tires NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

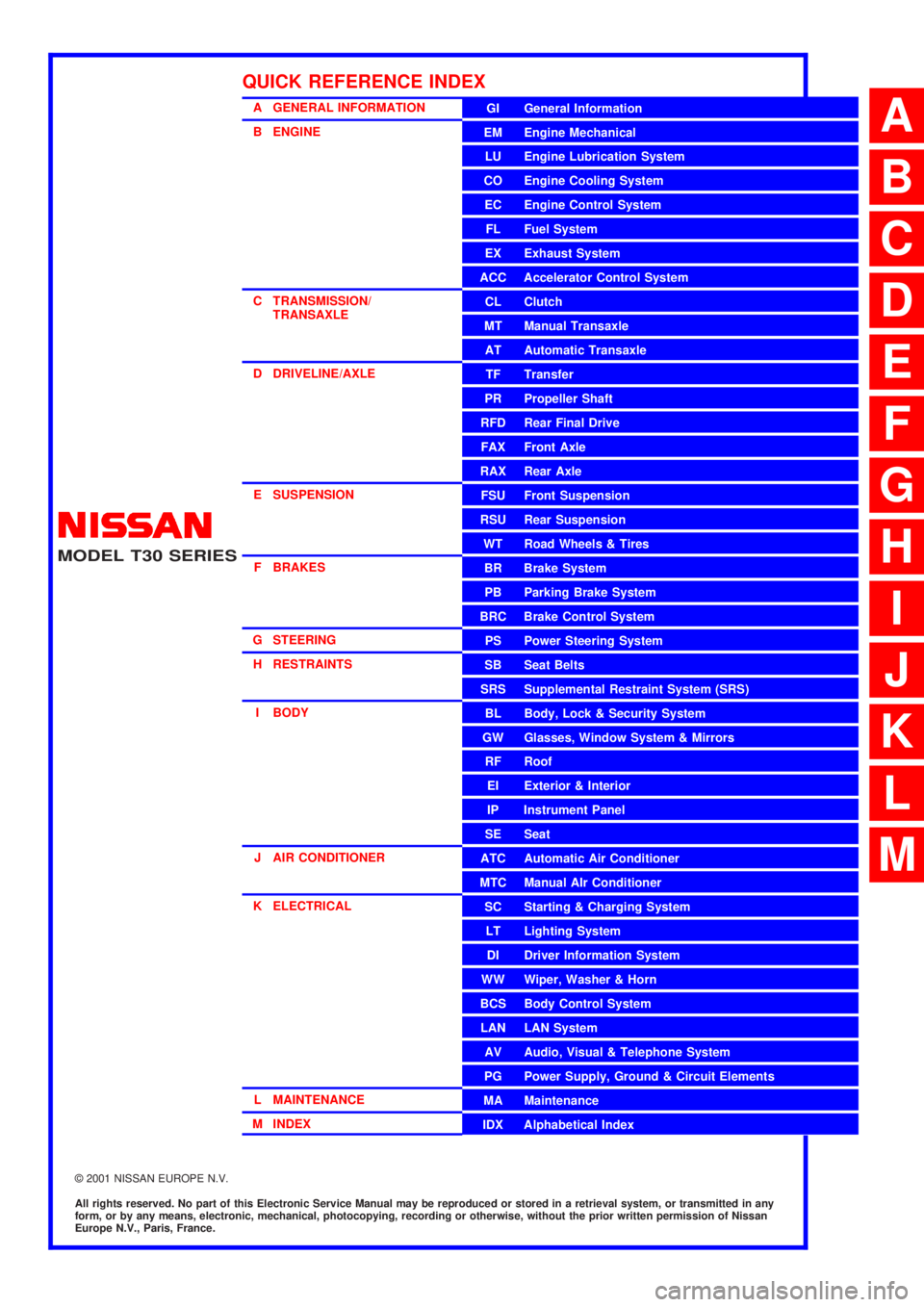

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 839 of 3066

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

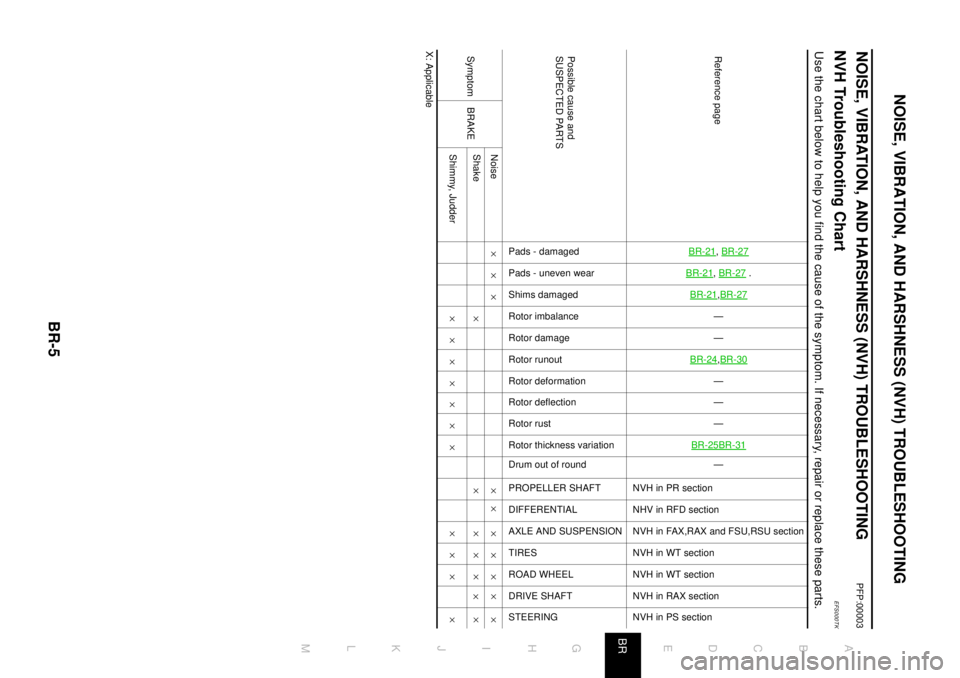

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEFS000TK

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

X: ApplicableReference page

BR-21

,BR-27

BR-21

,BR-27

.

BR-21

,BR-27—

—

BR-24,BR-30—

—

—

BR-25BR-31—

NVHinPRsection

NHV in RFD section

NVH in FAX,RAX and FSU,RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in PS section

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKENoise´´´ ´´ ´´´

´´

Shake´ ´ ´´´

´´

Shimmy, Judder´´´´´´´ ´´´ ´

Page 872 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref](/img/5/57402/w960_57402-871.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

lBefore working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WAR NIN G:

lClean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

lIf malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

lIf malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

lStopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

lFitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

l4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 909 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-41

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD MODES CANNOT BE SWITCHED AFTER ENGINE IS STARTED

1.INSPECTION USING 4WD MODE CHANGE-OVER SWITCH

lDrive modes cannot be switched after NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-41

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD MODES CANNOT BE SWITCHED AFTER ENGINE IS STARTED

1.INSPECTION USING 4WD MODE CHANGE-OVER SWITCH

lDrive modes cannot be switched after](/img/5/57402/w960_57402-908.png)

TROUBLE DIAGNOSIS

BRC-41

[4WD/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

4WD MODES CANNOT BE SWITCHED AFTER ENGINE IS STARTED

1.INSPECTION USING 4WD MODE CHANGE-OVER SWITCH

lDrive modes cannot be switched after the engine is started.

lOn data monitor screen of the CONSULT-II, check 4WD mode switch.

lCheck if the display changes from ## to 2WD mode when the 2WD switch is pressed.

