Set time NISSAN TIIDA 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: TIIDA, Model: NISSAN TIIDA 2011Pages: 3787, PDF Size: 78.35 MB

Page 57 of 3787

AT-40

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be disp layed on the CONSULT-III screen, not on the GST. For

detail, refer to EC-106, "

CONSULT-III Function" (HR16DE), EC-612, "CONSULT-III Function (ENGINE)"

(MR18DE).

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame dat a (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT- III, GST or ECM DIAGNOSTIC TEST MODE as

described following.

• If the battery cable is disconnected, the diagnosti c trouble code will be cleared within 24 hours.

• When you erase the DTC, using CONSULT-III or GS T is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-95, "

Diagnosis Description" (HR16DE), EC-542, "Emission-related

Diagnostic Information" (MR18DE).

• Diagnostic trouble codes (DTC)

• 1st trip diagnostic trou ble codes (1st trip DTC)

• Freeze frame data

• 1st trip freeze frame data

• System readiness test (SRT) codes

• Test values

HOW TO ERASE DTC (WITH CONSULT-III)

•If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-III “ON” and touch “TRANSMISSION”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Perform “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”. Refer to AT-82, "

Diagnosis Procedure

without CONSULT-III". (The engine warm-up step can be skipped when performing the diagnosis only\

to

erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC-103, "

On Board Diagnosis Function"

(HR16DE), EC-618, "Generic Scan Tool (GST) Function" (MR18DE).

HOW TO ERASE DTC (NO TOOLS)

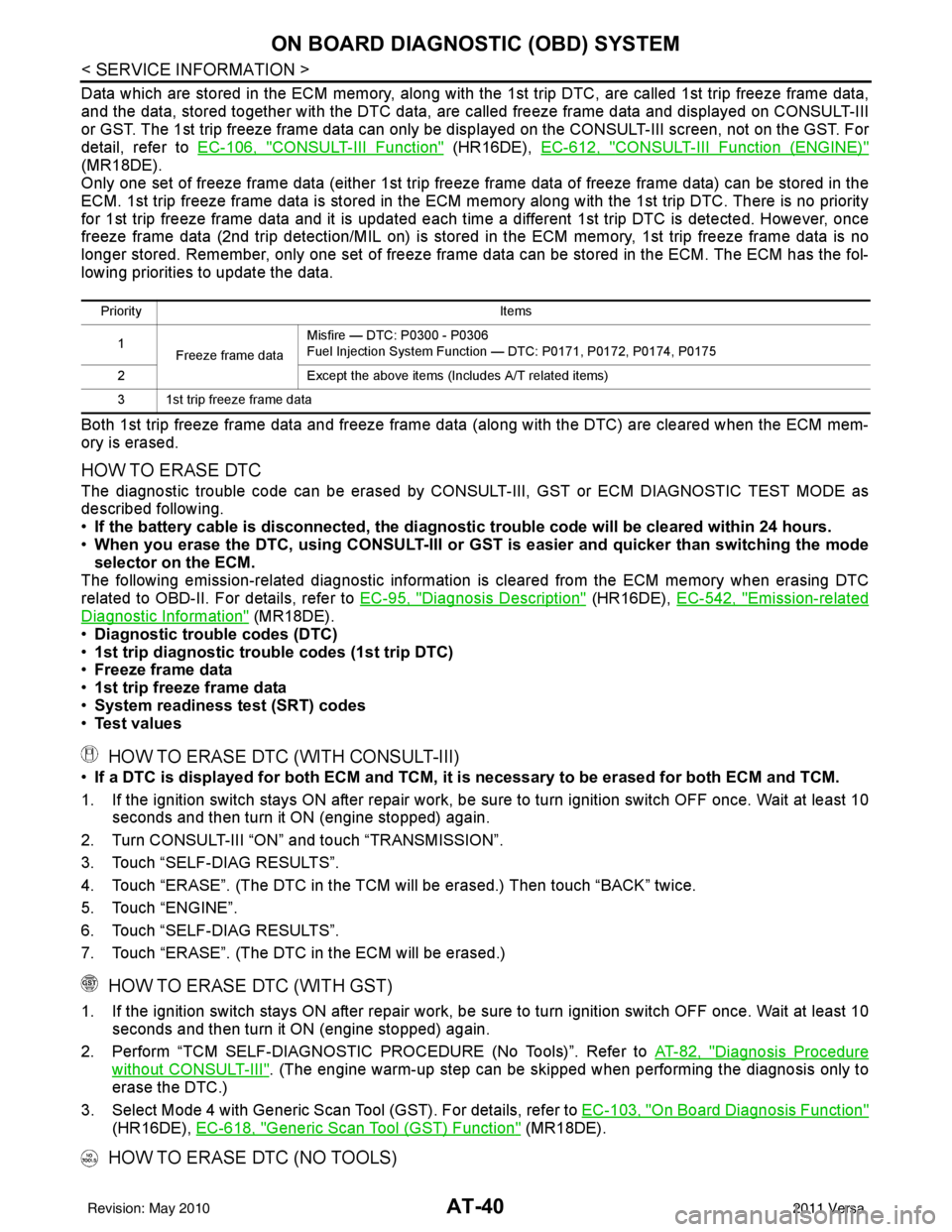

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Revision: May 2010 2011 Versa

