boot NISSAN X-TRAIL 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2772 of 3066

PS-12

POWER STEERING GEAR AND LINKAGE

POWER STEERING GEAR AND LINKAGE

PFP:49001

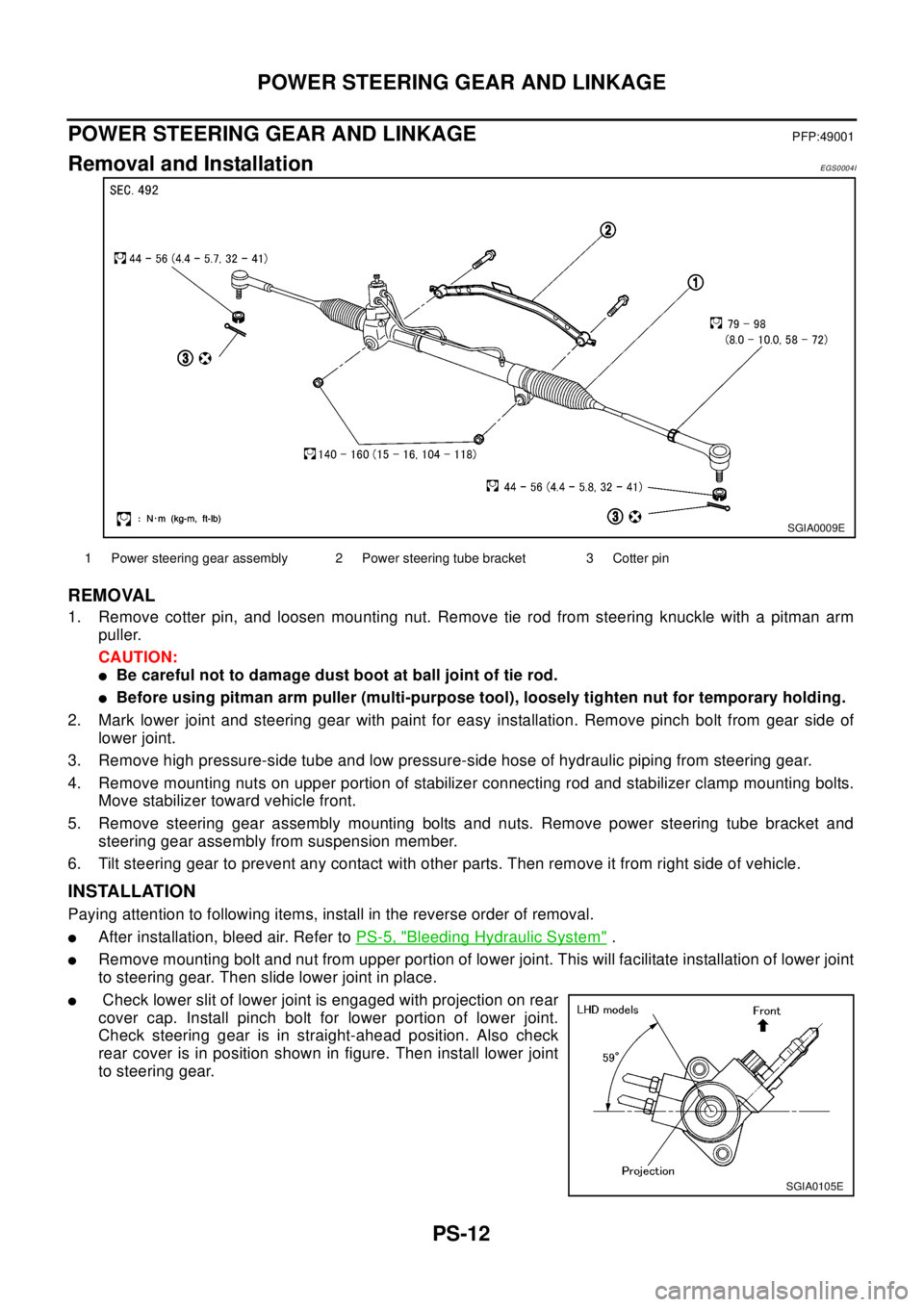

Removal and InstallationEGS0004I

REMOVAL

1. Remove cotter pin, and loosen mounting nut. Remove tie rod from steering knuckle with a pitman arm

puller.

CAUTION:

lBe careful not to damage dust boot at ball joint of tie rod.

lBefore using pitman arm puller (multi-purpose tool), loosely tighten nut for temporary holding.

2. Mark lower joint and steering gear with paint for easy installation. Remove pinch bolt from gear side of

lower joint.

3. Remove high pressure-side tube and low pressure-side hose of hydraulic piping from steering gear.

4. Remove mounting nuts on upper portion of stabilizer connecting rod and stabilizer clamp mounting bolts.

Move stabilizer toward vehicle front.

5. Remove steering gear assembly mounting bolts and nuts. Remove power steering tube bracket and

steering gear assembly from suspension member.

6. Tilt steering gear to prevent any contact with other parts. Then remove it from right side of vehicle.

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

lAfter installation, bleed air. Refer toPS-5, "Bleeding Hydraulic System".

lRemove mounting bolt and nut from upper portion of lower joint. This will facilitate installation of lower joint

to steering gear. Then slide lower joint in place.

lCheck lower slit of lower joint is engaged with projection on rear

cover cap. Install pinch bolt for lower portion of lower joint.

Check steering gear is in straight-ahead position. Also check

rear cover is in position shown in figure. Then install lower joint

to steering gear.

