automatic transmission NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

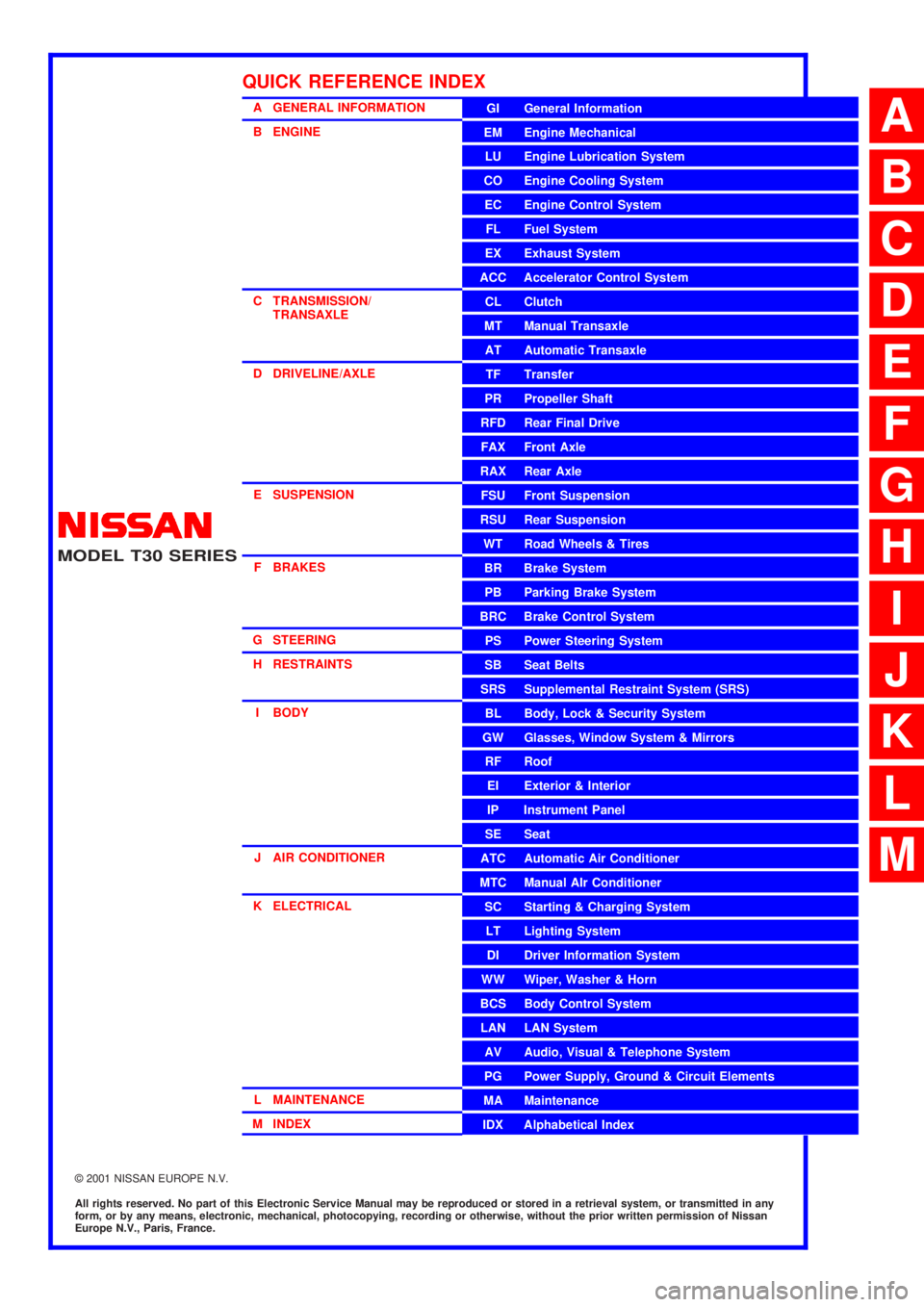

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 7 of 3066

AT-1

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

AT

AUTOMATIC TRANSAXLE

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for On Board Diagnostic (EURO-OBD)