Page 94 of 3787

TROUBLE DIAGNOSISAT-77

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

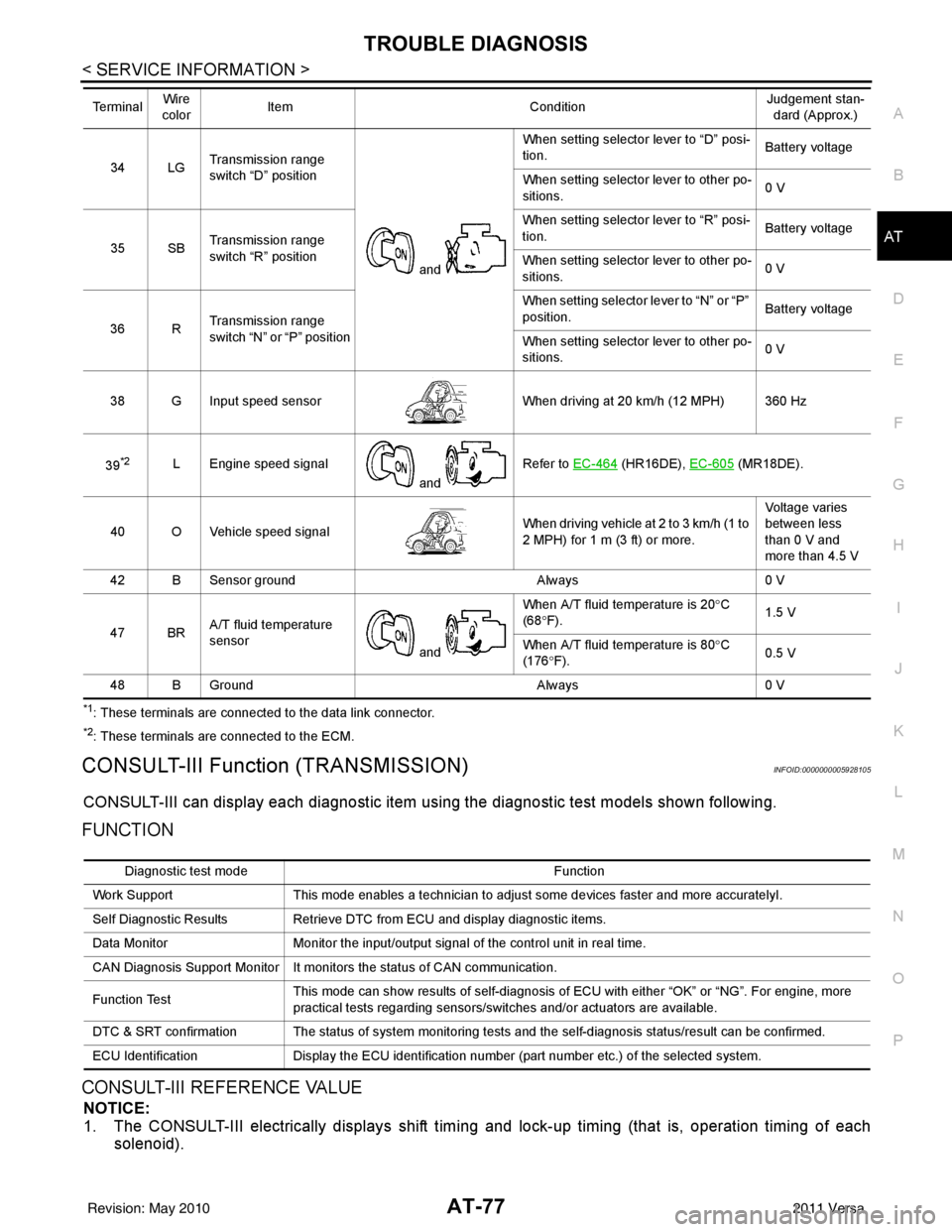

CONSULT-III Function (TRANSMISSION)INFOID:0000000005928105

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

34 LG Transmission range

switch “D” position

and When setting selector lever to “D” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

35 SB Transmission range

switch “R” position When setting selector lever to “R” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

36 R Transmission range

switch “N” or “P” position When setting selector

lever to “N” or “P”

position. Battery voltage

When setting selector lever to other po-

sitions. 0 V

38 G Input speed sensor When driving at 20 km/h (12 MPH) 360 Hz

39

*2L Engine speed signal and Refer to EC-464 (HR16DE),

EC-605 (MR18DE).

40 O Vehicle speed signal When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always0 V

47 BR A/T fluid temperature

sensor

and When A/T fluid temperature is 20°

C

(68 °F). 1.5 V

When A/T fluid temperature is 80° C

(176 °F). 0.5 V

48 B Ground Always0 V

Te r m i n a l

Wire

color Item

ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system.

Revision: May 2010 2011 Versa

Page 95 of 3787

AT-78

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

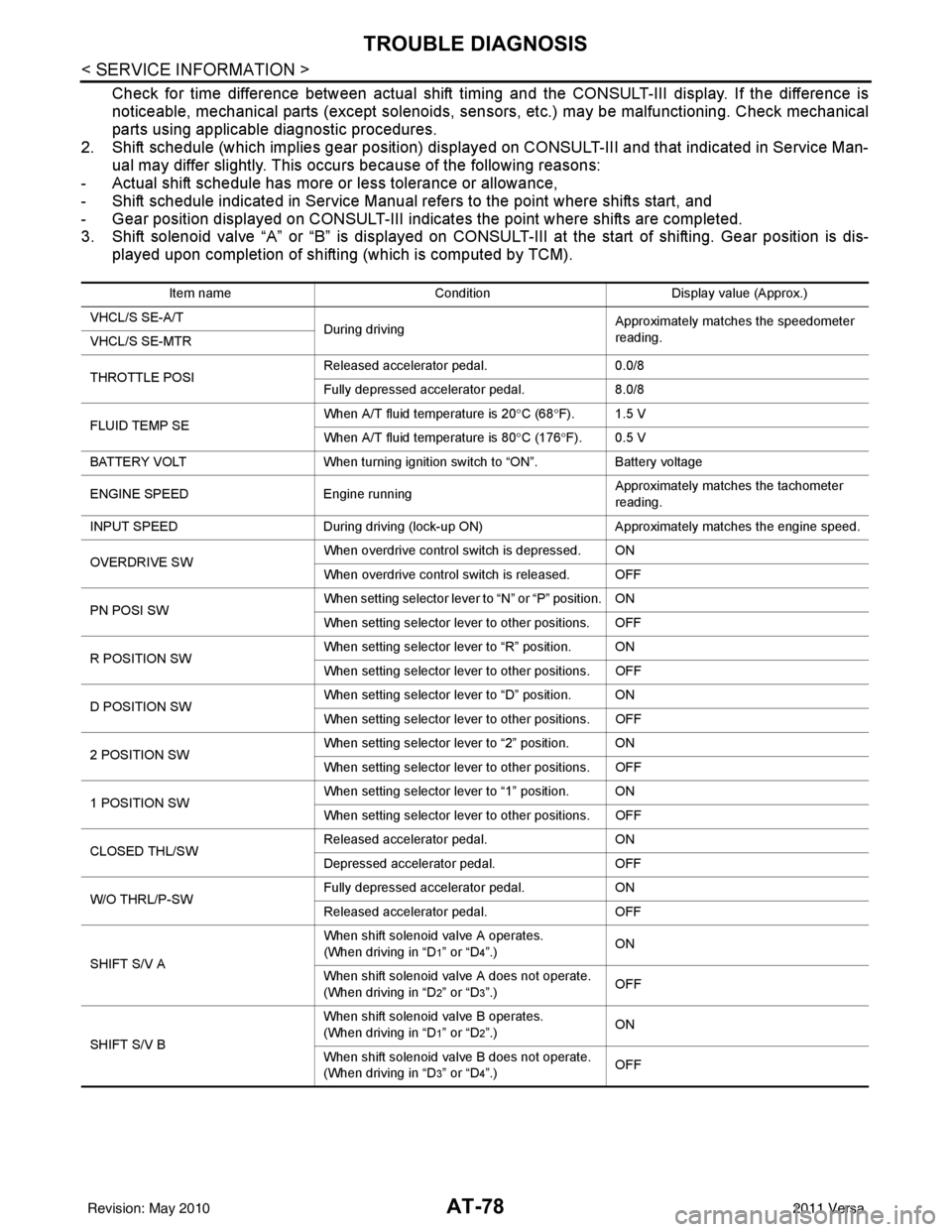

Check for time difference between actual shift timing and the CONSULT-III display. If the difference is

