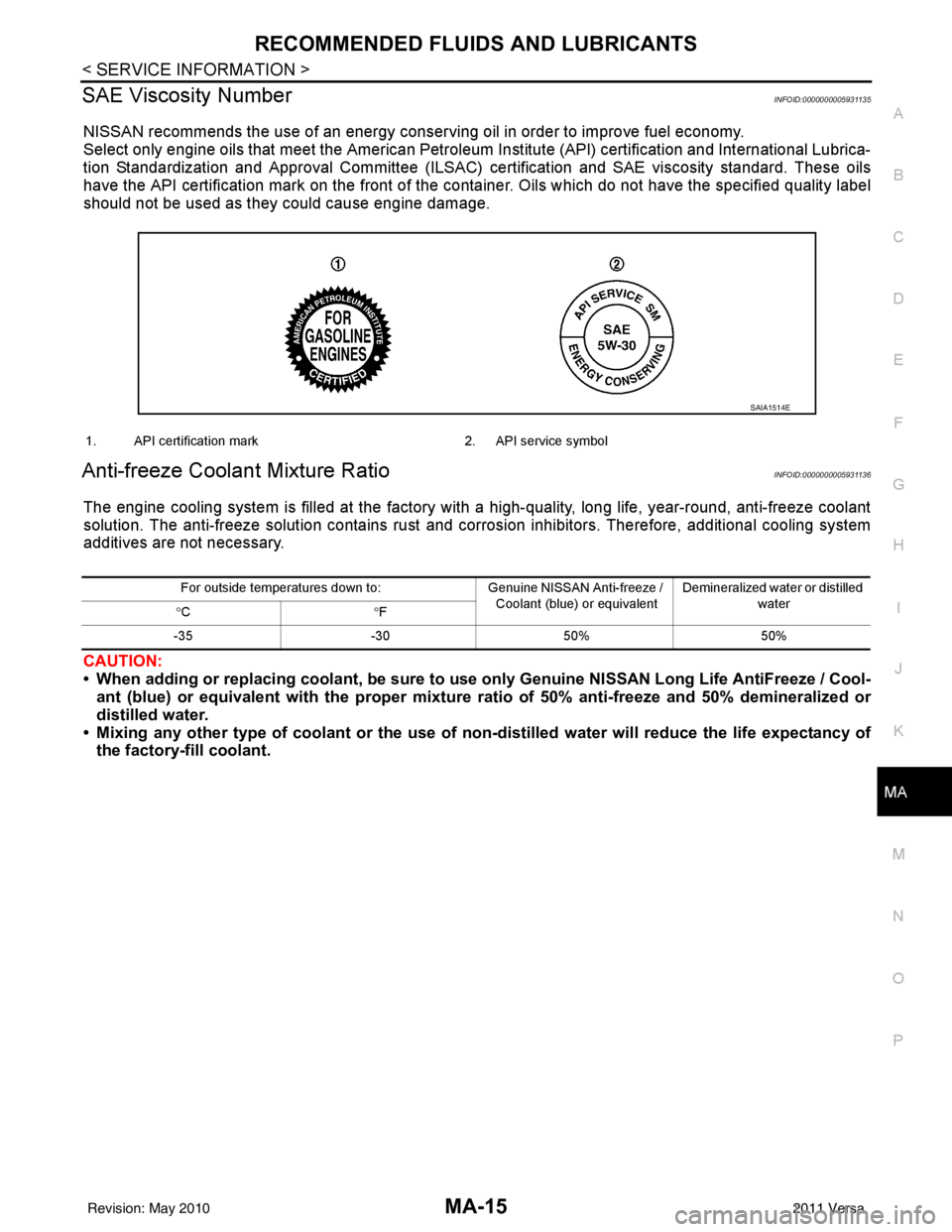

4. Install the Tool by installing the radiator cap adapter onto the radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is placed at floor level. Make sure the ball valve is in the closed

position.

•Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed with distil led water or demineralized

water.

Refer to MA-15, "

Anti-freeze Coolant Mixture Ratio".