SGIA0009E

1 Power steering gear assembly 2 Power steering tube bracket 3 Cotter pin

SGIA0105E

Page 2775 of 3066

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

MA

B

PS

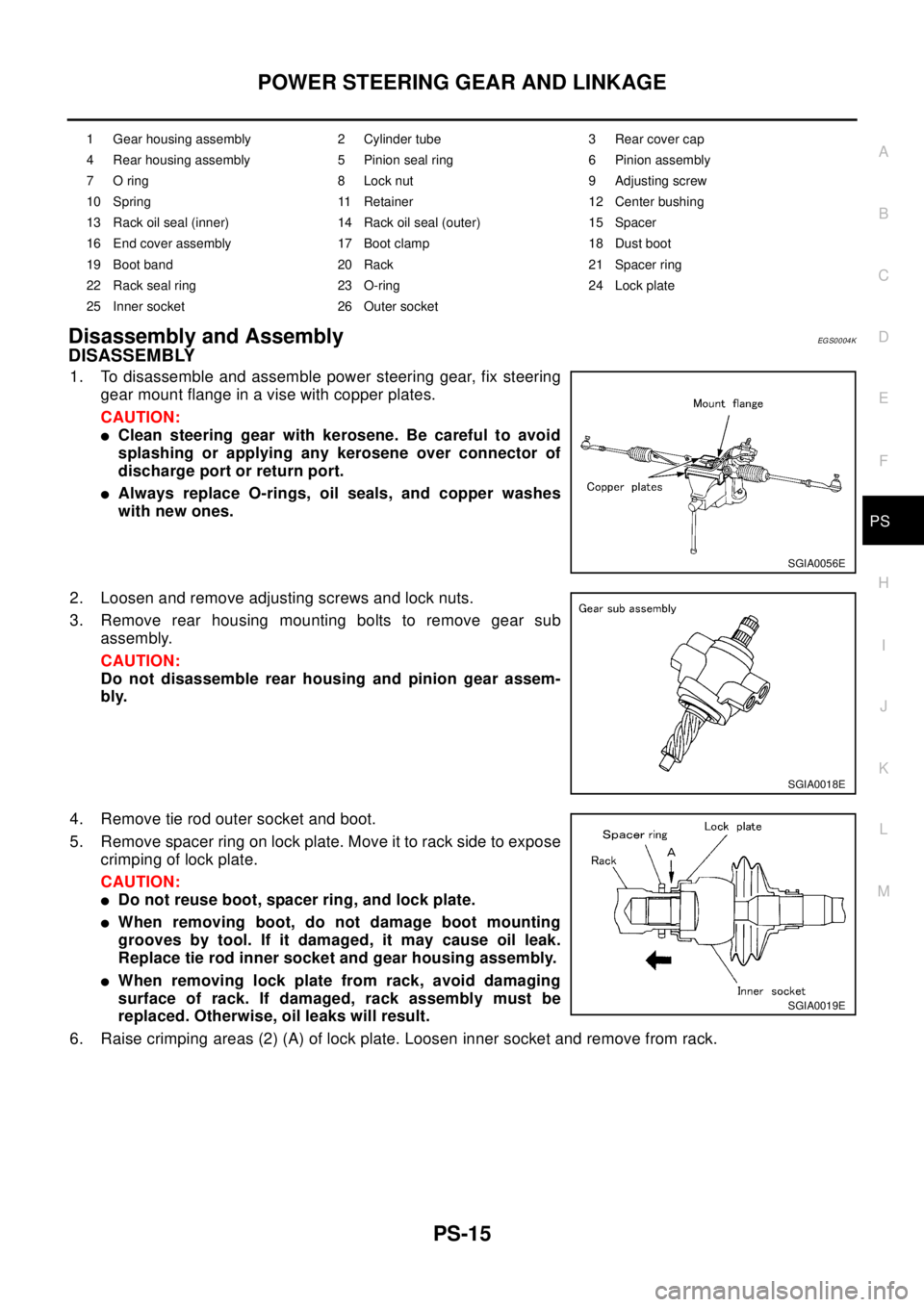

Disassembly and AssemblyEGS0004K

DISASSEMBLY

1. To disassemble and assemble power steering gear, fix steering

gear mount flange in a vise with copper plates.

CAUTION:

lClean steering gear with kerosene. Be careful to avoid

splashing or applying any kerosene over connector of

discharge port or return port.

lAlways replace O-rings, oil seals, and copper washes

with new ones.

2. Loosen and remove adjusting screws and lock nuts.

3. Remove rear housing mounting bolts to remove gear sub

assembly.

CAUTION:

Do not disassemble rear housing and pinion gear assem-

bly.

4. Remove tie rod outer socket and boot.

5. Remove spacer ring on lock plate. Move it to rack side to expose

crimping of lock plate.

CAUTION:

lDo not reuse boot, spacer ring, and lock plate.

lWhen removing boot, do not damage boot mounting

grooves by tool. If it damaged, it may cause oil leak.

Replace tie rod inner socket and gear housing assembly.

lWhen removing lock plate from rack, avoid damaging

surface of rack. If damaged, rack assembly must be

replaced. Otherwise, oil leaks will result.

