ECU NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

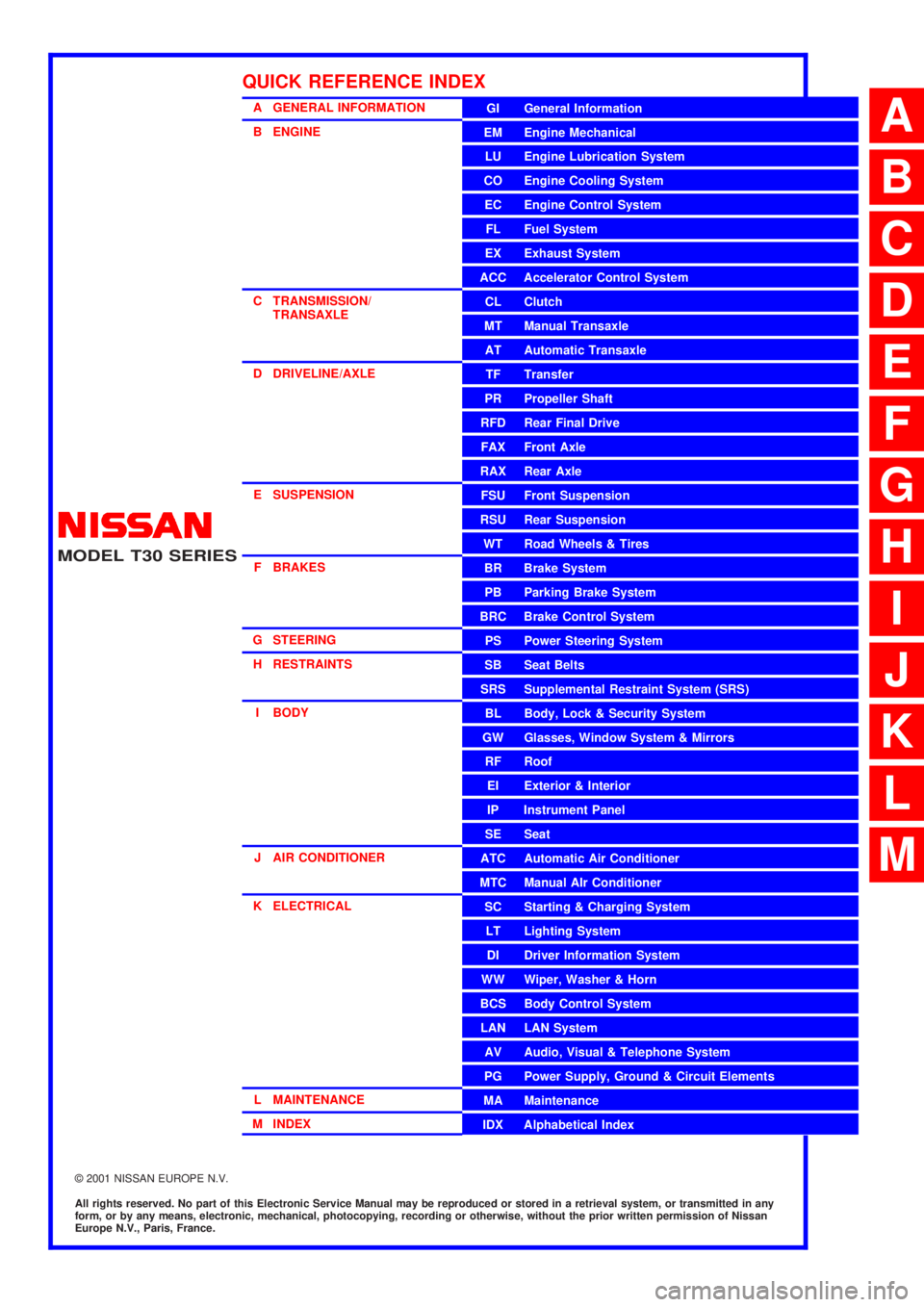

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 5 of 3066

ACCELERATOR CONTROL SYSTEM

ACC-3

C

D

E

F

G

H

I

J

K

L

MA

ACC

lDo not adjust the adjusting screw (painted white) of the accelerator work unit. (YD22DDTi)

lWhen the harness connector of the accelerator sensor is disconnected, perform²Accelerator

Pedal Released Position Learning².Referto²Basic Service Procedure²in EC section.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck that the accelerator pedal moves smoothly within the whole operation range.

lCheck that the accelerator pedal securely returns to the original position.

lFor the electrical inspection of the accelerator pedal assembly, refer toEC-154, "DTC P0121 APP SEN-

SOR"(WITH EURO-OBD) andEC-484, "DTC P0121 APP SENSOR"(WITHOUT EURO-OBD).