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Coolant will be vi sible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

PBIC3799E

Radiator drain plug : Refer to CO-16, "Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank) : Refer to

MA-14, "

Fluids

and Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)

LLIA0058E

Revision: May 2010 2011 Versa

Page 3198 of 3787

ENGINE MAINTENANCE (MR18DE)MA-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

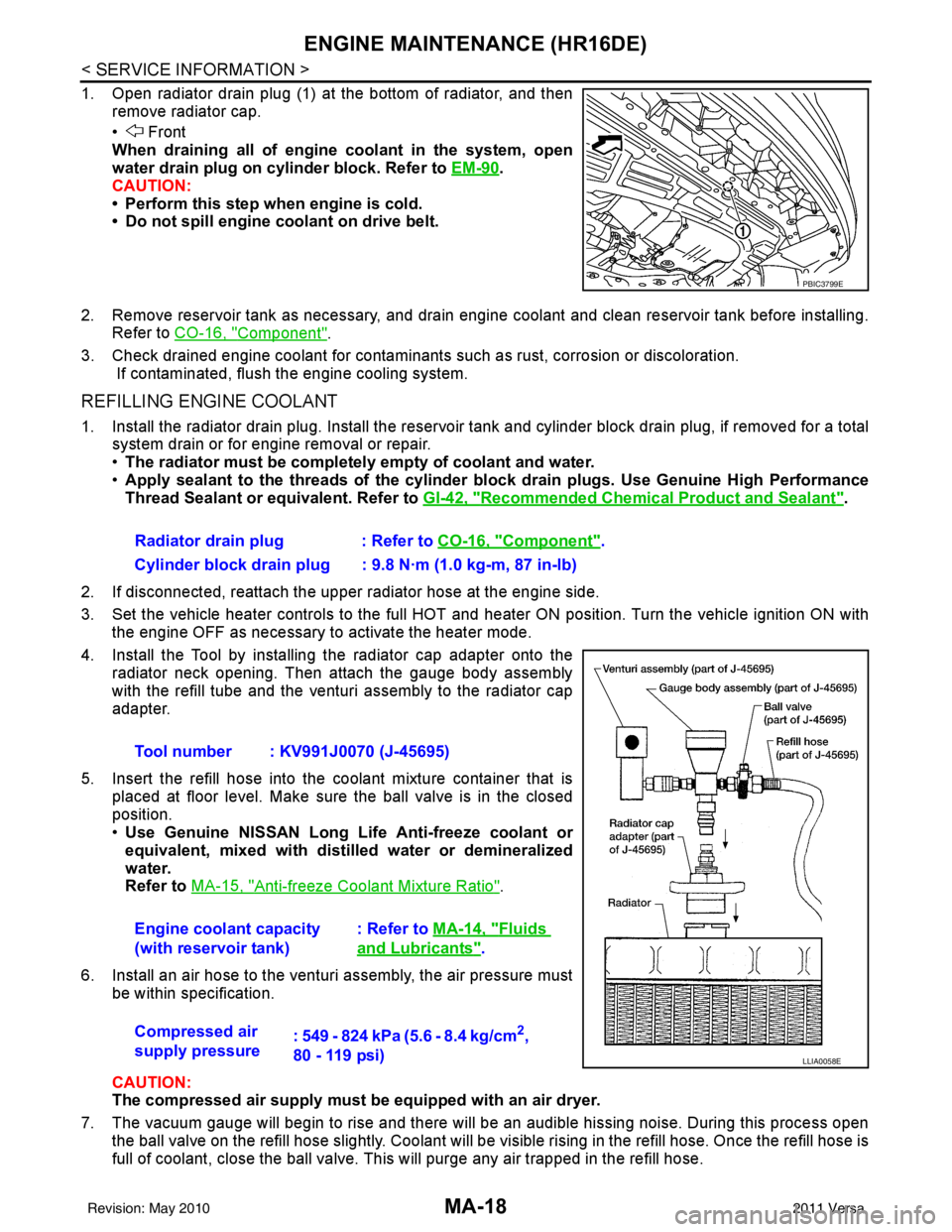

To check for leaks, apply pressure to the cooling system using suit-

able tool and Tool.

WARNING:

Never remove the radiator cap wh en the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Chang ing Engine CoolantINFOID:0000000005931154

WARNING:

• To avoid being scalded, do not change engine coolant when engine is hot.

• Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

CAUTION:

• Do not spill engine coolant on drive belt.