6. Raise crimping areas (2) (A) of lock plate. Loosen inner socket and remove from rack.

1 Gear housing assembly 2 Cylinder tube 3 Rear cover cap

4 Rear housing assembly 5 Pinion seal ring 6 Pinion assembly

7 O ring 8 Lock nut 9 Adjusting screw

10 Spring 11 Retainer 12 Center bushing

13 Rack oil seal (inner) 14 Rack oil seal (outer) 15 Spacer

16 End cover assembly 17 Boot clamp 18 Dust boot

19 Boot band 20 Rack 21 Spacer ring

22 Rack seal ring 23 O-ring 24 Lock plate

25 Inner socket 26 Outer socket

SGIA0056E

SGIA0018E

SGIA0019E

Page 2776 of 3066

PS-16

POWER STEERING GEAR AND LINKAGE

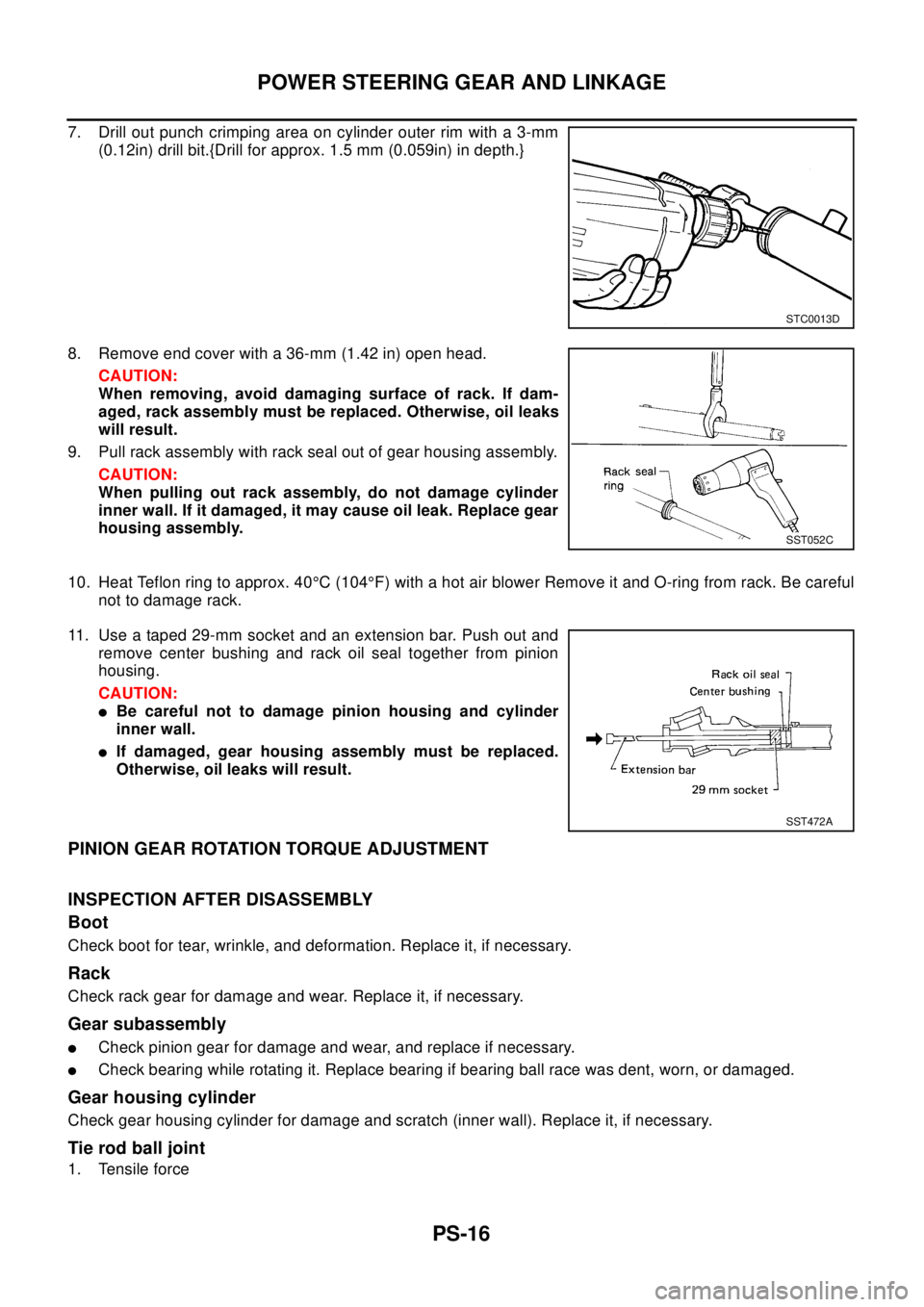

7. Drill out punch crimping area on cylinder outer rim with a 3-mm

(0.12in) drill bit.{Drill for approx. 1.5 mm (0.059in) in depth.}

8. Remove end cover with a 36-mm (1.42 in) open head.

CAUTION:

When removing, avoid damaging surface of rack. If dam-

aged, rack assembly must be replaced. Otherwise, oil leaks

will result.

9. Pull rack assembly with rack seal out of gear housing assembly.

CAUTION:

When pulling out rack assembly, do not damage cylinder

inner wall. If it damaged, it may cause oil leak. Replace gear

housing assembly.

10. Heat Teflon ring to approx. 40°C (104°F) with a hot air blower Remove it and O-ring from rack. Be careful

not to damage rack.

11. Use a taped 29-mm socket and an extension bar. Push out and

remove center bushing and rack oil seal together from pinion

housing.

CAUTION:

lBe careful not to damage pinion housing and cylinder

inner wall.

lIf damaged, gear housing assembly must be replaced.

Otherwise, oil leaks will result.

PINION GEAR ROTATION TORQUE ADJUSTMENT

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for tear, wrinkle, and deformation. Replace it, if necessary.

Rack

Check rack gear for damage and wear. Replace it, if necessary.

Gear subassembly

lCheck pinion gear for damage and wear, and replace if necessary.

lCheck bearing while rotating it. Replace bearing if bearing ball race was dent, worn, or damaged.

Gear housing cylinder

Check gear housing cylinder for damage and scratch (inner wall). Replace it, if necessary.

Tie rod ball joint

1. Tensile force

STC0013D

SST052C

SST472A

Page 2781 of 3066

POWER STEERING GEAR AND LINKAGE

PS-21

C

D

E

F

H

I

J

K

L

MA

B

PS

23. Using a preload gauge, measure rotational torque of pinion gear.

Check that reading is within range specified. If reading is outside

specification, readjust rack. If reading is still outside specifica-

tion, replace power steering gear.

24. With tie rod gear installed to gear assembly, turn pinion gear

fully to left.

25. Set dial gauge as shown in figure. Measure vertical movement

of rack when pinion is turned counterclockwise with torque of 4.9

N·m (0.5 kg·m,43in·lb). Check reading is within range specified.

If reading is outside of specification, readjust rack. If reading is

still outside of specification, replace power steering gear.

26. Position boot band on large-diameter side before installing it.

27. Apply multi-purpose grease to both large- and small- diameter

sides.

28. Install small-diameter side of boot to inner socket boot mounting

groove.