(QR20DE)

lFor the electrical inspection of the accelerator work unit, refer toEC-715, "DTC P0120 ACCELERATOR

PEDAL POSITION SENSOR"andEC-783, "DTC P1510 ACCELERATOR PEDAL RELEASED POSI-

TION SWITCH".(YD22DDTi)

lCheck that the drum of the accelerator work unit can be fully opened. (YD22DDTi)

Page 11 of 3066

PRECAUTIONS

AT-5

D

E

F

G

H

I

J

K

L

MA

B

AT

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ECS004Q0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WA RN ING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

Precautions for On Board Diagnostic (EURO-OBD) System of A/T and Engine —

Euro-OBD —

ECS004Q1

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

lBe sure to turn the ignition switch “OFF” and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves,

etc. will cause the MIL to light up.

lBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

lBe sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

lBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

lBe sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precautions For Trouble DiagnosisECS004VN

CAN SYSTEM

lDo not apply voltage of 7.0V or higher to the measurement terminals.

lUse the tester with its open terminal voltage being 7.0V or less.

Precautions For Harness RepairECS004VO

CAN SYSTEM

lSolder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in)]

PKIA0306E

Page 137 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If � NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If �](/img/5/57402/w960_57402-136.png)

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

AT-131

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DURE” has been previously conducted, always turn ignition

switch “OFF” and wait at least 5 seconds before conducting the

next test.

After the repair, perform the following procedure to confirm the mal-

function is eliminated.

With CONSULT-II

1. Turn ignition switch “ON”.

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-II.

3. Start engine and maintain the following conditions for at least 5

consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position (OD “ON” or “OFF”)

With GST

Follow the procedure “With CONSULT-II”.

SAT014K

SAT020K

Page 149 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR)

AT-143

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

lAlways drive vehicle at a safe speed. NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR)

AT-143

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

lAlways drive vehicle at a safe speed.](/img/5/57402/w960_57402-148.png)

DTC P0720 VEHICLE SPEED SENSOR·A/T (REVOLUTION SENSOR)

AT-143

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

lAlways drive vehicle at a safe speed.

lBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If “DIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DURE” has been previously conducted, always turn ignition

switch “OFF” and wait at least 5 seconds before conducting the

next test.

After the repair, perform the following procedure to confirm the mal-

function is eliminated.

With CONSULT-II

1. Turn ignition switch “ON” and select “DATA MONITOR” mode for

“A/T” with CONSULT-II.

2. Drive vehicle and check for an increase of “VHCL/S SE·MTR”

value increase.

If the check result is NG, go to “DIAGNOSTIC PROCEDURE”,

AT-145, "

Diagnostic Procedure".

If the check result is OK, go to following step.

3. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-II.

4. Start engine and maintain the following conditions for at least 5

consecutive seconds.

VHCL SPEED SE: 30 km/h (19 MPH) or more

THRTL POS SEN: More than 1.2V

Selector lever: D position (OD “ON”)

Driving location: Driving the vehicle uphill (increased

engine load) will help maintain the driving conditions

required for this test.

If the check result is NG, go to “DIAGNOSTIC PROCEDURE”,

AT-145, "

Diagnostic Procedure".

If the check result is OK, go to following step.

5. Maintain the following conditions for at least 5 consecutive sec-

onds.

CMPS·RPM (REF): 3,500 rpm or more

THRTL POS SEN: More than 1.2V

Selector lever: D position (OD “ON”)

Driving location: Driving the vehicle uphill (increased

engine load) will help maintain the driving conditions

required for this test.

With GST

Follow the procedure “With CONSULT-II”.

SAT014K

SAT971J

SAT014K

SAT020K

Page 153 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0725 ENGINE SPEED SIGNAL

AT-147

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0725 ENGINE SPEED SIGNALPFP:24825

DescriptionECS0 04 R7

The engine speed signal is sent from the ECM to the TCM.

TCM TERM NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0725 ENGINE SPEED SIGNAL

AT-147

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0725 ENGINE SPEED SIGNALPFP:24825

DescriptionECS0 04 R7

The engine speed signal is sent from the ECM to the TCM.

TCM TERM](/img/5/57402/w960_57402-152.png)

DTC P0725 ENGINE SPEED SIGNAL

AT-147

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0725 ENGINE SPEED SIGNALPFP:24825

DescriptionECS0 04 R7

The engine speed signal is sent from the ECM to the TCM.

TCM TERMINALS AND REFERENCE VALUE

Remarks: Specification data are reference values.

ON BOARD DIAGNOSIS LOGIC

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DURE” has been previously conducted, always turn ignition

switch “OFF” and wait at least 5 seconds before conducting the

next test.

After the repair, perform the following procedure to confirm the mal-

function is eliminated.

