charging NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 19 of 3066

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Checking A/T FluidECS004Q7

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

lIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

lIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer toCO-12,

"RADIATOR",CO-15, "RADIATOR (ALUMINUM TYPE)",,.

Changing A/T FluidECS004Q8

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”. If fluid is still dirty, repeat steps 2 through 5.

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer toMA-

17, "RECOMMENDED FLUIDS AND LUBRI-

CANTS".

Fluid capacity (With torque converter):

Approx. 8.0 (7.01 lmp qt)

Drain plug:

:29-39N·m(3.0-4.0kg-m,22-29ft-lb)

SMA027D

Page 126 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-120

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 6 4 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4 6 5 ,

" NISSAN X-TRAIL 2003 Electronic Repair Manual AT-120

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 6 4 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4 6 5 ,

"](/img/5/57402/w960_57402-125.png)

AT-120

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 6 4 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4 6 5 ,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬

3. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

4. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

5. High clutchAT- 5 0 7 ,

"High

Clutch"

¬

6. Brake bandAT- 5 3 0 ,

"Band

Servo Pis-

ton Assem-

bly"

¬

7. Forward clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

8. Overrun clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

9. Low & reverse brakeAT- 5 1 8 ,

"Low&

Reverse

Brake"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 348 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-342

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 2 8 6 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4 NISSAN X-TRAIL 2003 Electronic Repair Manual AT-342

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 2 8 6 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4](/img/5/57402/w960_57402-347.png)

AT-342

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Offensive smell at fluid charging

pipe.ON vehicle 1. Fluid levelAT- 2 8 6 ,

"FLUID

LEVEL

CHECK"

¬

OFF vehicle2. Torque converterAT- 4 6 5 ,

"Locations

of Adjusting

Shims, Nee-

dle Bear-

ings, Thrust

Washers

and Snap

Rings"

¬

3. Oil pumpAT- 4 8 5 , "

Oil

Pump"¬

4. Reverse clutchAT- 5 0 4 ,

"Reverse

Clutch"

¬

5. High clutchAT- 5 0 7 ,

"High

Clutch"

¬

6. Brake bandAT- 5 3 0 ,

"Band

Servo Pis-

ton Assem-

bly"

¬

7. Forward clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

8. Overrun clutchAT- 5 1 2 ,

"Forward

and Overrun

Clutches"

¬

9. Low & reverse brakeAT- 5 1 8 ,

"Low&

Reverse

Brake"

¬ Symptom Condition Diagnostic ItemReference Page

Except for

Euro-OBDEURO-OBD

Page 472 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at le NISSAN X-TRAIL 2003 Electronic Repair Manual AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at le](/img/5/57402/w960_57402-471.png)

AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at left.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. When fixing bearing support with check tool, rotate one- way

clutch spline using screwdriver.

c. Check that inner race rotates clockwise only. If not, replace

torque converter assembly.

4. Remove A/T fluid charging pipe and fluid cooler tube.

SAT008D

SAT009D

SAT768J

Page 568 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-562

[ALL]

ASSEMBLY

d. Use a 4 mm (0.16 in) pin for this adjustment.

i. Insert the pin straight into the manual shaft adjustment hole.

ii. Rotate park/neutral position (PNP) switch until the pin can NISSAN X-TRAIL 2003 Electronic Repair Manual AT-562

[ALL]

ASSEMBLY

d. Use a 4 mm (0.16 in) pin for this adjustment.

i. Insert the pin straight into the manual shaft adjustment hole.

ii. Rotate park/neutral position (PNP) switch until the pin can](/img/5/57402/w960_57402-567.png)

AT-562

[ALL]

ASSEMBLY

d. Use a 4 mm (0.16 in) pin for this adjustment.

i. Insert the pin straight into the manual shaft adjustment hole.

ii. Rotate park/neutral position (PNP) switch until the pin can also

be inserted straight into hole in park/neutral position (PNP)

switch.

e. Tighten park/neutral position (PNP) switch fixing bolts. Refer to

AT-461, "

OVERHAUL".

f. Remove pin from adjustment hole after adjusting park/neutral

position (PNP) switch.

