boot NISSAN X-TRAIL 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2209 of 3066

FRONT DRIVE SHAFT

FAX-13

C

E

F

G

H

I

J

K

L

MA

B

FA X

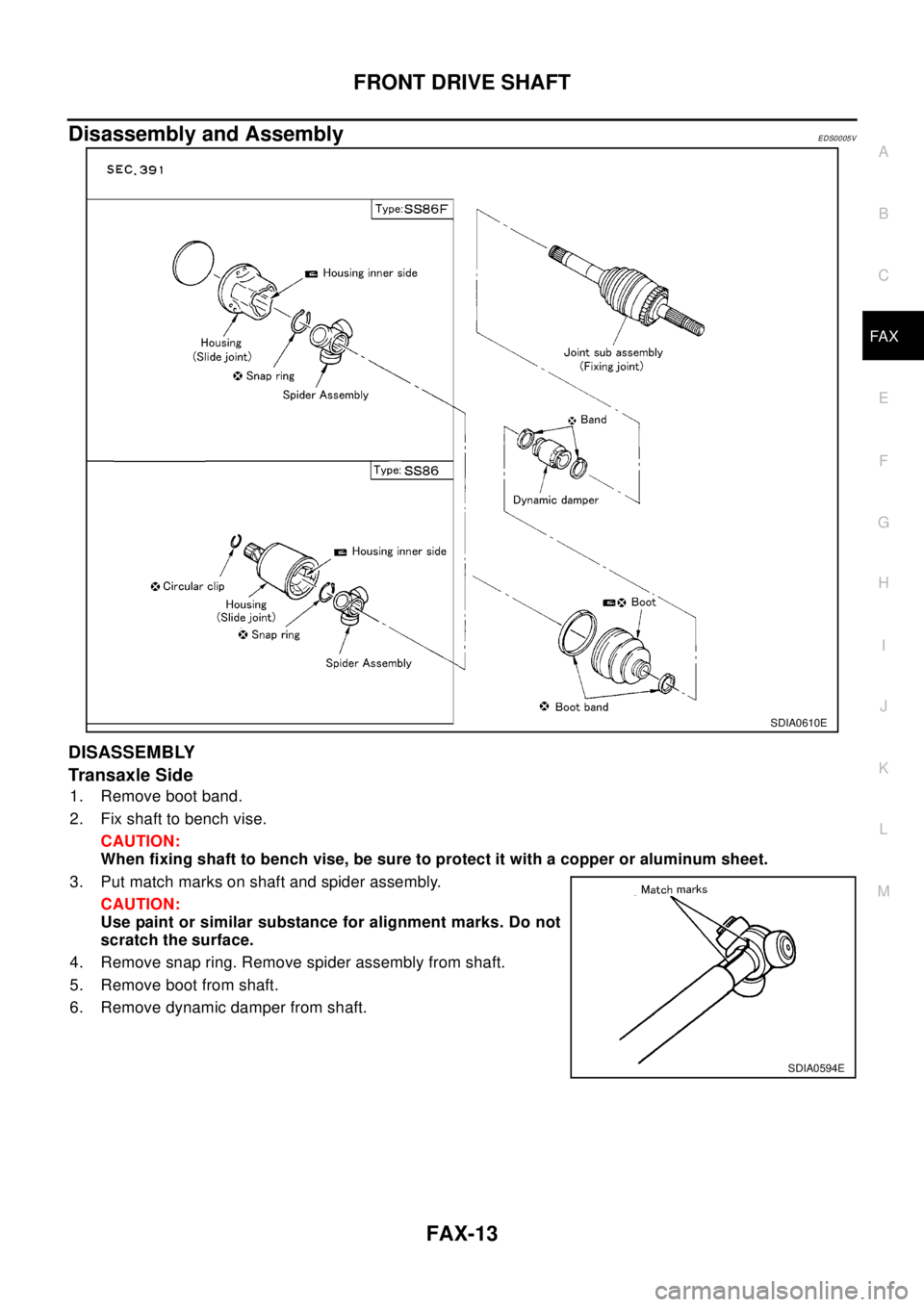

Disassembly and AssemblyEDS0005V

DISASSEMBLY

Transaxle Side

1. Remove boot band.

2. Fix shaft to bench vise.

CAUTION:

When fixing shaft to bench vise, be sure to protect it with a copper or aluminum sheet.

3. Put match marks on shaft and spider assembly.

CAUTION:

Use paint or similar substance for alignment marks. Do not

scratch the surface.

