MTC NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

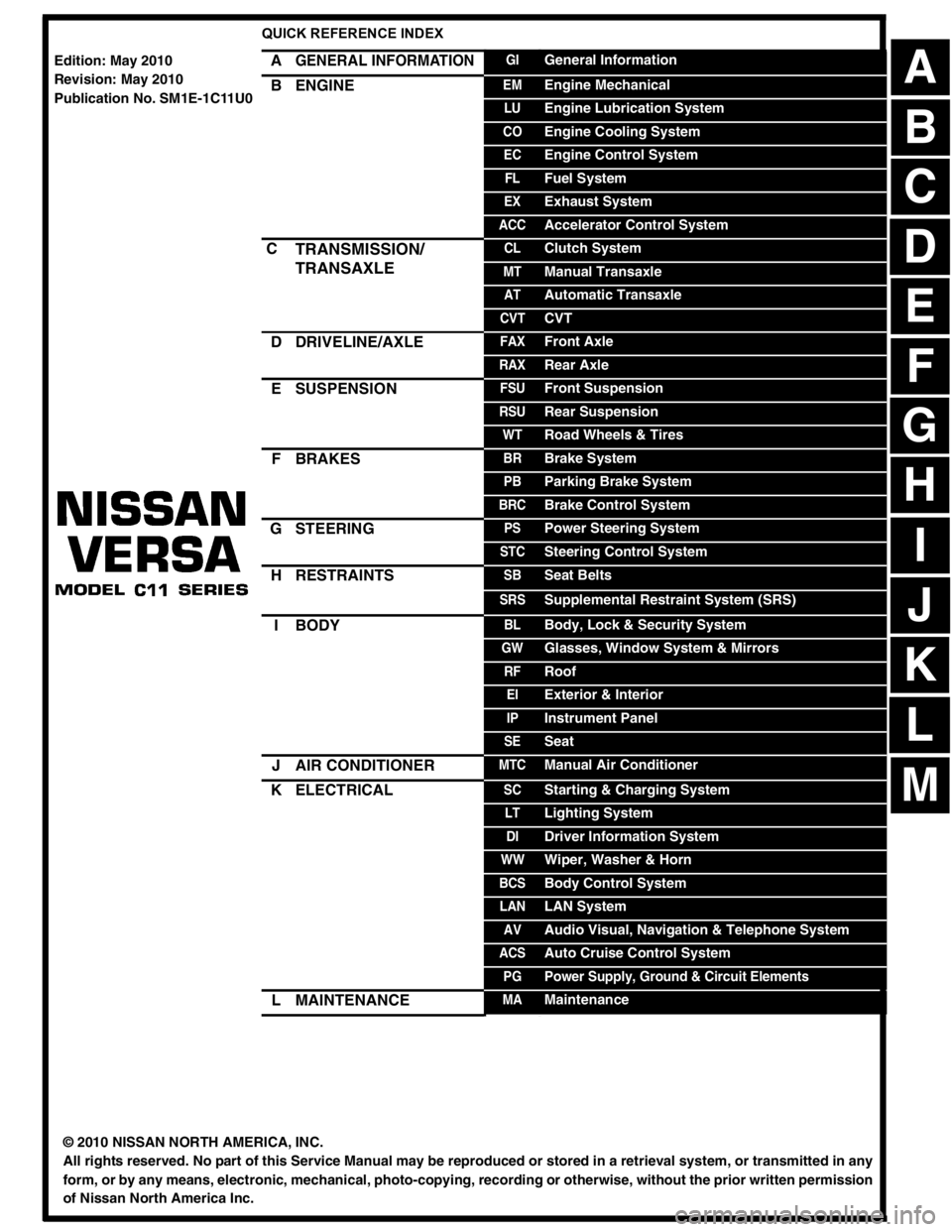

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 1726 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-432

< COMPONENT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Refer to LT-12, "

How to Perform Trouble Diagnosis" (For USA) or LT-35, "How to Perform Troubl NISSAN TIIDA 2011 Service Repair Manual EC-432

< COMPONENT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Refer to LT-12, "

How to Perform Trouble Diagnosis" (For USA) or LT-35, "How to Perform Troubl](/img/5/57396/w960_57396-1725.png)

EC-432

< COMPONENT DIAGNOSIS >[HR16DE]

ELECTRICAL LOAD SIGNAL

>> INSPECTION END

3.CHECK HEADLAMP SYSTEM

Refer to LT-12, "

How to Perform Trouble Diagnosis" (For USA) or LT-35, "How to Perform Trouble Diagnosis"

(For Canada).