With CONSULT-II

1. Turn ignition switch “ON” and select “DATA MONITOR” mode for

“ENGINE” with CONSULT-II.

2. Start engine and maintain the following conditions for at least 10

consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.2V

Selector lever: D position (OD “ON”)

With GST

Follow the procedure “With CONSULT-II”.

Te r m i -

nal No.Wire color Item ConditionJudgement stan-

dard

(Approx.)

39 L/OREngine speed sig-

nalandRefer toEC-79, "

ECM INSPECTION TABLE",

“ECM INSPECTION TABLE”.—

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: ENGINE SPEED SIG

TCM does not receive the proper voltage

signal from ECM.

lHarness or connectors

(The sensor circuit is open or shorted.)

: P0725

SAT014K

SAT020K

Page 210 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-204

[EURO-OBD]

DTC P1705 ACCELERATOR PEDAL POSITION (APP) SENSOR

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DIAGNOSTIC TROUBLE C NISSAN X-TRAIL 2003 Electronic Repair Manual AT-204

[EURO-OBD]

DTC P1705 ACCELERATOR PEDAL POSITION (APP) SENSOR

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DIAGNOSTIC TROUBLE C](/img/5/57402/w960_57402-209.png)

AT-204

[EURO-OBD]

DTC P1705 ACCELERATOR PEDAL POSITION (APP) SENSOR

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DURE” has been previously conducted, always turn ignition

switch “OFF” and wait at least 5 seconds before conducting the

next test.

After the repair, perform the following procedure to confirm the mal-

function is eliminated.

With CONSULT-II

1. Turn ignition switch “ON” and select “DATA MONITOR” mode for

“A/T” with CONSULT-II.

2. Check the following.

If the check result is NG, go to “DIAGNOSTIC PROCEDURE”,AT-206, "

Diagnostic Procedure".

If the check result is OK, go to following step.

3. Turn ignition switch “ON” and select “DATA MONITOR” mode for

“ENGINE” with CONSULT-II.

4. Start engine and maintain the following conditions for at least 3

consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: Approximately 3V or less

Selector lever: D position (OD “ON”)

If the check result is NG, go to “DIAGNOSTIC PROCEDURE”,

AT-206, "

Diagnostic Procedure".

If the check result is OK, go to following step.

5. Maintain the following conditions for at least 3 consecutive sec-

onds. Then release accelerator pedal completely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

Accelerator pedal: Wide open throttle

Selector lever: D position (OD “ON”)

With GST

Follow the procedure “With CONSULT-II”.

SAT014K

Accelerator pedal

conditionTHRTL POS SEN

Fully released Less than 4.7V

Partially

depressed0.1 - 4.6V

Fully depressed 1.9 - 4.6V

SAT971J

SAT014K

SAT020K

Page 458 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren NISSAN X-TRAIL 2003 Electronic Repair Manual AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

feren](/img/5/57402/w960_57402-457.png)

AT-452

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS00409

CAUTION:

lInstall key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

lAfter installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions.

RemovalECS0040A

1. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

SAT996J

SAT853J

Page 465 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t](/img/5/57402/w960_57402-464.png)

REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

toEM-61, "

ENGINE ASSEMBLY".

13. Remove suspension member. Refer toFSU-12, "

FRONT SUS-

PENSION MEMBER".

14. Remove dust cover from converter housing.

Rotate crankshaft to gain access to securing bolts.

15. Remove securing bolts between drive plate and torque con-

verter. when crank shaft rotates, turn to right at the front side of

engine.

16. Support engine with a jack.

17. Remove bolts fixing transaxle to engine.

18. Lower transaxle while supporting it with a jack.

InstallationECS004ND

1. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring

gear teeth.

lIf this runout is out of allowance, replace drive plate with ring

gear.

2. When connecting torque converter to transaxle, measure dis-

tance “A” to be certain that they are correctly assembled.

SCIA0794E

AAT259A

Maximum allowable runout :

Refer to EM-´´, “FLYWHEEL/DRIVE PLATE RUNOUT”.

SAT977H

Distance “A”: 19 mm (0.626 in) or more

SAT573D

Page 478 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pi NISSAN X-TRAIL 2003 Electronic Repair Manual AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pi](/img/5/57402/w960_57402-477.png)

AT-472

[ALL]

DISASSEMBLY

c. Remove thrust washer and bearing race from oil pump assem-

bly.

28. Remove brake band according to the following procedures.

a. Loosen lock nut, then back off anchor end pin.

lDo not reuse anchor end pin.

b. Remove brake band and strut from transmission case.

lTo prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown in

thefigureatleft.

Leave the clip in position after removing the brake band.

SAT013F

SAT014FA

SAT196F

SAT039D