jump cable NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 29 of 3833

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-27

C

D

E

F

G

H

I

J

K

L

MB

GI

VOLTAGE CHECK METHOD

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodically checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

●Connect one probe of the DMM to a known good ground.

●Begin probing at one end of the circuit and work your way to the other end.

●With SW1 open, probe at SW1 to check for voltage.

voltage; open is further down the circuit than SW1.

no voltage; open is between fuse block and SW1 (point A).

●Close SW1 and probe at relay.

voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

●Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

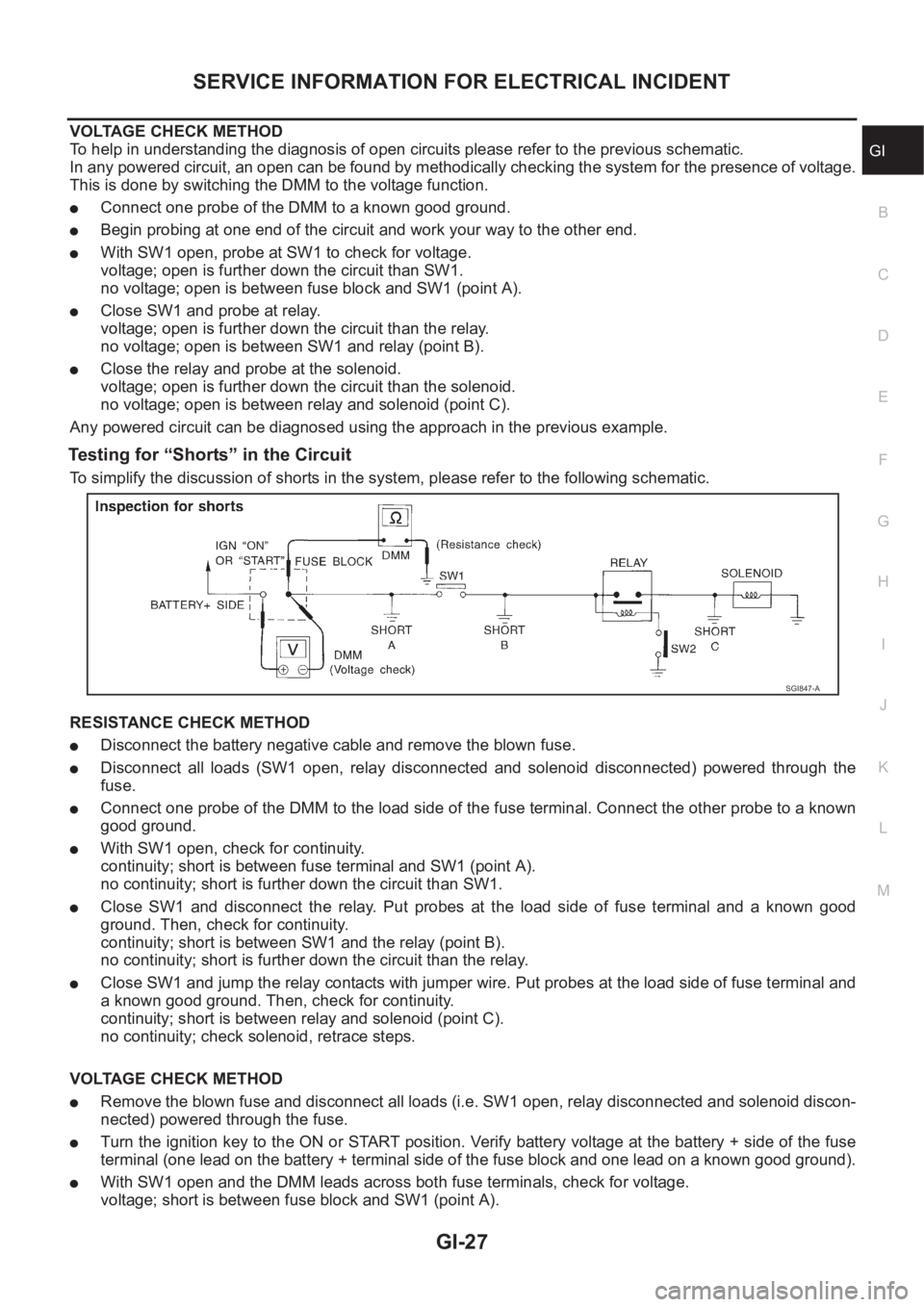

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

●Disconnect the battery negative cable and remove the blown fuse.

●Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the

fuse.

●Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

●With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

●Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good

ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

●Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and

a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

●Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

●Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse

terminal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

●With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

SGI847-A

Page 1892 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-1542

[YD]

DTC P1660 BATTERY VOLTAGE

DTC P1660 BATTERY VOLTAGE

PFP:AYBGL

On Board Diagnosis LogicEBS0035A

The ECM checks if battery voltage is within the tolerance range for the engine control syste NISSAN X-TRAIL 2001 Service Repair Manual EC-1542

[YD]

DTC P1660 BATTERY VOLTAGE

DTC P1660 BATTERY VOLTAGE

PFP:AYBGL

On Board Diagnosis LogicEBS0035A

The ECM checks if battery voltage is within the tolerance range for the engine control syste](/img/5/57405/w960_57405-1891.png)

EC-1542

[YD]

DTC P1660 BATTERY VOLTAGE

DTC P1660 BATTERY VOLTAGE

PFP:AYBGL

On Board Diagnosis LogicEBS0035A

The ECM checks if battery voltage is within the tolerance range for the engine control system.

DTC Confirmation ProcedureEBS0035B

With CONSULT-II

1. Check the following.

–Jumper cables are connected for jump starting.

–Battery or alternator has been replaced.

If the result is “Yes” for one item or more, skip the following steps and go to EC-1542, "

Diagnostic Proce-

dure" .

2. Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3. Check that the alternator functions properly. Refer to SC-12, "

CHARGING SYSTEM" .

4. Turn ignition switch “ON” and select “DATA MONITOR” mode with CONSULT-II.

5. Wait one minute.

6. If DTC is detected, go to EC-1542, "

Diagnostic Procedure" .

If DTC is not detected, go to next step.

7. Start engine and wait one minute at idle.

8. If DTC is detected, go to EC-1542, "

Diagnostic Procedure" .

Diagnostic ProcedureEBS0035C

1. INSPECTION START

Are jumper cables connected for the jump starting?

Ye s o r N o

Yes >> GO TO 3.

No >> GO TO 2.

2. CHECK BATTERY AND ALTERNATOR

Check that the proper type of battery and alternator is installed.

Refer to SC-3, "

BATTERY" , SC-12, "CHARGING SYSTEM" .

OK or NG

OK >> GO TO 5.

NG >> Replace with a proper one.

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1660

●An abnormally high or low voltage from the battery

is sent to ECM.●Incorrect jump starting

●Battery

●Alternator

●ECM

Page 1893 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P1660 BATTERY VOLTAGE

EC-1543

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

OK or NG

OK >> GO TO 4.

NG >> Re NISSAN X-TRAIL 2001 Service Repair Manual DTC P1660 BATTERY VOLTAGE

EC-1543

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

OK or NG

OK >> GO TO 4.

NG >> Re](/img/5/57405/w960_57405-1892.png)

DTC P1660 BATTERY VOLTAGE

EC-1543

[YD]

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK JUMPER CABLES INSTALLATION

Check that the jumper cables are connected in the correct sequence.

OK or NG

OK >> GO TO 4.

NG >> Reconnect jumper cables properly.

4.CHECK BATTERY FOR BOOSTER

Check that the battery for the booster is a 12V battery.

OK or NG

OK >> GO TO 5.

NG >> Change the vehicle for booster.

5.PERFORM DTC CONFIRMATION PROCEDURE AGAIN

Perform EC-1542, "

DTC Confirmation Procedure" , again.

OK or NG

OK >> GO TO 6.

NG >> Replace ECM.

6.CHECK ELECTRICAL PARTS DAMAGE

Check the following for damage.

●Wiring harness and harness connectors for burn

●Fuses for short

OK or NG

OK >>INSPECTION END

NG >> Repair or replace malfunctioning part.

SEF439Z

Page 3459 of 3833

BATTERY

SC-3

C

D

E

F

G

H

I

J

L

MA

B

SC

BATTERY PFP:00011

How to Handle Battery EKS00313

CAUTION:

●If it becomes necessary to start the engine with a booster battery and jumper cables, use a 12-volt

booster battery.

●After connecting battery cables, ensure that they are tightly clamped to battery terminals for good

contact.

●Never add distilled water through the hole used to check specific gravity.

