check engine light NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 26 of 3833

GI-24

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

●Heat sensitive

●Freezing

●Water intrusion

●Electrical load

●Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

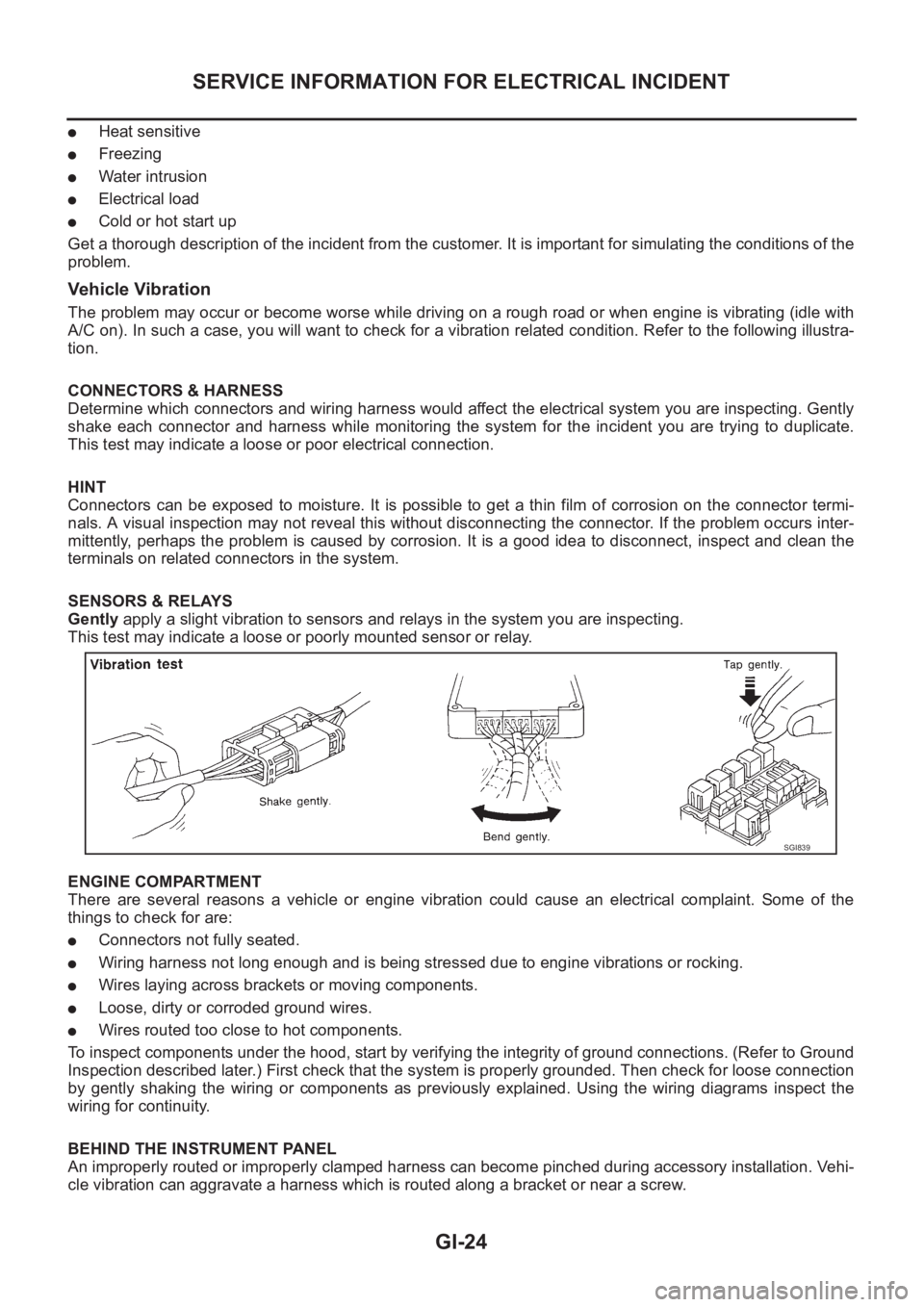

Vehicle Vibration

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

CONNECTORS & HARNESS

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

HINT

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

SENSORS & RELAYS

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

ENGINE COMPARTMENT

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

●Connectors not fully seated.

●Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

●Wires laying across brackets or moving components.

●Loose, dirty or corroded ground wires.

●Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

BEHIND THE INSTRUMENT PANEL

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

SGI839

Page 48 of 3833

GI-46

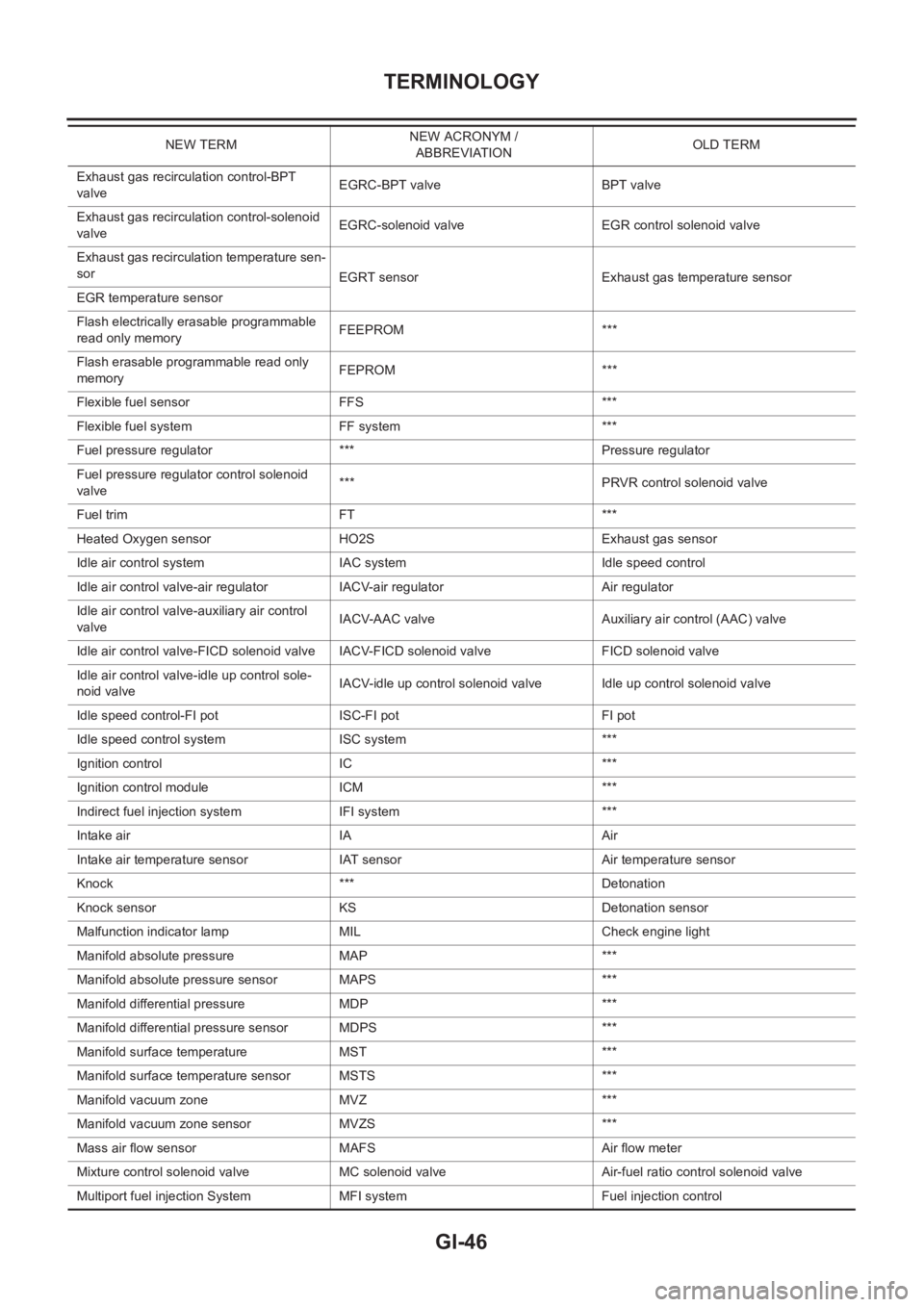

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 72 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and NISSAN X-TRAIL 2001 Service Repair Manual EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and](/img/5/57405/w960_57405-71.png)

EM-22

[QR]

INTAKE MANIFOLD

3. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and the second one is positioned

slightly below the quick connectors bottom end.

