AUX NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 48 of 3833

GI-46

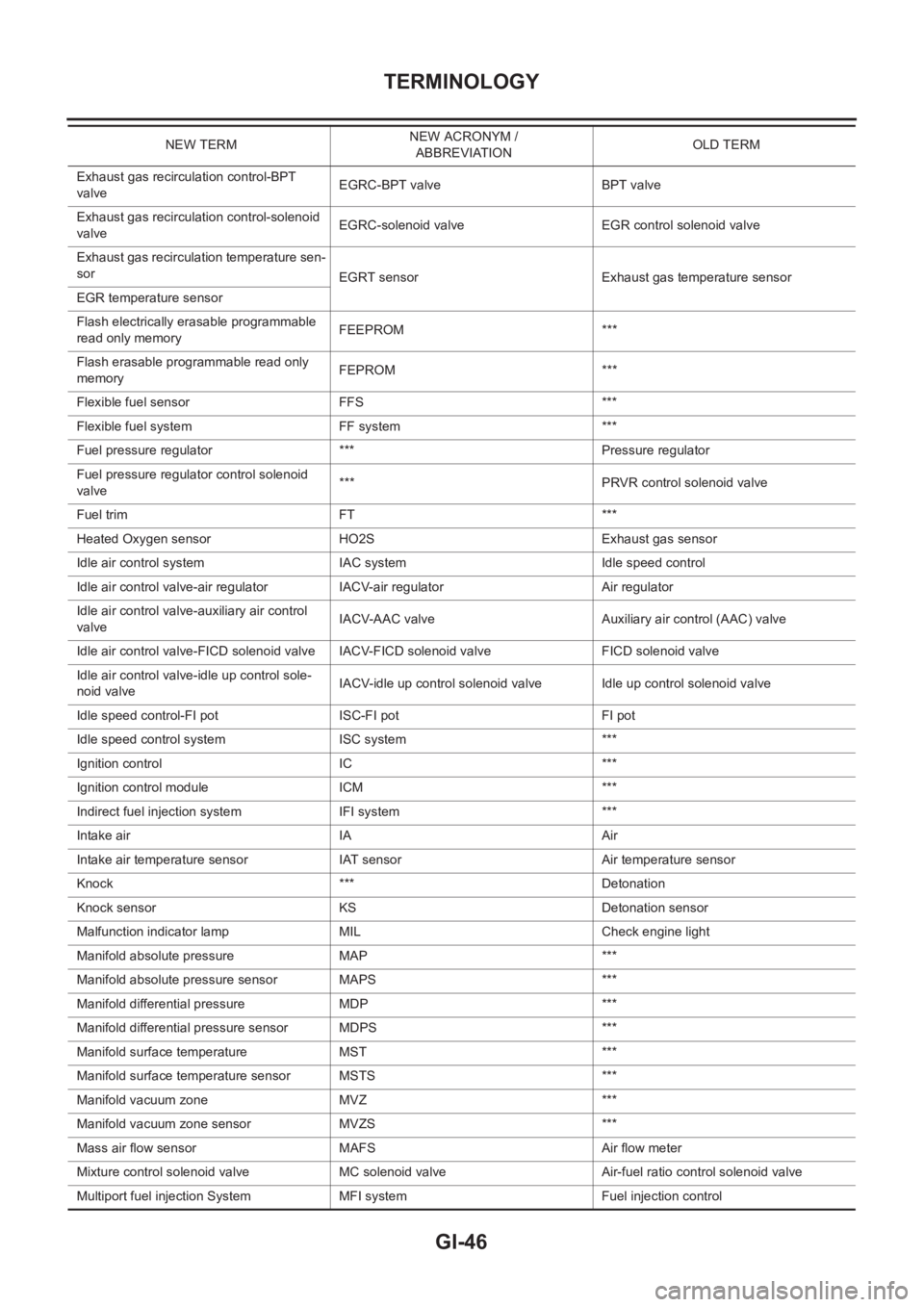

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2107 of 3833

OVERALL SYSTEM

AT-29

D

E

F

G

H

I

J

K

L

MA

B

AT

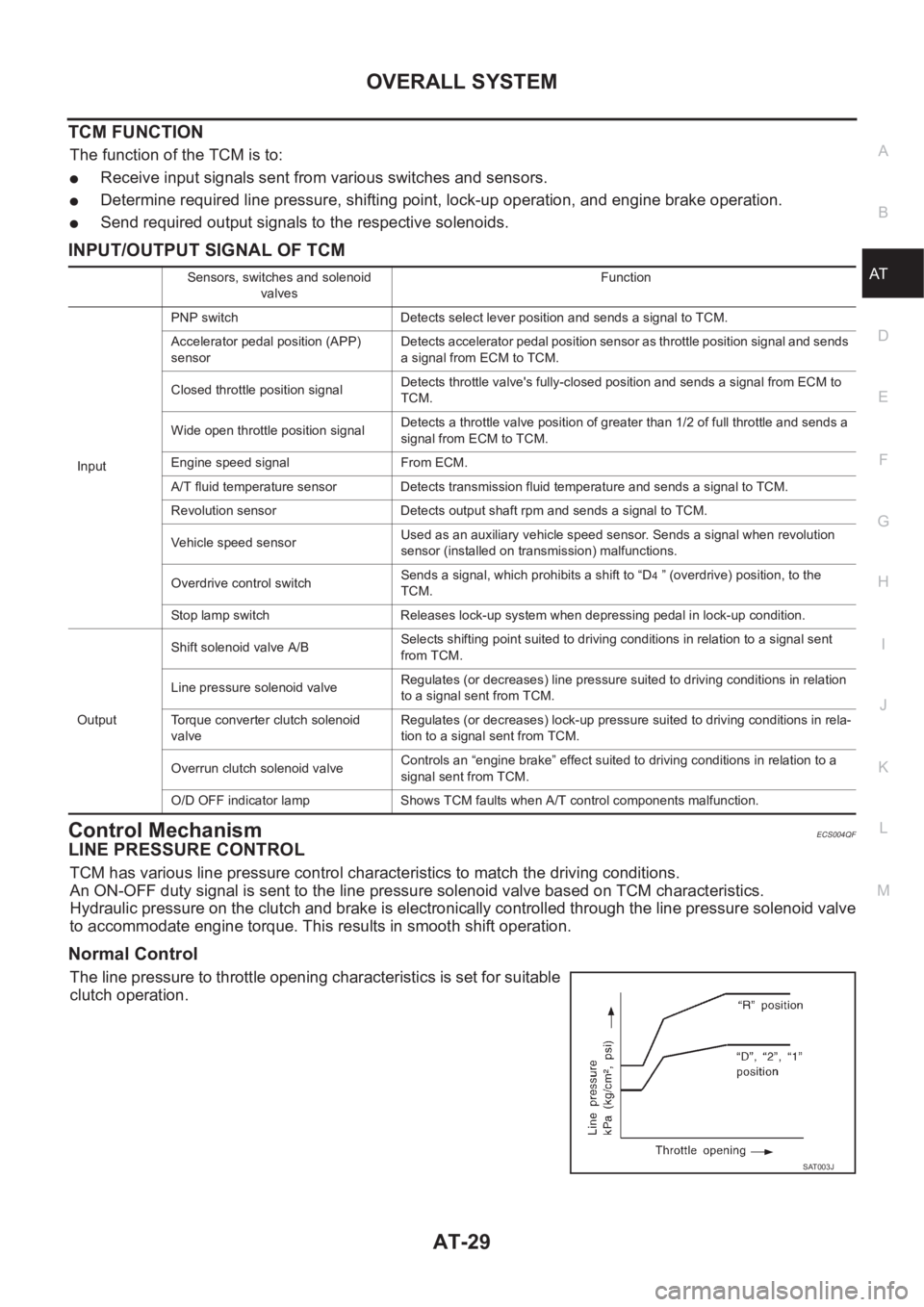

TCM FUNCTION

The function of the TCM is to:

●Receive input signals sent from various switches and sensors.

●Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

●Send required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

Control MechanismECS004QF

LINE PRESSURE CONTROL

TCM has various line pressure control characteristics to match the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve

to accommodate engine torque. This results in smooth shift operation.

Normal Control

The line pressure to throttle opening characteristics is set for suitable

clutch operation.

Sensors, switches and solenoid

valvesFunction

InputPNP switch Detects select lever position and sends a signal to TCM.

Accelerator pedal position (APP)

sensorDetects accelerator pedal position sensor as throttle position signal and sends

a signal from ECM to TCM.

Closed throttle position signalDetects throttle valve's fully-closed position and sends a signal from ECM to

TCM.

Wide open throttle position signalDetects a throttle valve position of greater than 1/2 of full throttle and sends a

signal from ECM to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Overdrive control switchSends a signal, which prohibits a shift to “D

4 ” (overdrive) position, to the

TCM.

Stop lamp switch Releases lock-up system when depressing pedal in lock-up condition.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent

from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation

to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Overrun clutch solenoid valveControls an “engine brake” effect suited to driving conditions in relation to a

signal sent from TCM.

O/D OFF indicator lamp Shows TCM faults when A/T control components malfunction.

SAT003J

Page 2277 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC VEHICLE SPEED SENSOR MTR

AT-199

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bl NISSAN X-TRAIL 2001 Service Repair Manual DTC VEHICLE SPEED SENSOR MTR

AT-199

