Engine front side NISSAN TIIDA 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 2601 of 3787

![NISSAN TIIDA 2011 Service Manual PDF CYLINDER BLOCKEM-211

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

26. Install flywheel (M/T models) or drive plate (1) (A/T or CVT mod-

els).

• Secure crankshaft using Tool (A), NISSAN TIIDA 2011 Service Manual PDF CYLINDER BLOCKEM-211

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

26. Install flywheel (M/T models) or drive plate (1) (A/T or CVT mod-

els).

• Secure crankshaft using Tool (A),](/img/5/57396/w960_57396-2600.png)

CYLINDER BLOCKEM-211

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

26. Install flywheel (M/T models) or drive plate (1) (A/T or CVT mod-

els).

• Secure crankshaft using Tool (A), and tighten bolts crosswiseover several times.

NOTE:

A/T model shown CVT and M/T similar.

• Install pilot converter (3), drive plate (1) and reinforcement plate (2) as shown (A/T or CVT models).

• Using a suitable tool of 33 mm (1.30 in) in diameter, press-fit pilot converter into the end of crankshaft until it stops (A/T or

CVT models).

NOTE:

M/T models have no pilot converter and reinforcement plate.

27. Install knock sensor (1) with connector facing toward the rear of engine.

CAUTION:

• Never tighten bolts while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Make sure that there is no foreign material on the cylinder

block mating surface and the back surface of knock sensor.

• Make sure that knock sensor does not interfere with other parts.

28. Install crankshaft position sensor (POS) and crankshaft position sensor (POS) cover.

CAUTION:

• Avoid impacts such as a dropping.

• Keep it away from metal particles.

• Never place sensor in a location wher e it is exposed to magnetism.

29. Install oil filter (for intake valve timing control) (1) in the direction shown.

• Make sure that the oil filter does not protrude from the uppersurface of cylinder block (2) after installation.

30. Assembly is in the reverse order of disassembly. Tool number : KV11105210 (J-44716)

PBIC3998E

A : Crankshaft rear end

B : Rounded

C : Chamfered

PBIC3259J

A : Cylinder block left side

: Engine front

PBIC3246J

PBIC3260J

Revision: May 2010 2011 Versa

Page 2602 of 3787

![NISSAN TIIDA 2011 Service Manual PDF EM-212

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

How to Select Piston and Bearing

INFOID:0000000005931034

DESCRIPTION

• The identification grade stamped on each part is the grade for the dimen NISSAN TIIDA 2011 Service Manual PDF EM-212

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

How to Select Piston and Bearing

INFOID:0000000005931034

DESCRIPTION

• The identification grade stamped on each part is the grade for the dimen](/img/5/57396/w960_57396-2601.png)

EM-212

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

How to Select Piston and Bearing

INFOID:0000000005931034

DESCRIPTION

• The identification grade stamped on each part is the grade for the dimension measured in new condition.

This grade cannot apply to reused parts.

• For reused or repaired parts, measure the dimension accurately. Determine the grade by comparing the measurement with the values of each selection table.

• For details of the measurement method of each part, the reuse standar ds and the selection method of the

selective fitting parts, follow the applicable procedures.

HOW TO SELECT PISTON

When New Cylinder Block is Used

• Check the cylinder bore grade on rear left side of cylinder block (L), and select piston of the same grade.

• If there is a correction stamp mark on the cylinder block, use it as a

correct reference.

When Cylinder Block is Reused

1. Measure the cylinder bore inner diameter. Refer to EM-219, "Inspection After Disassembly".

2. Determine the bore grade by comparing the measur ement with the values under the cylinder bore inner

diameter of the “Piston Selection Table”.

Selection points Selection parts Selection itemsSelection methods

Between cylinder block and

crankshaft Main bearing

Main bearing grade (bearing

thickness) Determined by match of cylin-

der block bearing housing

grade (inner diameter of hous-

ing) and crankshaft journal

grade (outer diameter of jour-

nal)

Between crankshaft and con-

necting rod Connecting rod bearing

Connecting rod bearing grade

(bearing thickness) Combining service grades for

connecting rod big end diame-

ter and crankshaft pin outer di-

ameter determine connecting

rod bearing selection.