20. Install A/T fluid charging pipe and fluid cooler tube to transmis-

sion case. Tighten A/T fluid charging pipe and fluid cooler tube

bolts to the specified torque. Refer toAT-461, "

OVERHAUL".

21. Install torque converter.

a. Pour ATF into torque converter.

lApproximately 1 liter (1-1/8 US qt, 7/8 Imp qt) of fluid is

required for a new torque converter.

lWhen reusing old torque converter, add the same amount

of fluid as was drained.

b. Install torque converter while aligning notches of torque con-

verter with notches of oil pump.

c. Measure distance “A” to check that torque converter is in proper

position.

AAT469A

SAT768J

SAT428DA

SAT429D

Distance A :

Refer toAT-563, "

SERVICE DATA AND SPECIFICA-

TIONS (SDS)".

SAT430D

Page 579 of 3066

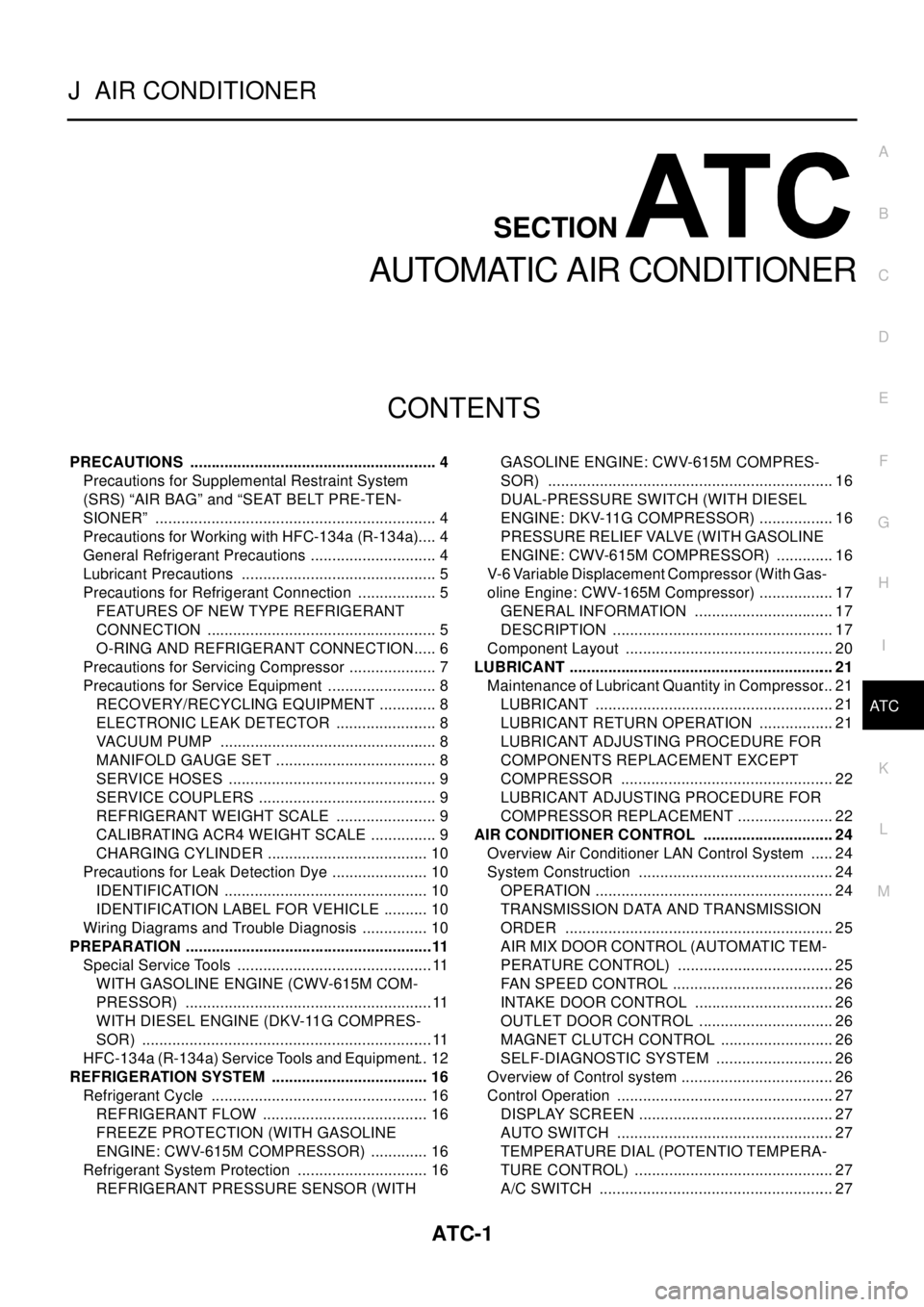

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION

A

B

AT C

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

General Refrigerant Precautions .............................. 4

Lubricant Precautions .............................................. 5

Precautions for Refrigerant Connection ................... 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 5