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bl](/img/5/57405/w960_57405-2276.png)

DTC VEHICLE SPEED SENSOR MTR

AT-199

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC VEHICLE SPEED SENSOR MTRPFP:24814

DescriptionECS004SM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an auxiliary device to the revolution sen-

sor when it is malfunctioning. The TCM will then use a signal sent

from the vehicle speed sensor·MTR.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

SCIA0716E

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

40 L/BVehicle speed

sensorWhen moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 1V and

more than 4.5V

Diagnostic trouble code Malfunction is detected when... Check items (Possible cause)

: VHCL SPEED SEN·MTR

TCM does not receive the proper voltage

signal from the sensor.

●Harness or connectors

(The sensor circuit is open or shorted.)

●Combination meter

●4WD/ABS control unit : 2nd judgement flicker

Page 2436 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual AT-358

[ALL]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an NISSAN X-TRAIL 2001 Service Repair Manual AT-358

[ALL]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an](/img/5/57405/w960_57405-2435.png)

AT-358

[ALL]

DTC VEHICLE SPEED SENSOR MTR

DTC VEHICLE SPEED SENSOR MTR

PFP:24814

DescriptionECS004TM

The vehicle speed sensor·MTR is built into the speedometer assem-

bly. The sensor functions as an auxiliary device to the revolution sen-

sor when it is malfunctioning. The TCM will then use a signal sent

from the vehicle speed sensor·MTR.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURE

After the repair, perform the following procedure to confirm the malfunction is eliminated.

With CONSULT-II

1. Start engine.

2. Select “SELF-DIAG RESULTS” mode for A/T with CONSULT-II.

3. Drive vehicle under the following conditions:

Selector lever in “D” position and vehicle speed higher than 20

km/h (12 MPH).

SCIA0716E

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

40 L/BVehicle speed

sensorWhen moving vehicle at 2 to 3 km/h

(1 to 2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0V and

more than 4.5V

Diagnostic trouble code Malfunction is detected when... Check items (Possible cause)

: VHCL SPEED SEN·MTR

TCM does not receive the proper voltage

signal from the sensor.