Between cylinder block and pis-

ton Piston and piston pin assembly

(piston is available together with

piston pin as an assembly.)Piston grade (piston outer diam-

eter)

Piston grade = cylinder bore

grade (inner diameter of bore)

A : Correction stamp

B : Standard stamp

C : Cylinder No. 1 bore grade

D : Cylinder No. 2 bore grade

E : Cylinder No. 3 bore grade

F : Cylinder No. 4 bore grade

G : No. 1 main bearing housing grade

H : No. 2 main bearing housing grade

I : No. 3 main bearing housing grade

J : No. 4 main bearing housing grade

K : No. 5 main bearing housing grade

: Engine front

PBIC3264J

Revision: May 2010 2011 Versa

Page 2606 of 3787

![NISSAN TIIDA 2011 Service Manual PDF EM-216

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

1. “Main Bearing Selection Table” rows correspond to main bearing

housing grade on rear left side of cylinder block (L).

• If there is a cor NISSAN TIIDA 2011 Service Manual PDF EM-216

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

1. “Main Bearing Selection Table” rows correspond to main bearing

housing grade on rear left side of cylinder block (L).

• If there is a cor](/img/5/57396/w960_57396-2605.png)

EM-216

< SERVICE INFORMATION >[MR18DE]

CYLINDER BLOCK

1. “Main Bearing Selection Table” rows correspond to main bearing

housing grade on rear left side of cylinder block (L).

• If there is a correction stamp mark on cylinder block, use it asa correct reference.

2. Apply main journal diameter grade stamped on crankshaft front side to column in the “Main Bearing Selection Table”.

3. Read the symbol at the cross point of selected ro w and column in the “Main Bearing Selection Table”.

CAUTION:

There are two main bearing selection tables. One is for No. 1, 4 and 5 journals and the other is for

No. 2 and 3 journals. Make certain to use the approp riate table. This is due to differences in the

specified clearances.

4. Apply the symbol obtained to the “Main Bearing Grade Table” to select main bearing. NOTE:

Service part is available as a set of both upper and lower.

When Cylinder Block and Crankshaft are Reused

1. Measure the dimensions of the cylinder block ma in bearing housing inner diameter and crankshaft main

journal diameter individually. Refer to EM-219, "

Inspection After Disassembly" and EM-219, "Inspection

After Disassembly".

2. Apply the measured dimension to the “Main Bearing Selection Table”.

3. Read the symbol at the cross point of selected ro w and column in the “Main Bearing Selection Table”.

CAUTION:

There are two main bearing selection tables. One is for No. 1, 4 and 5 journals and the other is for

No. 2 and 3 journals. Make certain to use the appr opriate table. This is due to differences in the

specified clearances.

4. Apply the symbol obtained to the “Main Bearing Grade Table” to select main bearing. NOTE:

A : Correction stamp

B : Standard stamp

C : Cylinder No. 1 bore grade

D : Cylinder No. 2 bore grade

E : Cylinder No. 3 bore grade

F : Cylinder No. 4 bore grade

G : No. 1 main bearing housing grade

H : No. 2 main bearing housing grade

I : No. 3 main bearing housing grade

J : No. 4 main bearing housing grade

K : No. 5 main bearing housing grade

: Engine front

PBIC3264J

A : No. 1 pin journal diameter grade

B : No. 2 pin journal diameter grade

C : No. 3 pin journal diameter grade

D : No. 4 pin journal diameter grade

E : No. 1 main journal diameter grade

F : No. 2 main journal diameter grade

G : No. 3 main journal diameter grade

H : No. 4 main journal diameter grade

I : No. 5 main journal diameter grade

PBIC3261J

Revision: May 2010 2011 Versa

Page 2613 of 3787

![NISSAN TIIDA 2011 Service Manual PDF CYLINDER BLOCKEM-223

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Measure the outer diameter of

piston pin with a micrometer (A).

Connecting Rod Bushing Oil Clearance

(Connecting NISSAN TIIDA 2011 Service Manual PDF CYLINDER BLOCKEM-223

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Measure the outer diameter of

piston pin with a micrometer (A).

Connecting Rod Bushing Oil Clearance

(Connecting](/img/5/57396/w960_57396-2612.png)

CYLINDER BLOCKEM-223

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Measure the outer diameter of

piston pin with a micrometer (A).

Connecting Rod Bushing Oil Clearance

(Connecting rod bushing oil clearance) = (Connecting rod bus hing inner diameter) – (Piston pin outer diame-

ter)

• If the measured value is out of the standard, repl ace connecting rod assembly and/or piston and piston pin

assembly.