29. Install boot band to small-diameter side of boot.

30. Install boot band.

a. Tighten large-diameter side of RH/LH boot with boot clamp

(stainless wire).

b. Wrap clamp around boot groove for two turns. Insert screwdriv-

ers in loops on both ends of wire. Twist 4 to 4.5 turns while pull-

ing them with force of approx. 98 N (10 kg,22.1 lb).Rotational torque

of pinion gear: Around neutral position

{within±11.5 mm (0.453 in)}

Average A : 167 - 225 N·m (17 - 23

kg·m,123-166 ft·lb)

Maximum varia-

tion B: 98 N·m (10 kg·m,72 ft·lb)

Other than above

Average A : 294 N·m (30 kg·m,217 ft·lb)

Maximum varia-

tion B: 147 N·m (15 kg·m,108 ft·lb)

SGIA0098E

Specification : 0.08 mm (0.0031 in) or less

SGIA0099E

Measuring point in shown in figure at right.Rack axle direction 5 mm from housing vertical surface

Rack radial direction Direction of adjusting screw

SGIA0024E

Wire length (L) : 370 mm (14.57 in)

SST097B

Page 2782 of 3066

PS-22

POWER STEERING GEAR AND LINKAGE

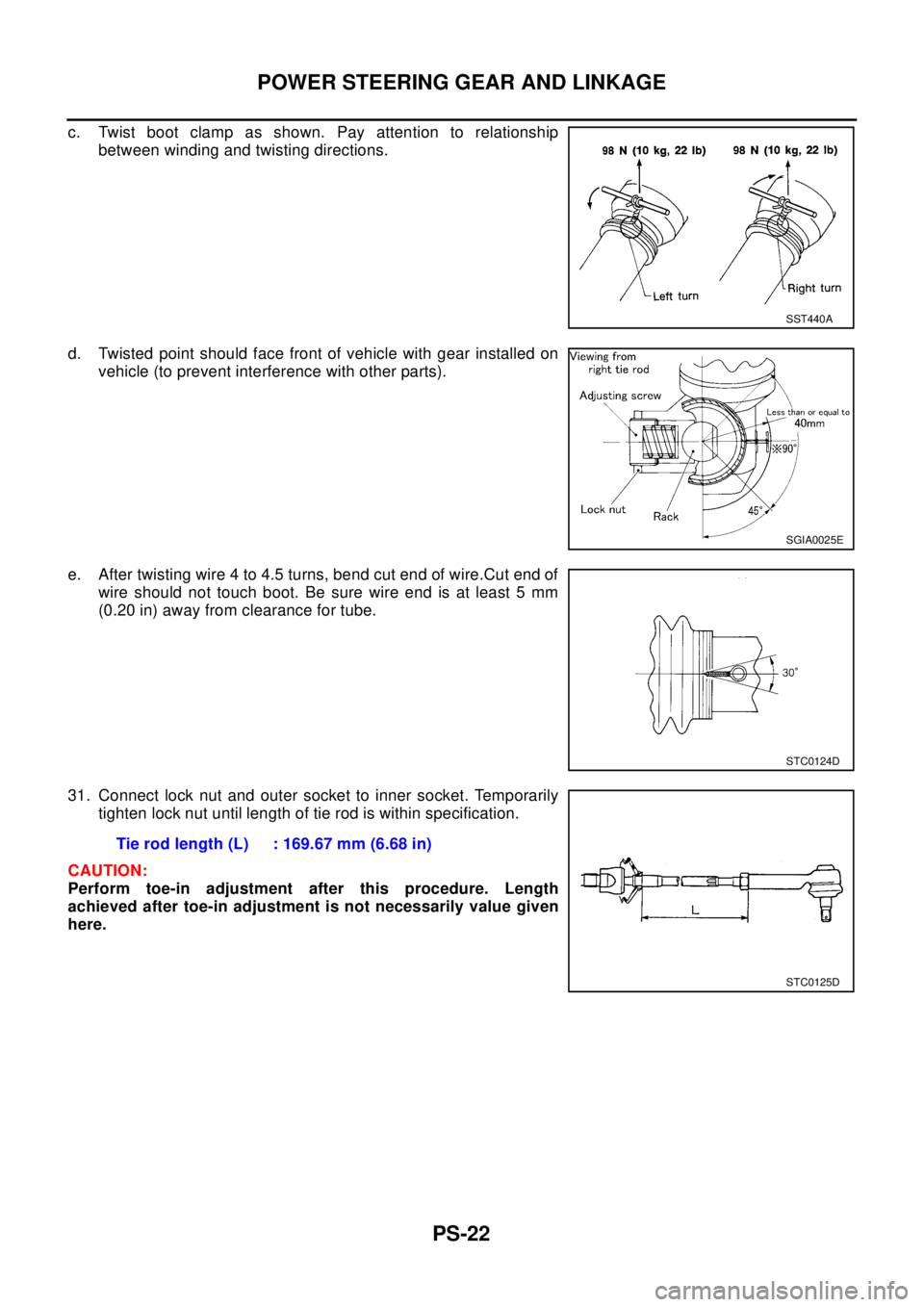

c. Twist boot clamp as shown. Pay attention to relationship

between winding and twisting directions.

d. Twisted point should face front of vehicle with gear installed on

vehicle (to prevent interference with other parts).

e. After twisting wire 4 to 4.5 turns, bend cut end of wire.Cut end of

wire should not touch boot. Be sure wire end is at least 5 mm

(0.20 in) away from clearance for tube.