noticeable, mechanical parts (except solenoids, sens ors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) display ed on CONSULT-III and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-III indicates the point where shifts are completed.

3. Shift solenoid valve “A” or “B” is displayed on CONSUL T-III at the start of shifting. Gear position is dis-

played upon completion of shifting (which is computed by TCM).

Item name Condition Display value (Approx.)

VHCL/S SE-A/T During driving Approximately matches the speedometer

reading.

VHCL/S SE-MTR

THROTTLE POSI Released accelerator pedal.

0.0/8

Fully depressed accelerator pedal. 8.0/8

FLUID TEMP SE When A/T fluid temperature is 20

°C (68 °F). 1.5 V

When A/T fluid temperature is 80 °C (176 °F). 0.5 V

BATTERY VOLT When turning ignition switch to “ON”. Battery voltage

ENGINE SPEED Engine running Approximately matches the tachometer

reading.

INPUT SPEED During driving (lock-up ON) Approximately matche s the engine speed.

OVERDRIVE SW When overdrive control switch is depressed. ON

When overdrive control switch is released. OFF

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

CLOSED THL/SW Released accelerator pedal.

ON

Depressed accelerator pedal. OFF

W/O THRL/P-SW Fully depressed accelerator pedal.

ON

Released accelerator pedal. OFF

SHIFT S/V A When shift solenoid valve A operates.

(When driving in “D

1” or “D4”.)

ON

When shift solenoid valve A does not operate.

(When driving in “D

2” or “D3”.) OFF

SHIFT S/V B When shift solenoid valve B operates.

(When driving in “D

1” or “D2”.)

ON

When shift solenoid valve B does not operate.

(When driving in “D

3” or “D4”.) OFF

Revision: May 2010

2011 Versa

Page 507 of 3787

BCM (BODY CONTROL MODULE)BCS-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BCS

N

O P

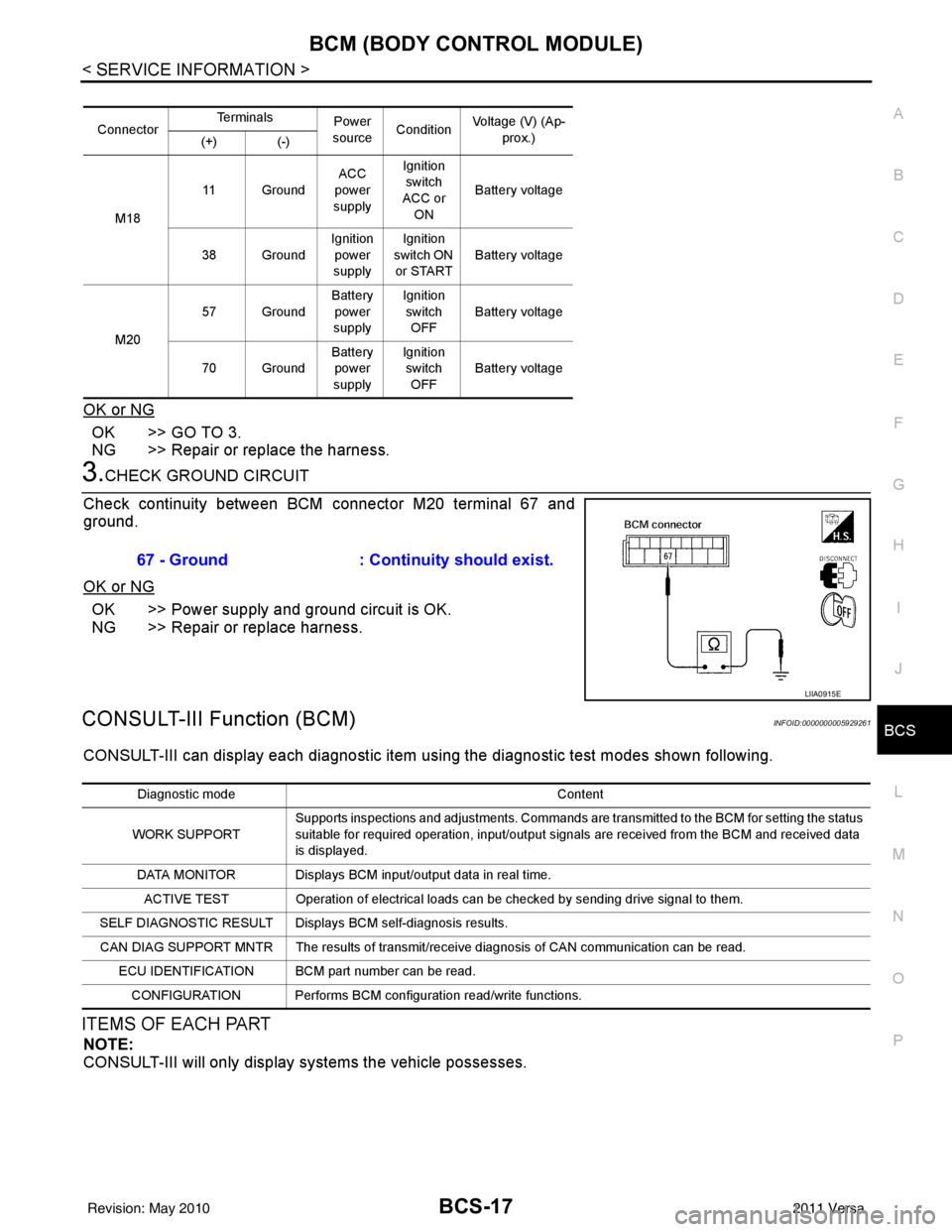

OK or NG

OK >> GO TO 3.