System of A/T and Engine — Euro-OBD — ............. 5

Precautions For Trouble Diagnosis .......................... 5

Precautions For Harness Repair .............................. 5

Precautions .............................................................. 6

Service Notice or Precautions .................................. 7

Wiring Diagrams and Trouble Diagnosis .................. 8

PREPARATION ........................................................... 9

Special Service Tools ............................................... 9

Commercial Service Tools .......................................11

A/T FLUID ................................................................. 13

Checking A/T Fluid ................................................. 13

Changing A/T Fluid ................................................ 13

OVERALL SYSTEM ................................................. 14

A/T Electrical Parts Location .................................. 14

Circuit Diagram ...................................................... 16

Cross-sectional View .............................................. 17

Hydraulic Control Circuit ........................................ 18

Shift Mechanism ..................................................... 19

Control System ....................................................... 27

Control Mechanism ................................................ 29

Control Valve .......................................................... 33

EURO-OBD

TROUBLE DIAGNOSIS — INDEX ........................... 35

Alphabetical & P No. Index for DTC ....................... 35

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION .......................................................................... 37

Introduction ............................................................ 37

EURO-OBD Function for A/T System .................... 37

One or Two Trip Detection Logic of EURO-OBD ... 37

EURO-OBD Diagnostic Trouble Code (DTC) ......... 37

Malfunction Indicator lamp (MIL) ............................ 41

CONSULT-II ........................................................... 41

Diagnostic Procedure Without CONSULT-II ........... 50TROUBLE DIAGNOSIS — INTRODUCTION ........... 56

Introduction ............................................................. 56

Work Flow ............................................................... 61

TROUBLE DIAGNOSIS — BASIC INSPECTION .... 64

A/T Fluid Check ...................................................... 64

Stall Test ................................................................. 65

Line Pressure Test .................................................. 68

Road Test ............................................................... 69

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION .......................................................................... 86

Symptom Chart ....................................................... 86

TCM Terminals and Reference Value ...................125

CAN COMMUNICATION .........................................129

System Description ...............................................129

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ..................................................................130

Description ............................................................130

Wiring Diagram — AT — PNP/SW .......................132

Diagnostic Procedure ...........................................133

Component Inspection ..........................................135

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................136

Description ............................................................136

Wiring Diagram — AT — FTS ..............................138

Diagnostic Procedure ...........................................139

Component Inspection ..........................................141

DTC P0720 VEHICLE SPEED SENSOR·A/T (REV-

OLUTION SENSOR) ...............................................142

Description ............................................................142

Wiring Diagram — AT — VSSA/T ........................144

Diagnostic Procedure ...........................................145

DTC P0725 ENGINESPEED SIGNAL ...................147

Description ............................................................147

Wiring Diagram — AT — ENGSS .........................148

Diagnostic Procedure ...........................................149

DTC P0731 A/T 1ST GEAR FUNCTION ................151

Description ............................................................151

Wiring Diagram — AT — 1ST ...............................154

Diagnostic Procedure ...........................................155

Component Inspection ..........................................156

Page 26 of 3066

AT-20

OVERALL SYSTEM

l*1: Operates when overdrive control switch is set in “OFF” position.

l*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

l*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

l*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

l*5: Operates when overdrive control switch is “OFF”.

l:Operates.

lA: Operates when throttle opening is less than 3/16, activating engine brake.

lB: Operates during “progressive” acceleration.

lC: Operates but does not affect power transmission.

lD: Operates when throttle opening is less than 3/16, but does not affect engine brake.