DRAINING ENGINE COOLANT

1. Open radiator drain plug (1) at the bottom of radiator, and then remove radiator cap.

• Front

When draining all of engine coolant in the system, open

water drain plug on cylinder block. Refer to EM-203

.

CAUTION:

• Perform this step when engine is cold.

• Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engi ne coolant and clean reservoir tank before installing.

Refer to CO-40, "

Component".

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration. If contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder blo ck drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-42, "

Recommended Chemical Product and Sealant".

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heat er ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode. Tool number : EG17650301 (J-33984-A)

Testing pressure

: 157 kPa (1.6 kg/cm

2, 23 psi)

WBIA0568E

PBIC3799E

Radiator drain plug : Refer to CO-40, "Component".

Cylinder block drain plug : 9.8 N·m (1.0 kg-m, 87 in-lb)

Revision: May 2010 2011 Versa

Page 3210 of 3787

![NISSAN TIIDA 2011 Service Manual Online CHASSIS AND BODY MAINTENANCEMA-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. NISSAN TIIDA 2011 Service Manual Online CHASSIS AND BODY MAINTENANCEMA-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2.](/img/5/57396/w960_57396-3209.png)

CHASSIS AND BODY MAINTENANCEMA-39

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to MA-37, "

CVT FLUID : Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CLUTCH FLUID

CLUTCH FLUID : Air Bleeding ProcedureINFOID:0000000005931169

CAUTION:

Do not spill clutch fluid onto painted surfaces. If it spills, wipe up immediately and wash the affected

area with water.

NOTE:

• Do not use a vacuum assist or any other type of power bleeder on this system. Use of a vacuum assist or power bleeder will not purge all the air from the system.

• Carefully monitor fluid level in reservoir tank during bleeding operation.

1. Fill master cylinder reservoir tank with new clutch fluid.

2. Connect a transparent vinyl tube and container to the bleeding connector (1) on the CSC.

3. Depress and release the clutch pedal slowly and fully 15 times at an interval of two to three seconds and release the clutch

pedal.

4. Push in the lock pin (1) of the bleeding connector (2), and maintain the position. • RS5F91R transaxle models

CAUTION:

Hold the lock pin in to preven t the bleeding connector from

separating when fluid pressure is applied.

Fluid capacity and grade: Refer to

MA-14, "