>> INSPECTION END

4.CHECK HEATER FAN CONTROL SYSTEM

Refer to MTC-23, "

How to Perform Trouble Diagnosis for Quick and Accurate Repair".

>> INSPECTION END

Revision: May 2010 2011 Versa

Page 1757 of 3787

![NISSAN TIIDA 2011 Service Repair Manual REFRIGERANT PRESSURE SENSOREC-463

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check th NISSAN TIIDA 2011 Service Repair Manual REFRIGERANT PRESSURE SENSOREC-463

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check th](/img/5/57396/w960_57396-1756.png)

REFRIGERANT PRESSURE SENSOREC-463

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Is the inspection result normal?

YES >> GO TO 8.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F8, E8

• Harness for open or short between ECM and refrigerant pressure sensor

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK INTERMITTENT INCIDENT

Refer to EC-122, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace refrigerant pressure sensor. Refer to MTC-76, "Component".

NO >> Repair or replace.

Revision: May 2010 2011 Versa

Page 1783 of 3787

![NISSAN TIIDA 2011 Service Repair Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-489

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MEC NISSAN TIIDA 2011 Service Repair Manual ENGINE CONTROL SYSTEM SYMPTOMSEC-489

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MEC](/img/5/57396/w960_57396-1782.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-489

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER

Crankshaft position sensor (POS) circuit 2 2

EC-267

Camshaft position sensor (PHASE) circuit 3 2EC-272

Vehicle speed signal circuit2 3 33EC-351

ECM 22333333333 EC-357EC-359

Intake valve timing control solenoid valve cir-

cuit32 13223 3

EC-146

PNP signal circuit3 3 3 33EC-366

Refrigerant pressure sensor circuit 233 4 EC-460

Electrical load signal circuit 3EC-431

Air conditioner circuit 223333333 3 2 MTC-23

ABS actuator and electric unit (control unit)4 BRC-9

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: May 2010 2011 Versa

Page 1887 of 3787

![NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISEC-593

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & O NISSAN TIIDA 2011 Service Repair Manual TROUBLE DIAGNOSISEC-593

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & O](/img/5/57396/w960_57396-1886.png)

TROUBLE DIAGNOSISEC-593

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1 - 6: The numbers refer to the order of inspection.

(continued on next table)

SYSTEM — ENGINE MECHANICAL & OTHER

Camshaft position sensor (PHASE) circuit 3 2

EC-799

Vehicle speed signal circuit2 3 33EC-887

ECM 22333333333 EC-895

Intake valve timing control solenoid valve cir-

cuit32 13223 3

EC-659

Park/neutral position (PNP) signal circuit3 3 3 33EC-903

Refrigerant pressure sensor circuit 233 4 EC-1028

Electrical load signal circuit 3EC-1007

Air conditioner circuit 223333333 3 2 MTC-23

ABS actuator and electric unit (control unit)4 BRC-46

SYMPTOM

Reference

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: May 2010 2011 Versa

Page 2144 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-850

< SERVICE INFORMATION >[MR18DE]

DTC P0451 EVAP CONTROL

SYSTEM PRESSURE SENSOR

• Refrigerant pressure sensor (Refer to MTC-38, "Magnet Clutch Circuit (If Equipped)".)

• Crankshaft position NISSAN TIIDA 2011 Service Repair Manual EC-850

< SERVICE INFORMATION >[MR18DE]

DTC P0451 EVAP CONTROL

SYSTEM PRESSURE SENSOR

• Refrigerant pressure sensor (Refer to MTC-38, "Magnet Clutch Circuit (If Equipped)".)