NG >> Repair or replace the harness.

3.CHECK GROUND CIRCUIT

Check continuity between BCM connector M20 terminal 67 and

ground.

OK or NG

OK >> Power supply and ground circuit is OK.

NG >> Repair or replace harness.

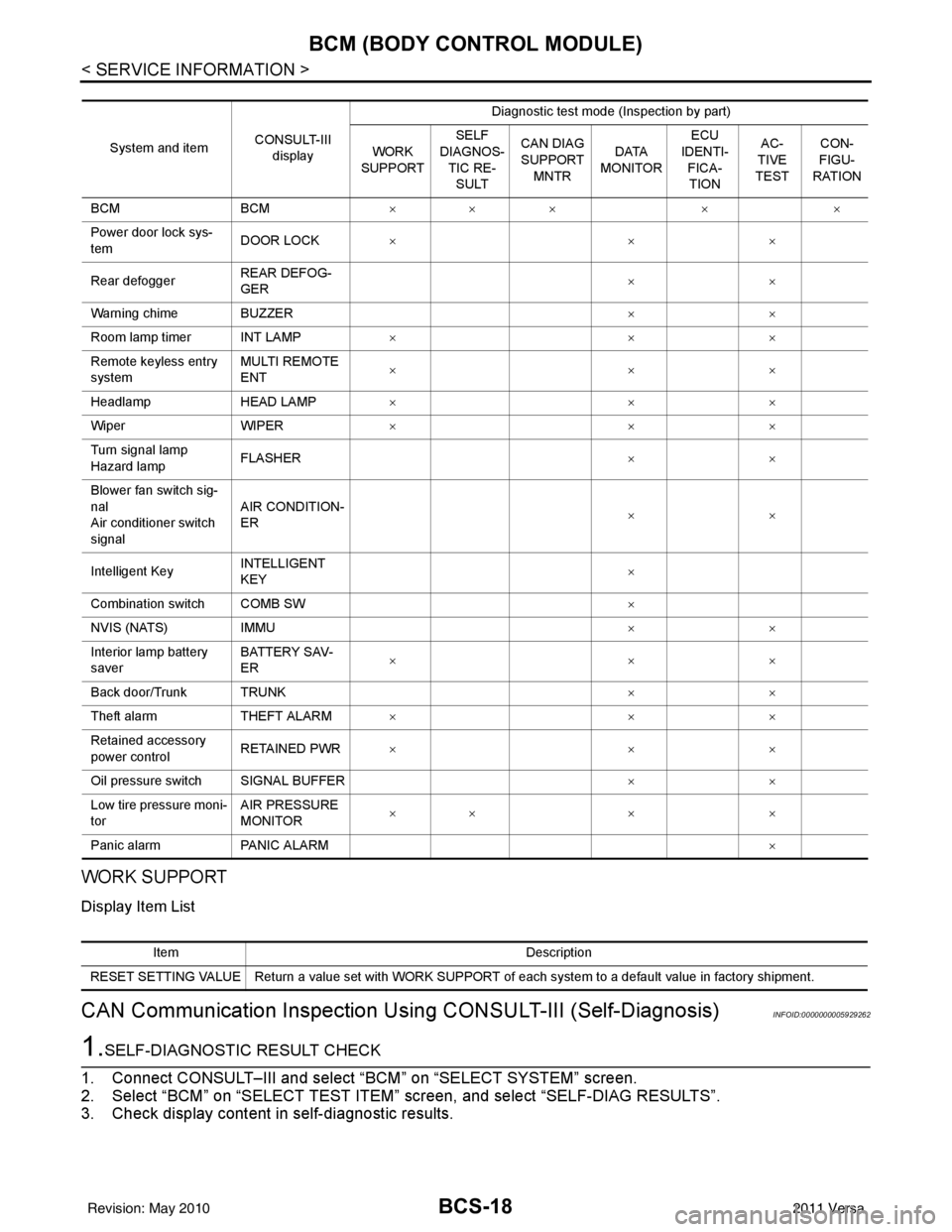

CONSULT-III Function (BCM)INFOID:0000000005929261

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

ITEMS OF EACH PART

NOTE:

CONSULT-III will only display systems the vehicle possesses.

Connector Te r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON

or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

67 - Ground

: Continuity should exist.

LIIA0915E

Diagnostic mode Content

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the status

suitable for required operation, input/output signals are received from the BCM and received data

is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Revision: May 2010 2011 Versa

Page 508 of 3787

BCS-18

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

WORK SUPPORT

Display Item List

CAN Communication Inspection Using CONSULT-III (Self-Diagnosis)INFOID:0000000005929262

1.SELF-DIAGNOSTIC RESULT CHECK

1. Connect CONSULT–III and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT TEST ITEM” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

System and item CONSULT-III

display Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

DIAGNOS- TIC RE-

SULT CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

IDENTI- FICA-

TION AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Remote keyless entry

system MULTI REMOTE

ENT

××

×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch sig-

nal

Air conditioner switch

signal AIR CONDITION-

ER

××

Intelligent Key INTELLIGENT

KEY ×

Combination switch COMB SW ×

NVIS (NATS) IMMU ××

Interior lamp battery

saver BATTERY SAV-

ER

××

×

Back door/Trunk TRUNK ××

Theft alarm THEFT ALARM×× ×

Retained accessory

power control RETAINED PWR

×× ×

Oil pressure swit ch SIGNAL BUFFER ××

Low tire pressure moni-

tor AIR PRESSURE

MONITOR

××

× ×

Panic alarm PANIC ALARM ×

ItemDescription

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

Revision: May 2010 2011 Versa

Page 534 of 3787

BL-24

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• through body grounds M57 and M61.

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 1

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 1

• through rear door switch RH case ground.

When the back door lock assembly (back door switch) ( hatchback) is ON (back door is OPEN), ground is sup-

plied

• to BCM terminal 43

• through back door lock assembly (back door switch) terminals 3 and 4

• through body grounds B117, B132 and D402.