POWER TRANSMISSION

“N” and “P” Positions

l“N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

l“P” position

NNEUTRAL

POSITION

D*41st *1D B B

Automatic

shift

1Û2Û3Û

4 2nd *1A B

3rd *1A *2C C B

*5

4th C *3C C

21st D B BAutomatic

shift

1Û2 2nd A B

11stBLocks (held

stationary) in

1st speed

1Ü2 2ndB Shift positionRever

se

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e

brake

19Lock-

upRemarks

2nd

apply3rd

releas

e4th

apply

Page 36 of 3066

AT-30

OVERALL SYSTEM

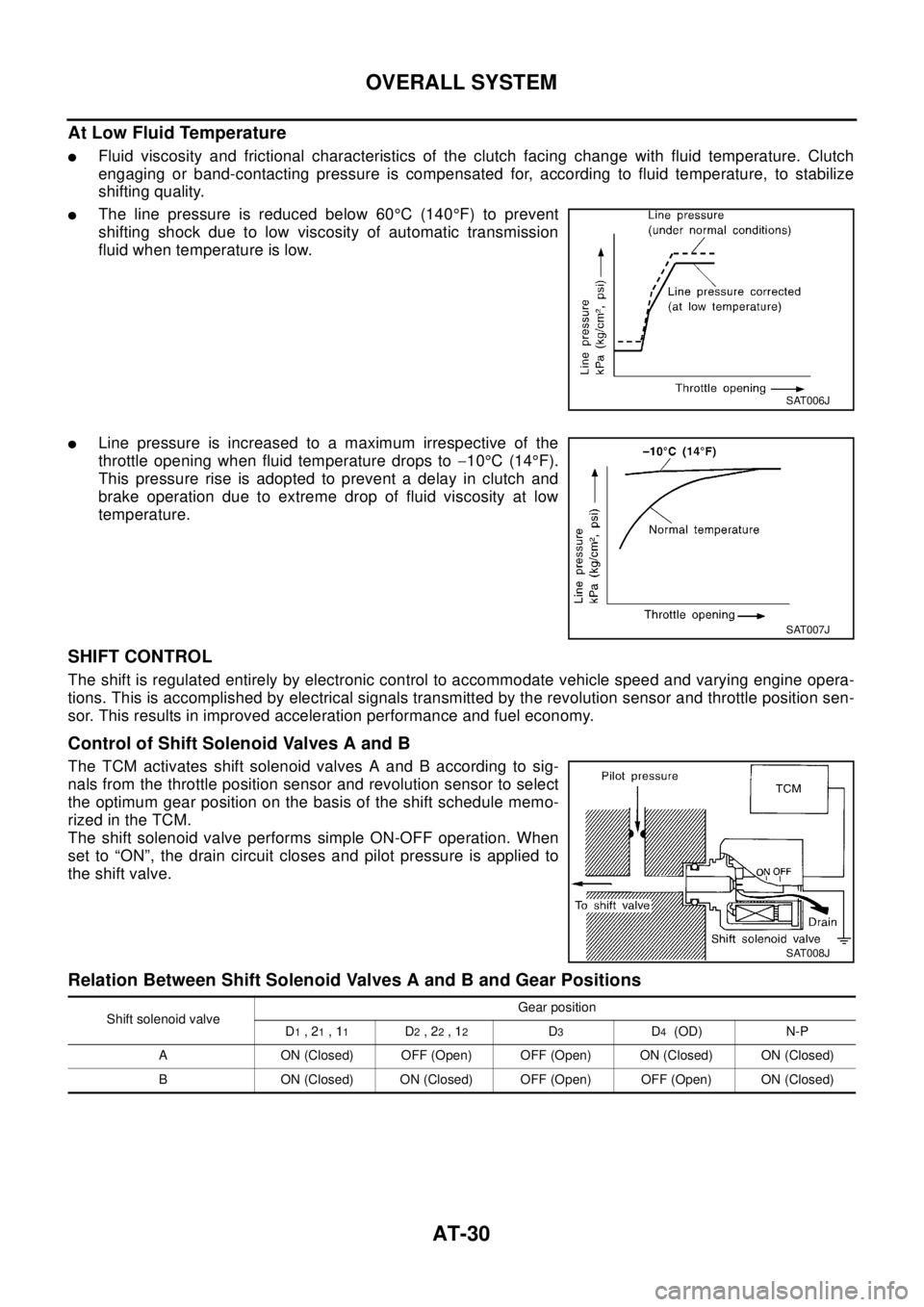

At Low Fluid Temperature

lFluid viscosity and frictional characteristics of the clutch facing change with fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to fluid temperature, to stabilize

shifting quality.

lThe line pressure is reduced below 60°C(140°F) to prevent

shifting shock due to low viscosity of automatic transmission

fluid when temperature is low.

lLine pressure is increased to a maximum irrespective of the

throttle opening when fluid temperature drops to-10°C(14°F).

