load capacity NISSAN X-TRAIL 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 316 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui NISSAN X-TRAIL 2001 Service Repair Manual CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genui](/img/5/57405/w960_57405-315.png)

CO-10

[QR]

ENGINE COOLANT

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

●Apply sealant to the thread of cylinder block drain plug.

Use Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

●Use genuine Nissan engine coolant or equivalent in its

quality. Refer to MA-16, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

●Pour engine coolant slowly of less than 2 (1-3/4 lmp qt)

a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

●If engine coolant overflows radiator filler hole, install

radiator cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

●Repeat two or three times.

Watch engine coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

●Cool down using a fan to reduce the time.

●If necessary, refill radiator up to filler neck with engine coolant.

6. Refill reservoir tank to MAX level line with engine coolant.

7. Repeat steps 4 through 6 two or more times with radiator cap installed until engine coolant level no longer

drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between COOL and WARM.

●Sound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 4 through 6 until engine coolant level

no longer drops.

●Clean excess engine coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator. Cylinder block drain plug:

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank: 0.6 (1/2 lmp qt)

SMA412B

Page 535 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P0138 HO2S2

EC-185

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0138 HO2S2PFP:226A0

Component DescriptionEBS00M42

The heated oxygen sensor 2, after three way catalyst (manifold),

NISSAN X-TRAIL 2001 Service Repair Manual DTC P0138 HO2S2

EC-185

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0138 HO2S2PFP:226A0

Component DescriptionEBS00M42

The heated oxygen sensor 2, after three way catalyst (manifold),](/img/5/57405/w960_57405-534.png)

DTC P0138 HO2S2

EC-185

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0138 HO2S2PFP:226A0

Component DescriptionEBS00M42

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the heated oxygen sensor 1 are

shifted, the air-fuel ratio is controlled to stoichiometric, by the signal

from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeEBS00M43

Specification data are reference values.

ECM Terminals and Reference ValueEBS00M44

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS00M45

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity before the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the voltage is unusually high during

the various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.LEAN←→ RICH

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

95 OR/BHeated oxygen sen-

sor 2[Engine is running]

●Warm-up condition

●Revving engine from idle up to 3,000 rpm quickly

after the following conditions are met.

●Keeping the engine speed between 3,500 and

4,000 rpm for one minute and at idle for one

minute under no load.0 - Approximately 1.0V

SEF305UA

Page 542 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual EC-192

[QR25(WITH EURO-OBD)]

DTC P0139 HO2S2

DTC P0139 HO2S2

PFP:226A0

Component DescriptionEBS00M4C

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level NISSAN X-TRAIL 2001 Service Repair Manual EC-192

[QR25(WITH EURO-OBD)]

DTC P0139 HO2S2

DTC P0139 HO2S2

PFP:226A0

Component DescriptionEBS00M4C

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level](/img/5/57405/w960_57405-541.png)

EC-192

[QR25(WITH EURO-OBD)]

DTC P0139 HO2S2

DTC P0139 HO2S2

PFP:226A0

Component DescriptionEBS00M4C

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1 are

shifted, the air-fuel ratio is controlled to stoichiometric, by the signal

from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeEBS00M4D

Specification data are reference values.

ECM Terminals and Reference ValueEBS00M4E

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS00M4F

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity before the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the switching response of the sen-

sor's voltage is faster than specified during the various driving condi-

tion such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.LEAN ←→ RICH

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

95 OR/BHeated oxygen sen-

sor 2[Engine is running]

●Warm-up condition

●Revving engine from idle up to 3,000 rpm quickly

after the following conditions are met.

●Keeping the engine speed between 3,500 and

4,000 rpm for one minute and at idle for one

minute under no load.0 - Approximately 1.0V

SEF302U

Page 589 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-239

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0420 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicEBS00M5U

The ECM monitors the sw NISSAN X-TRAIL 2001 Service Repair Manual DTC P0420 THREE WAY CATALYST FUNCTION

EC-239

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0420 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicEBS00M5U

The ECM monitors the sw](/img/5/57405/w960_57405-588.png)

DTC P0420 THREE WAY CATALYST FUNCTION

EC-239

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0420 THREE WAY CATALYST FUNCTIONPFP:20905

On Board Diagnosis LogicEBS00M5U

The ECM monitors the switching frequency ratio of heated oxygen

sensors 1 and 2.

A three way catalyst (Manifold) with high oxygen storage capacity

will indicate a low switching frequency of heated oxygen sensor 2.

As oxygen storage capacity decreases, the heated oxygen sensor 2

switching frequency will increase.