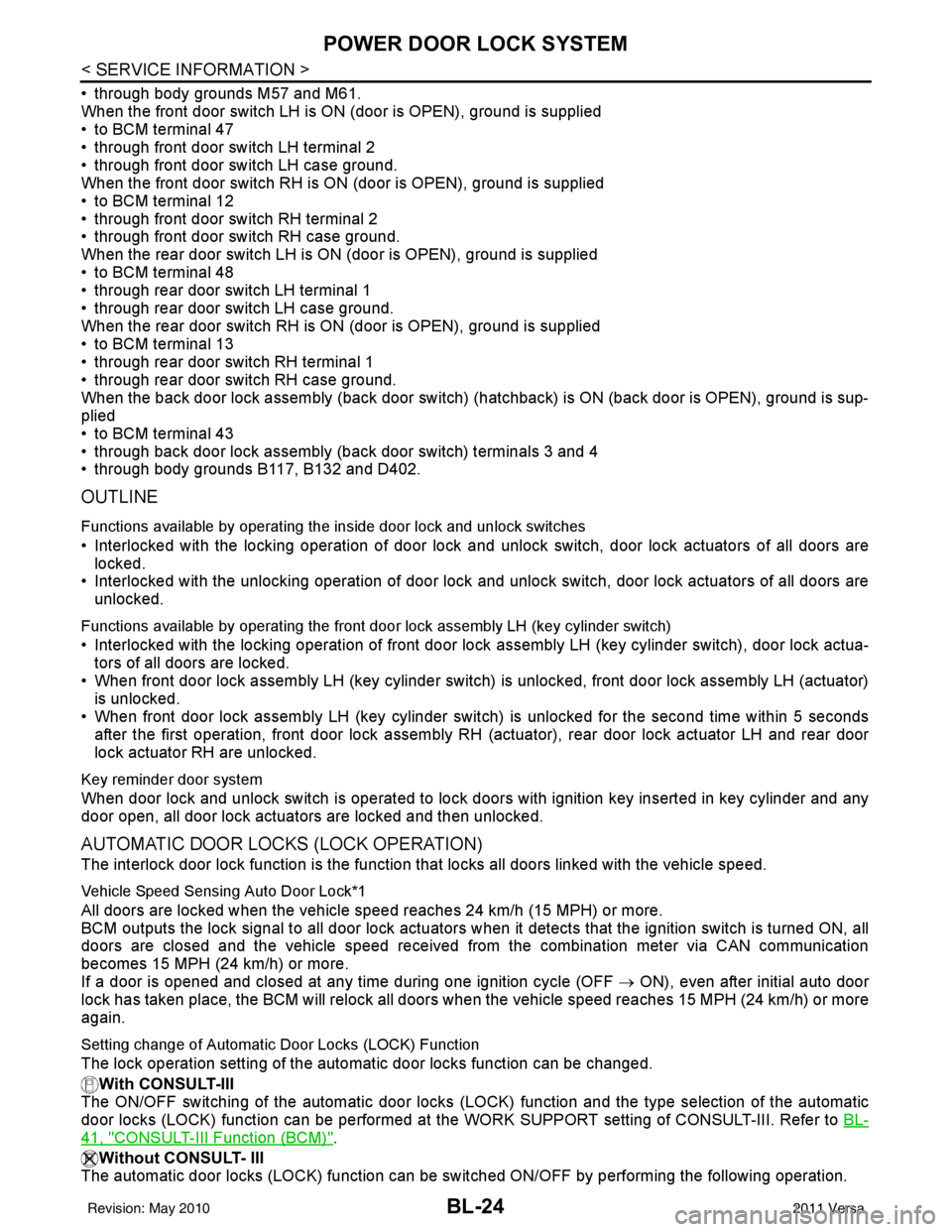

OUTLINE

Functions available by operating the inside door lock and unlock switches

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors are

locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors are

unlocked.

Functions available by operating the front door lock assembly LH (key cylinder switch)

• Interlocked with the locking operation of front door lock assembly LH (key cylinder switch), door lock actua-

tors of all doors are locked.

• When front door lock assembly LH (key cylinder switch) is unlocked, front door lock assembly LH (actuator)

is unlocked.

• When front door lock assembly LH (key cylinder swit ch) is unlocked for the second time within 5 seconds

after the first operation, front door lock assembly RH (actuator), rear door lock actuator LH and rear door

lock actuator RH are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key inserted in key cylinder and any

door open, all door lock actuators are locked and then unlocked.

AUTOMATIC DOOR LOCKS (LOCK OPERATION)

The interlock door lock function is the function that locks all doors linked with the vehicle speed.

Vehicle Speed Sensing Auto Door Lock*1

All doors are locked when the vehicle speed reaches 24 km/h (15 MPH) or more.

BCM outputs the lock signal to all door lock actuators when it detects that the ignition switch is turned ON, all

doors are closed and the vehicle speed received from the combination meter via CAN communication

becomes 15 MPH (24 km/h) or more.

If a door is opened and closed at any time during one ignition cycle (OFF → ON), even after initial auto door

lock has taken place, the BCM will relock all doors when the vehicle speed reaches 15 MPH (24 km/h) or more

again.

Setting change of Automatic Door Locks (LOCK) Function

The lock operation setting of the autom atic door locks function can be changed.

With CONSULT-III

The ON/OFF switching of the automatic door locks (LOC K) function and the type selection of the automatic

door locks (LOCK) function can be performed at the WO RK SUPPORT setting of CONSULT-III. Refer to BL-

41, "CONSULT-III Function (BCM)".

Without CONSULT- III

The automatic door locks (LOCK) function can be swit ched ON/OFF by performing the following operation.