●Harness or connectors

(The sensor circuit is open or shorted.)

●Combination meter

●4WD/ABS control unit : 2nd judgement flicker

SAT014K

Page 3278 of 3833

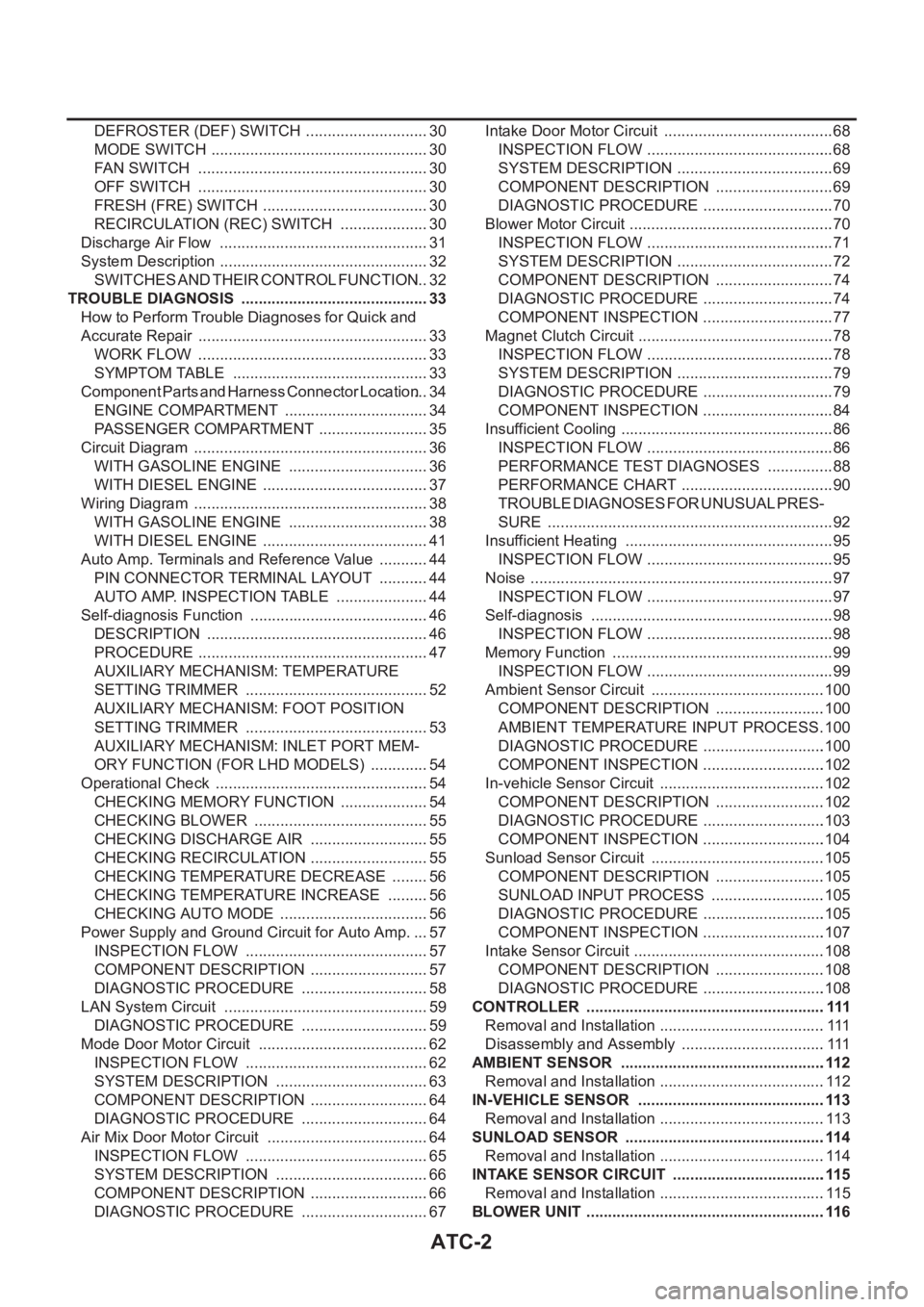

ATC-2

DEFROSTER (DEF) SWITCH ............................. 30

MODE SWITCH ................................................... 30

FAN SWITCH ...................................................... 30

OFF SWITCH ...................................................... 30

FRESH (FRE) SWITCH ....................................... 30

RECIRCULATION (REC) SWITCH ..................... 30

Discharge Air Flow ................................................. 31

System Description ................................................. 32

SWITCHES AND THEIR CONTROL FUNCTION ... 32

TROUBLE DIAGNOSIS ............................................ 33

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ...................................................... 33