Fluids

and Lubricants".SCIA6088E

PCIB1494E

PCIB1495E

Revision: May 2010 2011 Versa

Page 3213 of 3787

MA-42

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

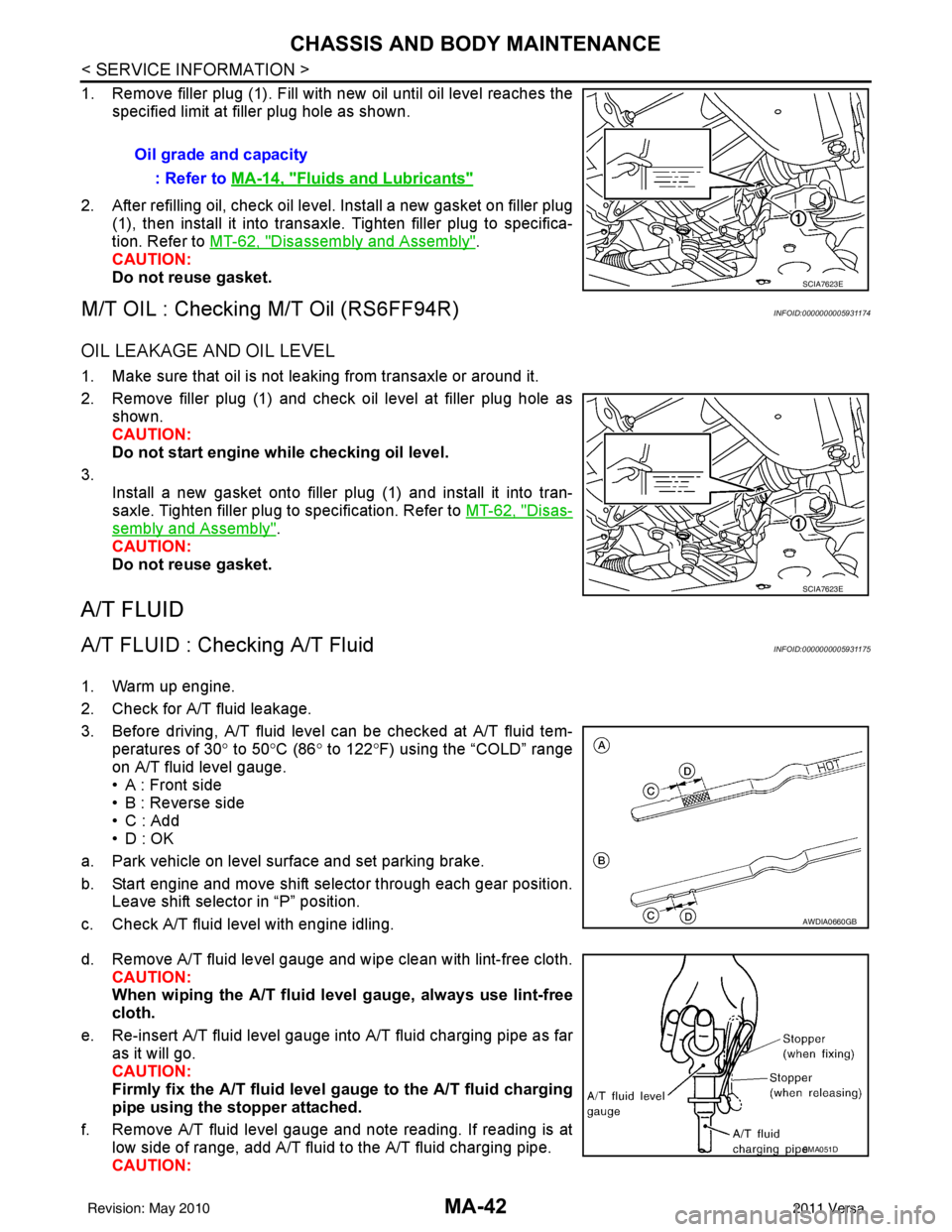

1. Remove filler plug (1). Fill with new oil until oil level reaches thespecified limit at filler plug hole as shown.

2. After refilling oil, check oil level. Install a new gasket on filler plug (1), then install it into transaxle. Tighten filler plug to specifica-

tion. Refer to MT-62, "

Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

M/T OIL : Checking M/T Oil (RS6FF94R)INFOID:0000000005931174

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as shown.

CAUTION:

Do not start engine wh ile checking oil level.

3. Install a new gasket onto filler plug (1) and install it into tran-

saxle. Tighten filler plug to specification. Refer to MT-62, "

Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

A/T FLUID

A/T FLUID : Checking A/T FluidINFOID:0000000005931175

1. Warm up engine.

2. Check for A/T fluid leakage.

3. Before driving, A/T fluid level can be checked at A/T fluid tem- peratures of 30 ° to 50 °C (86° to 122° F) using the “COLD” range

on A/T fluid level gauge.

• A : Front side

• B : Reverse side

• C : Add

• D : OK

a. Park vehicle on level surface and set parking brake.

b. Start engine and move shift selector through each gear position. Leave shift selector in “P” position.

c. Check A/T fluid level with engine idling.

d. Remove A/T fluid level gauge and wipe clean with lint-free cloth. CAUTION:

When wiping the A/T fluid level gauge, always use lint-free

cloth.

e. Re-insert A/T fluid level gauge into A/T fluid charging pipe as far as it will go.

CAUTION:

Firmly fix the A/T fluid level gauge to the A/T fluid charging

pipe using the stopper attached.

f. Remove A/T fluid level gauge and note reading. If reading is at low side of range, add A/T fluid to the A/T fluid charging pipe.

CAUTION:Oil grade and capacity

: Refer to MA-14, "

Fluids and Lubricants"

SCIA7623E

SCIA7623E

AWDIA0660GB

SMA051D

Revision: May 2010 2011 Versa

Page 3238 of 3787

![NISSAN TIIDA 2011 Service Manual Online TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005929672

Removal and InstallationINFOID:0000000005929673

CAUTI NISSAN TIIDA 2011 Service Manual Online TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005929672

Removal and InstallationINFOID:0000000005929673

CAUTI](/img/5/57396/w960_57396-3237.png)

TRANSAXLE ASSEMBLYMT-17

< SERVICE INFORMATION > [RS5F91R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

Exploded ViewINFOID:0000000005929672

Removal and InstallationINFOID:0000000005929673

CAUTION:

If transaxle assembly is removed from the vehicle , always replace CSC (Concentric Slave Cylinder).