CAUTION:

●Hold A position in illustration when inserting fuel tube

into quick connector.

●Carefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

●Insert until you hear a “click” sound and actually feel

the engagement.

●To avoid misidentification of engagement with a similar sound, be sure to perform the next

step.

4. Before clamping fuel hose with hose clamps, pull quick connector hard by hand holding A position. Make

sure it is completely engaged (connected) so that it does not come out from fuel tube.

NOTE:

Recommended pulling force is 50 N (5.1 kg, 11.2 lb).

5. Install quick connector cap on quick connector joint.

●Direct arrow mark on quick connector cap to upper side.

6. Install fuel hose to hose clamp.

Connecting Quick Connector of Fuel Hose (Vehicle side)

Install quick connector as follows.

1. Make sure no foreign substances are deposited in and around tube and quick connector and no damage

on them.

2. Align center to insert quick connector straightly into fuel tube.

●Insert fuel tube until a click is heard.

●Install quick connector cap on quick connector joint. Direct

arrow mark on quick connector cap to upper side.

3. Install fuel hose to hose clamp.

INSPECTION AFTER INSTALLATION

Make sure there is no fuel leakage at connections in the following steps.

1. Apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then check for fuel

leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped as engine becomes extremely hot.

KBIA0272E

KBIA0298E

PBIC0662E

Page 114 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve sp NISSAN X-TRAIL 2001 Service Repair Manual EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve sp](/img/5/57405/w960_57405-113.png)

EM-64

[QR]

CYLINDER HEAD

5. Install valve spring.

●Install smaller pitch (valve spring seat side) to cylinder head

side.

●Confirm identification color of valve spring.

6. Install valve spring retainer.

7. Install valve collet.

●Compress valve spring with valve spring compressor. Install

valve collet with magnet hand.

●Tap stem edge lightly with plastic hammer after installation to check its installed condition.

8. Install valve lifter.

9. Install spark plug tube.

●Press fit it into cylinder head as follows.

a. Remove old liquid gasket from cylinder head side mounting

hole.

b. Apply liquid gasket all round on spark plug tube with a 12 mm

(0.47 in) width from edge of spark plug tube on the press fit side.

Use Genuine Liquid gasket or equivalent.

c. Using a drift (commercial service tool), press fit spark plug tube

so that height is as same as H shown in figure.

CAUTION:

●When press fitting be careful not to deform spark plug tube.

●After press fitting, wipe off any protruding liquid gasket on top surface of cylinder head.

10. Install spark plug with spark plug wrench.

Inspection After DisassemblyEBS00KNS

CYLINDER HEAD DISTORTION

1. Wipe off engine oil and remove water scale (like deposit), gas-

ket, sealer, carbon, etc with scraper.

CAUTION:

Use utmost care not to allow gasket debris to enter pas-

sages for engine oil or water.

2. At each of several locations on bottom surface of cylinder head,

measure distortion in six directions.

VALVE DIMENSIONS

Check dimensions of each valve. For dimensions, refer to SDS, EM-

99, "Valve Dimensions" . Intake : Blue

Exhaust : Yellow

Press fit height “H” standard value:

38.55 - 38.65 mm (1.518 - 1.522 in)

PBIC0525E

SBIA0252E

Standard: 0.1mm (0.004 in)

PBIC0075E

SEM188A

Page 145 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge strai NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge strai](/img/5/57405/w960_57405-144.png)

CYLINDER BLOCK

EM-95

[QR]

C

D

E

F

G

H

I

J

K

L

MA

EM

CRANKSHAFT RUNOUT

●Place a V-block on a precise flat table to support the journals on

the both end of the crankshaft.

●Place a dial gauge straight up on the No. 3 journal.

●While rotating the crankshaft, read the movement of the pointer

on the dial gauge. (Total indicator reading)

CONNECTING ROD BEARING OIL CLEARANCE

Method of Measurement

●Install the connecting rod bearings to the connecting rod and the

cap, and tighten the connecting rod bolts to the specified torque.

Using a inside micrometer measure the inner diameter of con-

necting rod bearing.