4. Remove snap ring. Remove spider assembly from shaft.

5. Remove boot from shaft.

6. Remove dynamic damper from shaft.

SDIA0610E

SDIA0594E

Page 2210 of 3066

FAX-14

FRONT DRIVE SHAFT

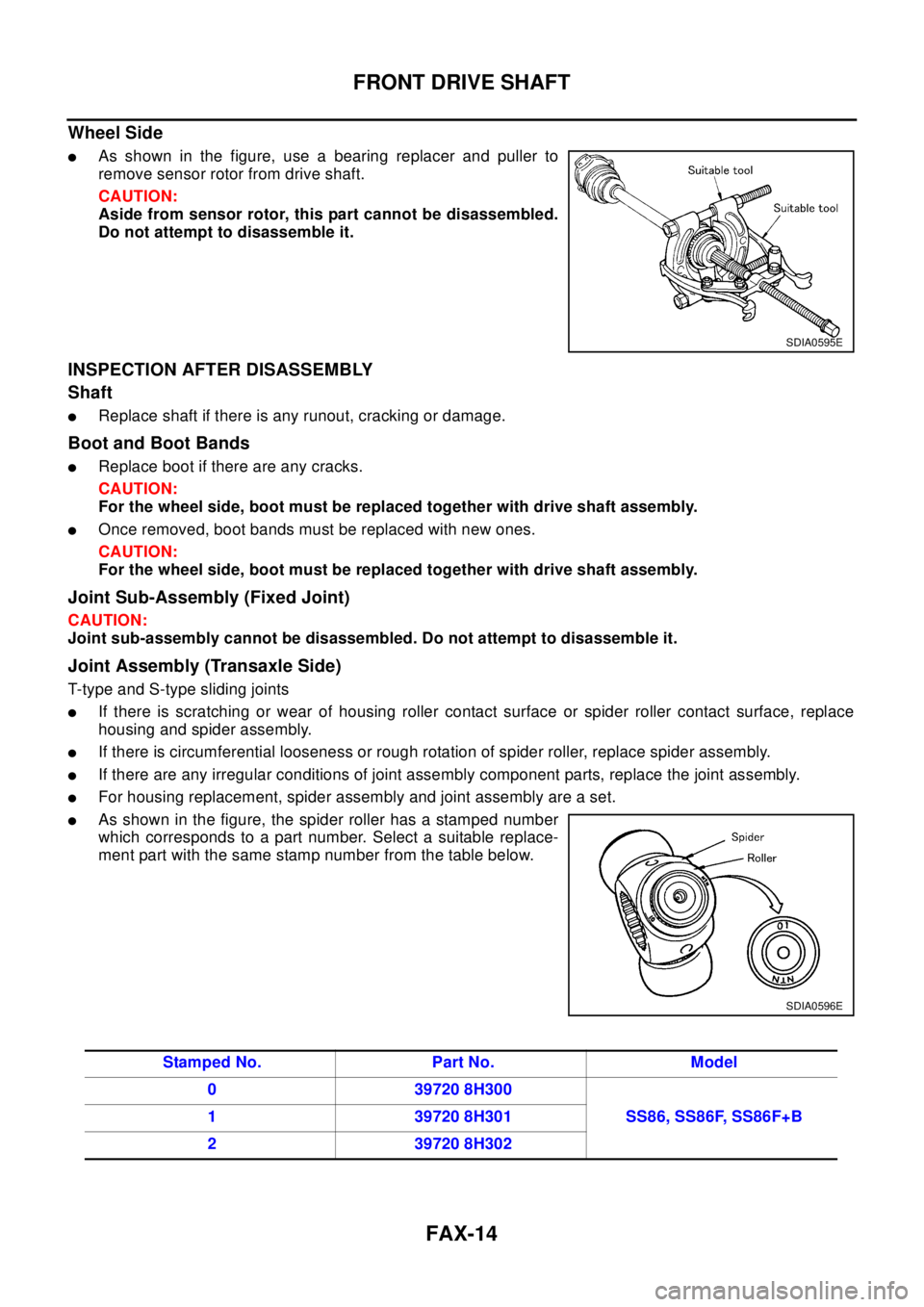

Wheel Side

lAs shown in the figure, use a bearing replacer and puller to

remove sensor rotor from drive shaft.

CAUTION:

Aside from sensor rotor, this part cannot be disassembled.

Do not attempt to disassemble it.

INSPECTION AFTER DISASSEMBLY

Shaft

lReplace shaft if there is any runout, cracking or damage.

Boot and Boot Bands

lReplace boot if there are any cracks.

CAUTION:

For the wheel side, boot must be replaced together with drive shaft assembly.

lOnce removed, boot bands must be replaced with new ones.

CAUTION:

For the wheel side, boot must be replaced together with drive shaft assembly.

Joint Sub-Assembly (Fixed Joint)

CAUTION:

Joint sub-assembly cannot be disassembled. Do not attempt to disassemble it.

Joint Assembly (Transaxle Side)

T-typeandS-typeslidingjoints

lIf there is scratching or wear of housing roller contact surface or spider roller contact surface, replace

housing and spider assembly.

lIf there is circumferential looseness or rough rotation of spider roller, replace spider assembly.

lIf there are any irregular conditions of joint assembly component parts, replace the joint assembly.

lFor housing replacement, spider assembly and joint assembly are a set.

lAs shown in the figure, the spider roller has a stamped number

which corresponds to a part number. Select a suitable replace-

ment part with the same stamp number from the table below.

SDIA0595E

SDIA0596E

Stamped No. Part No. Model

0 39720 8H300

SS86, SS86F, SS86F+B 1 39720 8H301

2 39720 8H302

Page 2211 of 3066

FRONT DRIVE SHAFT

FAX-15

C

E

F

G

H

I

J

K

L

MA

B

FA X

Joint Assembly (Wheel Side)

CAUTION:

Joint assembly cannot be disassembled. Do not attempt to disassemble it.