This pressure rise is adopted to prevent a delay in clutch and

brake operation due to extreme drop of fluid viscosity at low

temperature.

SHIFT CONTROL

The shift is regulated entirely by electronic control to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals transmitted by the revolution sensor and throttle position sen-

sor. This results in improved acceleration performance and fuel economy.

Control of Shift Solenoid Valves A and B

The TCM activates shift solenoid valves A and B according to sig-

nals from the throttle position sensor and revolution sensor to select

the optimum gear position on the basis of the shift schedule memo-

rizedintheTCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

Relation Between Shift Solenoid Valves A and B and Gear Positions

SAT006J

SAT007J

SAT008J

Shift solenoid valveGear position

D1,21,11D2,22,12D3D4(OD) N-P

A ON (Closed) OFF (Open) OFF (Open) ON (Closed) ON (Closed)

B ON (Closed) ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Page 579 of 3066

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION

A

B

AT C

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

General Refrigerant Precautions .............................. 4

Lubricant Precautions .............................................. 5

Precautions for Refrigerant Connection ................... 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 5

O-RING AND REFRIGERANT CONNECTION..... 6

Precautions for Servicing Compressor ..................... 7

Precautions for Service Equipment .......................... 8

RECOVERY/RECYCLING EQUIPMENT .............. 8

ELECTRONIC LEAK DETECTOR ........................ 8

VACUUM PUMP ................................................... 8

MANIFOLD GAUGE SET ...................................... 8

SERVICE HOSES ................................................. 9

SERVICE COUPLERS .......................................... 9

REFRIGERANT WEIGHT SCALE ........................ 9

CALIBRATING ACR4 WEIGHT SCALE ................ 9

CHARGING CYLINDER ...................................... 10

Precautions for Leak Detection Dye ....................... 10

IDENTIFICATION ................................................ 10

IDENTIFICATION LABEL FOR VEHICLE ........... 10

Wiring Diagrams and Trouble Diagnosis ................ 10

PREPARATION ..........................................................11

Special Service Tools ..............................................11

WITH GASOLINE ENGINE (CWV-615M COM-

PRESSOR) ..........................................................11

WITH DIESEL ENGINE (DKV-11G COMPRES-

SOR) ....................................................................11

HFC-134a (R-134a) Service Tools and Equipment... 12

REFRIGERATION SYSTEM ..................................... 16

Refrigerant Cycle ................................................... 16

REFRIGERANT FLOW ....................................... 16