When the frequency ratio of heated oxygen sensors 1 and 2

approaches a specified limit value, the three way catalyst (Manifold)

malfunction is diagnosed.

DTC Confirmation ProcedureEBS00M5V

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch “OFF” and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

TESTING CONDITION:

●Open engine hood before conducting the following procedure.

●Do not hold engine speed for more than the specified minutes below.

1. Start engine and warm it up to the normal operating temperature.

2. Turn ignition switch ″OFF″ and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least one minute under no

load.

4. Let engine idle for one minute.

5. Select “DTC & SRT CONFIRMATION” then “SRT WORK SUP-

PORT” mode with CONSULT-II.

6. Rev engine up to 2,000 to 3,000 rpm and hold it for 3 consecu-

tive minutes then release the accelerator pedal completely.

If “INCMP” of “CATALYST” changed to “COMPLT”, go to step 9

7. Wait 5 seconds at idle.

SEF484YF

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0420

0420Catalyst system effi-

ciency below threshold

●Three way catalyst (Manifold) does not oper-

ate properly.

●Three way catalyst (Manifold) does not have

enough oxygen storage capacity.

●Three way catalyst (Manifold)

●Exhaust tube

●Intake air leaks

●Fuel injectors

●Fuel injector leaks

●Spark plug

●Improper ignition timing

PBIB0822E

Page 657 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P1146 HO2S2

EC-307

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1146 HO2S2PFP:226A0

Component DescriptionEBS00M8F

The heated oxygen sensor 2, after three way catalyst (manifold),

NISSAN X-TRAIL 2001 Service Repair Manual DTC P1146 HO2S2

EC-307

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1146 HO2S2PFP:226A0

Component DescriptionEBS00M8F

The heated oxygen sensor 2, after three way catalyst (manifold),](/img/5/57405/w960_57405-656.png)

DTC P1146 HO2S2

EC-307

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1146 HO2S2PFP:226A0

Component DescriptionEBS00M8F

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the heated oxygen sensor 1 are

shifted, the air-fuel ratio is controlled to stoichiometric, by the signal

from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeEBS00M8G

Specification data are reference values.

ECM Terminals and Reference ValueEBS00M8H

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS00M8I

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity before the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the minimum voltage of sensor is

sufficiently low during the various driving condition such as fuel-cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.LEAN←→ RICH

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

95 OR/BHeated oxygen sen-

sor 2[Engine is running]

●Warm-up condition

●Revving engine from idle up to 3,000 rpm quickly

after the following conditions are met.

●Keeping the engine speed between 3,500 and

4,000 rpm for one minute and at idle for one

minute under no load.0 - Approximately 1.0V

PBIB0554E

Page 665 of 3833

![NISSAN X-TRAIL 2001 Service Repair Manual DTC P1147 HO2S2

EC-315

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1147 HO2S2PFP:226A0

Component DescriptionEBS00M8P

The heated oxygen sensor 2, after three way catalyst (manifold),

NISSAN X-TRAIL 2001 Service Repair Manual DTC P1147 HO2S2

EC-315

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1147 HO2S2PFP:226A0

Component DescriptionEBS00M8P

The heated oxygen sensor 2, after three way catalyst (manifold),](/img/5/57405/w960_57405-664.png)

DTC P1147 HO2S2

EC-315

[QR25(WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P1147 HO2S2PFP:226A0

Component DescriptionEBS00M8P

The heated oxygen sensor 2, after three way catalyst (manifold),

monitors the oxygen level in the exhaust gas on each bank.

Even if switching characteristics of the heated oxygen sensor 1 are

shifted, the air-fuel ratio is controlled to stoichiometric, by the signal

from the heated oxygen sensor 2.

This sensor is made of ceramic zirconia. The zirconia generates volt-

age from approximately 1V in richer conditions to 0V in leaner condi-

tions.

Under normal conditions the heated oxygen sensor 2 is not used for

engine control operation.

CONSULT-II Reference Value in Data Monitor ModeEBS00M8Q

Specification data are reference values.

ECM Terminals and Reference ValueEBS00M8R

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS00M8S

The heated oxygen sensor 2 has a much longer switching time

between rich and lean than the heated oxygen sensor 1. The oxygen

storage capacity before the three way catalyst (manifold) causes the

longer switching time. To judge the malfunctions of heated oxygen

sensor 2, ECM monitors whether the maximum voltage of the sensor

is sufficiently high during the various driving condition such as fuel-

cut.