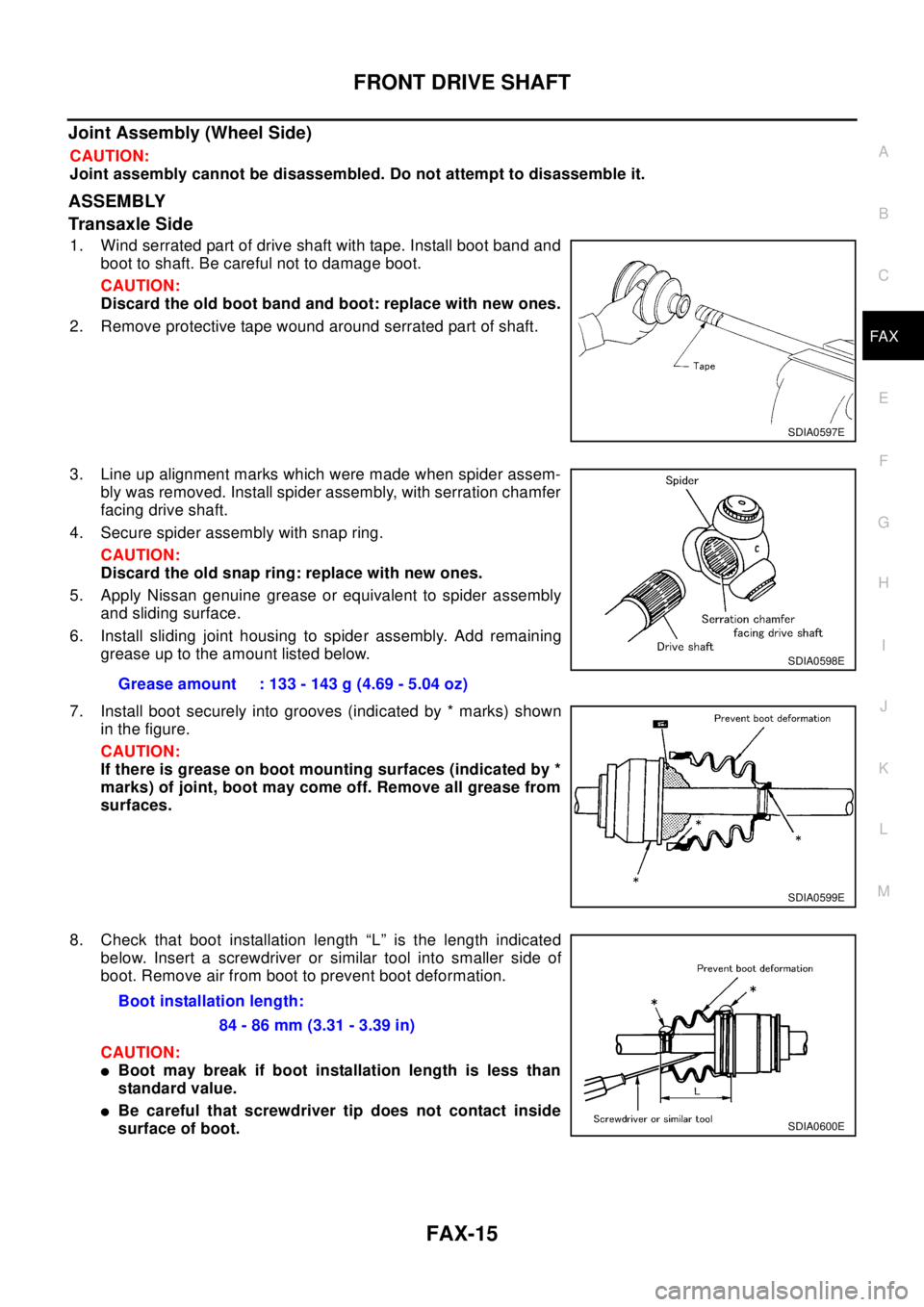

ASSEMBLY

Transaxle Side

1. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot: replace with new ones.

2. Remove protective tape wound around serrated part of shaft.

3. Line up alignment marks which were made when spider assem-

bly was removed. Install spider assembly, with serration chamfer

facing drive shaft.

4. Secure spider assembly with snap ring.

CAUTION:

Discard the old snap ring: replace with new ones.

5. Apply Nissan genuine grease or equivalent to spider assembly

and sliding surface.

6. Install sliding joint housing to spider assembly. Add remaining

grease up to the amount listed below.

7. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint, boot may come off. Remove all grease from

surfaces.

8. Check that boot installation length “L” is the length indicated

below. Insert a screwdriver or similar tool into smaller side of

boot. Remove air from boot to prevent boot deformation.

CAUTION:

lBoot may break if boot installation length is less than

standard value.

lBe careful that screwdriver tip does not contact inside

surface of boot.

SDIA0597E

Grease amount : 133 - 143 g (4.69 - 5.04 oz)

SDIA0598E

SDIA0599E

Boot installation length:

84 - 86 mm (3.31 - 3.39 in)