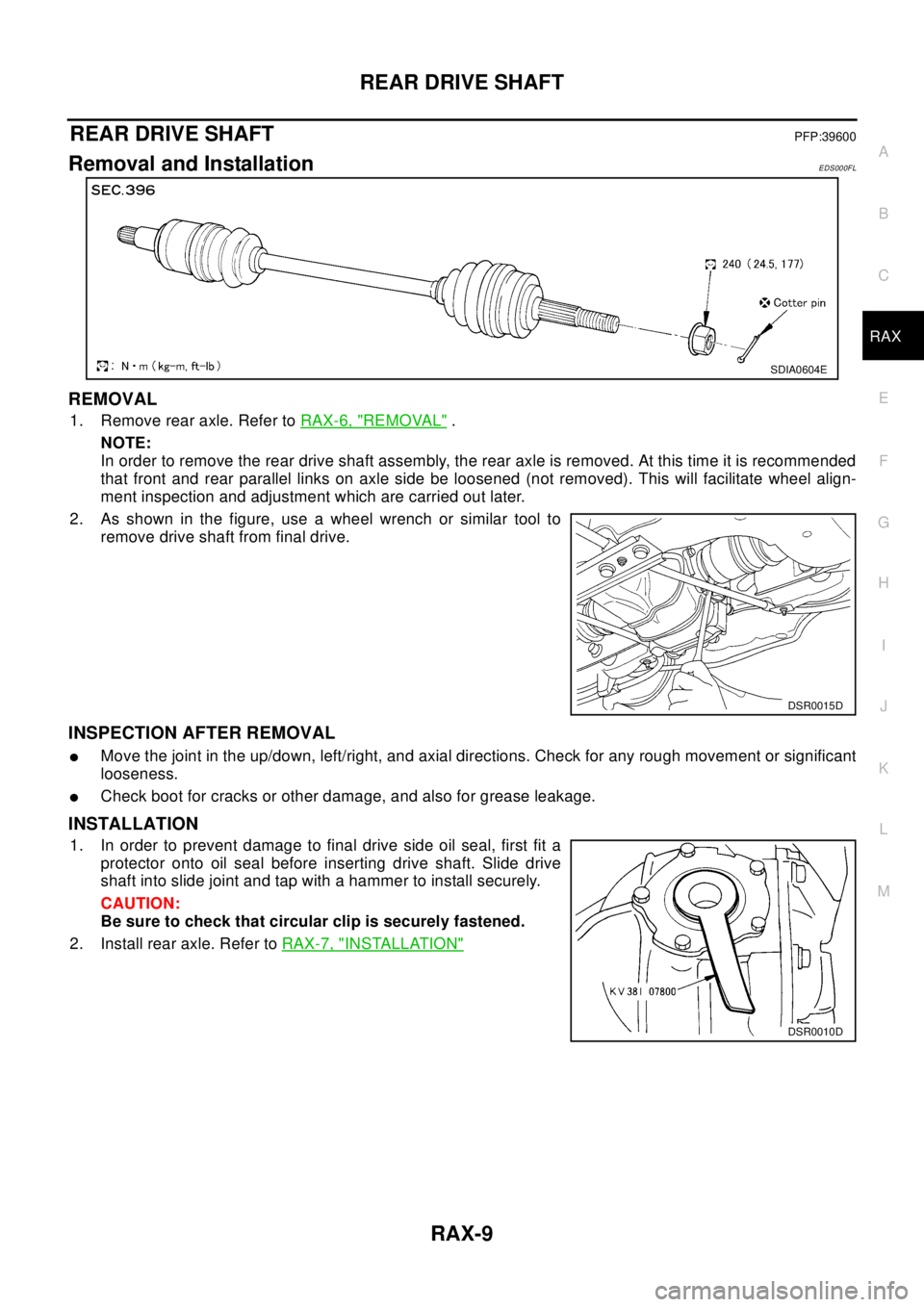

31. Connect lock nut and outer socket to inner socket. Temporarily

tighten lock nut until length of tie rod is within specification.

CAUTION:

Perform toe-in adjustment after this procedure. Length

achieved after toe-in adjustment is not necessarily value given

here.

SST440A

SGIA0025E

STC0124D

Tie rod length (L) : 169.67 mm (6.68 in)

STC0125D

Page 2805 of 3066

REAR DRIVE SHAFT

RAX-9

C

E

F

G

H

I

J

K

L

MA

B

RAX

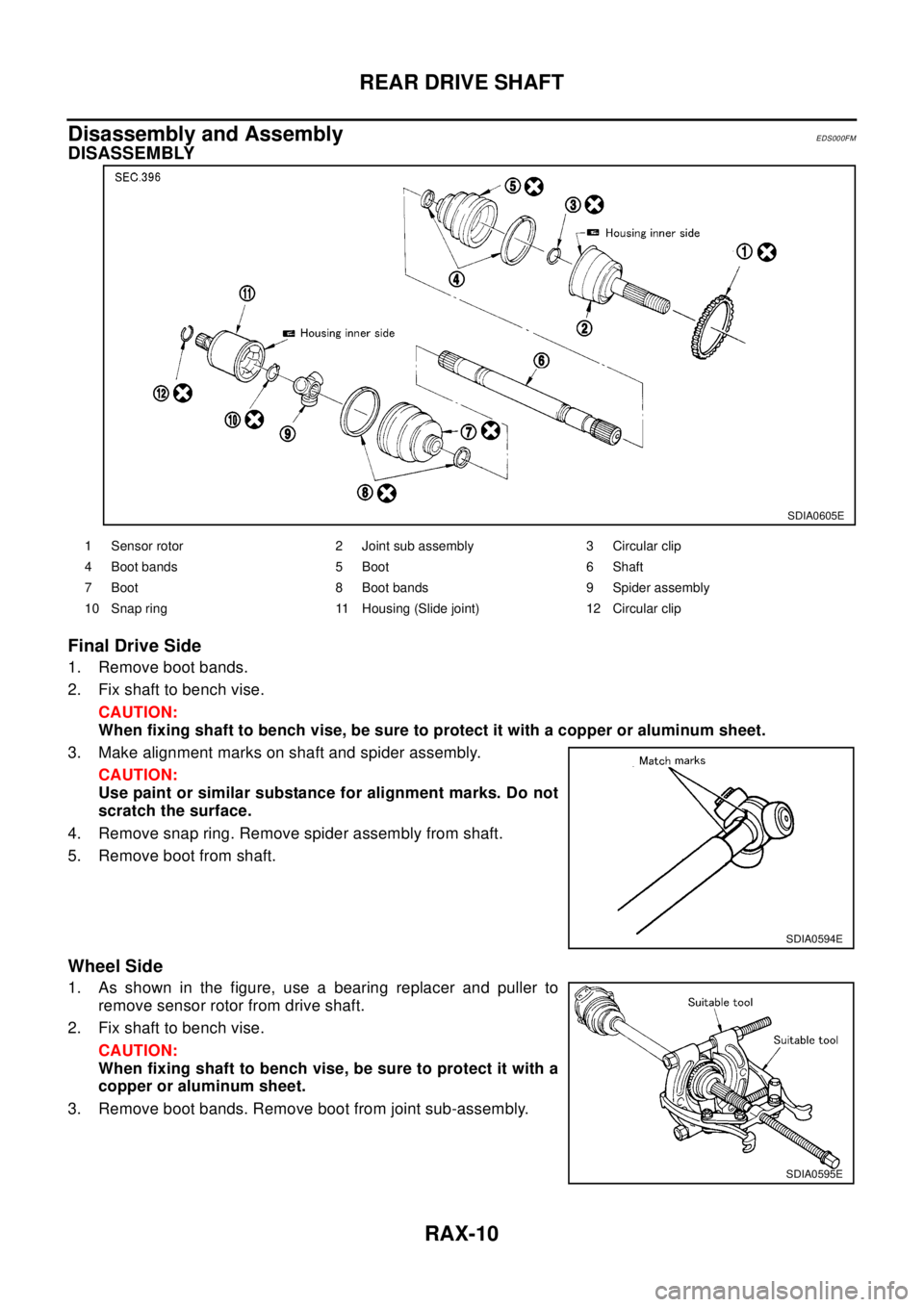

REAR DRIVE SHAFTPFP:39600

Removal and InstallationEDS000FL

REMOVAL

1. Remove rear axle. Refer toRAX-6, "REMOVAL".

NOTE:

In order to remove the rear drive shaft assembly, the rear axle is removed. At this time it is recommended

that front and rear parallel links on axle side be loosened (not removed). This will facilitate wheel align-

ment inspection and adjustment which are carried out later.

2. As shown in the figure, use a wheel wrench or similar tool to

remove drive shaft from final drive.

INSPECTION AFTER REMOVAL

lMove the joint in the up/down, left/right, and axial directions. Check for any rough movement or significant

looseness.

lCheck boot for cracks or other damage, and also for grease leakage.

INSTALLATION

1. In order to prevent damage to final drive side oil seal, first fit a

protector onto oil seal before inserting drive shaft. Slide drive

shaft into slide joint and tap with a hammer to install securely.

CAUTION:

Be sure to check that circular clip is securely fastened.

2. Install rear axle. Refer toRAX-7, "

INSTALLATION"

SDIA0604E

DSR0015D

DSR0010D

Page 2806 of 3066

RAX-10

REAR DRIVE SHAFT

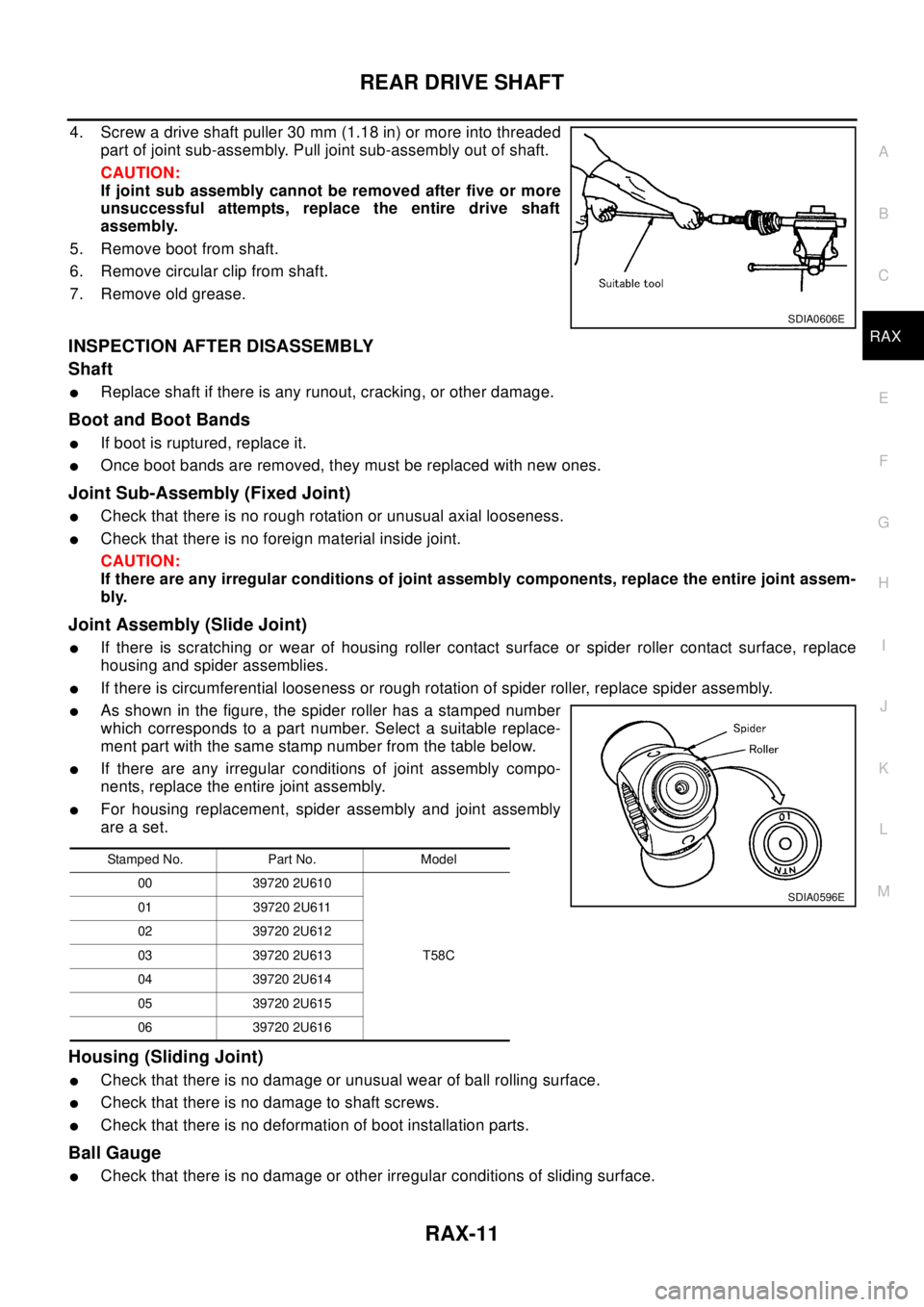

Disassembly and Assembly

EDS000FM

DISASSEMBLY

Final Drive Side

1. Remove boot bands.

2. Fix shaft to bench vise.

CAUTION:

When fixing shaft to bench vise, be sure to protect it with a copper or aluminum sheet.

3. Make alignment marks on shaft and spider assembly.

CAUTION:

Use paint or similar substance for alignment marks. Do not

scratch the surface.

4. Remove snap ring. Remove spider assembly from shaft.

5. Remove boot from shaft.

Wheel Side

1. As shown in the figure, use a bearing replacer and puller to

remove sensor rotor from drive shaft.