SEF327R

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.0 - 0.3V ←→ Approx. 0.6 - 1.0V

HO2S2 MNTR (B1)

●Engine: After warming up

●Keeping the engine speed at

between 3,500 to 4,000 rpm for

one minute and at idle for one

minute under no loadRevving engine from idle up to 3,000

rpm quickly.LEAN←→ RICH

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

95 OR/BHeated oxygen sen-

sor 2[Engine is running]

●Warm-up condition

●Revving engine from idle up to 3,000 rpm quickly

after the following conditions are met.

●Keeping the engine speed between 3,500 and

4,000 rpm for one minute and at idle for one

minute under no load.0 - Approximately 1.0V

SEF259VA

Page 2669 of 3833

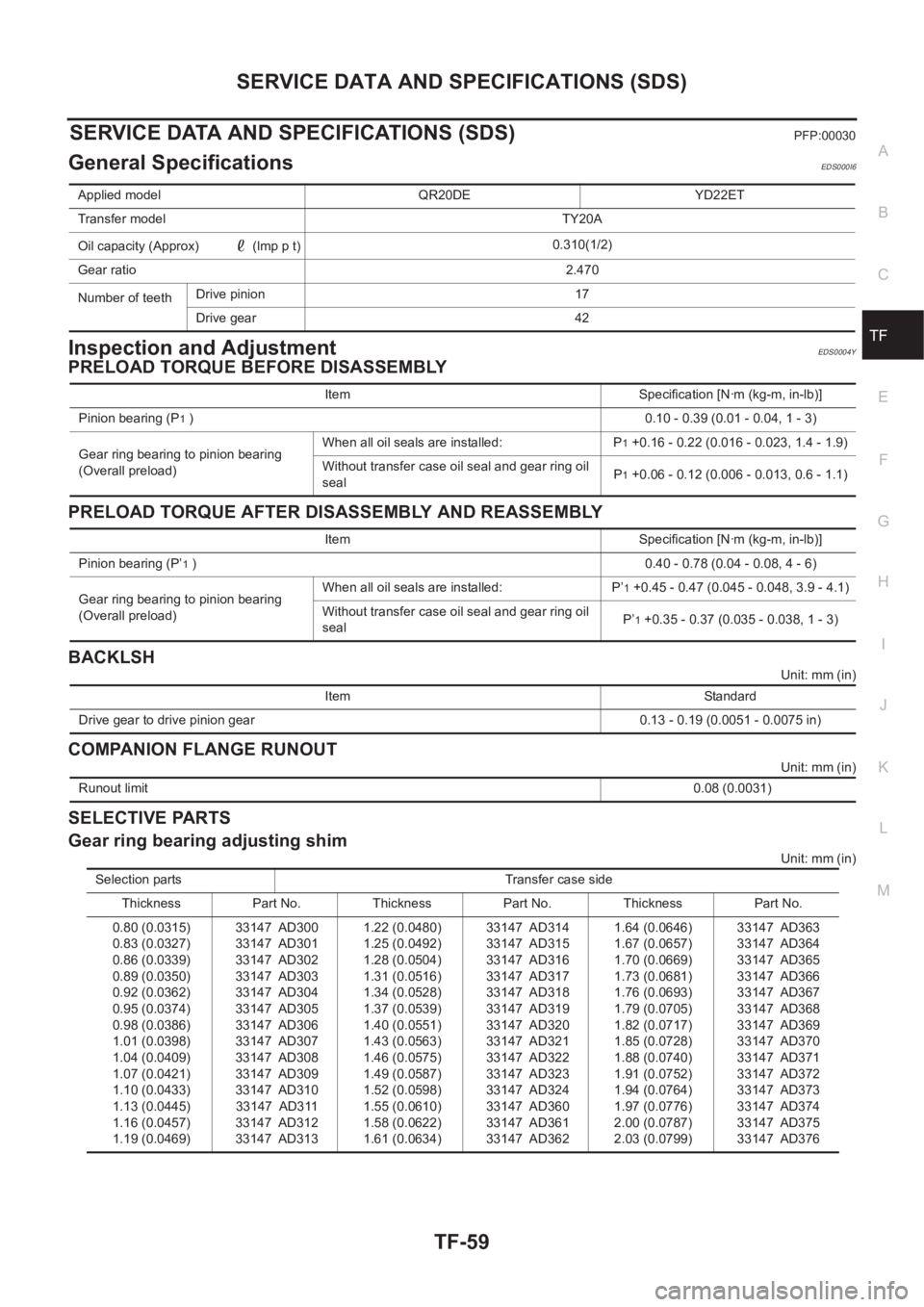

SERVICE DATA AND SPECIFICATIONS (SDS)