SDIA0600E

Page 2212 of 3066

FAX-16

FRONT DRIVE SHAFT

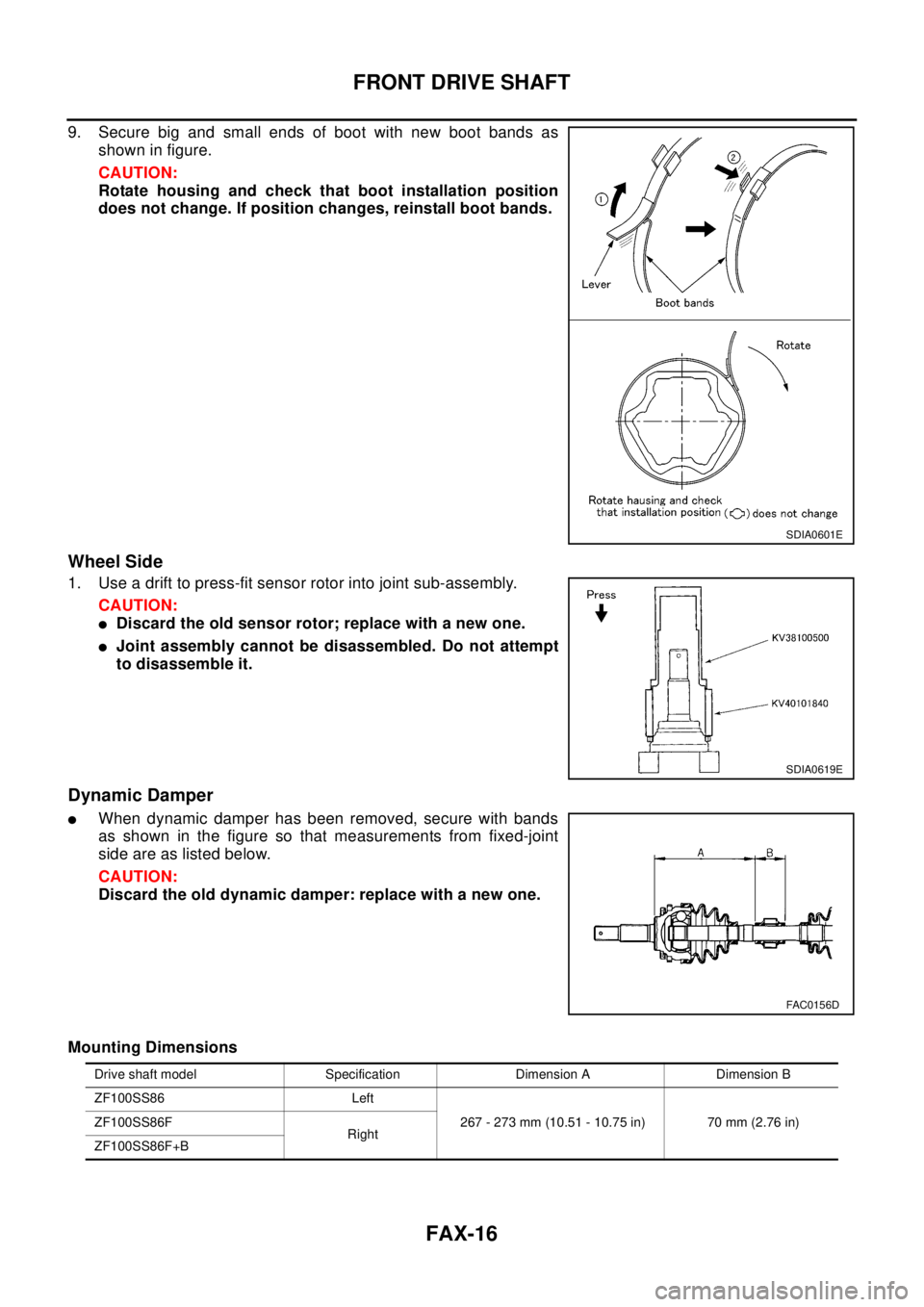

9. Secure big and small ends of boot with new boot bands as

shown in figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.

Wheel Side

1. Use a drift to press-fit sensor rotor into joint sub-assembly.

CAUTION:

lDiscard the old sensor rotor; replace with a new one.

lJoint assembly cannot be disassembled. Do not attempt

to disassemble it.

Dynamic Damper

lWhen dynamic damper has been removed, secure with bands

as shown in the figure so that measurements from fixed-joint

side are as listed below.

CAUTION:

Discard the old dynamic damper: replace with a new one.

Mounting Dimensions

SDIA0601E

SDIA0619E

FAC0156D

Drive shaft model Specification Dimension A Dimension B

ZF100SS86 Left

267 - 273 mm (10.51 - 10.75 in) 70 mm (2.76 in) ZF100SS86F

Right

ZF100SS86F+B

Page 2213 of 3066

SERVICE DATA AND SPECIFICATIONS (SDS)

FAX-17

C

E

F

G

H

I

J

K

L

MA

B

FA X

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

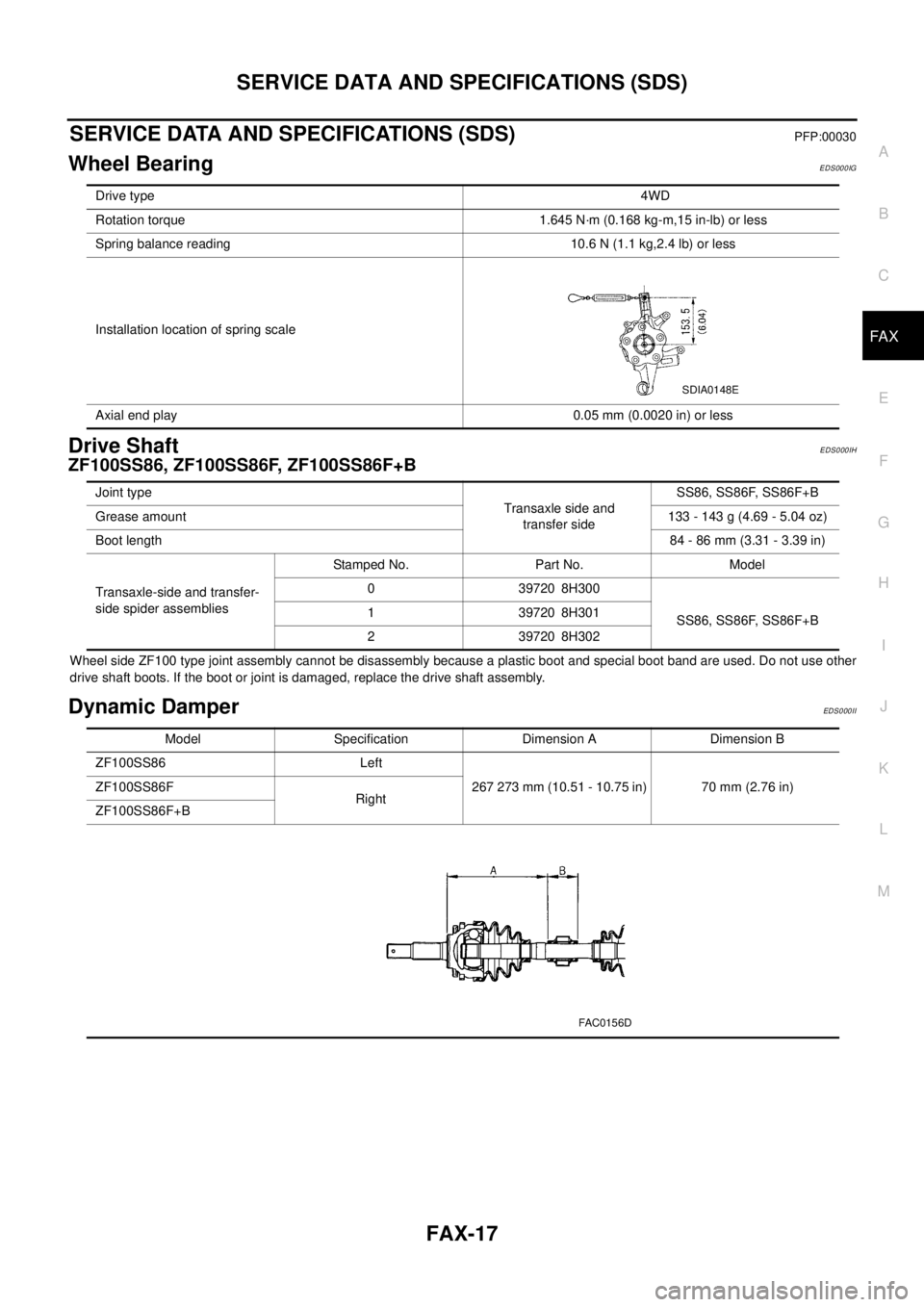

Wheel BearingEDS000IG

Drive ShaftEDS000IH

ZF100SS86, ZF100SS86F, ZF100SS86F+B

Wheel side ZF100 type joint assembly cannot be disassembly because a plastic boot and special boot band are used. Do not use other

drive shaft boots. If the boot or joint is damaged, replace the drive shaft assembly.