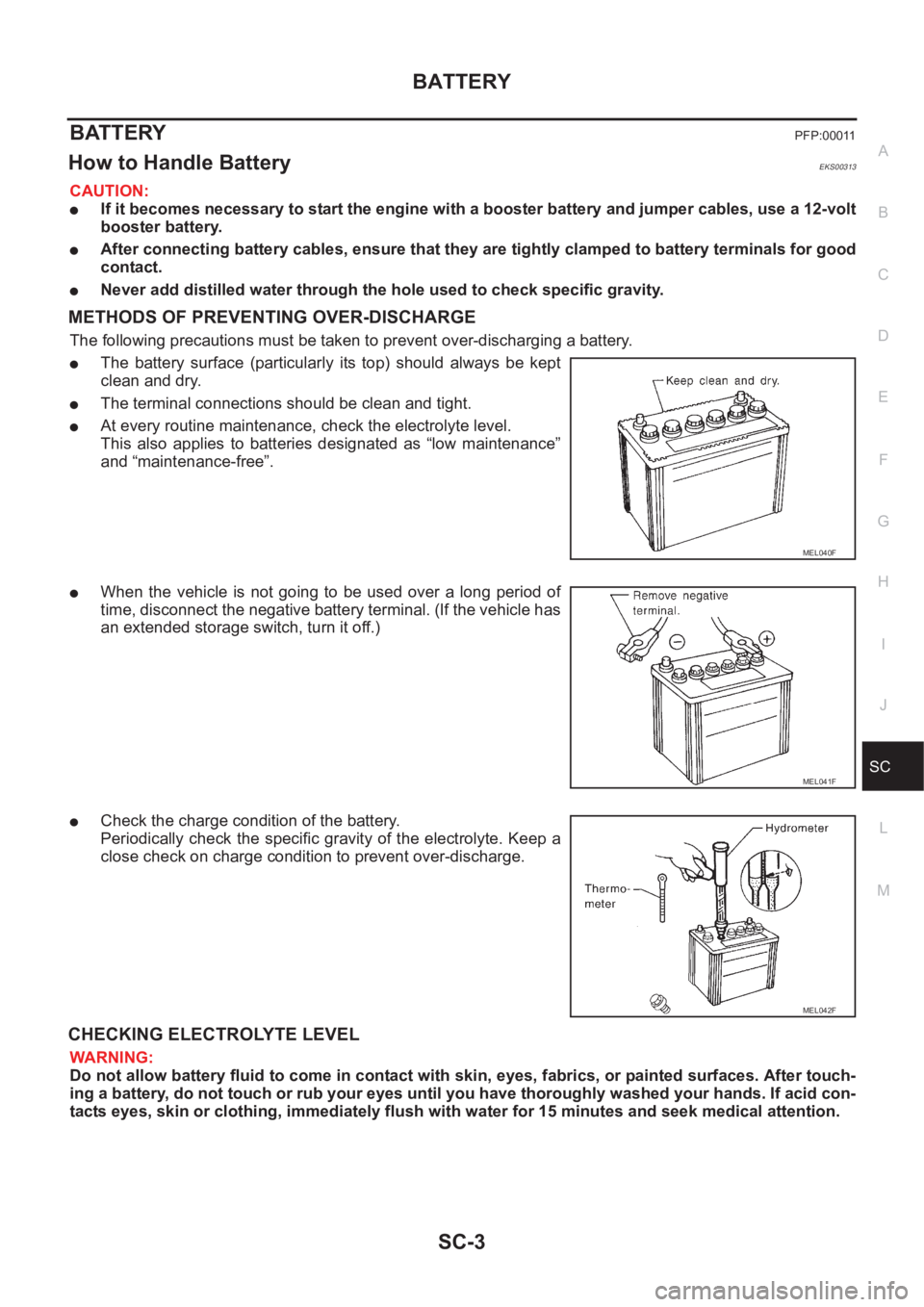

METHODS OF PREVENTING OVER-DISCHARGE

The following precautions must be taken to prevent over-discharging a battery.

●The battery surface (particularly its top) should always be kept

clean and dry.

●The terminal connections should be clean and tight.

●At every routine maintenance, check the electrolyte level.

This also applies to batteries designated as “low maintenance”

and “maintenance-free”.

●When the vehicle is not going to be used over a long period of

time, disconnect the negative battery terminal. (If the vehicle has

an extended storage switch, turn it off.)

●Check the charge condition of the battery.

Periodically check the specific gravity of the electrolyte. Keep a

close check on charge condition to prevent over-discharge.

CHECKING ELECTROLYTE LEVEL

WARNING:

Do not allow battery fluid to come in contact with skin, eyes, fabrics, or painted surfaces. After touch-

ing a battery, do not touch or rub your eyes until you have thoroughly washed your hands. If acid con-

tacts eyes, skin or clothing, immediately flush with water for 15 minutes and seek medical attention.