TF-59

C

E

F

G

H

I

J

K

L

MA

B

TF

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS000I6

Inspection and AdjustmentEDS0004Y

PRELOAD TORQUE BEFORE DISASSEMBLY

PRELOAD TORQUE AFTER DISASSEMBLY AND REASSEMBLY

BACKLSH

Unit: mm (in)

COMPANION FLANGE RUNOUT

Unit: mm (in)

SELECTIVE PARTS

Gear ring bearing adjusting shim

Unit: mm (in) Applied model QR20DE YD22ET

Transfer model TY20A

Oil capacity (Approx) (lmp p t)0.310(1/2)

Gear ratio2.470

Number of teeth Drive pinion 17

Drive gear 42

Item Specification [N·m (kg-m, in-lb)]

Pinion bearing (P

1 )0.10 - 0.39 (0.01 - 0.04, 1 - 3)

Gear ring bearing to pinion bearing

(Overall preload)When all oil seals are installed: P

1 +0.16 - 0.22 (0.016 - 0.023, 1.4 - 1.9)

Without transfer case oil seal and gear ring oil

sealP

1 +0.06 - 0.12 (0.006 - 0.013, 0.6 - 1.1)

Item Specification [N·m (kg-m, in-lb)]

Pinion bearing (P’

1 )0.40 - 0.78 (0.04 - 0.08, 4 - 6)

Gear ring bearing to pinion bearing

(Overall preload)When all oil seals are installed: P’

1 +0.45 - 0.47 (0.045 - 0.048, 3.9 - 4.1)

Without transfer case oil seal and gear ring oil

sealP’

1 +0.35 - 0.37 (0.035 - 0.038, 1 - 3)

Item Standard

Drive gear to drive pinion gear 0.13 - 0.19 (0.0051 - 0.0075 in)

Runout limit 0.08 (0.0031)

Selection parts Transfer case side

Thickness Part No. Thickness Part No. Thickness Part No.

0.80 (0.0315)

0.83 (0.0327)

0.86 (0.0339)

0.89 (0.0350)

0.92 (0.0362)

0.95 (0.0374)

0.98 (0.0386)

1.01 (0.0398)

1.04 (0.0409)

1.07 (0.0421)

1.10 (0.0433)

1.13 (0.0445)

1.16 (0.0457)

1.19 (0.0469)33147 AD300

33147 AD301

33147 AD302

33147 AD303

33147 AD304

33147 AD305

33147 AD306

33147 AD307

33147 AD308

33147 AD309

33147 AD310

33147 AD311

33147 AD312

33147 AD3131.22 (0.0480)

1.25 (0.0492)

1.28 (0.0504)

1.31 (0.0516)

1.34 (0.0528)

1.37 (0.0539)

1.40 (0.0551)

1.43 (0.0563)

1.46 (0.0575)

1.49 (0.0587)

1.52 (0.0598)

1.55 (0.0610)

1.58 (0.0622)

1.61 (0.0634)33147 AD314

33147 AD315

33147 AD316

33147 AD317

33147 AD318

33147 AD319

33147 AD320

33147 AD321

33147 AD322

33147 AD323

33147 AD324

33147 AD360

33147 AD361

33147 AD3621.64 (0.0646)

1.67 (0.0657)

1.70 (0.0669)

1.73 (0.0681)

1.76 (0.0693)

1.79 (0.0705)

1.82 (0.0717)

1.85 (0.0728)

1.88 (0.0740)

1.91 (0.0752)

1.94 (0.0764)

1.97 (0.0776)

2.00 (0.0787)