Revision: May 2010 2011 Versa

Page 551 of 3787

POWER DOOR LOCK SYSTEMBL-41

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

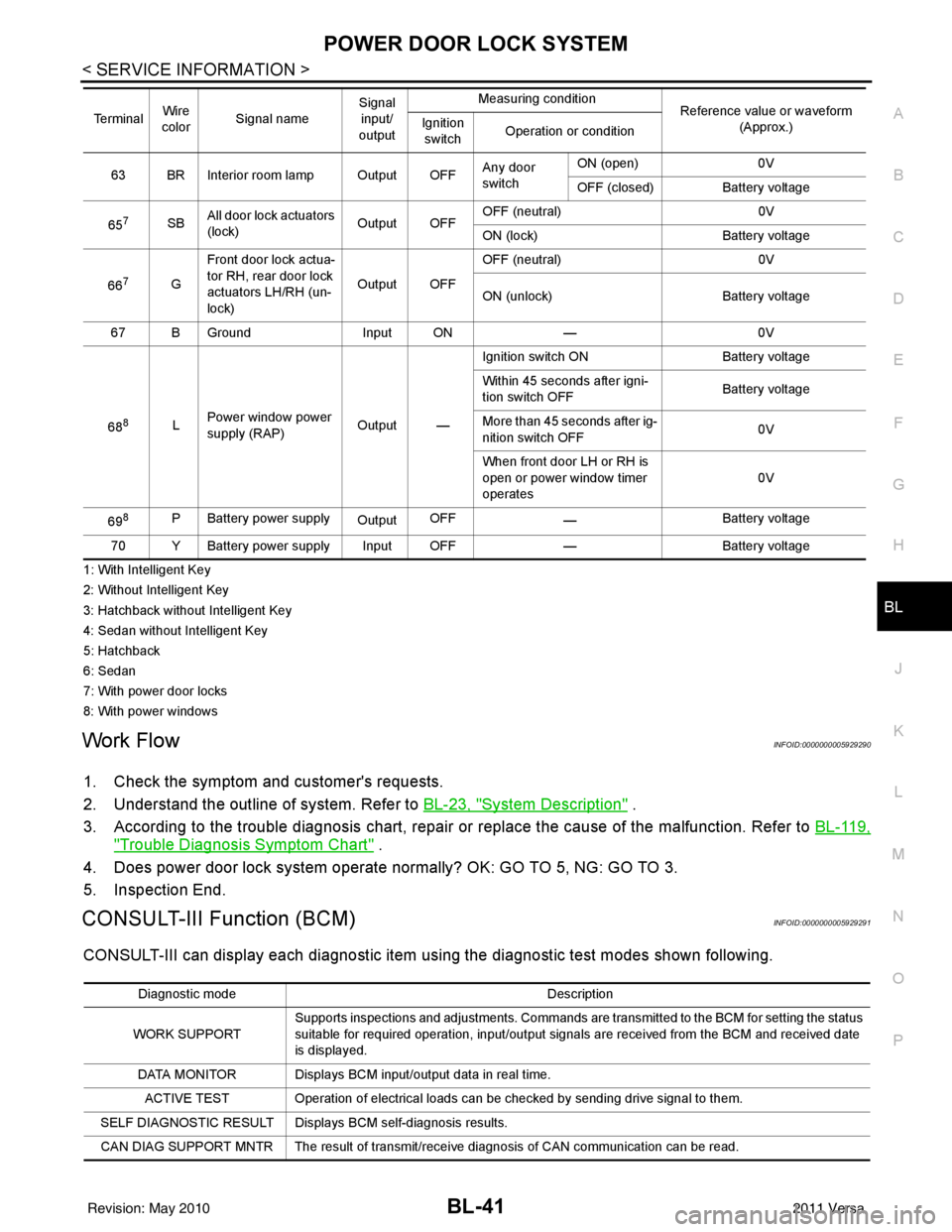

Work FlowINFOID:0000000005929290

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to BL-23, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to BL-119,

"Trouble Diagnosis Symptom Chart" .

4. Does power door lock system operate normally? OK: GO TO 5, NG: GO TO 3.

5. Inspection End.

CONSULT-III Function (BCM)INFOID:0000000005929291

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

63 BR Interior room lamp Output OFF Any door

switchON (open)

0V

OFF (closed) Battery voltage

65

7SB All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66

7G Front door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68

8L Power window power

supply (RAP)

Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69

8P Battery power supply OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Diagnostic mode

Description

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting the status

suitable for required operation, input/output signals are received from the BCM and received date

is displayed.

DATA MONITOR Displays BCM input/output data in real time. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