WORK FLOW ...................................................... 33

SYMPTOM TABLE .............................................. 33

Component Parts and Harness Connector Location ... 34

ENGINE COMPARTMENT .................................. 34

PASSENGER COMPARTMENT .......................... 35

Circuit Diagram ....................................................... 36

WITH GASOLINE ENGINE ................................. 36

WITH DIESEL ENGINE ....................................... 37

Wiring Diagram ....................................................... 38

WITH GASOLINE ENGINE ................................. 38

WITH DIESEL ENGINE ....................................... 41

Auto Amp. Terminals and Reference Value ............ 44

PIN CONNECTOR TERMINAL LAYOUT ............ 44

AUTO AMP. INSPECTION TABLE ...................... 44

Self-diagnosis Function .......................................... 46

DESCRIPTION .................................................... 46

PROCEDURE ...................................................... 47

AUXILIARY MECHANISM: TEMPERATURE

SETTING TRIMMER ........................................... 52

AUXILIARY MECHANISM: FOOT POSITION

SETTING TRIMMER ........................................... 53

AUXILIARY MECHANISM: INLET PORT MEM-

ORY FUNCTION (FOR LHD MODELS) .............. 54

Operational Check .................................................. 54

CHECKING MEMORY FUNCTION ..................... 54

CHECKING BLOWER ......................................... 55

CHECKING DISCHARGE AIR ............................ 55

CHECKING RECIRCULATION ............................ 55

CHECKING TEMPERATURE DECREASE ......... 56

CHECKING TEMPERATURE INCREASE .......... 56

CHECKING AUTO MODE ................................... 56

Power Supply and Ground Circuit for Auto Amp. ... 57

INSPECTION FLOW ........................................... 57

COMPONENT DESCRIPTION ............................ 57

DIAGNOSTIC PROCEDURE .............................. 58

LAN System Circuit ............................................. ... 59

DIAGNOSTIC PROCEDURE .............................. 59

Mode Door Motor Circuit ........................................ 62

INSPECTION FLOW ........................................

... 62

SYSTEM DESCRIPTION .................................... 63

COMPONENT DESCRIPTION ............................ 64

DIAGNOSTIC PROCEDURE .............................. 64

Air Mix Door Motor Circuit ...................................... 64

INSPECTION FLOW ........................................... 65

SYSTEM DESCRIPTION .................................... 66

COMPONENT DESCRIPTION ............................ 66

DIAGNOSTIC PROCEDURE .............................. 67Intake Door Motor Circuit ........................................ 68