FREEZE PROTECTION (WITH GASOLINE

ENGINE: CWV-615M COMPRESSOR) .............. 16

Refrigerant System Protection ............................... 16

REFRIGERANT PRESSURE SENSOR (WITHGASOLINE ENGINE: CWV-615M COMPRES-

SOR) ................................................................... 16

DUAL-PRESSURE SWITCH (WITH DIESEL

ENGINE: DKV-11G COMPRESSOR) .................. 16

PRESSURE RELIEF VALVE (WITH GASOLINE

ENGINE: CWV-615M COMPRESSOR) .............. 16

V-6 Variable Displacement Compressor (With Gas-

oline Engine: CWV-165M Compressor) .................. 17

GENERAL INFORMATION ................................. 17

DESCRIPTION .................................................... 17

Component Layout ................................................. 20

LUBRICANT .............................................................. 21

Maintenance of Lubricant Quantity in Compressor... 21

LUBRICANT ........................................................ 21

LUBRICANT RETURN OPERATION .................. 21

LUBRICANT ADJUSTING PROCEDURE FOR

COMPONENTS REPLACEMENT EXCEPT

COMPRESSOR .................................................. 22

LUBRICANT ADJUSTING PROCEDURE FOR

COMPRESSOR REPLACEMENT ....................... 22

AIR CONDITIONER CONTROL ............................... 24

Overview Air Conditioner LAN Control System ...... 24

System Construction .............................................. 24

OPERATION ........................................................ 24

TRANSMISSION DATA AND TRANSMISSION

ORDER ............................................................... 25

AIR MIX DOOR CONTROL (AUTOMATIC TEM-

PERATURE CONTROL) ..................................... 25

FAN SPEED CONTROL ...................................... 26

INTAKE DOOR CONTROL ................................. 26

OUTLET DOOR CONTROL ................................ 26

MAGNET CLUTCH CONTROL ........................... 26

SELF-DIAGNOSTIC SYSTEM ............................ 26

Overview of Control system .................................... 26

Control Operation ................................................... 27

DISPLAY SCREEN .............................................. 27

AUTO SWITCH ................................................... 27

TEMPERATURE DIAL (POTENTIO TEMPERA-

TURE CONTROL) ............................................... 27

A/C SWITCH ....................................................... 27

Page 603 of 3066

AIR CONDITIONER CONTROL

ATC-25

C

D

E

F

G

H

I

K

L

MA

B

AT C

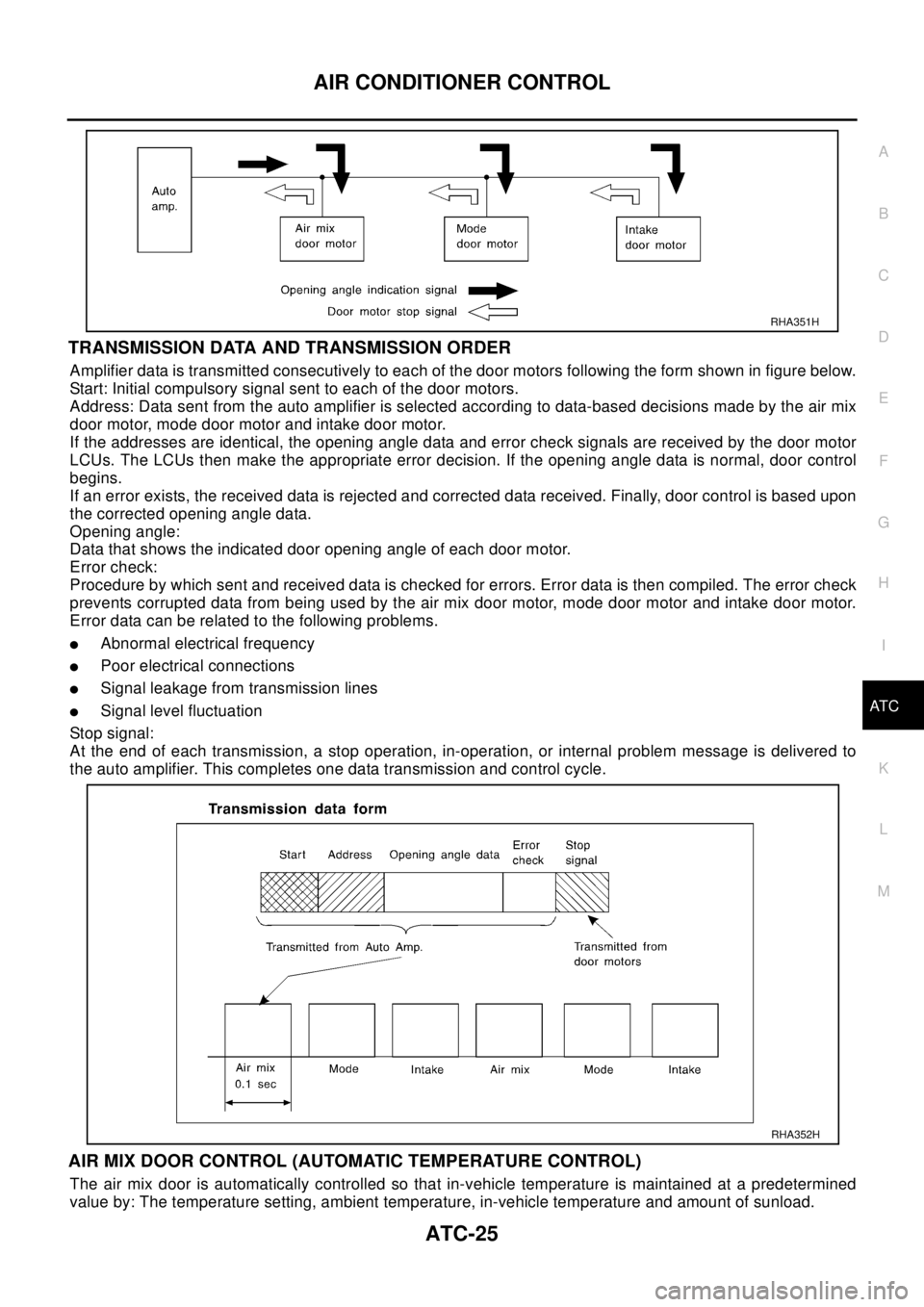

TRANSMISSION DATA AND TRANSMISSION ORDER

Amplifier data is transmitted consecutively to each of the door motors following the form shown in figure below.

Start: Initial compulsory signal sent to each of the door motors.

Address: Data sent from the auto amplifier is selected according to data-based decisions made by the air mix

door motor, mode door motor and intake door motor.