• If replacing piston and piston pin assembly, follow t he "PISTON TO PISTON PIN OIL CLEARANCE" proce-

dure.

• If replacing connecting rod assembly, follow the "Connecting Rod Bushing Oil Clearance" procedure to select connecting rod bearing.

CYLINDER BLOCK TOP SURFACE DISTORTION

• Using a scraper, remove gasket on the cylinder block surface, and also remove engine oil, scale, carbon, or

other contamination.

CAUTION:

Be careful not to allow gasket flakes to en ter engine oil or engine coolant passages.

• Measure the distortion on the cylinder block upper face at some

different points in six directions with a straight edge (A) and feeler

gauge (B).

• If it exceeds the limit, replace cylinder block.

MAIN BEARING HOUSING INNER DIAMETER

• Install main bearing cap without main bearings insta lled, and tighten main bearing cap bolts to the specified

torque. Refer to EM-203, "

Disassembly and Assembly" for the tightening procedure.

• Measure the inner diameter of main bearing housing with a bore gauge.

• Measure the position shown [5 mm (0.20 in)] backward from main bearing housing front side in the 2 directions as shown. The

smaller one is the measured value.

• If out of the standard, replace cylinder block and main bearing caps assembly.

NOTE: Standard: 19.989 - 19.995 mm (0.7870 - 0.7872 in)

PBIC3266J

Standard : 0.005 - 0.023 mm (0.0002 - 0.0009 in)

Limit : 0.03 mm (0.0012 in)

Limit: 0.1 mm (0.004 in)

PBIC3250J

1 : Cylinder block

2 : Main bearing cap

: Engine front

Standard: 55.997 - 56.017 mm (2.2046 - 2.2054 in)

PBIC4005E

Revision: May 2010 2011 Versa

Page 2636 of 3787

![NISSAN TIIDA 2011 Service Manual PDF EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bear

ings with new ones when instal NISSAN TIIDA 2011 Service Manual PDF EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bear

ings with new ones when instal](/img/5/57396/w960_57396-2635.png)

EX-6

< ON-VEHICLE REPAIR >[HR16DE]

EXHAUST SYSTEM

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bear

ings with new ones when installing.

• Before installing a new heated oxygen sensor, clean and apply anti-seize lubricant to exhaust sys-

tem threads using suitable tool.

• Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a co ncrete floor; install a new one.

• Do not over-tighten the heated oxygen sensor. Doing so may damage the heated oxygen sensor,

resulting in the MIL coming on.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

• Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

• When installing each mounting rubb er, avoid twisting or unusual extension in up/down and right/left

directions.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in

the direction shown.

• Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4). • Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side

in the direction shown.

• Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten bolt (4). • Be careful that the stud bolt does not interfere with the flanged

area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

INSPECTION AFTER INSTALLATION

• With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

• Check to ensure that brackets and mounting rubber s are installed properly and free from undue stress.

Improper installation could result in excessive noise and vibration. Oxygen sensor thread cleaner : — (J-43897-18)

Oxygen sensor thread cleaner : — (J-43897-12)

PBIC3797E

PBIC3798E

Revision: May 2010

2011 Versa

Page 2641 of 3787

![NISSAN TIIDA 2011 Service Manual PDF EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

CAUTION:

• Use genuine NISSAN exhaust system parts or equi

valent, which are specially designed for heat

resistan NISSAN TIIDA 2011 Service Manual PDF EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

CAUTION:

• Use genuine NISSAN exhaust system parts or equi

valent, which are specially designed for heat

resistan](/img/5/57396/w960_57396-2640.png)

EXHAUST SYSTEMEX-11

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EX

NP

O

CAUTION:

• Use genuine NISSAN exhaust system parts or equi

valent, which are specially designed for heat

resistance, corrosion resistance and shape.

REMOVAL

Remove exhaust system components using power tools.

• Remove heated oxygen sensor using Tool as needed.

CAUTION:

Be careful not to damage heated oxygen sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Always replace exhaust gaskets and seal bearings with new ones when installing.

• Before installing a new heated oxygen sensor, clean and apply an ti-seize lubricant to exhaust sys-

tem threads using suitable tool.

• Discard any heated oxygen sensor which has been dr opped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a co ncrete floor; install a new one.