INSPECTION FLOW ............................................ 68

SYSTEM DESCRIPTION ..................................... 69

COMPONENT DESCRIPTION ............................ 69

DIAGNOSTIC PROCEDURE ............................... 70

Blower Motor Circuit ................................................ 70

INSPECTION FLOW ............................................ 71

SYSTEM DESCRIPTION ..................................... 72

COMPONENT DESCRIPTION ............................ 74

DIAGNOSTIC PROCEDURE ............................... 74

COMPONENT INSPECTION ............................... 77

Magnet Clutch Circuit .............................................. 78

INSPECTION FLOW ............................................ 78

SYSTEM DESCRIPTION ..................................... 79

DIAGNOSTIC PROCEDURE ............................... 79

COMPONENT INSPECTION ............................... 84

Insufficient Cooling .................................................. 86

INSPECTION FLOW ............................................ 86

PERFORMANCE TEST DIAGNOSES ................ 88

PERFORMANCE CHART .................................... 90

TROUBLE DIAGNOSES FOR UNUSUAL PRES-

SURE ................................................................... 92

Insufficient Heating ................................................. 95

INSPECTION FLOW ............................................ 95

Noise ....................................................................... 97

INSPECTION FLOW ............................................ 97

Self-diagnosis ......................................................... 98

INSPECTION FLOW ............................................ 98

Memory Function .................................................... 99

INSPECTION FLOW ............................................ 99

Ambient Sensor Circuit .........................................100

COMPONENT DESCRIPTION ..........................100

AMBIENT TEMPERATURE INPUT PROCESS .100

DIAGNOSTIC PROCEDURE .............................100

COMPONENT INSPECTION .............................102

In-vehicle Sensor Circuit .......................................102

COMPONENT DESCRIPTION ..........................102

DIAGNOSTIC PROCEDURE .............................103

COMPONENT INSPECTION .............................104

Sunload Sensor Circuit .........................................105

COMPONENT DESCRIPTION ..........................105

SUNLOAD INPUT PROCESS ...........................105

DIAGNOSTIC PROCEDURE .............................105

COMPONENT INSPECTION .............................107

Intake Sensor Circuit .............................................108

COMPONENT DESCRIPTION ..........................108

DIAGNOSTIC PROCEDURE .............................108

CONTROLLER ........................................................ 111

Removal and Installation .......................................111

Disassembly and Assembly ..................................111

AMBIENT SENSOR ................................................112

Removal and Installation .......................................112

IN-VEHICLE SENSOR ............................................113

Removal and Installation .......................................113

SUNLOAD SENSOR ...............................................114

Removal and Installation .......................................114

INTAKE SENSOR CIRCUIT ....................................115

Removal and Installation .......................................115

BLOWER UNIT ........................................................116

Page 3322 of 3833

ATC-46

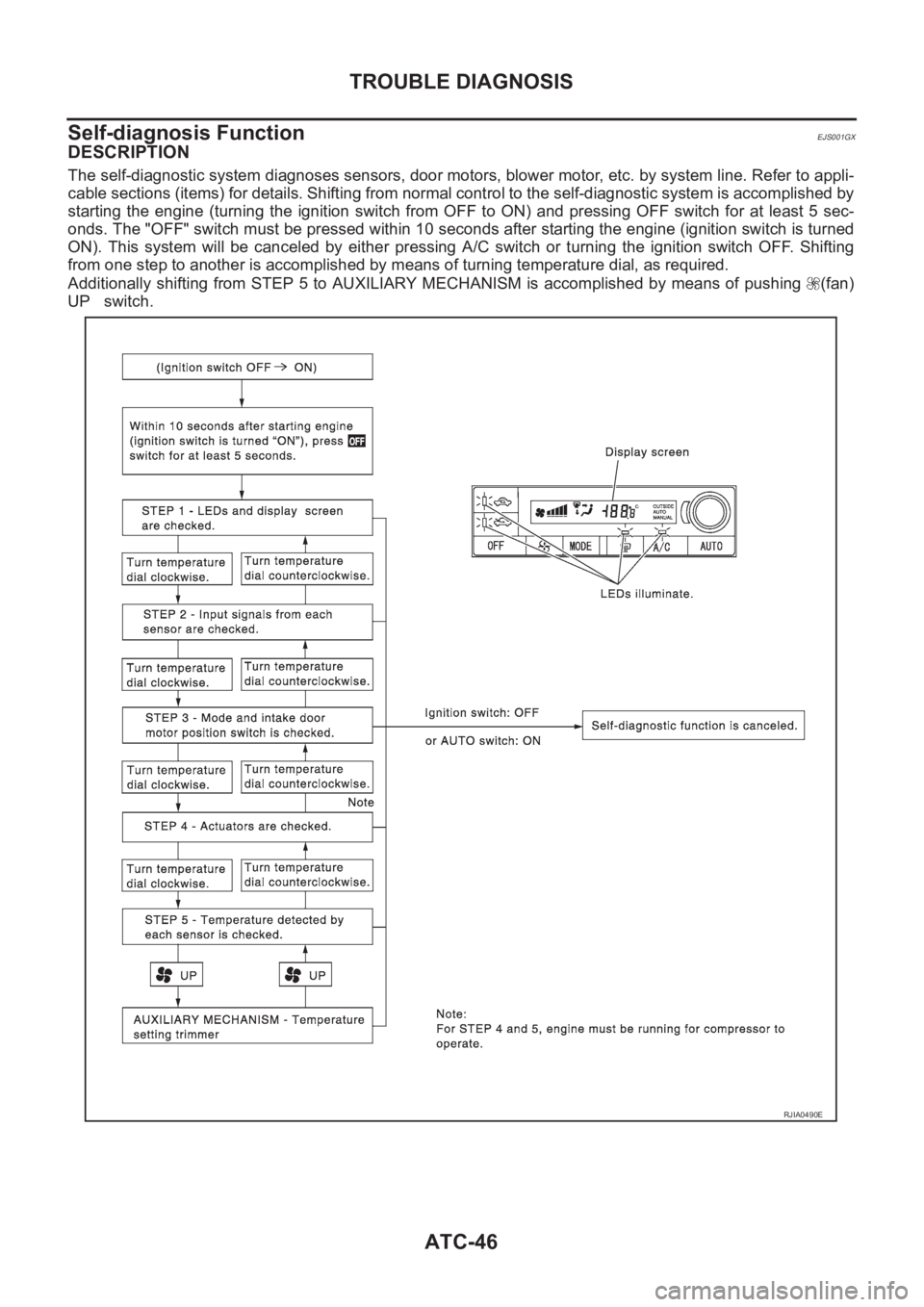

TROUBLE DIAGNOSIS

Self-diagnosis Function

EJS001GX

DESCRIPTION

The self-diagnostic system diagnoses sensors, door motors, blower motor, etc. by system line. Refer to appli-

cable sections (items) for details. Shifting from normal control to the self-diagnostic system is accomplished by

starting the engine (turning the ignition switch from OFF to ON) and pressing OFF switch for at least 5 sec-

onds. The "OFF" switch must be pressed within 10 seconds after starting the engine (ignition switch is turned

ON). This system will be canceled by either pressing A/C switch or turning the ignition switch OFF. Shifting

from one step to another is accomplished by means of turning temperature dial, as required.

Additionally shifting from STEP 5 to AUXILIARY MECHANISM is accomplished by means of pushing (fan)

UP switch.