If the addresses are identical, the opening angle data and error check signals are received by the door motor

LCUs. The LCUs then make the appropriate error decision. If the opening angle data is normal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle:

Data that shows the indicated door opening angle of each door motor.

Error check:

Procedure by which sent and received data is checked for errors. Error data is then compiled. The error check

prevents corrupted data from being used by the air mix door motor, mode door motor and intake door motor.

Error data can be related to the following problems.

lAbnormal electrical frequency

lPoor electrical connections

lSignal leakage from transmission lines

lSignal level fluctuation

Stop signal:

At the end of each transmission, a stop operation, in-operation, or internal problem message is delivered to

the auto amplifier. This completes one data transmission and control cycle.

AIR MIX DOOR CONTROL (AUTOMATIC TEMPERATURE CONTROL)

The air mix door is automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by: The temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

RHA351H

RHA352H

Page 2257 of 3066

GI-4

PRECAUTIONS

General Precautions

EAS000FQ

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

SGI285

SGI231

SEF289H

SGI233

Page 2262 of 3066

HOW TO USE THIS MANUAL

GI-9

HOW TO USE THIS MANUALPFP:00008

DescriptionEAS000FY

This volume explains “Removal, Disassembly, Installation, Inspection and Adjustment” and “Trouble Diag-

noses”.

Te r m sEAS000FZ

lThe captionsWA RN INGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WAR NIN Gindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWA RN INGandCAUTIONgive you helpful information.

Standard value:Tolerance at inspection and adjustment.

Limit value:The maximum or minimum limit value that should not be exceeded at inspection and adjust-

ment.

UnitsEAS000G0

lTheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

“Example”

ContentsEAS000G1

lALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

lA QUICK REFERENCE INDEX, a black tab (e.g. ) is provided on the first page. You can quickly find

the first page of each section by matching it to the section's black tab.

lTHE CONTENTSare listed on the first page of each section.

lTHE TITLEis indicated on the upper portion of each page and shows the part or system.

lTHEPAGENUMBERof each section consists of two or three letters which designate the particular sec-

tion and a number (e.g. “BR-5”).

lTHE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic tran-

saxle or transmission, etc. are presented in a step-by-step format where necessary.

ComponentsEAS000G2

lTHE LARGE ILLUSTRATIONSare exploded views (See the following) and contain tightening torques,

lubrication points, section number of thePARTS CATALOG(e.g. SEC.440) and other information neces-

sary to perform repairs.Tightening torque :59 - 78 N-m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