• Crankshaft position](/img/5/57396/w960_57396-2143.png)

EC-850

< SERVICE INFORMATION >[MR18DE]

DTC P0451 EVAP CONTROL

SYSTEM PRESSURE SENSOR

• Refrigerant pressure sensor (Refer to MTC-38, "Magnet Clutch Circuit (If Equipped)".)

• Crankshaft position sensor (POS) (Refer to EC-798, "

Component Inspection".)

OK or NG

OK >> GO TO 5.

NG >> Replace malfunctioning components.

5.CHECK APP SENSOR

Refer to EC-969, "

Component Inspection".

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

>> INSPECTION END

7.CHECK EVAP CONTROL SY STEM PRESSURE SENSOR

Refer to EC-850, "

Component Inspection".

OK or NG

OK >> GO TO 8.

NG >> Replace EVAP control system pressure sensor.

8.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

For wiring diagram, refer to EC-853, "

Wiring Diagram".

>> INSPECTION END

Component InspectionINFOID:0000000006342020

EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector connected from EVAP canister.

Always replace O-ring with a new one.

2. Install a vacuum pump to EVAP control system pressure sensor.

3. Turn ignition switch ON and check output voltage between ECM terminal 42 (EVAP control system pressure sensor signal) and

ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Do not apply below -93.3 kP a (-700 mmHg, -27.56 inHg) or

pressure over 101.3 kPa (760 mmHg, 29.92 inHg).

4. If NG, replace EVAP control system pressure sensor.

Applied vacuum kPa (mmHg, inHg) Voltage (V)

Not applied 1.8 - 4.8

-26.7 (-200, -7.87) 2.1 to 2.5 V lower than above value

PBIB3314E

Revision: May 2010 2011 Versa

Page 2150 of 3787

![NISSAN TIIDA 2011 Service Repair Manual EC-856

< SERVICE INFORMATION >[MR18DE]

DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness or connectors.

8.CHECK COMPONENT NISSAN TIIDA 2011 Service Repair Manual EC-856

< SERVICE INFORMATION >[MR18DE]

DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness or connectors.

8.CHECK COMPONENT](/img/5/57396/w960_57396-2149.png)

EC-856

< SERVICE INFORMATION >[MR18DE]

DTC P0452 EVAP CONTROL

SYSTEM PRESSURE SENSOR

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness or connectors.

8.CHECK COMPONENTS

Check the following.

• Refrigerant pressure sensor (Refer to MTC-38, "

Magnet Clutch Circuit (If Equipped)".)

• Crankshaft position sensor (POS) (Refer to EC-798, "

Component Inspection".)

OK or NG

OK >> GO TO 9.

NG >> Replace malfunctioning components.

9.CHECK APP SENSOR

Refer to EC-969, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

>> INSPECTION END

11 .CHECK EVAP CONTROL SYSTEM PRESSURE SE NSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between EVAP control sy stem pressure sensor terminal 1 and ECM terminal

51. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.CHECK EVAP CONTROL SYSTEM PRESSURE SEN SOR INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

ECM terminalSensor terminalReference Wiring Diagram

74 Refrigerant pressure sensor terminal 3 EC-1029, "

Wiring Diagram"

75Crankshaft position sensor (POS) terminal 1 EC-794, "Wiring Diagram"

76EVAP control system pressure sensor terminal 3 EC-853, "Wiring Diagram"

102APP sensor terminal 5 EC-972, "Wiring Diagram"

Continuity should exist.

Revision: May 2010 2011 Versa

Page 2157 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-863

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness NISSAN TIIDA 2011 Service Repair Manual DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-863

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness](/img/5/57396/w960_57396-2156.png)

DTC P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-863

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 8.

NG >> Repair short to ground or short to power in harness or connectors.

8.CHECK COMPONENTS

Check the following.

• Refrigerant pressure sensor (Refer to MTC-38, "

Magnet Clutch Circuit (If Equipped)".)

• Crankshaft position sensor (POS) (Refer to EC-798, "

Component Inspection".)

OK or NG

OK >> GO TO 9.

NG >> Replace malfunctioning components.

9.CHECK APP SENSOR

Refer to EC-969, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

>> INSPECTION END

11 .CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between EVAP control s ystem pressure sensor terminal 1 and ECM terminal

51. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> GO TO 12.