• Do not over-tighten the heated oxygen sensor. Doing so may damage the heated oxygen sensor, resulting in the MIL coming on.

• Remove deposits from the sealing surface of each connection. Connect them securely to avoid

exhaust leakage.

• Temporarily tighten nuts on the exhaust manifold side and bolts on the vehicle side. Check each part

for unusual interference, and then tighten them to the specified torque.

• When installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left

directions.

Exhaust Manifold to Exhaust Front Tube

1. Securely insert seal bearing (2) into exhaust manifold (1) side in the direction shown.

• Exhaust front tube (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten nut (4). • Be careful that the stud bolt nut does not interfere with the

flanged area ( ).

• Make sure the spring (3) sits properly on the flange surface by aligning it to the locator dimples.

Exhaust Front Tube to Center Muffler

1. Securely insert seal bearing (2) into exhaust front tube (1) side in the direction shown.

• Center muffler (5)

CAUTION:

Be careful not to damage seal bearing surface when install-

ing.

2. Install spring (3), tighten bolt (4). • Be careful that the stud bolt does not interfere with the flanged

area ( ).

• Make sure the spring (3) sits properly on the flange surface by

aligning it to the locator dimples.

INSPECTION AFTER INSTALLATION

• With the engine running, check exhaust tube joints for exhaust leakage and unusual noise.

Tool number : KV10114400 (J-38365)

Oxygen sensor thread cleaner : — (J-43897-18)

Oxygen sensor thread cleaner : — (J-43897-12)