RJIA0490E

Page 3328 of 3833

ATC-52

TROUBLE DIAGNOSIS

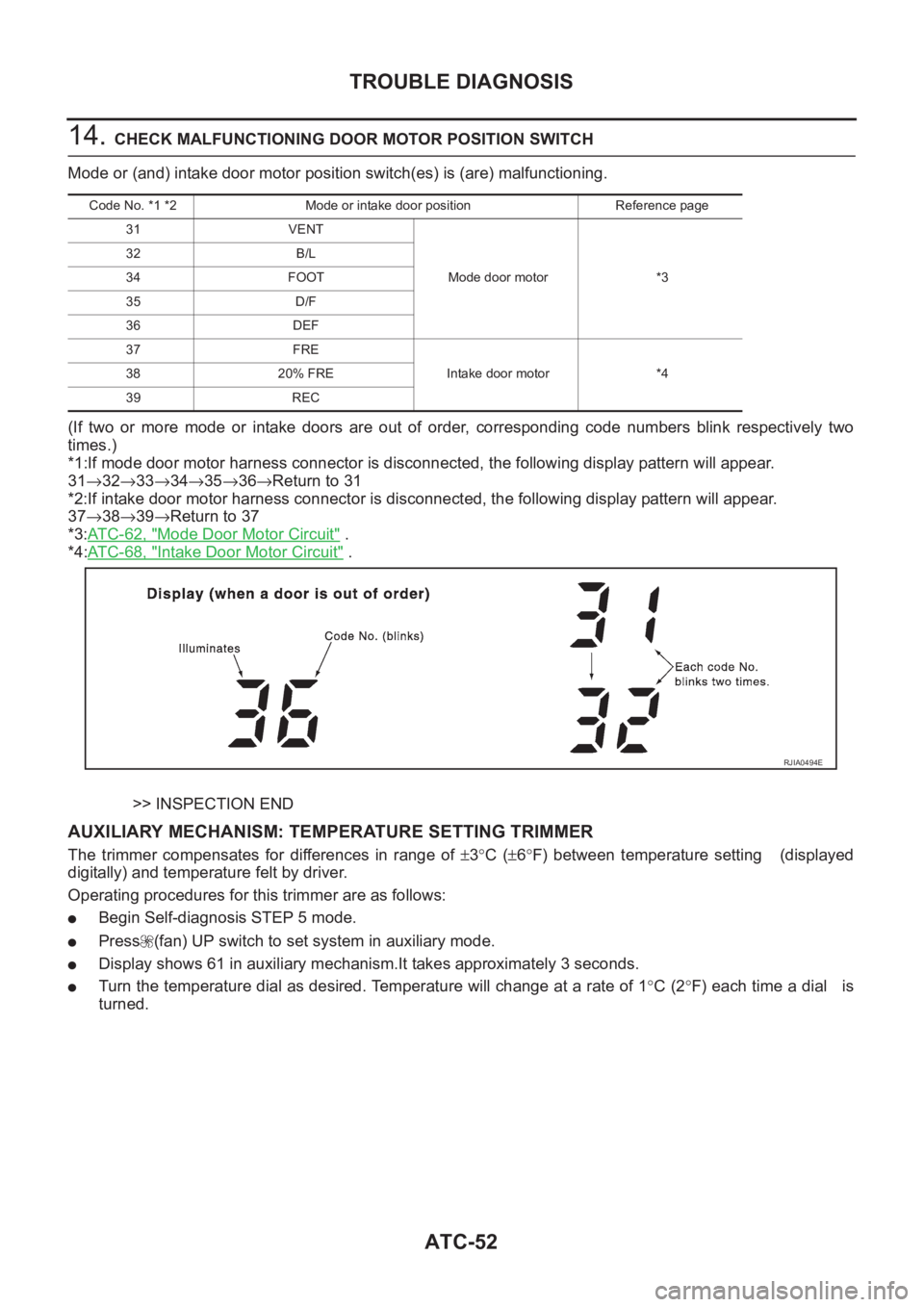

14. CHECK MALFUNCTIONING DOOR MOTOR POSITION SWITCH

Mode or (and) intake door motor position switch(es) is (are) malfunctioning.

(If two or more mode or intake doors are out of order, corresponding code numbers blink respectively two

times.)

*1:If mode door motor harness connector is disconnected, the following display pattern will appear.

31→32→33→34→35→36→Return to 31

*2:If intake door motor harness connector is disconnected, the following display pattern will appear.

37→38→39→Return to 37

*3:AT C - 6 2 , "

Mode Door Motor Circuit" .

*4:AT C - 6 8 , "

Intake Door Motor Circuit" .

>> INSPECTION END

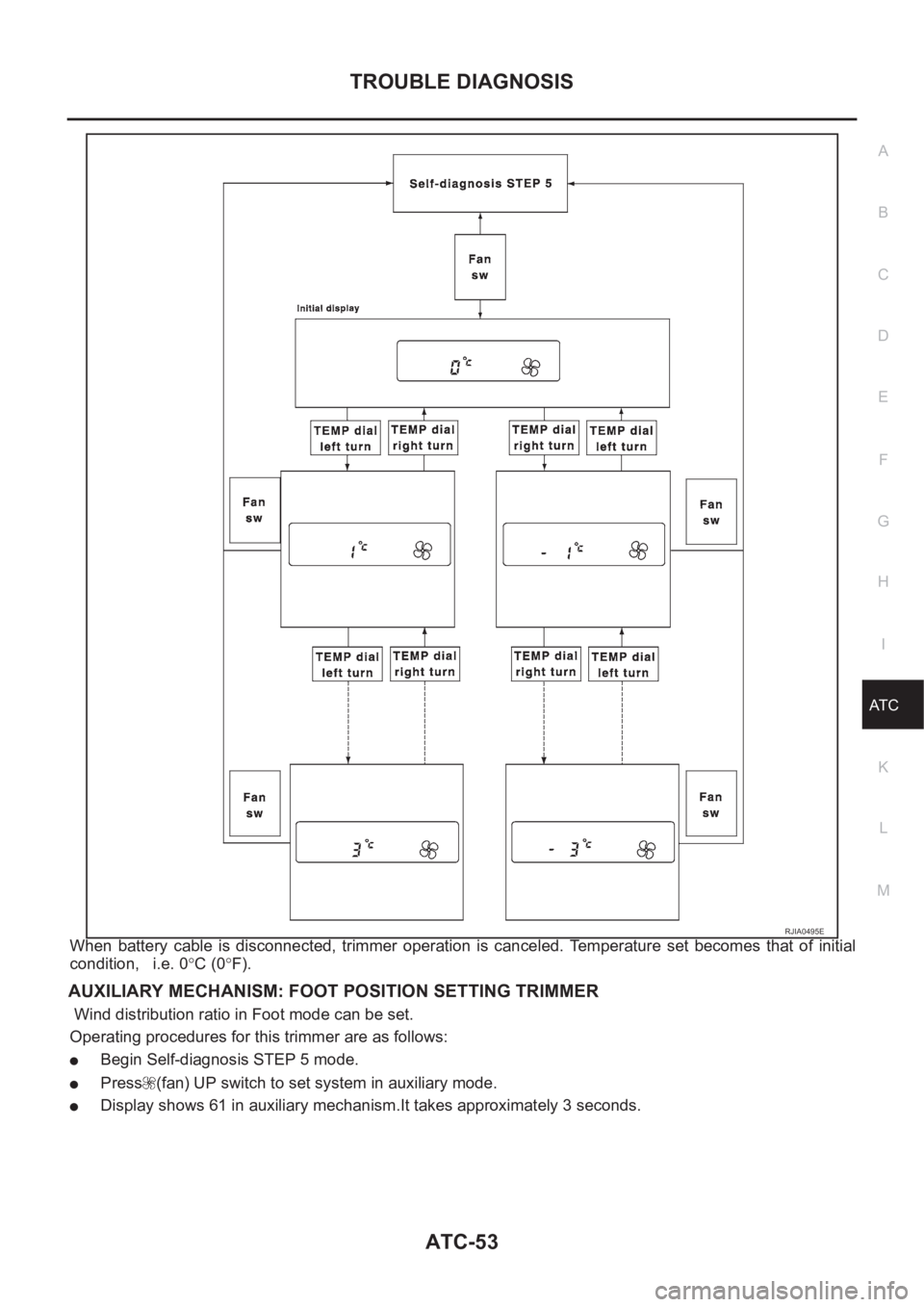

AUXILIARY MECHANISM: TEMPERATURE SETTING TRIMMER

The trimmer compensates for differences in range of ±3°C (±6°F) between temperature setting (displayed

digitally) and temperature felt by driver.