(Oil clearance) = (Inner diameter of connecting rod bearing) –

(Outer diameter of crankshaft pin)

●If out of specifications, check connecting rod big end inner diam-

eter and crankshaft pin outer diameter, and select appropriate

connecting rod bearing to adjust clearance to specifications.

Refer to EM-83, "

HOW TO SELECT CONNECTING ROD BEARING" .

Method of Using Plastigage

●Remove engine oil and dust on the crankshaft pin and the sur-

faces of each bearing completely.

●Cut a plastigage slightly shorter than the bearing width, and

place it in crankshaft axial direction, avoiding oil holes.

●Install the connecting rod bearings to the connecting rod cap,

and tighten the connecting rod bolts to the specified torque.

CAUTION:

Never rotate the crankshaft.

●Remove the connecting rod cap and bearings, and using the

scale on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is same as that described in “Method of Mea-

surement”.

MAIN BEARING OIL CLEARANCE

Method of Measurement

●Install the main bearings to the cylinder block and bearing cap. Measure the main bearing inner diameter

with the bearing cap bolt tightened to the specified torque.

(Oil clearance) = (Inner diameter of main bearing) – (Outer diameter of crankshaft journal)

●If out of specification, check main bearing housing inner diameter and crankshaft journal outer diameter,

and select appropriate main bearing to adjust clearance to specifications. Refer to EM-85, "

HOW TO

SELECT MAIN BEARING" . Limit: Less than 0.05 mm (0.002 in)

PBIC0271E

Standard : 0.028 - 0.045 mm (0.0011 - 0.0018 in)

Limit : 0.10 mm (0.0039 in)

PBIC0119E

EM142

Standard

No. 1, 3 and 5 journals : 0.012 - 0.022 mm (0.0005 - 0.0009 in)

No. 2 and 4 journals : 0.018 - 0.028 mm (0.0007 - 0.0011 in)

Limit : 0.1 mm (0.004 in)

Page 227 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual PRIMARY TIMING CHAIN

EM-177

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check for cracks and excessive wear at roller links. Replace

chain if necessary.

INSTALL NISSAN X-TRAIL 2001 Service Repair Manual PRIMARY TIMING CHAIN

EM-177

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check for cracks and excessive wear at roller links. Replace

chain if necessary.

INSTALL](/img/5/57405/w960_57405-226.png)

PRIMARY TIMING CHAIN

EM-177

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

INSPECTION AFTER REMOVAL

Timing Chain

Check for cracks and excessive wear at roller links. Replace

chain if necessary.

INSTALLATION

1. Install rear chain case.

a. Apply a continuous bead of Genuine Liquid Gasket or equivalent

on locations shown in the figure. Refer to E M - 111 , "

Precautions

For Liquid Gasket" .

A: Apply bead so that it does not protrude into the oil passage.

B, C: Minimize overlapping area of bead, by starting and ending

at areas of bead as shown in the figure. Apply so that the portion

marked * comes at an external location but cannot be viewed

externally after engine assembly.

D: Leave the start and end areas of the bead slightly protruding

from the case surface.

SEM984C

JEM139G

PBIC1255E

Page 230 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-180

[YD22DDTi]

PRIMARY TIMING CHAIN

13. Install oil pump housing.

a. Apply a continuous bead of Genuine Liquid Gasket or equivalent

on locations shown in the figure. Refer to EM-111, "

Precauti NISSAN X-TRAIL 2001 Service Repair Manual EM-180

[YD22DDTi]

PRIMARY TIMING CHAIN

13. Install oil pump housing.

a. Apply a continuous bead of Genuine Liquid Gasket or equivalent

on locations shown in the figure. Refer to EM-111, "

Precauti](/img/5/57405/w960_57405-229.png)

EM-180

[YD22DDTi]

PRIMARY TIMING CHAIN

13. Install oil pump housing.

a. Apply a continuous bead of Genuine Liquid Gasket or equivalent

on locations shown in the figure. Refer to EM-111, "

Precautions

For Liquid Gasket" .

A: Leave the start and end areas of the bead slightly protruding

from the surface.

B: Apply liquid gasket along upper end surface of oil pump hous-

ing.

b. Install oil pump drive spacer to crankshaft.

●Install with the front mark (punched mark) facing the front of

the engine.

c. Install O-ring into the groove of rear chain case.

d. Install oil pump housing.