PBIC3797E

PBIC3798E

Revision: May 2010

2011 Versa

Page 2742 of 3787

GI-38

< SERVICE INFORMATION >

LIFTING POINT

LIFTING POINT

Special Service ToolINFOID:0000000005929733

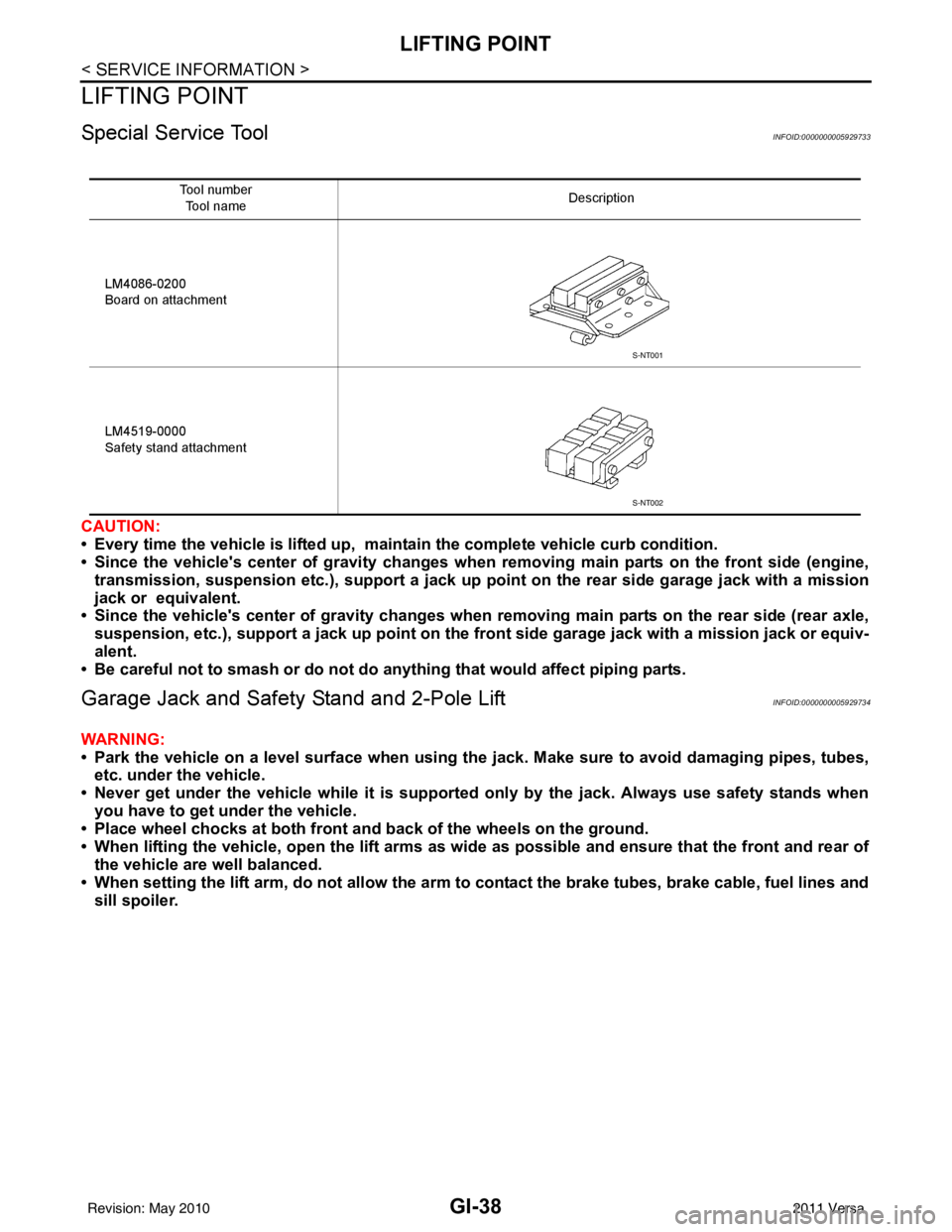

CAUTION:

• Every time the vehicle is lifted up, maintain the complete vehicle curb condition.

• Since the vehicle's center of gravity changes when removing main parts on the front side (engine,

transmission, suspension etc.), support a jack up point on the rear side garage jack with a mission

jack or equivalent.

• Since the vehicle's center of gravity changes when removing main parts on the rear side (rear axle,

suspension, etc.), support a jack up point on the front side garage jack with a mission jack or equiv-

alent.

• Be careful not to smash or do not do an ything that would affect piping parts.

Garage Jack and Safety Stand and 2-Pole LiftINFOID:0000000005929734

WARNING:

• Park the vehicle on a level surface when using the jack. Make sure to avoid damaging pipes, tubes,

etc. under the vehicle.

• Never get under the vehicle while it is supported only by the jack. Always use safety stands when you have to get under the vehicle.

• Place wheel chocks at both front an d back of the wheels on the ground.

• When lifting the vehicle, open the lift arms as wid e as possible and ensure that the front and rear of

the vehicle are well balanced.