2.03 (0.0799)33147 AD363

33147 AD364

33147 AD365

33147 AD366

33147 AD367

33147 AD368

33147 AD369

33147 AD370

33147 AD371

33147 AD372

33147 AD373

33147 AD374

33147 AD375

33147 AD376

Page 2705 of 3833

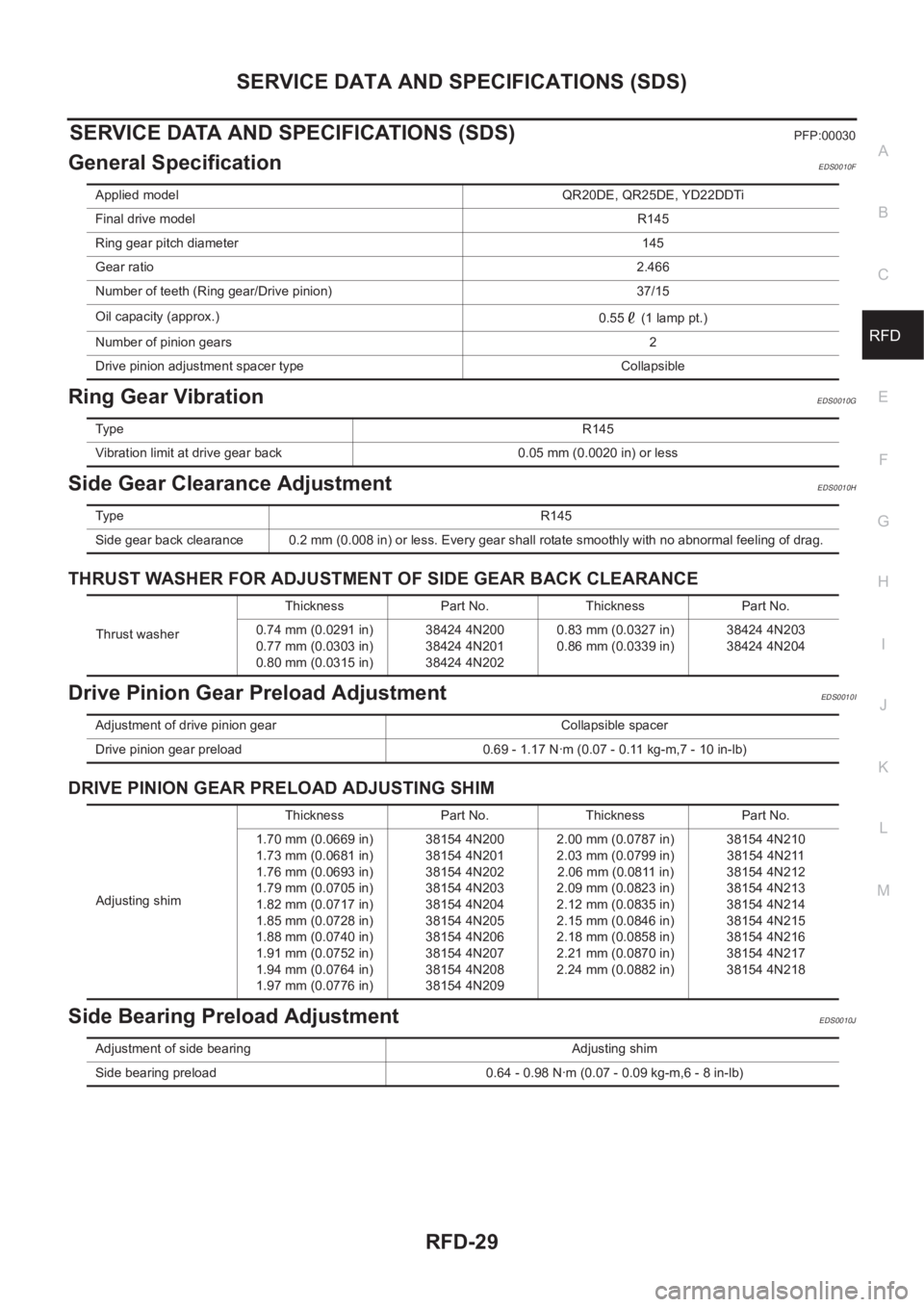

SERVICE DATA AND SPECIFICATIONS (SDS)

RFD-29

C

E

F

G

H

I

J

K

L

MA

B

RFD

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationEDS0010F

Ring Gear VibrationEDS0010G

Side Gear Clearance AdjustmentEDS0010H

THRUST WASHER FOR ADJUSTMENT OF SIDE GEAR BACK CLEARANCE

Drive Pinion Gear Preload AdjustmentEDS0010I

DRIVE PINION GEAR PRELOAD ADJUSTING SHIM

Side Bearing Preload AdjustmentEDS0010J

Applied model QR20DE, QR25DE, YD22DDTi

Final drive modelR145

Ring gear pitch diameter 145

Gear ratio2.466

Number of teeth (Ring gear/Drive pinion) 37/15

Oil capacity (approx.)

0.55 (1 lamp pt.)

Number of pinion gears2

Drive pinion adjustment spacer type Collapsible

Ty p eR145

Vibration limit at drive gear back 0.05 mm (0.0020 in) or less

Ty p e R 1 4 5

Side gear back clearance 0.2 mm (0.008 in) or less. Every gear shall rotate smoothly with no abnormal feeling of drag.

Thrust washerThickness Part No. Thickness Part No.