Return CSC insert to original pos ition to remove transaxle assembly. Du st on clutch disc sliding parts

may damage seal of CSC and may cau se clutch fluid leakage. Refer to CL-13, "

Removal and Installa-

tion".

REMOVAL

1. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-13, "Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

2. Remove the engine and transaxle as an assembly from the vehicle. Refer t\

o EM-82, "

Removal and Instal-

lation".

3. Remove the transaxle to engine and engine to transaxle bolts.

4. Separate the transaxle assembly from the engine.

INSTALLATION

Installation is in the reverse order of removal.

1. LH engine mount bracket (transaxle side) 2. Transaxle assembly 3. Rear engine mount bracket

4. Washer 5. Rear torque rod Front

: Refer to installation.

PCIB1514E

Revision: May 2010

2011 Versa

Page 3282 of 3787

![NISSAN TIIDA 2011 Service Manual Online TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005929696

Removal and InstallationINFOID:0000000005929697

CAUTION:

NISSAN TIIDA 2011 Service Manual Online TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005929696

Removal and InstallationINFOID:0000000005929697

CAUTION:](/img/5/57396/w960_57396-3281.png)

TRANSAXLE ASSEMBLYMT-61

< SERVICE INFORMATION > [RS6F94R]

D

E

F

G H

I

J

K L

M A

B

MT

N

O P

TRANSAXLE ASSEMBLY

ComponentINFOID:0000000005929696

Removal and InstallationINFOID:0000000005929697

CAUTION:

If transaxle assembly is removed from the vehicle , always replace CSC (Concentric Slave Cylinder).

Inserted CSC returns to the origin al position when removing transaxle assembly. Dust on clutch disc

sliding parts may damage CSC seal, and may cause clutch fluid leakage.

REMOVAL

1. Drain clutch fluid and remove clutch tube from CSC. Refer to CL-13, "Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

2. Remove engine and transaxle assembly. Refer to EM-197, "

Removal and Installation".

3. Remove starter motor. Refer to SC-20, "

Removal and Installation MR18DE".

4. Remove transaxle assembly to engine bolts.

5. Separate transaxle assembly from engine.

INSTALLATION

Installation is in the reverse order of removal.

• If transaxle is removed from the v ehicle, always replace CSC. Refer to CL-13, "

Removal and Installation" .

1. LH engine mount bracket (transaxle side) 2. Transaxle assembly 3. Rear engine mount bracket

4. Washer 5. Rear torque rod Front

: Refer to MT-61, "

Removal and Installation".

SCIA7631E

Revision: May 2010 2011 Versa

Page 3326 of 3787

MTC-10

< SERVICE INFORMATION >

PRECAUTIONS

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed.

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bot tle (1/4 ounce /7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/C s ystem or CFC-12 (R-12) leak detector dye in HFC-

134a (R-134a) A/C syst em or A/C system damage may result.

• The fluorescent properties of the dye will remain for over three (3) years unless a compressor malfunction

occurs.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have an identification label on the front underside of the hood.

NOTE:

• Vehicles with factory installed fluorescent dye have a green label.

• Vehicles without factory installed fluorescent dye have a blue label.

Revision: May 2010 2011 Versa

Page 3369 of 3787

TROUBLE DIAGNOSISMTC-53

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Insufficient HeatingINFOID:0000000005930855

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERAT IONAL CHECK - TEMPERATURE INCREASE

1. Turn temperature control dial clockwise to maximum heat position.

2. Check for hot air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to MTC-31, "

Operational Check" .

Does another symptom exist?

YES >> Refer to MTC-23, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK COOLANT SYSTEM

1. Check engine coolant level. Refer to CO-11, "

Inspection" (HR16DE) or CO-36, "Inspection" (MR18DE).