• When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

Tool number

Tool name Description

LM4086-0200

Board on attachment

LM4519-0000

Safety stand attachment

S-NT001

S-NT002

Revision: May 2010 2011 Versa

Page 2748 of 3787

GI-44

< SERVICE INFORMATION >

IDENTIFICATION INFORMATION

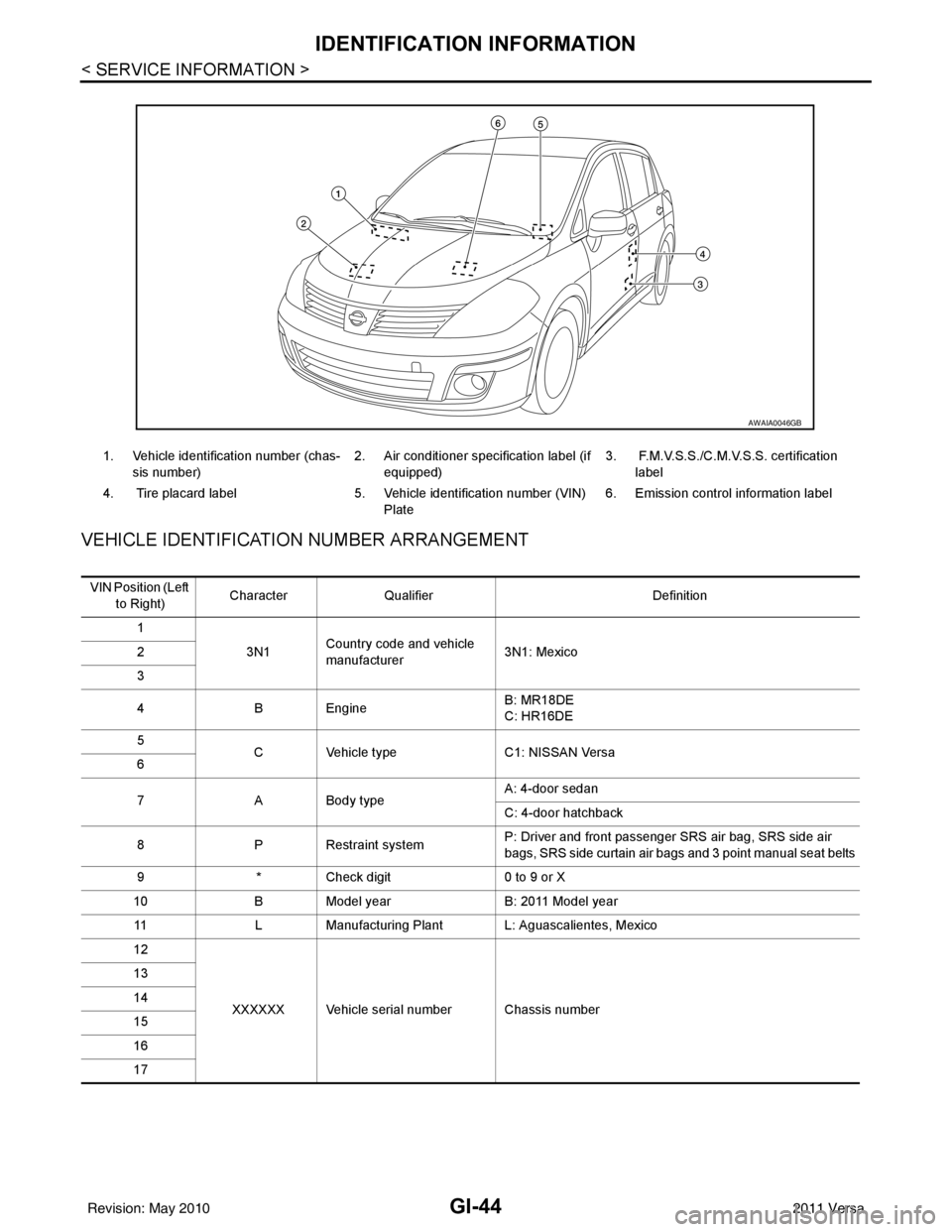

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Vehicle identification number (chas-