2. Fix shaft to bench vise.

CAUTION:

When fixing shaft to bench vise, be sure to protect it with a

copper or aluminum sheet.

3. Remove boot bands. Remove boot from joint sub-assembly.

SDIA0605E

1 Sensor rotor 2 Joint sub assembly 3 Circular clip

4 Boot bands 5 Boot 6 Shaft

7 Boot 8 Boot bands 9 Spider assembly

10 Snap ring 11 Housing (Slide joint) 12 Circular clip

SDIA0594E

SDIA0595E

Page 2807 of 3066

REAR DRIVE SHAFT

RAX-11

C

E

F

G

H

I

J

K

L

MA

B

RAX

4. Screw a drive shaft puller 30 mm (1.18 in) or more into threaded

part of joint sub-assembly. Pull joint sub-assembly out of shaft.

CAUTION:

If joint sub assembly cannot be removed after five or more

unsuccessful attempts, replace the entire drive shaft

assembly.

5. Remove boot from shaft.

6. Remove circular clip from shaft.

7. Remove old grease.

INSPECTION AFTER DISASSEMBLY

Shaft

lReplace shaft if there is any runout, cracking, or other damage.

Boot and Boot Bands

lIf boot is ruptured, replace it.

lOnce boot bands are removed, they must be replaced with new ones.

Joint Sub-Assembly (Fixed Joint)

lCheck that there is no rough rotation or unusual axial looseness.

lCheck that there is no foreign material inside joint.

CAUTION:

If there are any irregular conditions of joint assembly components, replace the entire joint assem-

bly.

Joint Assembly (Slide Joint)

lIf there is scratching or wear of housing roller contact surface or spider roller contact surface, replace

housing and spider assemblies.

lIf there is circumferential looseness or rough rotation of spider roller, replace spider assembly.

lAs shown in the figure, the spider roller has a stamped number

which corresponds to a part number. Select a suitable replace-

ment part with the same stamp number from the table below.

lIf there are any irregular conditions of joint assembly compo-

nents, replace the entire joint assembly.

lFor housing replacement, spider assembly and joint assembly

are a set.

Housing (Sliding Joint)

lCheck that there is no damage or unusual wear of ball rolling surface.

lCheck that there is no damage to shaft screws.

lCheck that there is no deformation of boot installation parts.

Ball Gauge

lCheck that there is no damage or other irregular conditions of sliding surface.

SDIA0606E

Stamped No. Part No. Model

00 39720 2U610

T58C 01 39720 2U611

02 39720 2U612

03 39720 2U613

04 39720 2U614

05 39720 2U615

06 39720 2U616

SDIA0596E

Page 2808 of 3066

RAX-12

REAR DRIVE SHAFT

Steel Ball

lCheck that there is no damage or unusual wear.

Inner Case

lCheck that there is no damage or other irregular conditions of ball rolling surface.

lCheck that there is no damage to serrated part.

ASSEMBLY

Final Drive Side

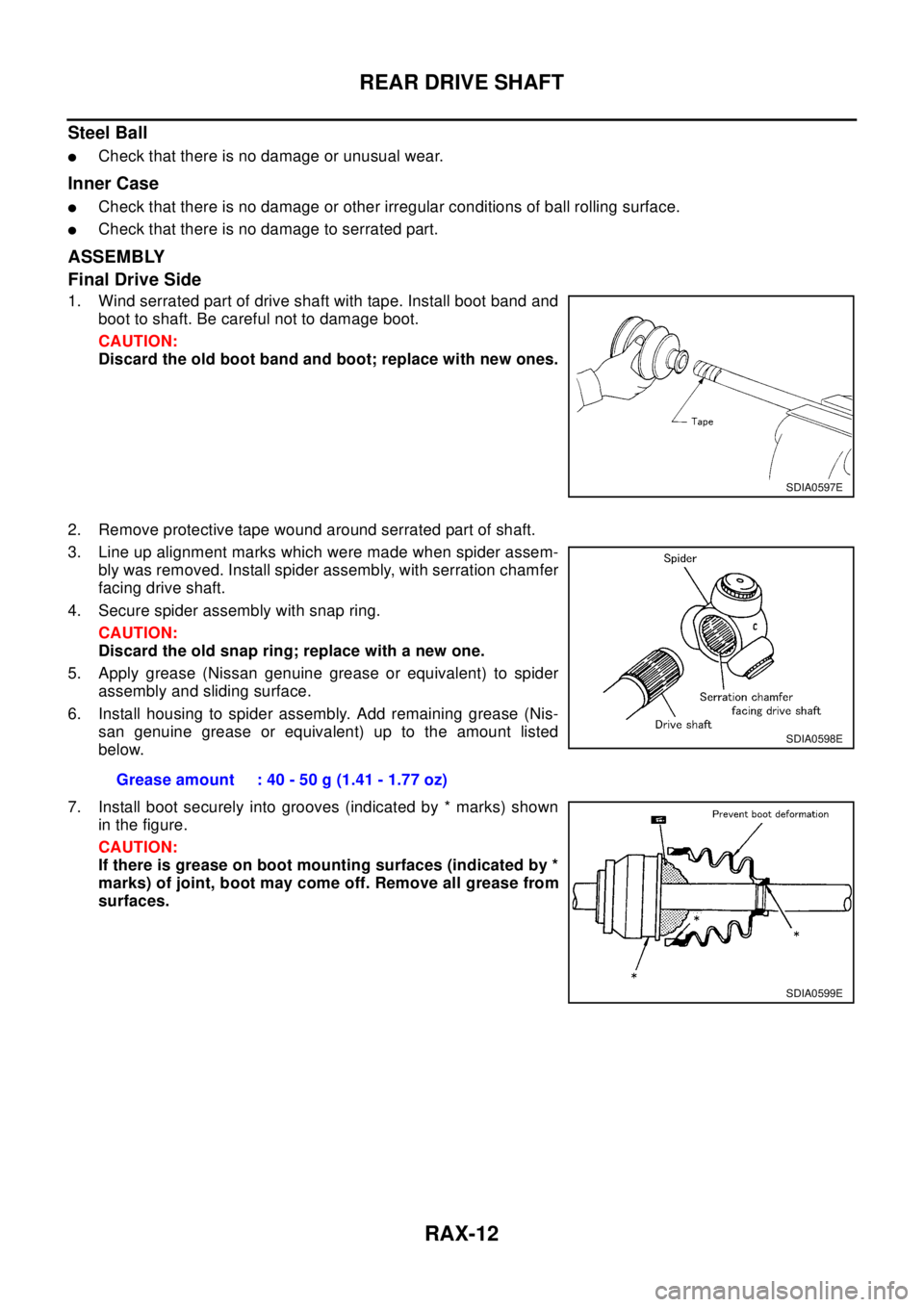

1. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

2. Remove protective tape wound around serrated part of shaft.

3. Line up alignment marks which were made when spider assem-

bly was removed. Install spider assembly, with serration chamfer

facing drive shaft.