Page 2275 of 3066

GI-22

HOW TO USE THIS MANUAL

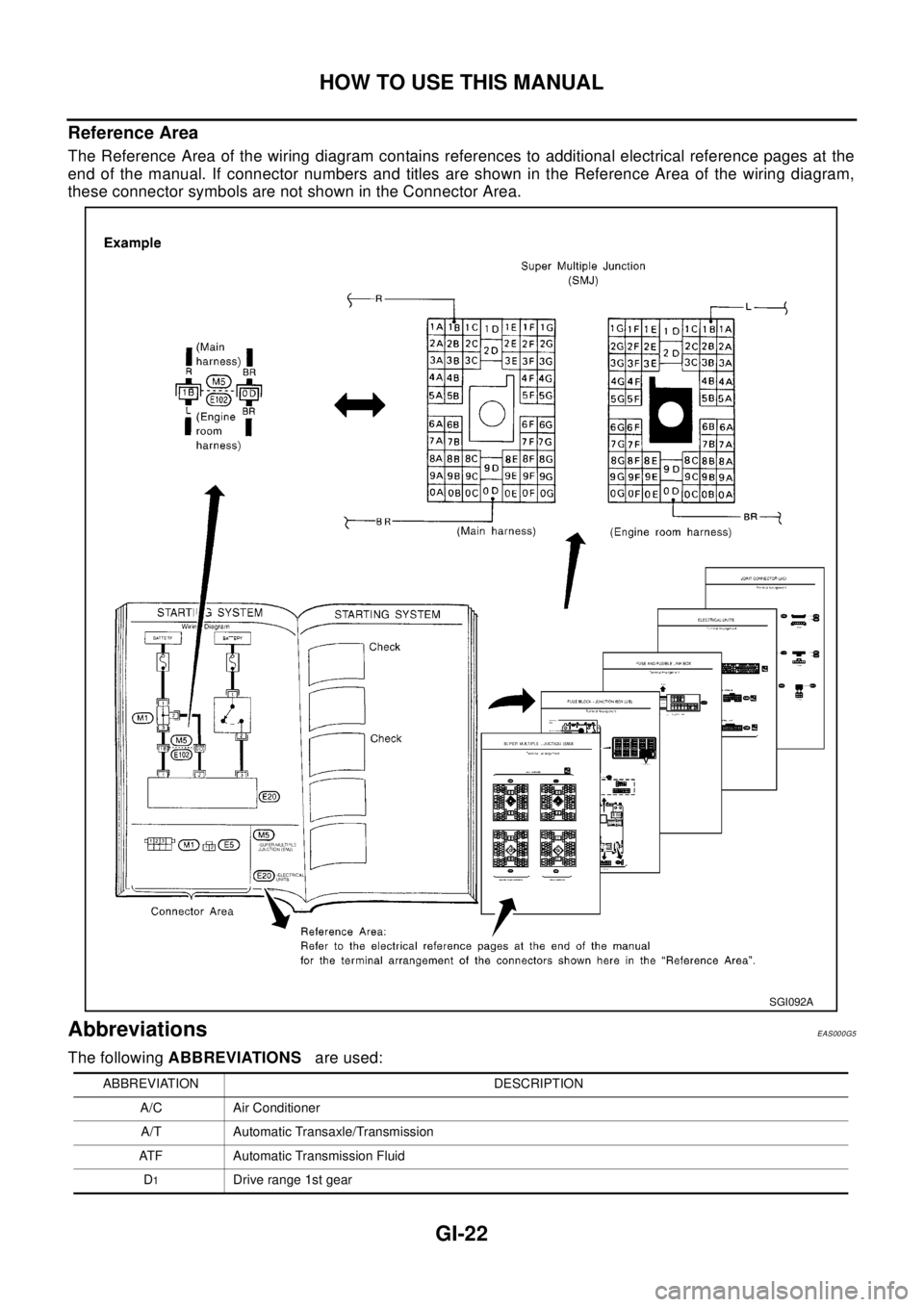

Reference Area

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are shown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

AbbreviationsEAS000G5

The followingABBREVIATIONSare used:

SGI092A

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

D

1Driverange1stgear

Page 2293 of 3066

GI-40

TOW TRUCK TOWING

TOW TRUCK TOWING

PFP:00000

To w Tr u c k To w i n gEAS000FL

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and power train are in good order.

If any unit is damaged, dollies must be used.

lNever tow an automatic transmission model from the rear (that is backward) with four wheels on

the ground. This may cause serious and expensive damage to the transmission.