●When installing, align the inner rotor in the direction of the two

facing flats of the oil pump drive spacer.

●When installing, align the dowel pin with the pin hole.

e. Tighten fixing bolts in the numerical order shown in the figure.

f. After tightening all the bolts, re-tighten in the same order.

14. Check gaps on upper oil pan mounting surface.

●Using straightedge and feeler gauge, measure gaps between

the locations of the following parts:

●If the measured value is out of the above range, install again.

15. Install crankshaft pulley.

a. Install crankshaft pulley to crankshaft.

b. Hold crankshaft pulley with the pulley holder (SST).

c. Tighten bolt to 20 to 29 N·m (2.0 to 3.0 kg-m, 15 to 21 ft-lb).

d. Put an alignment mark on crankshaft pulley that aligns with one

of the punched marks on the bolt.

e. Tighten fixing bolt another 60° - 66° [target: 60° (turn by one

notch)].

16. Install secondary timing chain and the associated parts.

JEM144G

JEM145G

JEM133G

Oil pump housing and rear chain case:

Standard : – 0.14 to 0.14 mm (– 0.0055 to 0.0055 in)

Rear chain case and cylinder block:

Standard : – 0.25 to 0.13 mm (– 0.0098 to 0.0051 in)

JEM146G

JEM147G

Page 266 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rota NISSAN X-TRAIL 2001 Service Repair Manual EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rota](/img/5/57405/w960_57405-265.png)

EM-216

[YD22DDTi]

CYLINDER BLOCK

CRANKSHAFT RUNOUT

●Place V-block onto surface plate to support journals at both ends

of crankshaft.

●Position dial indicator vertically onto No. 3 journal.

●Rotate crankshaft to read needle movement on dial indicator.

(Total indicator reading)

CONNECTING ROD BEARING OIL CLEARANCE

Method by Measurement

●Install connecting rod bearings to connecting rod and cap, and

tighten connecting nuts to the specified torque. Use inside

micrometer to measure connecting rod bearing inner diameter.

(Bearing clearance) = (Connecting rod bearing inner diameter) −

(Crankshaft pin outer diameter)

●If out of specifications, check connecting rod big end inner diam-

eter and crankshaft pin outer diameter, and select appropriate

connecting rod bearing to adjust clearance to specifications.

Refer to EM-207, "

HOW TO SELECT CONNECTING ROD

BEARING" .

Method Using Plastigage

●Remove contamination such as engine oil, dust completely from

crankshaft pins and each bearing surface.

●Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

●Install connecting rod bearings to caps, and tighten connecting

rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

●Remove connecting rod caps and bearings, and measure plasti-

gage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in “Method by Measurement”.

MAIN BEARING OIL CLEARANCE

Method by Measurement

●Install main bearings to the cylinder block and bearing cap, and tighten the bolts to the specified torque.

Then, measure the inner diameter of the main bearings.

(Bearing clearance) = (Bearing inner diameter) − (Crankshaft journal outer diameter)

●If out of specification, check main bearing housing inner diameter and crankshaft journal outer diameter,

and select appropriate main bearing to adjust clearance to specifications. Refer to EM-208, "

HOW TO

SELECT MAIN BEARING" . Standard : 0.05 mm (0.0020 in)

Limit : 0.10 mm (0.0039 in)

FEM116

Standard : 0.031 - 0.061 mm (0.0012 - 0.0024 in)

PBIC0119E

EM142

Standard : 0.039 - 0.066 mm (0.0015 - 0.0026 in)

Page 267 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surf NISSAN X-TRAIL 2001 Service Repair Manual CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surf](/img/5/57405/w960_57405-266.png)

CYLINDER BLOCK

EM-217

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

Method Using Plastigage

●Remove contamination such as engine oil and dust completely

from crankshaft journals and each bearing surface.

●Cut plastigage slightly shorter than bearing width. Place it in

crankshaft turning direction, avoiding oil holes.

●Install main bearings and bearing cap and tighten to the speci-

fied torque.

CAUTION:

Never rotate crankshaft.

●Remove main bearings and bearing caps, and measure plasti-

gage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in “Method by Measurement”.