0.74 mm (0.0291 in)

0.77 mm (0.0303 in)

0.80 mm (0.0315 in)38424 4N200

38424 4N201

38424 4N2020.83 mm (0.0327 in)

0.86 mm (0.0339 in)38424 4N203

38424 4N204

Adjustment of drive pinion gear Collapsible spacer

Drive pinion gear preload 0.69 - 1.17 N·m (0.07 - 0.11 kg-m,7 - 10 in-lb)

Adjusting shimThickness Part No. Thickness Part No.

1.70 mm (0.0669 in)

1.73 mm (0.0681 in)

1.76 mm (0.0693 in)

1.79 mm (0.0705 in)

1.82 mm (0.0717 in)

1.85 mm (0.0728 in)

1.88 mm (0.0740 in)

1.91 mm (0.0752 in)

1.94 mm (0.0764 in)

1.97 mm (0.0776 in)38154 4N200

38154 4N201

38154 4N202

38154 4N203

38154 4N204

38154 4N205

38154 4N206

38154 4N207

38154 4N208

38154 4N2092.00 mm (0.0787 in)

2.03 mm (0.0799 in)

2.06 mm (0.0811 in)

2.09 mm (0.0823 in)

2.12 mm (0.0835 in)

2.15 mm (0.0846 in)

2.18 mm (0.0858 in)

2.21 mm (0.0870 in)

2.24 mm (0.0882 in)38154 4N210

38154 4N211

38154 4N212

38154 4N213

38154 4N214

38154 4N215

38154 4N216

38154 4N217

38154 4N218

Adjustment of side bearing Adjusting shim

Side bearing preload 0.64 - 0.98 N·m (0.07 - 0.09 kg-m,6 - 8 in-lb)