12.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E85, F8

• Harness connectors M69, E7

• Harness connectors B102, M13

• Harness for open or short between EVAP c ontrol system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

13.CHECK EVAP CONTROL SYSTEM PRESSURE SENS OR INPUT SIGNAL CIRCUIT FOR OPEN AND

SHORT

ECM terminalSensor terminalReference Wiring Diagram

74 Refrigerant pressure sensor terminal 3 EC-1029, "

Wiring Diagram"

75Crankshaft position sensor (POS) terminal 1 EC-794, "Wiring Diagram"

76EVAP control system pressure sensor terminal 3 EC-853, "Wiring Diagram"

102APP sensor terminal 5 EC-972, "Wiring Diagram"

Continuity should exist.

Revision: May 2010 2011 Versa

Page 2269 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DTC P2127, P2128 APP SENSOREC-975

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Refrigerant pressure sensor (Refer to

MTC-38, "Magnet Clutch Circuit (If Equipped)".)

OK or NG

O NISSAN TIIDA 2011 Service Repair Manual DTC P2127, P2128 APP SENSOREC-975

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Refrigerant pressure sensor (Refer to

MTC-38, "Magnet Clutch Circuit (If Equipped)".)

OK or NG

O](/img/5/57396/w960_57396-2268.png)

DTC P2127, P2128 APP SENSOREC-975

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

• Refrigerant pressure sensor (Refer to

MTC-38, "Magnet Clutch Circuit (If Equipped)".)

OK or NG

OK >> GO TO 10.

NG >> Replace malfunctioning component.

6.CHECK APP SENSOR 2 GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 104 and APP sensor terminal 1. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

7.CHECK APP SENSOR 2 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 103 and APP sensor terminal 6. Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK APP SENSOR

Refer to EC-975, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> GO TO 9.

9.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

>> INSPECTION END

10.CHECK INTERMITTENT INCIDENT

Refer to EC-632

.

>> INSPECTION END

Component InspectionINFOID:0000000006342194

ACCELERATOR PEDAL POSITION SENSOR

1. Reconnect all harness connectors disconnected.

2. Turn ignition switch ON. Continuity should exist.

Continuity should exist.

Revision: May 2010

2011 Versa

Page 2281 of 3787

![NISSAN TIIDA 2011 Service Repair Manual DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COM NISSAN TIIDA 2011 Service Repair Manual DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COM](/img/5/57396/w960_57396-2280.png)

DTC P2138 APP SENSOREC-987

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

OK or NG

OK >> GO TO 6.

NG >> Repair short to ground or short to power in harness or connectors.

6.CHECK COMPONENTS

Check the following.

• Crankshaft position sensor (POS) (Refer to EC-798, "

Component Inspection".)

• EVAP control system pressure sensor (Refer to EC-850, "

Component Inspection".)

• Refrigerant pressure sensor (Refer to MTC-38, "

Magnet Clutch Circuit (If Equipped)".)

OK or NG

OK >> GO TO 11.

NG >> Replace malfunctioning component.

7.CHECK APP SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between the following; ECM terminal 111 and APP sensor terminal 2,

ECM terminal 104 and APP sensor terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK APP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between the following; ECM terminal 110 and APP sensor terminal 3,

ECM terminal 103 and APP sensor terminal 6.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9.CHECK APP SENSOR

Refer to EC-988, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.REPLACE ACCELERATOR PEDAL ASSEMBLY

1. Replace accelerator pedal assembly.

2. Perform EC-580, "

Accelerator Pedal Released Position Learning".

3. Perform EC-580, "

Throttle Valve Closed Position Learning".

4. Perform EC-580, "

Idle Air Volume Learning".

ECM terminal Sensor terminalReference Wiring Diagram

74 Refrigerant pressure sensor terminal 3 EC-1029, "

Wiring Diagram"

75Crankshaft position sensor (POS) terminal 1 EC-794, "Wiring Diagram"

76EVAP control system pressure sensor terminal 3 EC-853, "Wiring Diagram"

102APP sensor terminal 5 EC-984, "Wiring Diagram"

Continuity should exist.

Continuity should exist.

Revision: May 2010 2011 Versa