O-RING AND REFRIGERANT CONNECTION..... 6

Precautions for Servicing Compressor ..................... 7

Precautions for Service Equipment .......................... 8

RECOVERY/RECYCLING EQUIPMENT .............. 8

ELECTRONIC LEAK DETECTOR ........................ 8

VACUUM PUMP ................................................... 8

MANIFOLD GAUGE SET ...................................... 8

SERVICE HOSES ................................................. 9

SERVICE COUPLERS .......................................... 9

REFRIGERANT WEIGHT SCALE ........................ 9

CALIBRATING ACR4 WEIGHT SCALE ................ 9

CHARGING CYLINDER ...................................... 10

Precautions for Leak Detection Dye ....................... 10

IDENTIFICATION ................................................ 10

IDENTIFICATION LABEL FOR VEHICLE ........... 10

Wiring Diagrams and Trouble Diagnosis ................ 10

PREPARATION ..........................................................11

Special Service Tools ..............................................11

WITH GASOLINE ENGINE (CWV-615M COM-

PRESSOR) ..........................................................11

WITH DIESEL ENGINE (DKV-11G COMPRES-

SOR) ....................................................................11

HFC-134a (R-134a) Service Tools and Equipment... 12

REFRIGERATION SYSTEM ..................................... 16

Refrigerant Cycle ................................................... 16

REFRIGERANT FLOW ....................................... 16

FREEZE PROTECTION (WITH GASOLINE

ENGINE: CWV-615M COMPRESSOR) .............. 16

Refrigerant System Protection ............................... 16

REFRIGERANT PRESSURE SENSOR (WITHGASOLINE ENGINE: CWV-615M COMPRES-

SOR) ................................................................... 16

DUAL-PRESSURE SWITCH (WITH DIESEL

ENGINE: DKV-11G COMPRESSOR) .................. 16

PRESSURE RELIEF VALVE (WITH GASOLINE

ENGINE: CWV-615M COMPRESSOR) .............. 16

V-6 Variable Displacement Compressor (With Gas-

oline Engine: CWV-165M Compressor) .................. 17

GENERAL INFORMATION ................................. 17

DESCRIPTION .................................................... 17

Component Layout ................................................. 20

LUBRICANT .............................................................. 21

Maintenance of Lubricant Quantity in Compressor... 21

LUBRICANT ........................................................ 21

LUBRICANT RETURN OPERATION .................. 21

LUBRICANT ADJUSTING PROCEDURE FOR

COMPONENTS REPLACEMENT EXCEPT

COMPRESSOR .................................................. 22

LUBRICANT ADJUSTING PROCEDURE FOR