Operating procedures for this trimmer are as follows:

●Begin Self-diagnosis STEP 5 mode.

●Press (fan) UP switch to set system in auxiliary mode.

●Display shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

●Turn the temperature dial as desired. Temperature will change at a rate of 1°C (2°F) each time a dial is

turned.

Code No. *1 *2 Mode or intake door position Reference page

31 VENT

Mode door motor *3 32 B/L

34 FOOT

35 D/F

36 DEF

37 FRE

Intake door motor *4 38 20% FRE

39 REC

RJIA0494E

Page 3329 of 3833

TROUBLE DIAGNOSIS

ATC-53

C

D

E

F

G

H

I

K

L

MA

B

AT C

When battery cable is disconnected, trimmer operation is canceled. Temperature set becomes that of initial

condition, i.e. 0°C (0°F).

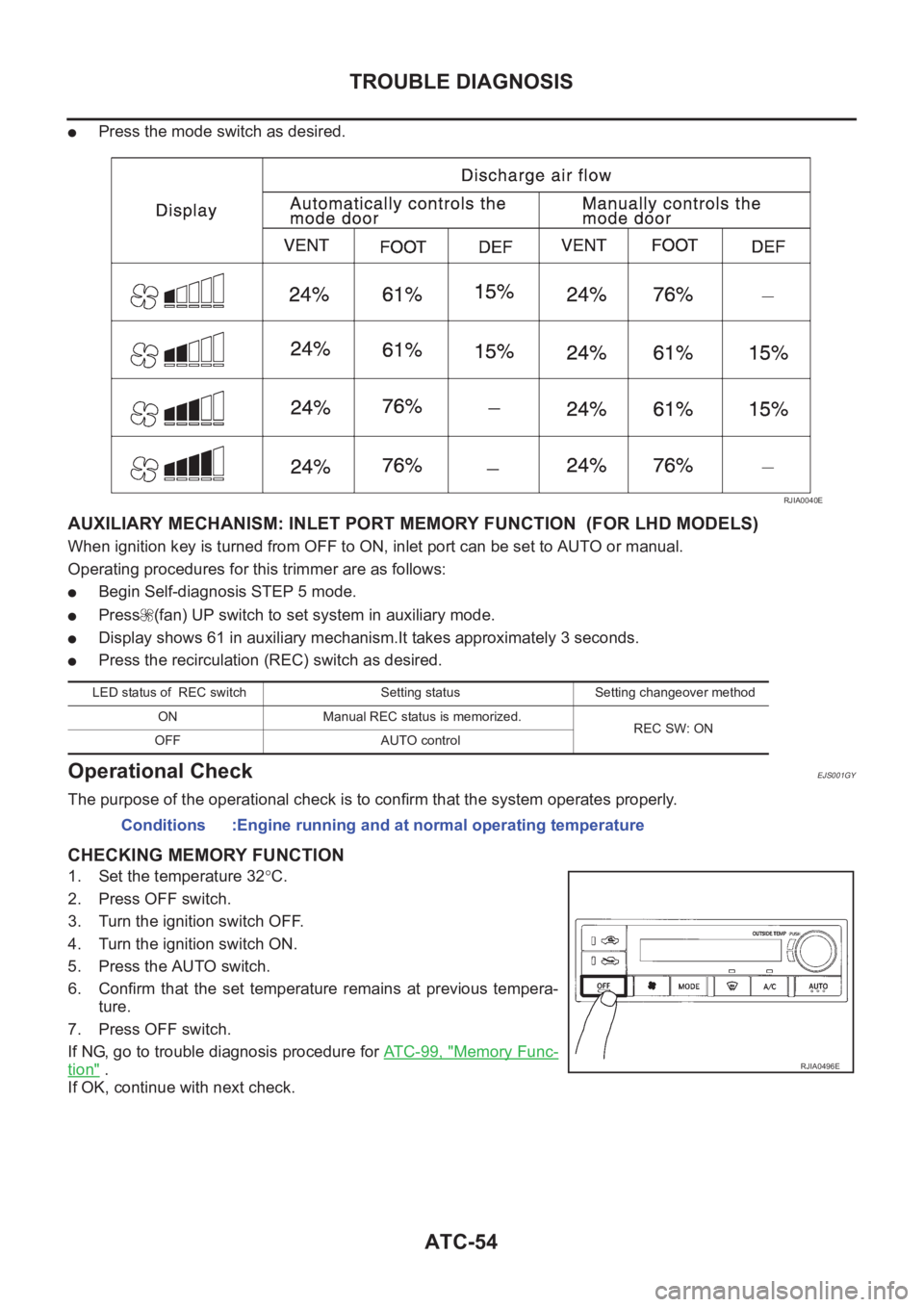

AUXILIARY MECHANISM: FOOT POSITION SETTING TRIMMER

Wind distribution ratio in Foot mode can be set.

Operating procedures for this trimmer are as follows:

●Begin Self-diagnosis STEP 5 mode.

●Press (fan) UP switch to set system in auxiliary mode.

●Display shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

RJIA0495E

Page 3330 of 3833

ATC-54

TROUBLE DIAGNOSIS

●Press the mode switch as desired.