Dynamic DamperEDS0 00 II

Drive type4WD

Rotation torque 1.645 N·m (0.168 kg-m,15 in-lb) or less

Spring balance reading 10.6 N (1.1 kg,2.4 lb) or less

Installation location of spring scale

Axial end play 0.05 mm (0.0020 in) or less

SDIA0148E

Joint type

Transaxle side and

transfer sideSS86, SS86F, SS86F+B

Grease amount133-143g(4.69-5.04oz)

Boot length84 - 86 mm (3.31 - 3.39 in)

Transaxle-side and transfer-

side spider assembliesStamped No. Part No. Model

0 39720 8H300

SS86, SS86F, SS86F+B 1 39720 8H301

2 39720 8H302

Model Specification Dimension A Dimension B

ZF100SS86 Left

267 273 mm (10.51 - 10.75 in) 70 mm (2.76 in) ZF100SS86F

Right

ZF100SS86F+B

FAC0156D

Page 2245 of 3066

FSU-6

FRONT SUSPENSION ASSEMBLY

On-Vehicle Inspection and Service

EES00072

LOOSENESS, BACKLASH AND DAMAGE OF MOUNTING PARTS AND CONNECTIONS

Lift vehicle and inspect the following:

lCheck mounting point of each component for looseness, backlash and damage.

lCheck lower ball joint end play.

1. Attach a dial gauge so that the contact rests on the brake caliper.

2. Set front wheels in a straight-ahead position. Do not depress brake pedal.

3. Measure axial endplay by placing an iron pry bar or something similar between transverse link and steer-

ing knuckle.

CAUTION:

Be careful not to damage ball joint boot.

4. If axial endplay is outside the standard, remove transverse link and check lower ball joint.

Wheel AlignmentEES00073

DESCRIPTION

lMeasure wheel alignment under unladen conditions. “Unladen conditions” means that fuel, coolant, and

lubricant are full. However, spare tire, jack, and hand tools should be unloaded.

PRELIMINARY INSPECTION

1. Check the tires for improper air pressure and wear.

2. Check road wheels for runout.

3. Check wheel bearing axial endplay.

4. Check lower ball joint axial endplay.

5. Check strut operation.

6. Check each mounting point of axle and suspension for looseness and deformation.

7. Check each link and arm for cracks, deformation, and other damage.

8. Check the vehicle posture.

INSPECTION OF CAMBER, CASTER, AND KINGPIN INCLINATION ANGLES

lCamber, caster, and kingpin inclination angles cannot be adjusted.

lBefore inspection, mount front wheels onto turning radius gauge. Mount rear wheels onto a stand that has

same height so the vehicle will remain horizontal.