Revision: May 2010 2011 Versa

Page 579 of 3787

REMOTE KEYLESS ENTRY SYSTEMBL-69

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

1: With Intelligent Key

2: Without Intelligent Key

3: Hatchback without Intelligent Key

4: Sedan without Intelligent Key

5: Hatchback

6: Sedan

7: With power door locks

8: With power windows

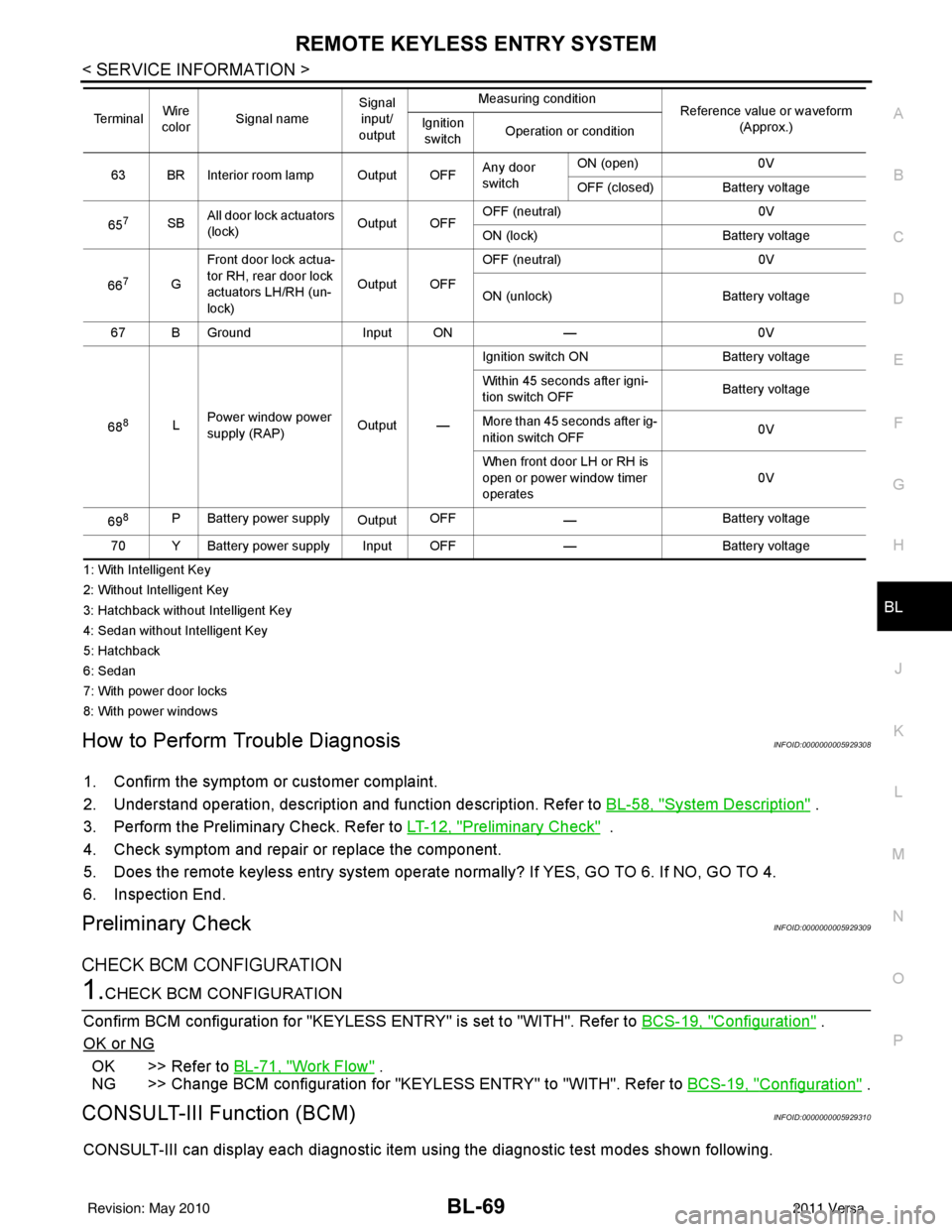

How to Perform Trouble DiagnosisINFOID:0000000005929308

1. Confirm the symptom or customer complaint.

2. Understand operation, description and function description. Refer to BL-58, "

System Description" .

3. Perform the Preliminary Check. Refer to LT-12, "

Preliminary Check" .

4. Check symptom and repair or replace the component.

5. Does the remote keyless entry system operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000005929309

CHECK BCM CONFIGURATION

1.CHECK BCM CONFIGURATION

Confirm BCM configuration for "KEYLESS ENTRY" is set to "WITH". Refer to BCS-19, "

Configuration" .

OK or NG

OK >> Refer to BL-71, "Work Flow" .

NG >> Change BCM configuration for "KEYLESS ENTRY" to "WITH". Refer to BCS-19, "

Configuration" .

CONSULT-III Function (BCM)INFOID:0000000005929310

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

63 BR Interior room lamp Output OFFAny door

switchON (open)

0V

OFF (closed) Battery voltage

65

7SB All door lock actuators

(lock) Output OFFOFF (neutral)

0V

ON (lock) Battery voltage

66

7G Front door lock actua-

tor RH, rear door lock

actuators LH/RH (un-

lock) Output OFFOFF (neutral)

0V

ON (unlock) Battery voltage

67 B Ground Input ON—0V

68

8L Power window power

supply (RAP)

Output —Ignition switch ON

Battery voltage

Within 45 seconds after igni-

tion switch OFF Battery voltage

More than 45 seconds after ig-

nition switch OFF 0V

When front door LH or RH is

open or power window timer

operates 0V

69

8P Battery power supply OutputOFF

— Battery voltage

70 Y Battery power supply Input OFF —Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

Revision: May 2010

2011 Versa

Page 580 of 3787

BL-70

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

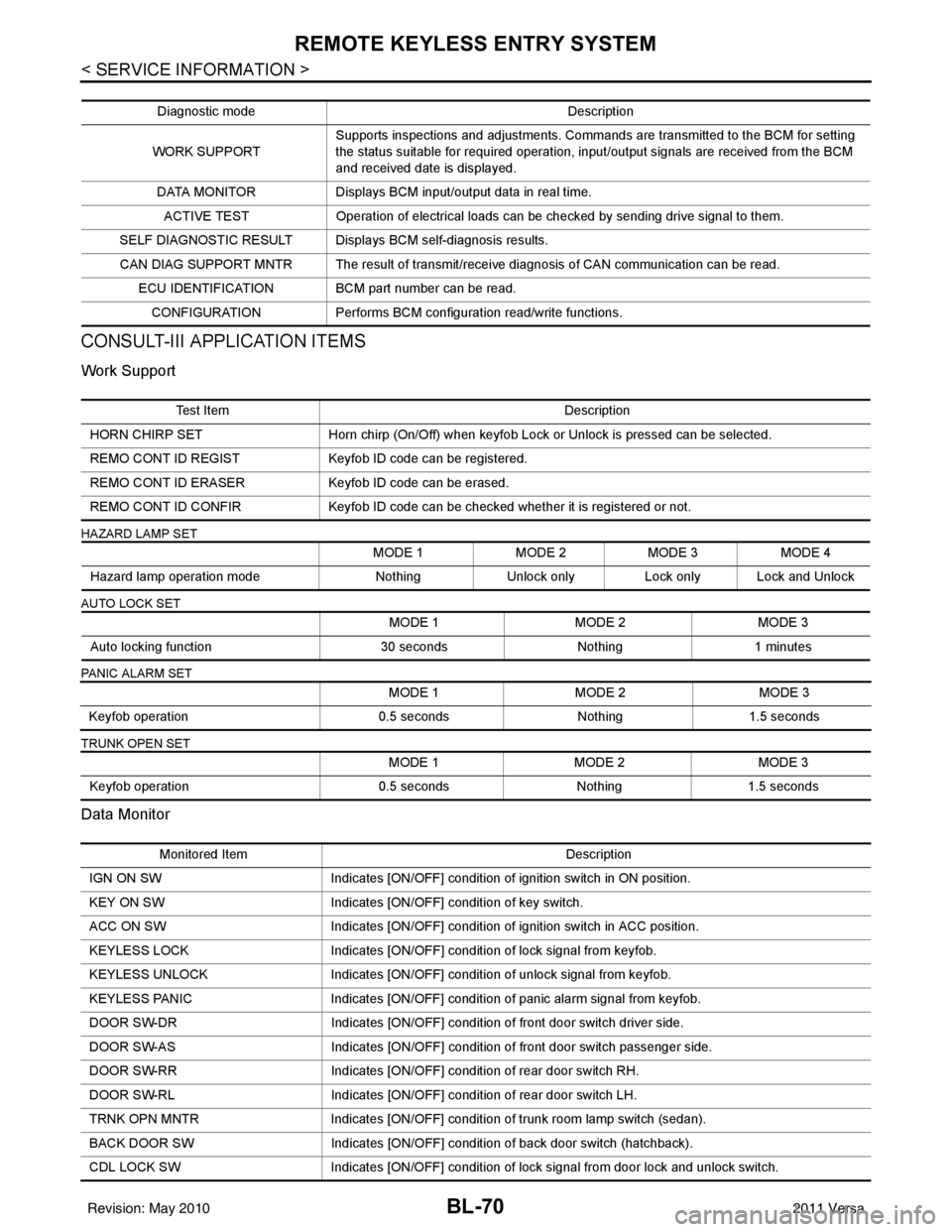

CONSULT-III APPLICATION ITEMS

Work Support

HAZARD LAMP SET

AUTO LOCK SET

PANIC ALARM SET

TRUNK OPEN SET

Data Monitor

Diagnostic modeDescription

WORK SUPPORT Supports inspections and adjustments. Commands are transmitted to the BCM for setting

the status suitable for required operation, input/output signals are received from the BCM

and received date is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF DIAGNOSTIC RESULT Displays BCM self-diagnosis results. CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ECU IDENTIFICATION BCM part number can be read.CONFIGURATION Performs BCM configuration read/write functions.