Page 3297 of 3833

REFRIGERATION SYSTEM

ATC-21

C

D

E

F

G

H

I

K

L

MA

B

AT C

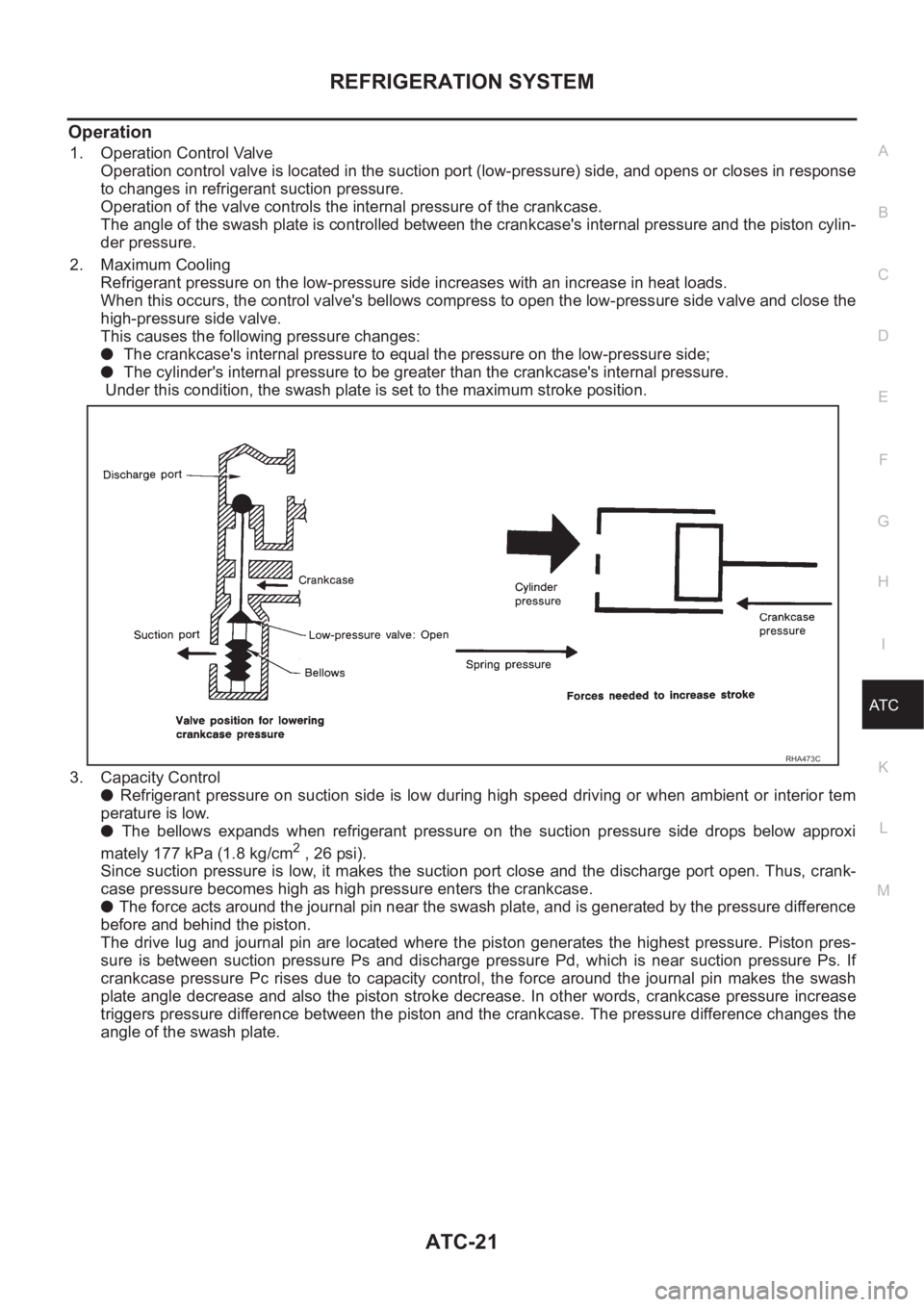

Operation

1. Operation Control Valve

Operation control valve is located in the suction port (low-pressure) side, and opens or closes in response

to changes in refrigerant suction pressure.

Operation of the valve controls the internal pressure of the crankcase.

The angle of the swash plate is controlled between the crankcase's internal pressure and the piston cylin-

der pressure.

2. Maximum Cooling

Refrigerant pressure on the low-pressure side increases with an increase in heat loads.

When this occurs, the control valve's bellows compress to open the low-pressure side valve and close the

high-pressure side valve.

This causes the following pressure changes:

● The crankcase's internal pressure to equal the pressure on the low-pressure side;

● The cylinder's internal pressure to be greater than the crankcase's internal pressure.

Under this condition, the swash plate is set to the maximum stroke position.

3. Capacity Control

● Refrigerant pressure on suction side is low during high speed driving or when ambient or interior tem

perature is low.

● The bellows expands when refrigerant pressure on the suction pressure side drops below approxi

mately 177 kPa (1.8 kg/cm

2 , 26 psi).

Since suction pressure is low, it makes the suction port close and the discharge port open. Thus, crank-

case pressure becomes high as high pressure enters the crankcase.

● The force acts around the journal pin near the swash plate, and is generated by the pressure difference

before and behind the piston.

The drive lug and journal pin are located where the piston generates the highest pressure. Piston pres-

sure is between suction pressure Ps and discharge pressure Pd, which is near suction pressure Ps. If

crankcase pressure Pc rises due to capacity control, the force around the journal pin makes the swash

plate angle decrease and also the piston stroke decrease. In other words, crankcase pressure increase

triggers pressure difference between the piston and the crankcase. The pressure difference changes the

angle of the swash plate.