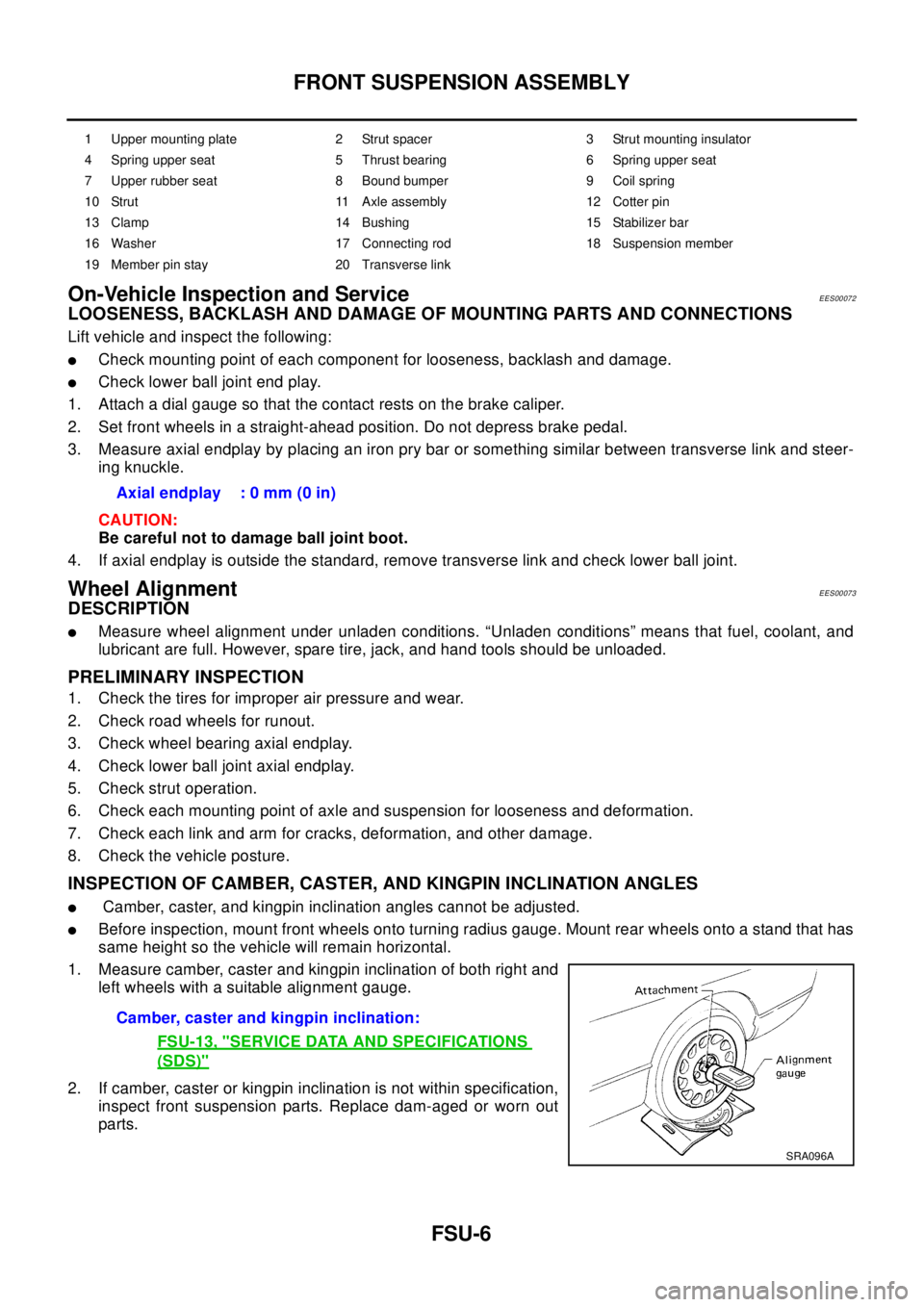

1. Measure camber, caster and kingpin inclination of both right and

left wheels with a suitable alignment gauge.

2. If camber, caster or kingpin inclination is not within specification,

inspect front suspension parts. Replace dam-aged or worn out

parts.

1 Upper mounting plate 2 Strut spacer 3 Strut mounting insulator

4 Spring upper seat 5 Thrust bearing 6 Spring upper seat

7 Upper rubber seat 8 Bound bumper 9 Coil spring

10 Strut 11 Axle assembly 12 Cotter pin

13 Clamp 14 Bushing 15 Stabilizer bar

16 Washer 17 Connecting rod 18 Suspension member

19 Member pin stay 20 Transverse link

Axial endplay : 0 mm (0 in)

Camber, caster and kingpin inclination:

FSU-13, "

SERVICE DATA AND SPECIFICATIONS

(SDS)"

SRA096A

Page 2532 of 3066

MA-40

CHASSIS AND BODY MAINTENANCE

PA D

lCheck for wear or damage.

Checking Drum BrakeELS000BN

WHEEL CYLINDER

Check for leakage.

DRUM

Check condition and inner surface.

LINING

Check wear or damage.

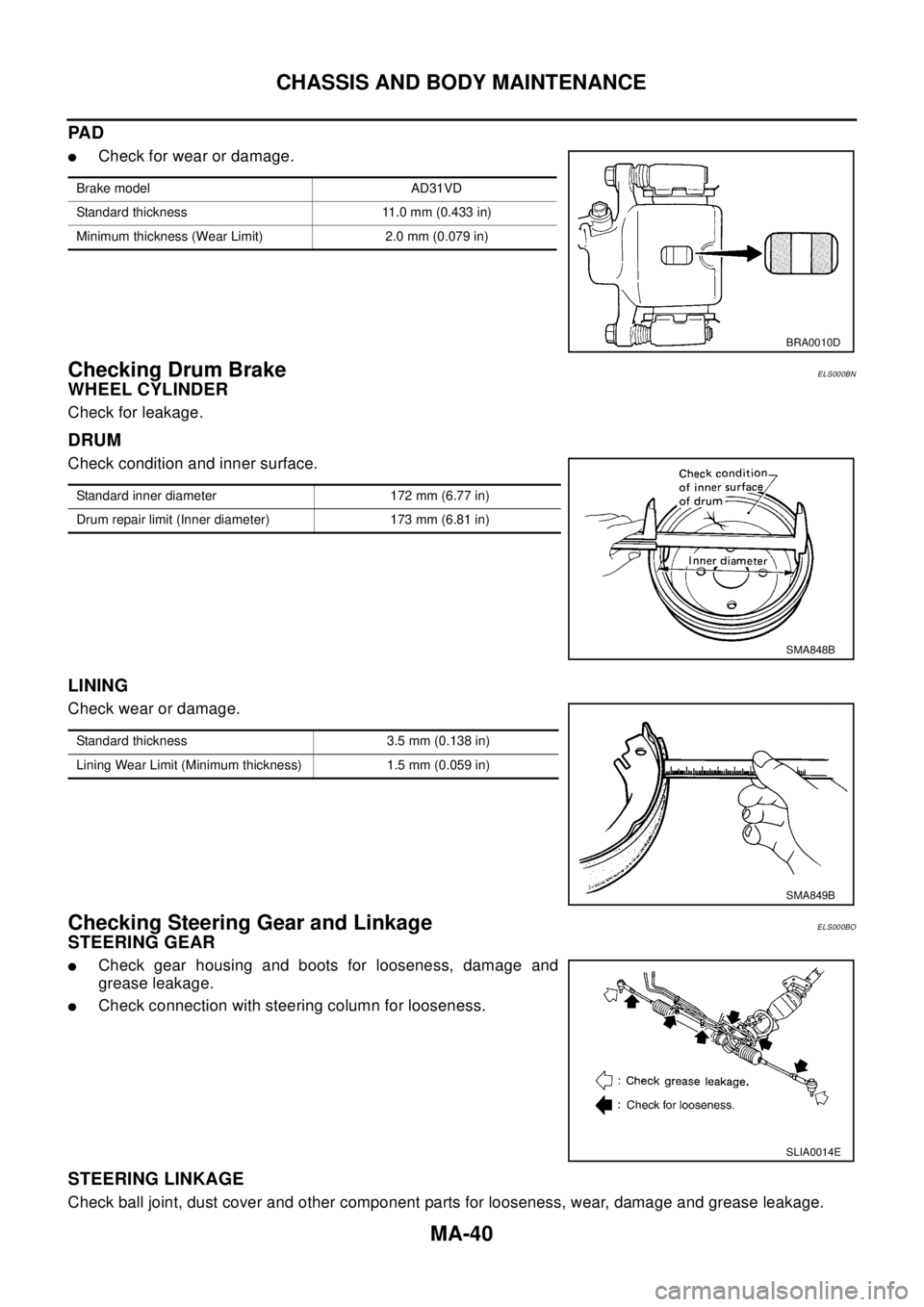

Checking Steering Gear and LinkageELS000BO

STEERING GEAR

lCheck gear housing and boots for looseness, damage and

grease leakage.

lCheck connection with steering column for looseness.