MAIN BEARING CRUSH HEIGHT

●When the bearing cap is removed after being tightened to the

specified torque with main bearings installed, the tip end of bear-

ing must protrude.

●If out of specification, replace main bearings.

MAIN BEARING CAP BOLT DEFORMATION

●Measure the outer diameter of threaded area, d1 and d2, at the

points specified in the figure.

●When the necked point is identified at a point other than where

specified, measure at the point as d2.

●Calculate the difference between d1 and d2.

CONNECTING ROD BOLT DEFORMATION

●Install nuts to connecting rod bolts. Check that the nut can be

screwed smoothly on bolt threads by hand to the last thread on

the bolt.

●If the nut does not screw in smoothly, measure the outer diame-

ter of the bolt thread at the point specified in the figure.

●If a necked point is identified, measure at that point.

●If the measurement exceeds the limit, replace connecting rod

bolts and nuts.

EM142

Standard : Crush height must exist.

SEM502G

Limit : 0.13 mm (0.0051 in)

JEM219G

Standard : 8.90 - 9.00 mm (0.3504 - 0.3543 in) dia.

Limit : 8.75 mm (0. 3445 in) dia.

JEM220G

Page 370 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-20

[QR25(WITH EURO-OBD)]

INDEX FOR DTC

[QR25(WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00M01

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type appr NISSAN X-TRAIL 2001 Service Repair Manual EC-20

[QR25(WITH EURO-OBD)]

INDEX FOR DTC

[QR25(WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00M01

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type appr](/img/5/57405/w960_57405-369.png)

EC-20

[QR25(WITH EURO-OBD)]

INDEX FOR DTC

[QR25(WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00M01

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approval number” on the

identification plate. Refer to GI-43, "

IDENTIFICATION PLATE" .

NOTE:

If DTC U1000 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000. Refer to

EC-122

.

×: Applicable –: Not applicable

Items

(CONSULT-II screen terms)DTC*

1

TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

APP SENSOR P2138 2138 1×EC-373

APP SEN 1/CIRC P2122 2122 1×EC-355

APP SEN 1/CIRC P2123 2123 1×EC-355

APP SEN 2/CIRC P2127 2127 1×EC-361

APP SEN 2/CIRC P2128 2128 1×EC-361

A/T 1ST GR FNCTN P0731 0731 2×AT- 1 3 1

A/T 2ND GR FNCTN P0732 0732 2×AT- 1 3 7

A/T 3RD GR FNCTN P0733 0733 2×AT- 1 4 3

A/T 4TH GR FNCTN P0734 0734 2×AT- 1 4 9

ATF TEMP SEN/CIRC P0710 0710 2×AT- 11 6

BRAKE SW/CIRCUIT P1805 1805 2 –EC-349

CAN COMM CIRCUIT*6U1000

1000*51×EC-122

CKP SEN/CIRCUIT P0335 0335 2×EC-227

CMP SEN/CIRCUIT P0340 0340 2×EC-233

CTP LEARNING P1225 1225 2 –EC-337

CTP LEARNING P1226 1226 2 –EC-339

CYL 1 MISFIRE P0301 0301 2×EC-217

CYL 2 MISFIRE P0302 0302 2×EC-217

CYL 3 MISFIRE P0303 0303 2×EC-217

CYL 4 MISFIRE P0304 0304 2×EC-217

ECM P0605 0605 1 or 2× or –EC-260

ECM BACK UP/CIRC P1065 1065 2×EC-267

ECT SEN/CIRCUIT P0117 0117 1×EC-149

ECT SEN/CIRCUIT P0118 0118 1×EC-149

ENG OVER TEMP P1217 1217 1×EC-323

ENGINE SPEED SIG P0725 0725 2×AT- 1 2 7

ETC ACTR P1121 1121 1 or 2×EC-276

ETC FUNCTION/CIRC P1122 1122 1×EC-278

ETC MOT P1128 1128 1×EC-290

ETC MOT PWR P1124 1124 1×EC-285

ETC MOT PWR P1126 1126 1×EC-285

FUEL SYS-LEAN-B1 P0171 0171 2×EC-200

FUEL SYS-RICH-B1 P0172 0172 2×EC-206

HO2S1 (B1) P0132 0132 2×EC-163

HO2S1 (B1) P0133 0133 2×EC-169