RHA473C

Page 3489 of 3833

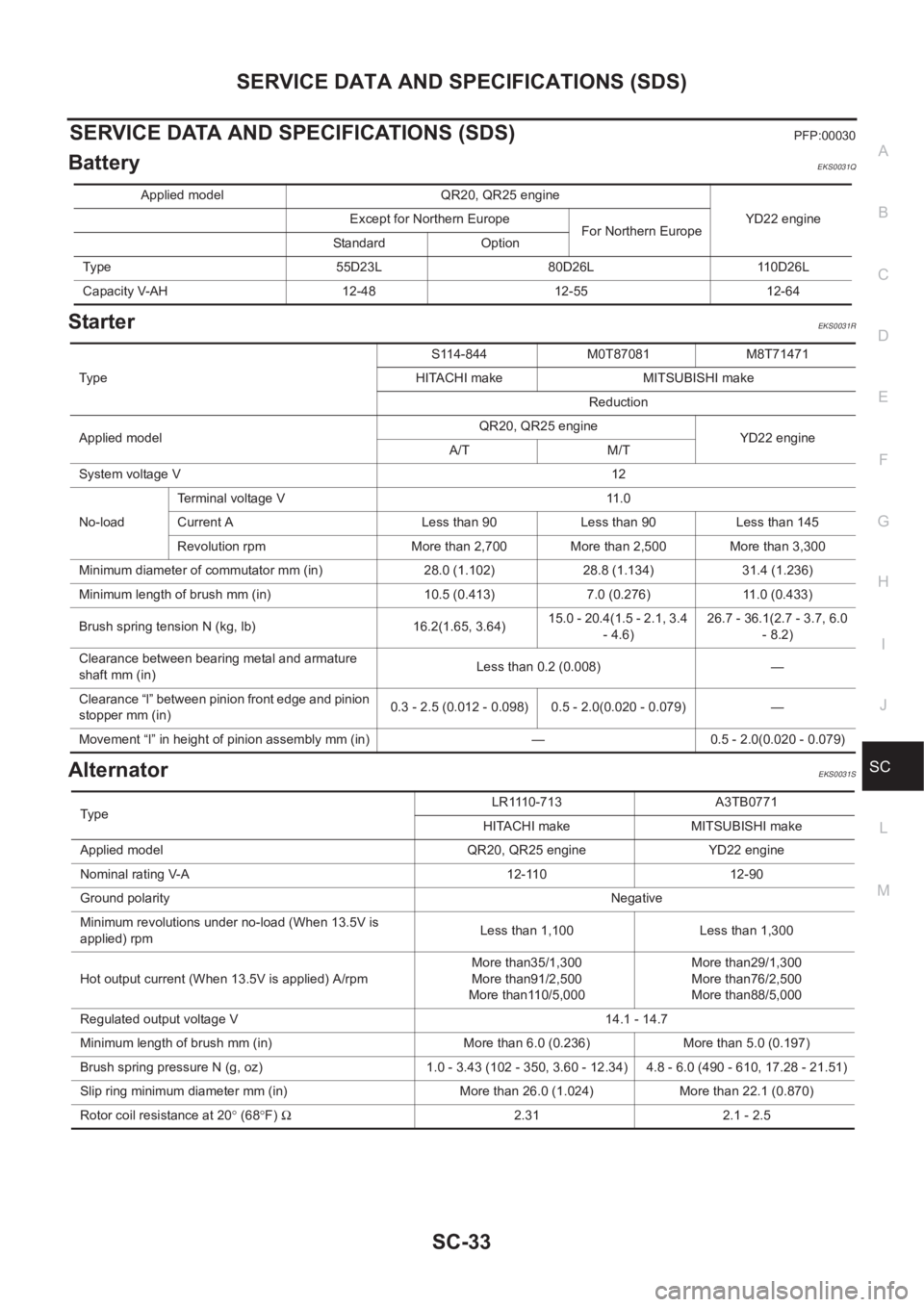

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-33

C

D

E

F

G

H

I

J

L

MA

B

SC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

BatteryEKS0031Q

StarterEKS0031R

AlternatorEKS0031S

Applied model QR20, QR25 engine

YD22 engine Except for Northern Europe

For Northern Europe

Standard Option

Type 55D23L 80D26L 110D26L

Capacity V-AH 12-48 12-55 12-64

TypeS114-844 M0T87081 M8T71471

HITACHI make MITSUBISHI make

Reduction

Applied modelQR20, QR25 engine

YD22 engine

A/T M/T

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 90 Less than 90 Less than 145

Revolution rpm More than 2,700 More than 2,500 More than 3,300

Minimum diameter of commutator mm (in) 28.0 (1.102) 28.8 (1.134) 31.4 (1.236)

Minimum length of brush mm (in) 10.5 (0.413) 7.0 (0.276) 11.0 (0.433)

Brush spring tension N (kg, lb) 16.2(1.65, 3.64)15.0 - 20.4(1.5 - 2.1, 3.4

- 4.6)26.7 - 36.1(2.7 - 3.7, 6.0

- 8.2)

Clearance between bearing metal and armature

shaft mm (in)Less than 0.2 (0.008) —

Clearance “l” between pinion front edge and pinion

stopper mm (in)0.3 - 2.5 (0.012 - 0.098) 0.5 - 2.0(0.020 - 0.079) —

Movement “l” in height of pinion assembly mm (in) — 0.5 - 2.0(0.020 - 0.079)

TypeLR1110-713 A3TB0771

HITACHI make MITSUBISHI make

Applied model QR20, QR25 engine YD22 engine

Nominal rating V-A 12-110 12-90

Ground polarityNegative

Minimum revolutions under no-load (When 13.5V is

applied) rpmLess than 1,100 Less than 1,300

Hot output current (When 13.5V is applied) A/rpmMore than35/1,300

More than91/2,500

More than110/5,000More than29/1,300

More than76/2,500

More than88/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 6.0 (0.236) More than 5.0 (0.197)

Brush spring pressure N (g, oz) 1.0 - 3.43 (102 - 350, 3.60 - 12.34) 4.8 - 6.0 (490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 26.0 (1.024) More than 22.1 (0.870)

Rotor coil resistance at 20° (68°F) Ω2.31 2.1 - 2.5