STEERING LINKAGE

Check ball joint, dust cover and other component parts for looseness, wear, damage and grease leakage.

Brake model AD31VD

Standard thickness 11.0 mm (0.433 in)

Minimum thickness (Wear Limit) 2.0 mm (0.079 in)

BRA0010D

Standard inner diameter 172 mm (6.77 in)

Drum repair limit (Inner diameter) 173 mm (6.81 in)

SMA848B

Standard thickness 3.5 mm (0.138 in)

Lining Wear Limit (Minimum thickness) 1.5 mm (0.059 in)

SMA849B

SLIA0014E

Page 2533 of 3066

CHASSIS AND BODY MAINTENANCE

MA-41

C

D

E

F

G

H

I

J

K

MA

B

MA

Checking Power Steering Fluid and LinesELS000BP

Check fluid level in reservoir tank with engine off.

Use “HOT” range at fluid temperatures of 50 to 80°C (122 to 176°F)

or “COLD” range at fluid temperatures of 0 to 30°C(32to86°F).

CAUTION:

lDo not overfill.

lRecommended fluid is DEXRONTMIII or equivalent.

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS"

lCheck lines for improper attachment, leaks, cracks, dam-

age, loose connections, chafing and deterioration.

lCheck rack boots for accumulation of power steering fluid.

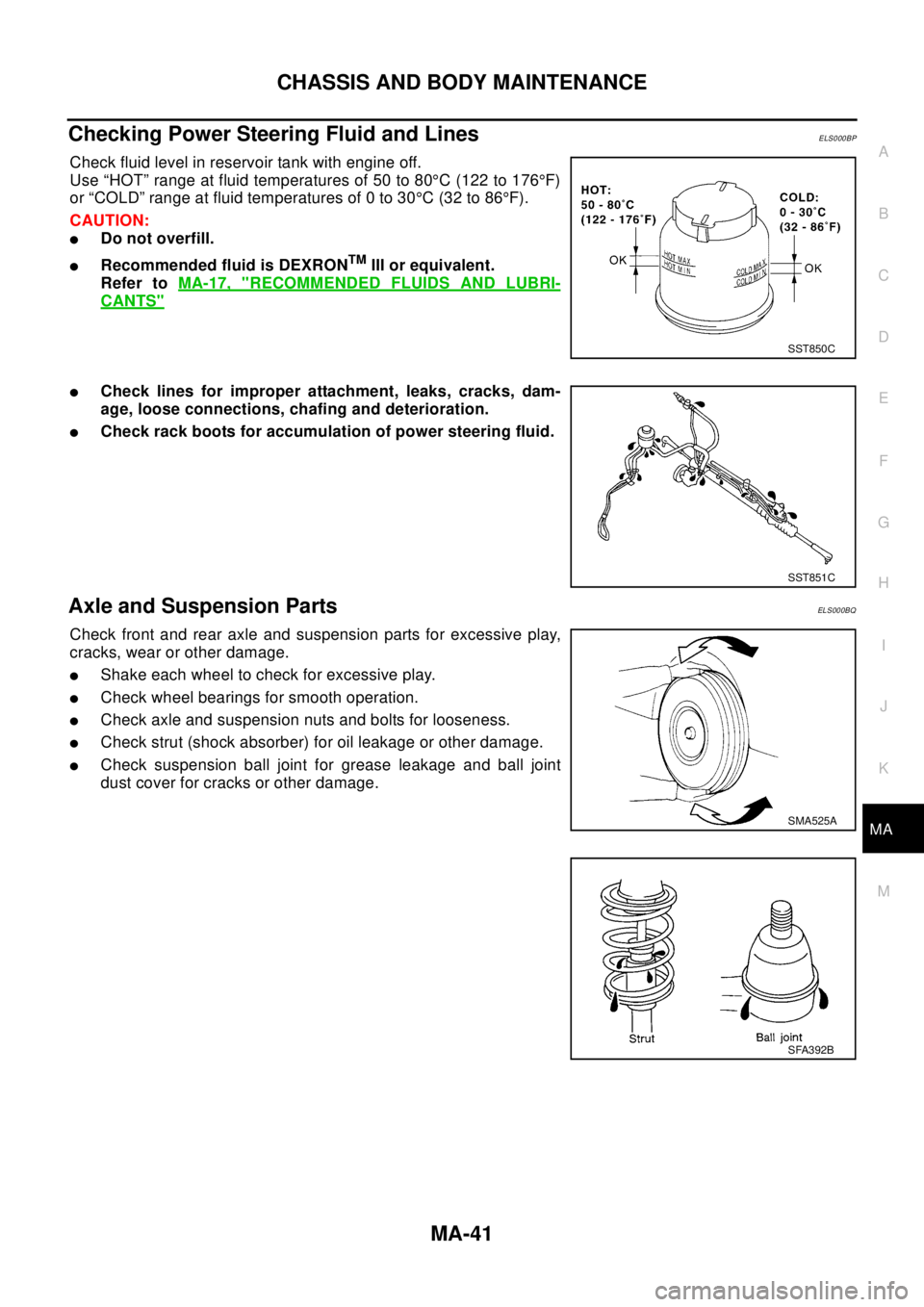

Axle and Suspension PartsELS000BQ

Check front and rear axle and suspension parts for excessive play,

cracks, wear or other damage.

lShake each wheel to check for excessive play.

lCheck wheel bearings for smooth operation.

lCheck axle and suspension nuts and bolts for looseness.

lCheck strut (shock absorber) for oil leakage or other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks or other damage.

SST850C

SST851C

SMA525A

SFA392B

Page 2534 of 3066

MA-42

CHASSIS AND BODY MAINTENANCE

Drive Shaft

ELS000CL

lCheck boot and drive shaft for cracks, wear, damage and

grease leakage.

Lubricating Locks, Hinges and Hood LatchesELS000BR

Checking Seat Belts, Buckles, Retractors, Anchors and AdjustersELS000BS

Checking Body CorrosionELS000C0

Visually check body panels for collision damage (scratches, chipping, rubbing, etc.) or damage to the anti-cor-

rosion materials. In particular, check the following locations.