4. Secure spider assembly with snap ring.

CAUTION:

Discard the old snap ring; replace with a new one.

5. Apply grease (Nissan genuine grease or equivalent) to spider

assembly and sliding surface.

6. Install housing to spider assembly. Add remaining grease (Nis-

san genuine grease or equivalent) up to the amount listed

below.

7. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of joint, boot may come off. Remove all grease from

surfaces.

SDIA0597E

Grease amount : 40 - 50 g (1.41 - 1.77 oz)

SDIA0598E

SDIA0599E

Page 2809 of 3066

REAR DRIVE SHAFT

RAX-13

C

E

F

G

H

I

J

K

L

MA

B

RAX

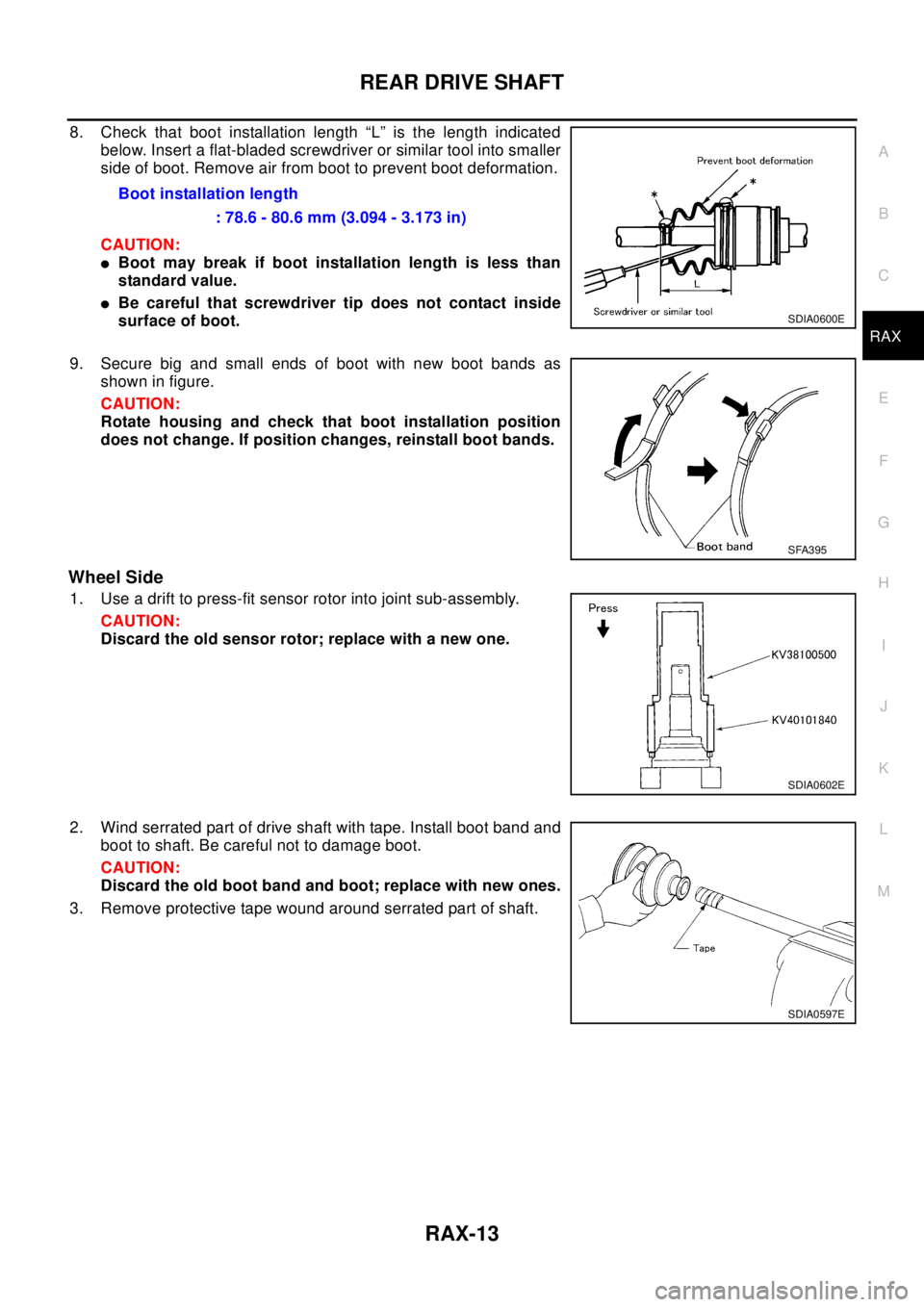

8. Check that boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Remove air from boot to prevent boot deformation.

CAUTION:

lBoot may break if boot installation length is less than

standard value.

lBe careful that screwdriver tip does not contact inside

surface of boot.

9. Secure big and small ends of boot with new boot bands as

shown in figure.

CAUTION:

Rotate housing and check that boot installation position

does not change. If position changes, reinstall boot bands.

Wheel Side

1. Use a drift to press-fit sensor rotor into joint sub-assembly.

CAUTION:

Discard the old sensor rotor; replace with a new one.

2. Wind serrated part of drive shaft with tape. Install boot band and

boot to shaft. Be careful not to damage boot.

CAUTION:

Discard the old boot band and boot; replace with new ones.

3. Remove protective tape wound around serrated part of shaft.Boot installation length

: 78.6 - 80.6 mm (3.094 - 3.173 in)

SDIA0600E

SFA395

SDIA0602E

SDIA0597E