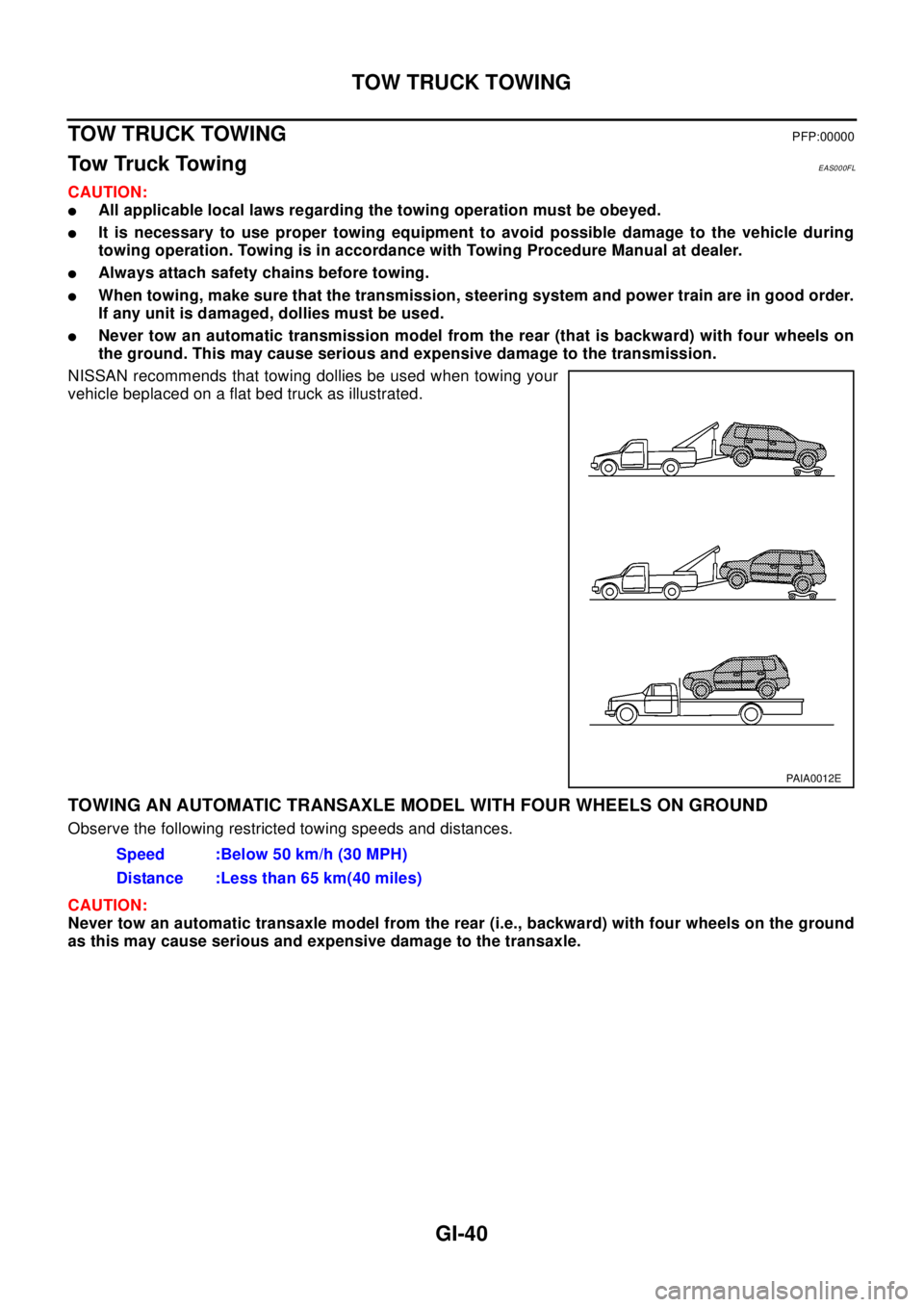

NISSAN recommends that towing dollies be used when towing your

vehicle beplaced on a flat bed truck as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

Observe the following restricted towing speeds and distances.

CAUTION:

Never tow an automatic transaxle model from the rear (i.e., backward) with four wheels on the ground

as this may cause serious and expensive damage to the transaxle.

PAIA0012E

Speed :Below 50 km/h (30 MPH)

Distance :Less than 65 km(40 miles)