Te s t I t e m D e s c r i p t i o n

HORN CHIRP SET Horn chirp (On/Off) when keyfob Lock or Unlock is pressed can be selected.

REMO CONT ID REGIST Keyfob ID code can be registered.

REMO CONT ID ERASER Keyfob ID code can be erased.

REMO CONT ID CONFIR Keyfob ID code can be checked whether it is registered or not.

MODE 1 MODE 2MODE 3 MODE 4

Hazard lamp operation mode NothingUnlock only Lock only Lock and Unlock

MODE 1 MODE 2MODE 3

Auto locking function 30 secondsNothing1 minutes

MODE 1 MODE 2MODE 3

Keyfob operation 0.5 secondsNothing1.5 seconds

MODE 1 MODE 2MODE 3

Keyfob operation 0.5 secondsNothing1.5 seconds

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch in ON position.

KEY ON SW Indicates [ON/OFF] condition of key switch.

ACC ON SW Indicates [ON/OFF] condition of ignition switch in ACC position.

KEYLESS LOCK Indicates [ON/OFF] condition of lock signal from keyfob.

KEYLESS UNLOCK Indicates [ON/OFF] condition of unlock signal from keyfob.

KEYLESS PANIC Indicates [ON/OFF] condition of panic alarm signal from keyfob.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch driver side.

DOOR SW-AS Indicates [ON/OFF] condition of front door switch passenger side.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

TRNK OPN MNTR Indicates [ON/OFF] condition of trunk room lamp switch (sedan).

BACK DOOR SW Indicates [ON/OFF] condition of back door switch (hatchback).

CDL LOCK SW Indicates [ON/OFF] condition of lock signal from door lock and unlock switch.

Revision: May 2010 2011 Versa

Page 594 of 3787

BL-84

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

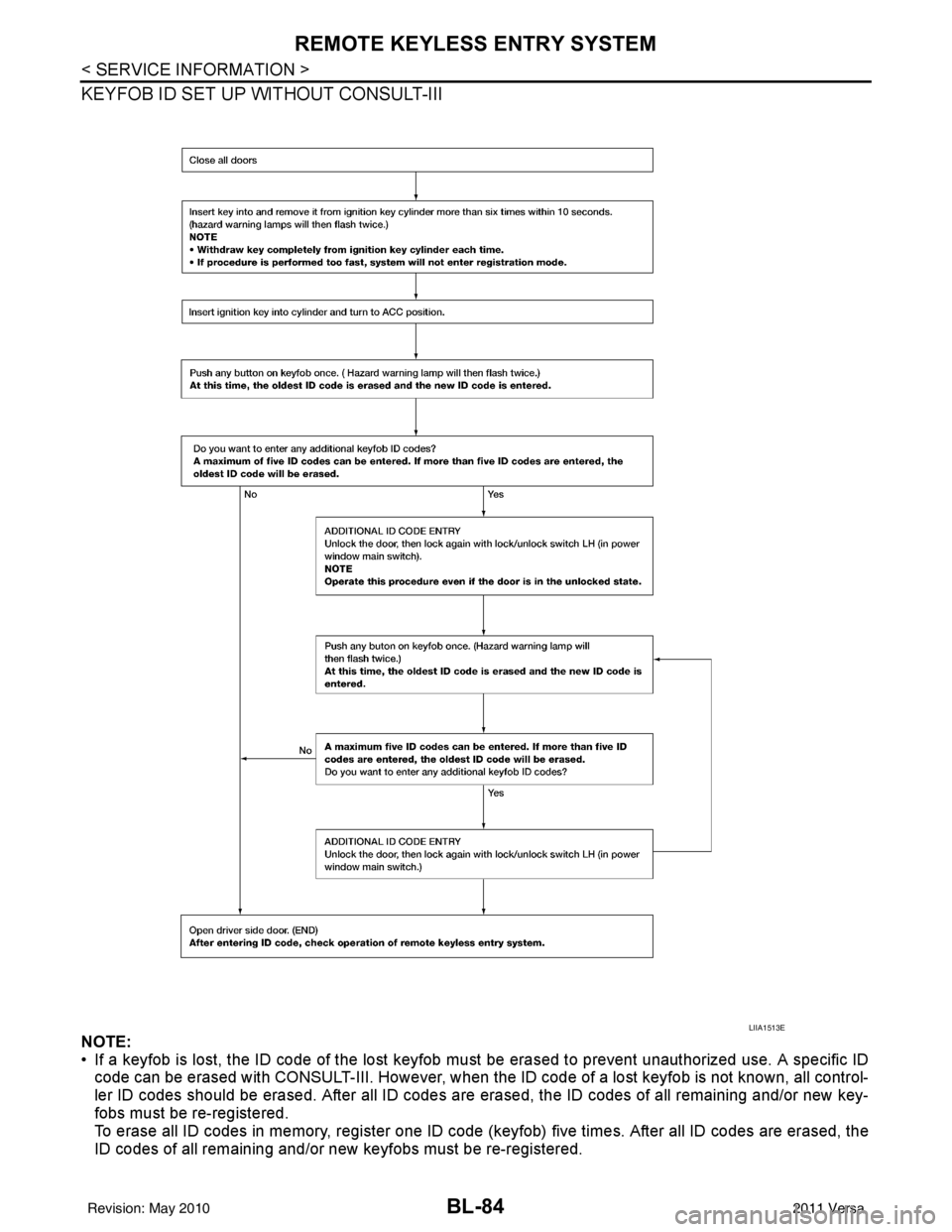

KEYFOB ID SET UP WITHOUT CONSULT-III

NOTE:

• If a keyfob is lost, the ID code of the lost keyfob must be erased to prevent unauthorized use. A specific ID

code can be erased with CONSULT-III. However, when the ID code of a lost keyfob is not known, all control-

ler ID codes should be erased. After all ID codes are erased, the ID codes of all remaining and/or new key-

fobs must be re-registered.

To erase all ID codes in memory, register one ID code (keyfob) five times. After all ID codes are erased, the

ID codes of all remaining and/or new keyfobs must be re-registered.

LIIA1513E

Revision: May 2010 2011 Versa