MEL040F

MEL041F

MEL042F

Page 3701 of 3833

AUDIO

AV-13

C

D

E

F

G

H

I

J

L

MA

B

AV

InspectionEKS002F6

AUDIO UNIT

All voltage inspections are made with:

●Ignition switch ON or ACC

●Audio unit ON

●Audio unit connected (If audio unit is removed for inspection, supply a ground to the case using a jumper

wire.)

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

●If reception improves, check antenna ground (at body surface).

●If reception does not improve, check main feeder cable for short circuit or open circuit.

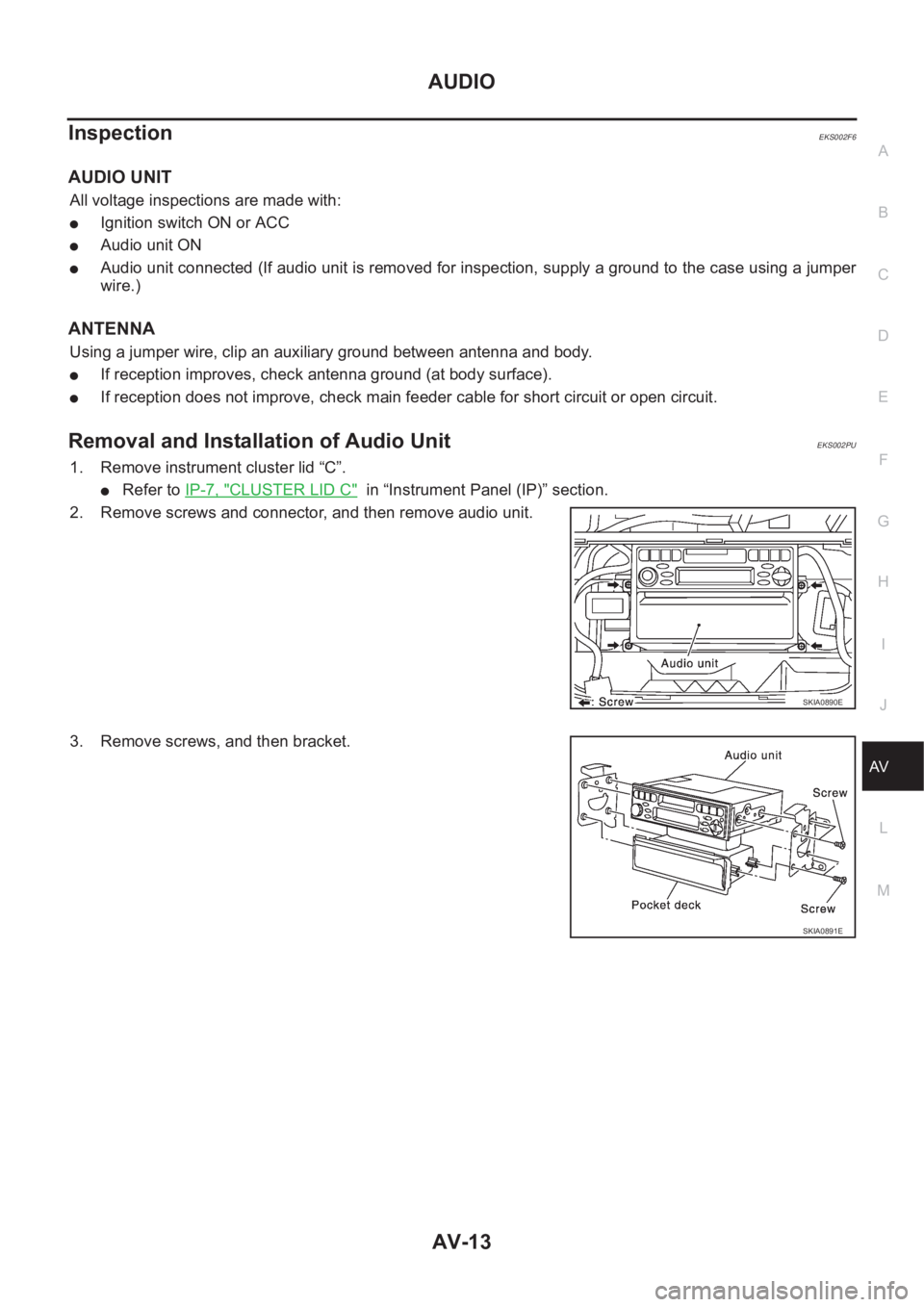

Removal and Installation of Audio UnitEKS002PU

1. Remove instrument cluster lid “C”.

● Refer to IP-7, "CLUSTER LID C" in “Instrument Panel (IP)” section.

2. Remove screws and connector, and then remove audio unit.

3. Remove screws, and then bracket.

SKIA0890E

SKIA0891E