HEMMED PANELS

Hood front end, door lower end, trunk lid rear end, etc.

PANEL JOINT

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine com-

partment, etc.

PANEL EDGE

Trunk lid opening, sunroof opening, fender wheel-arch flange, fuel filler lid flange, around holes in panel, etc.

PA R T S C O N TA C T

Waist moulding, windshield moulding, bumper, etc.

SFA108A

Front door Refer toBL-8, "DOOR".

Back door Refer toBL-60, "

BACK DOOR".

Page 2757 of 3066

REAR PROPELLER SHAFT

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

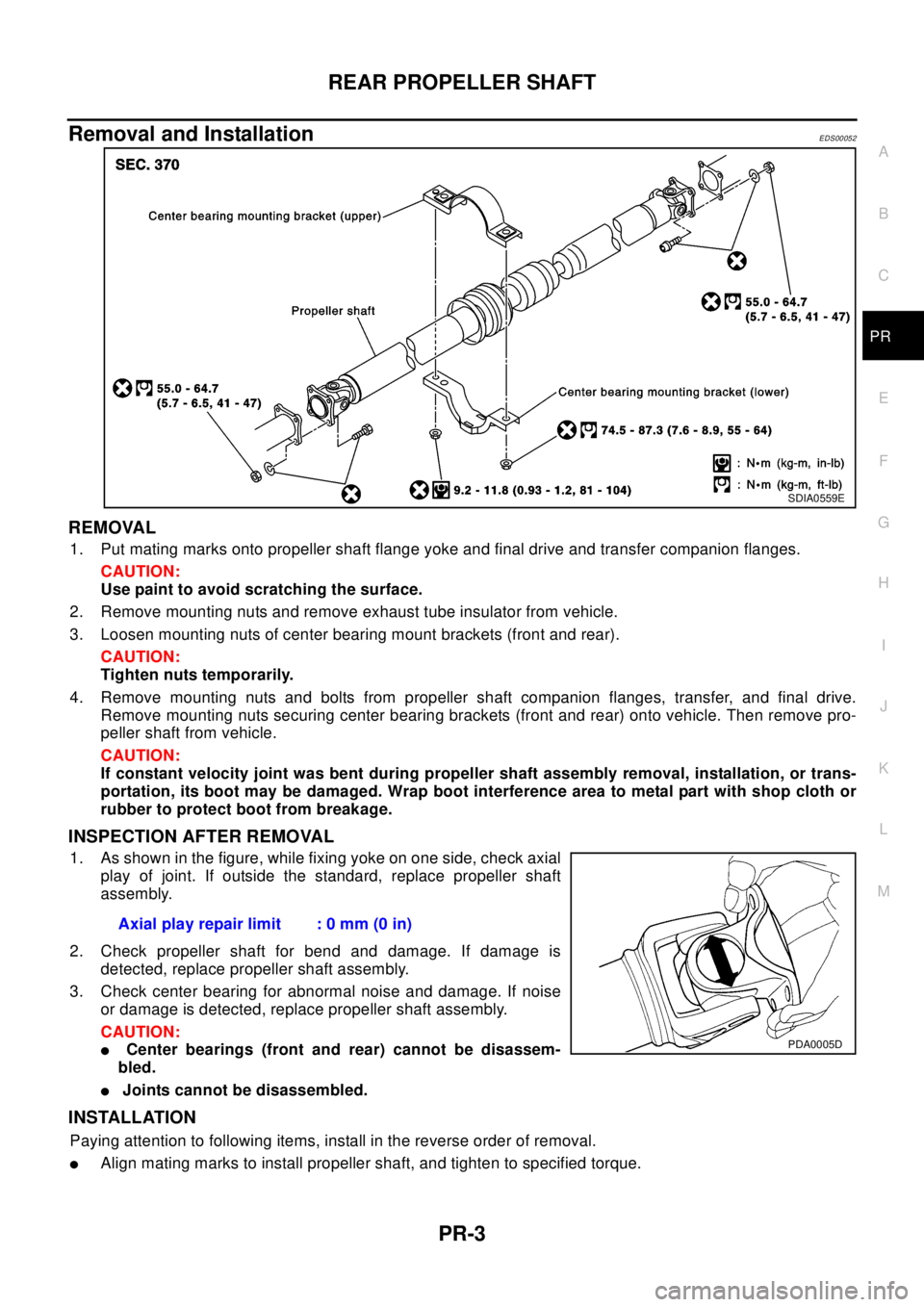

Removal and InstallationEDS00052

REMOVAL

1. Put mating marks onto propeller shaft flange yoke and final drive and transfer companion flanges.

CAUTION:

Use paint to avoid scratching the surface.

2. Remove mounting nuts and remove exhaust tube insulator from vehicle.

3. Loosen mounting nuts of center bearing mount brackets (front and rear).

CAUTION:

Tighten nuts temporarily.

4. Remove mounting nuts and bolts from propeller shaft companion flanges, transfer, and final drive.

Remove mounting nuts securing center bearing brackets (front and rear) onto vehicle. Then remove pro-

peller shaft from vehicle.

CAUTION:

If constant velocity joint was bent during propeller shaft assembly removal, installation, or trans-

portation, its boot may be damaged. Wrap boot interference area to metal part with shop cloth or

rubber to protect boot from breakage.

INSPECTION AFTER REMOVAL

1. As shown in the figure, while fixing yoke on one side, check axial

play of joint. If outside the standard, replace propeller shaft

assembly.

2. Check propeller shaft for bend and damage. If damage is

detected, replace propeller shaft assembly.

3. Check center bearing for abnormal noise and damage. If noise

or damage is detected, replace propeller shaft assembly.

CAUTION:

lCenter bearings (front and rear) cannot be disassem-

bled.

lJoints cannot be disassembled.

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

lAlign mating marks to install propeller shaft, and tighten to specified torque.

SDIA0559E

Axial play repair limit : 0 mm (0 in)

PDA0005D