AUXILIARY MECHANISM: INLET PORT MEMORY FUNCTION (FOR LHD MODELS)

When ignition key is turned from OFF to ON, inlet port can be set to AUTO or manual.

Operating procedures for this trimmer are as follows:

●Begin Self-diagnosis STEP 5 mode.

●Press (fan) UP switch to set system in auxiliary mode.

●Display shows 61 in auxiliary mechanism.It takes approximately 3 seconds.

●Press the recirculation (REC) switch as desired.

Operational CheckEJS001GY

The purpose of the operational check is to confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature 32°C.

2. Press OFF switch.

3. Turn the ignition switch OFF.

4. Turn the ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous tempera-

ture.

7. Press OFF switch.

If NG, go to trouble diagnosis procedure for AT C - 9 9 , "

Memory Func-

tion" .

If OK, continue with next check.

RJIA0040E

LED status of REC switch Setting status Setting changeover method

ON Manual REC status is memorized.

REC SW: ON

OFF AUTO control

Conditions :Engine running and at normal operating temperature

RJIA0496E

Page 3362 of 3833

ATC-86

TROUBLE DIAGNOSIS

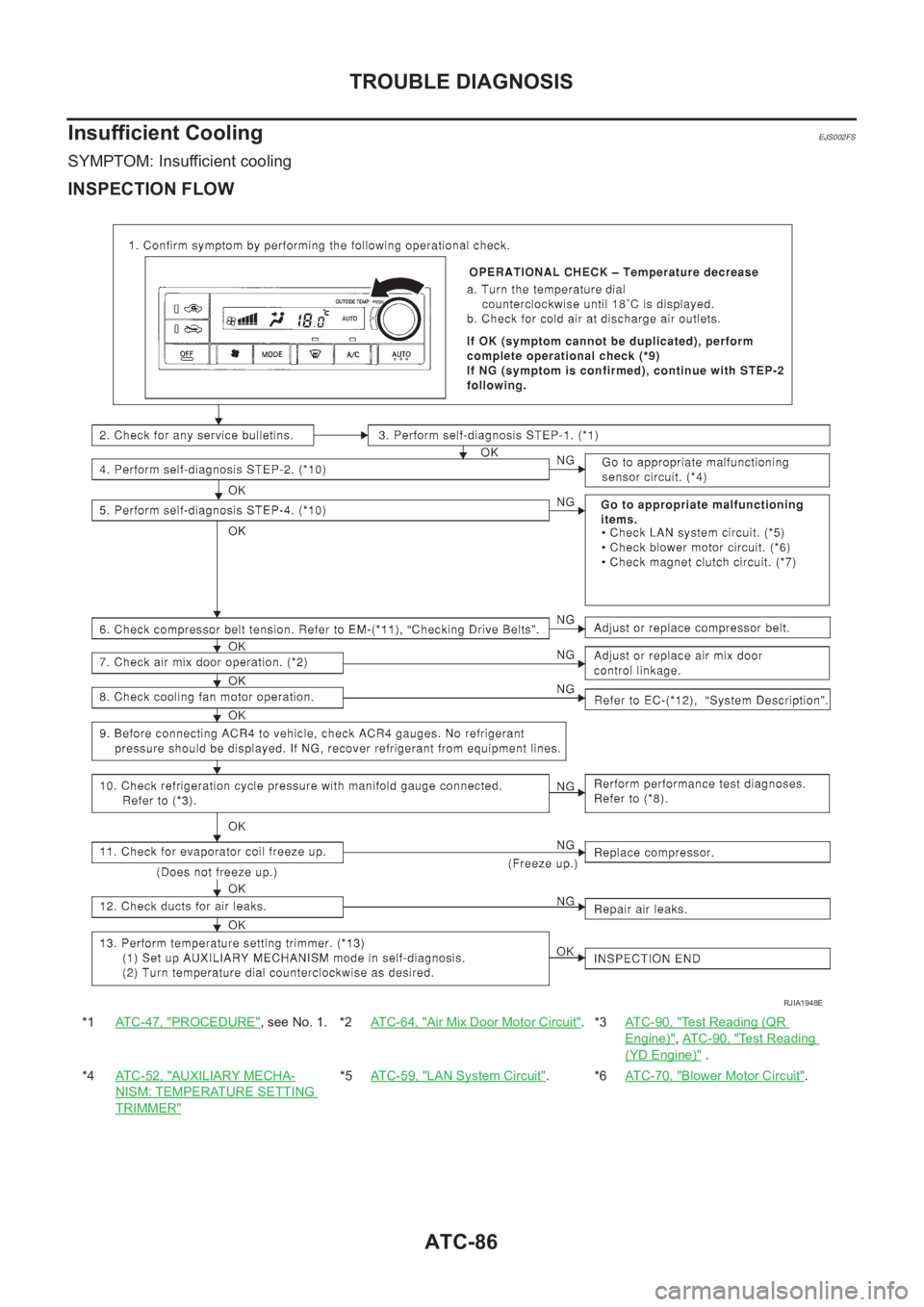

Insufficient Cooling

EJS002FS

SYMPTOM: Insufficient cooling

INSPECTION FLOW

*1ATC-47, "PROCEDURE", see No. 1. *2ATC-64, "Air Mix Door Motor Circuit".*3AT C - 9 0 , "Test Reading (QR

Engine)",AT C - 9 0 , "Test Reading

(YD Engine)" .

*4ATC-52, "

AUXILIARY MECHA-

NISM: TEMPERATURE SETTING

TRIMMER"

*5ATC-59, "LAN System Circuit".*6AT C - 7 0 , "Blower Motor Circuit".

RJIA1948E