COMPRESSOR REPLACEMENT ....................... 22

AIR CONDITIONER CONTROL ............................... 24

Overview Air Conditioner LAN Control System ...... 24

System Construction .............................................. 24

OPERATION ........................................................ 24

TRANSMISSION DATA AND TRANSMISSION

ORDER ............................................................... 25

AIR MIX DOOR CONTROL (AUTOMATIC TEM-

PERATURE CONTROL) ..................................... 25

FAN SPEED CONTROL ...................................... 26

INTAKE DOOR CONTROL ................................. 26

OUTLET DOOR CONTROL ................................ 26

MAGNET CLUTCH CONTROL ........................... 26

SELF-DIAGNOSTIC SYSTEM ............................ 26

Overview of Control system .................................... 26

Control Operation ................................................... 27

DISPLAY SCREEN .............................................. 27

AUTO SWITCH ................................................... 27

TEMPERATURE DIAL (POTENTIO TEMPERA-

TURE CONTROL) ............................................... 27

A/C SWITCH ....................................................... 27

Page 585 of 3066

PRECAUTIONS

ATC-7

C

D

E

F

G

H

I

K

L

MA

B

AT C

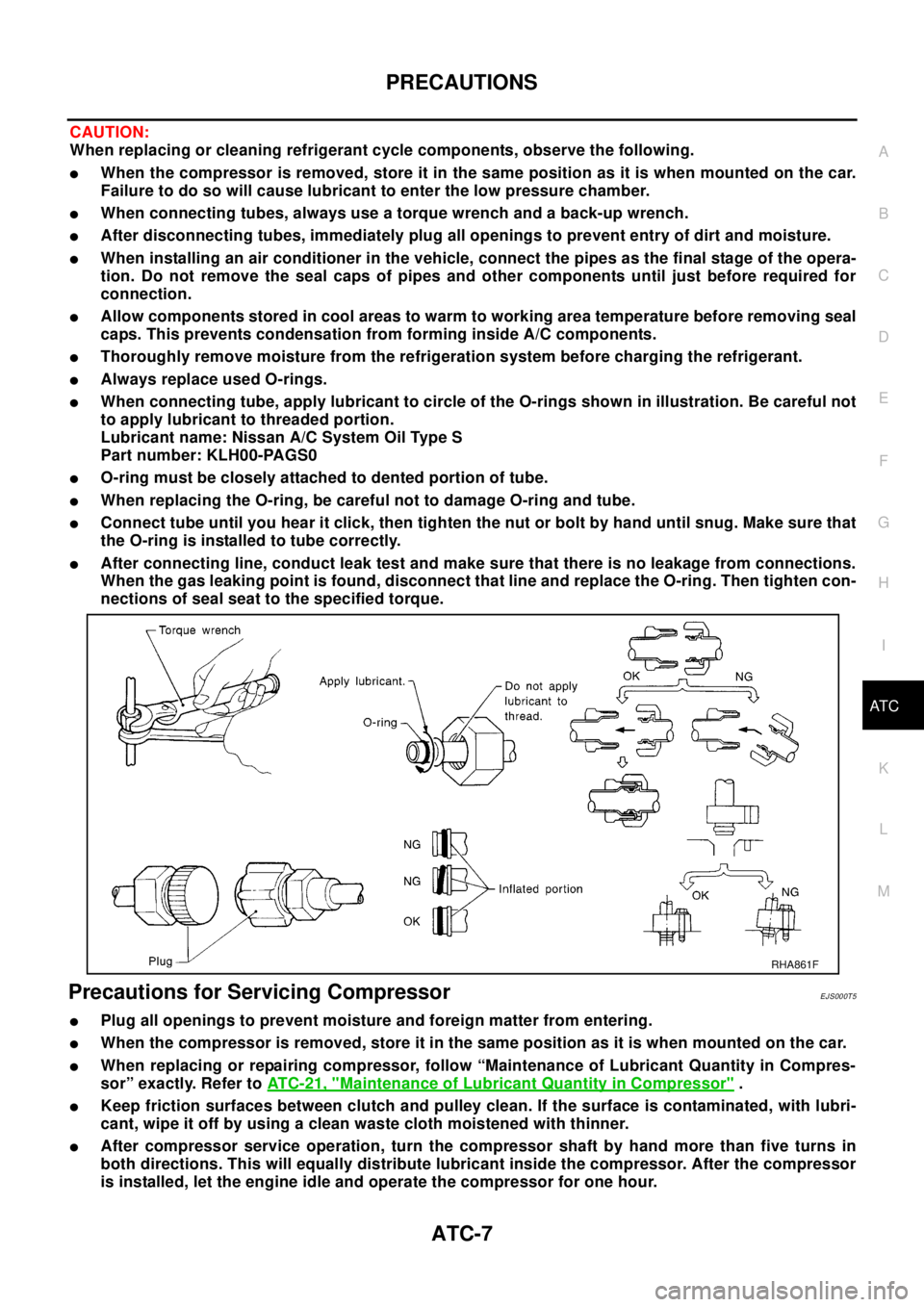

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

lWhen the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

lWhen connecting tubes, always use a torque wrench and a back-up wrench.

lAfter disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

lWhen installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

lAllow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

lThoroughly remove moisture from the refrigeration system before charging the refrigerant.

lAlways replace used O-rings.

lWhen connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

lO-ring must be closely attached to dented portion of tube.

lWhen replacing the O-ring, be careful not to damage O-ring and tube.

lConnect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

lAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Precautions for Servicing CompressorEJS000T5

lPlug all openings to prevent moisture and foreign matter from entering.

lWhen the compressor is removed, store it in the same position as it is when mounted on the car.

lWhen replacing or repairing compressor, follow “Maintenance of Lubricant Quantity in Compres-

sor” exactly. Refer toATC-21, "

Maintenance of Lubricant Quantity in Compressor".

lKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with lubri-

cant, wipe it off by using a clean waste cloth moistened with thinner.

lAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

RHA861F

Page 587 of 3066

PRECAUTIONS

ATC-9

C

D

E

F

G

H

I

K

L

MA

B

AT C

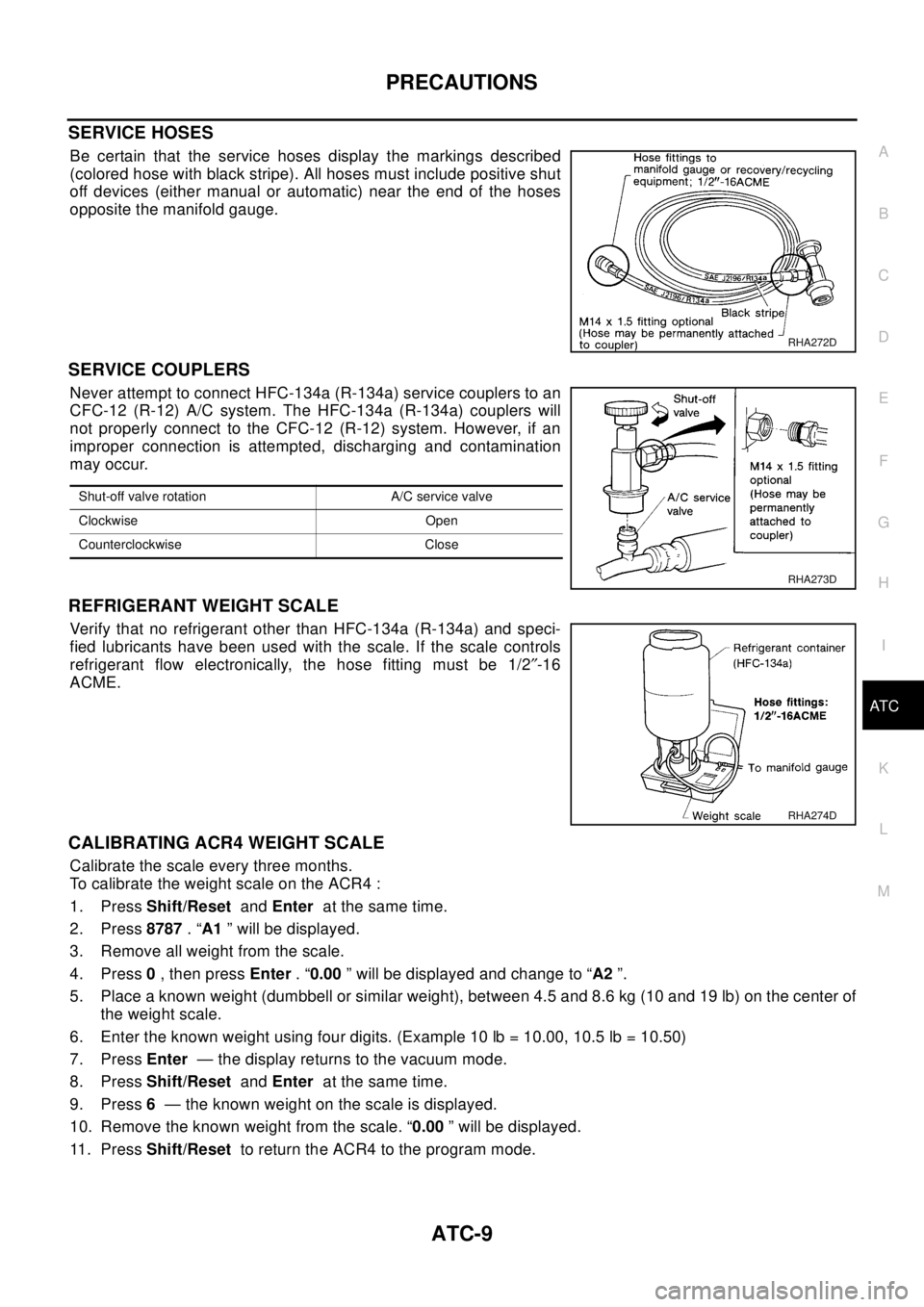

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to an

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale every three months.

To calibrate the weight scale on the ACR4 :

1. PressShift/ResetandEnterat the same time.

2. Press8787.“A1” will be displayed.

3. Remove all weight from the scale.

4. Press0,thenpressEnter.“0.00” will be displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb) on the center of

the weight scale.

6. Enter the known weight using four digits. (Example 10 lb = 10.00, 10.5 lb = 10.50)

7. PressEnter— the display returns to the vacuum mode.

8. PressShift/ResetandEnterat the same time.

9. Press6— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” will be displayed.

11 . P r e s sShift/Resetto return the ACR4 to the program mode.

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 588 of 3066

ATC-10

PRECAUTIONS

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder's top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precautions for Leak Detection DyeEJS000T7

lThe A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

lAlways wear fluorescence enhancing UV safety glasses to protect your eyes and enhance the visibility of

the fluorescent dye.

lThe fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector to (J-

41995) pin-point refrigerant leaks.

lFor your safety and your Customer's satisfaction, read and follow all manufacture's operating instructions

and precautions prior to performing the work.

lA compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal

should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

lAlways remove any remaining dye from the leak area after repairs are complete to avoid a misdiagnosis

during a future service.

lDo not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period

of time cannot be removed.

lDo not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

lDo not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

lLeak detection dyes for R-134a and R12 A/C systems are different. Do not use R-134a leak detection dye

in R-12 A/C system or R-12 leak detector dye in R-134a A/C systems or A/C system damage may result.

lThe fluorescent properties of the dye will remain for over three (3) years unless a compressor failure

occurs.

IDENTIFICATION

NOTE:

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have this identification

label on the front side of hood.

Wiring Diagrams and Trouble DiagnosisEJS000T9

When you read wiring diagrams, refer to the followings:

lGI-14, "How to Read Wiring Diagrams"in GI section.

lPG-3, "Wiring Diagram—POWER—"in PG section.

When you perform trouble diagnosis, refer to the followings:

lGI-10, "How to Follow Trouble Diagnoses"in GI section.

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section.

SHA436FA