2. Check hoses for leaks or kinks.

3. Check Radiator cap. Refer to CO-14, "

Checking Radiator Cap" HR16DE or CO-39, "Checking Radiator

Cap" (MR18DE).

OK or NG

OK >> GO TO 5.

NG >> Repair/replace as necessary.

5.CHECK AIR MIX DOOR CABLE

Check air mix door cable operation. Refer to MTC-65, "

Air Mix Door Cable Adjustment" .

OK or NG

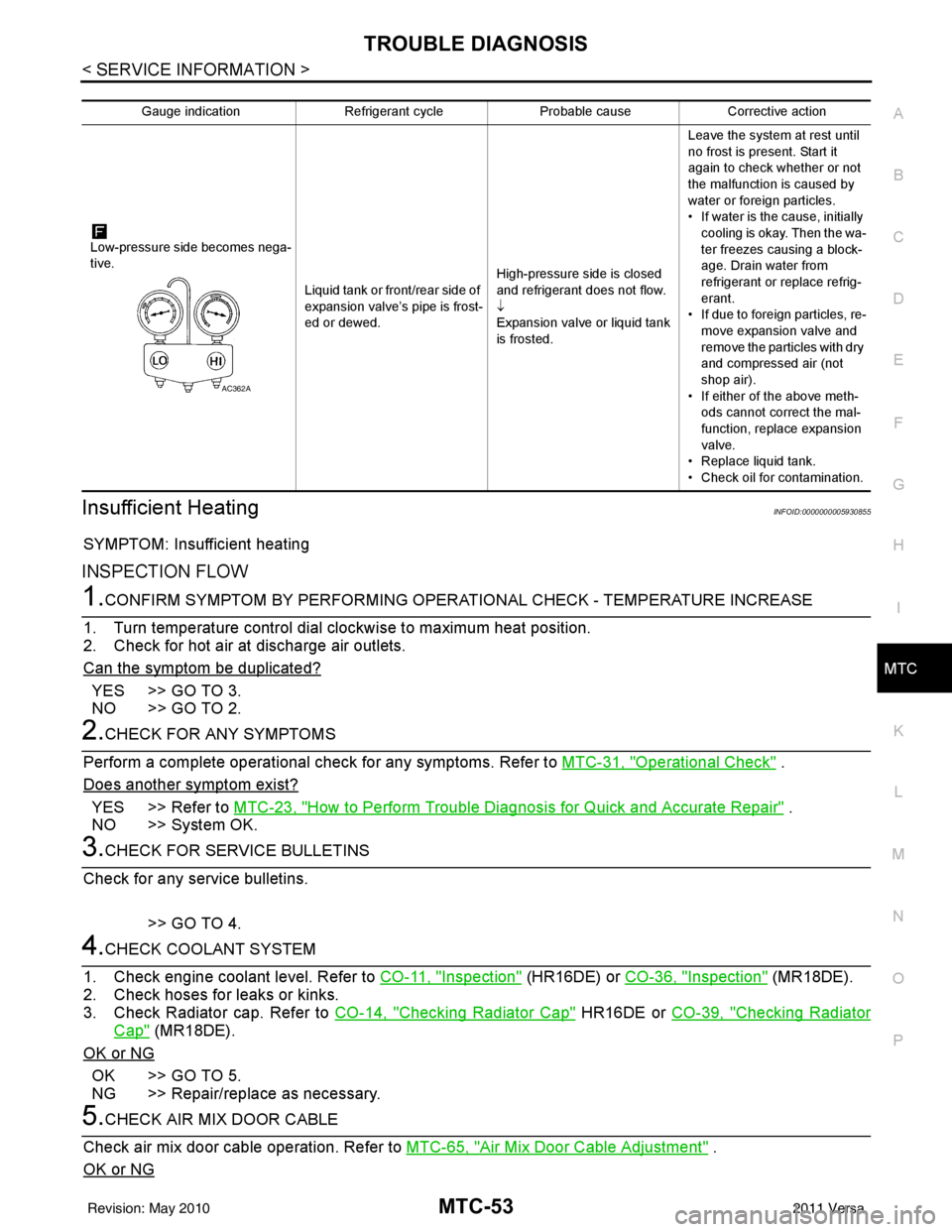

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve’s pipe is frost-

ed or dewed.High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: May 2010 2011 Versa