sis number) 2. Air conditioner specification label (if

equipped) 3. F.M.V.S.S./C.M.V.S.S. certification

label

4. Tire placard label 5. Vehicle identification number (VIN)

Plate 6. Emission control information label

AWAIA0046GB

VIN Position (Left

to Right) Character

Qualifier Definition

1 3N1Country code and vehicle

manufacturer

3N1: Mexico

2

3

4 B Engine B: MR18DE

C: HR16DE

5 C Vehicle type C1: NISSAN Versa

6

7 A Body type A: 4-door sedan

C: 4-door hatchback

8 P Restraint system P: Driver and front passenger SRS air bag, SRS side air

bags, SRS side curtain air bags and 3 point manual seat belts

9 * Check digit 0 to 9 or X

10 B Model year B: 2011 Model year

11 L Manufacturing Plant L: Aguascalientes, Mexico

12

XXXXXX Vehicle serial number Chassis number

13

14

15

16

17

Revision: May 2010

2011 Versa

Page 3073 of 3787

FRONT FOG LAMPLT-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

FRONT FOG LAMP

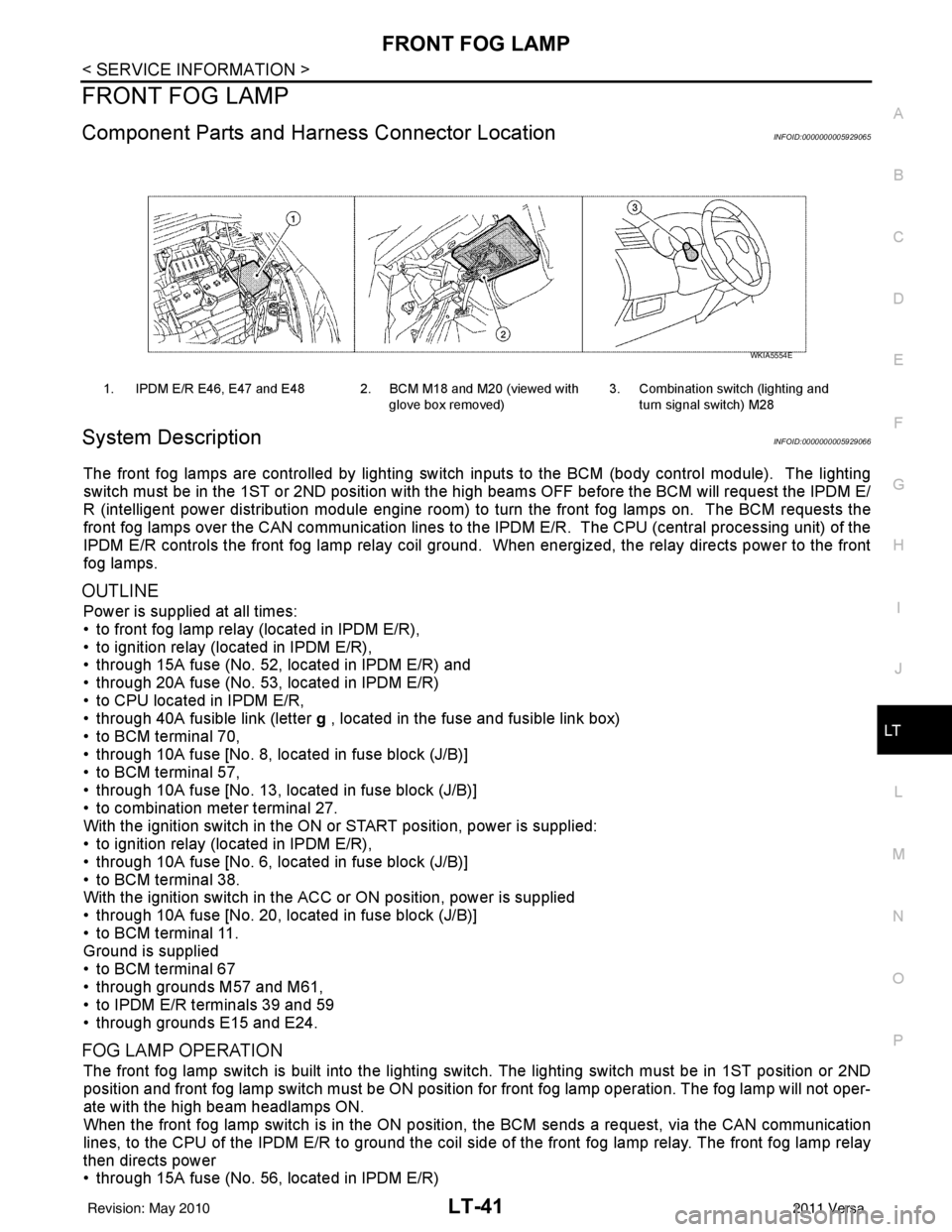

Component Parts and Har ness Connector LocationINFOID:0000000005929065

System DescriptionINFOID:0000000005929066

The front fog lamps are controlled by lighting switch inputs to the BCM (body control module). The lighting

switch must be in the 1ST or 2ND position with the high beams OFF before the BCM will request the IPDM E/

R (intelligent power distribution module engine room) to turn the front fog lamps on. The BCM requests the

front fog lamps over the CAN communication lines to the IPDM E/R. The CPU (central processing unit) of the

IPDM E/R controls the front fog lamp relay coil ground. When energized, the relay directs power to the front

fog lamps.

OUTLINE

Power is supplied at all times:

• to front fog lamp relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied:

• to ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through grounds M57 and M61,

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

FOG LAMP OPERATION

The front fog lamp switch is built into the lighting switch. The lighting switch must be in 1ST position or 2ND

position and front fog lamp switch must be ON position for front fog lamp operation. The fog lamp will not oper-

ate with the high beam headlamps ON.

When the front fog lamp switch is in the ON positi on, the BCM sends a request, via the CAN communication

lines, to the CPU of the IPDM E/R to ground the coil side of the front fog lamp relay. The front fog lamp relay

then directs power

• through 15A fuse (No. 56, located in IPDM E/R)

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (viewed with

glove box removed)3. Combination switch (lighting and

turn signal switch) M28

WKIA5554E

Revision: May 2010 2011 Versa

Page 3150 of 3787

![NISSAN TIIDA 2011 Service Manual PDF LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Res NISSAN TIIDA 2011 Service Manual PDF LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Res](/img/5/57396/w960_57396-3149.png)

LU-2

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928680

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution for Liquid GasketINFOID:0000000005928682

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2)

as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful no t to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

Tool number : KV10111100 (J-37228)

WBIA0566E

Revision: May 2010 2011 Versa