lCheck if the display changes from ## to AUTO mode when the AUTO switch is pressed.

lCheck if the display changes from ## to LOCK mode when the LOCK switch is pressed.

OK or NG

OK >> No malfunction detected.

NG >>

lCONSULT-II display does not change from ## when the 2WD switch is pressed. Check harness

of the 2WD switch.

lCONSULT-II display does not change from ## when the AUTO switch is pressed. Check har-

ness of the 2WD switch and LOCK switch.

lCONSULT-II display does not change from ## when the LOCK switch is pressed. Check har-

ness of the LOCK switch.

lPerform 4WD mode change-over switch inspection.

WHILE DRIVING, 4WD WARNING LAMP FLASHES RAPIDLY. (WHEN IT FLASHERS FOR

APPROX. ONE MINUTE, THEN DOES NOT ILLUMINATE.)

lWhile driving, 4WD warning lamp flashes rapidly. (When it flashes for Approx. One minute, then does not

illuminate.)

Rapid flashing: 2 times/second

This phenomenon protects drivetrain parts when a heavy load is applied to the electronically controlled

coupling and multiple disc clutch temperature increases. It is not a malfunction.

When the difference of revolution speed by or with the front and rear wheel with AUTO mode, the shift

switch occasionally changes to LOCK mode automatically. This is not a malfunction.

When the difference of revolution speed between the front and rear wheel with AUTO mode, the shift

switch occasionally changes to LOCK mode automatically. This is not a malfunction.

WHILE DRIVING, 4WD WARNING LAMP FLASHES SLOWLY. (WHEN IT CONTINUES TO ILLU-

MINATE UNTIL ENGINE TURNS OFF.)

1. Check using the data monitor function of the CONSULT-II.

lPerform inspection with the data monitor function of the CONSULT-II.

lCheck if the value of IMPROPER SIZE TIRE MONITOR is 8 mm (0.31 in) or more.

lStop the engine. Restart the engine and drive the vehicle at 20 km/h (12 MPH) or faster for approxi-

mately 200 seconds. Confirm the 4WD warning lamp flashes slowly.

(Check if the value of IMPROPER SIZE TIRE MONITOR is 8 mm (0.31 in) or more.)

When the tire size is normal, the value of IMPROPER SIZE TIRE MONITOR will change from 8 mm

(0.31 in) or more to 0 to 4 mm (0 to 0.16 in) (normal condition) after the vehicle is driven 20 km/h (12

MPH) or faster for approximately 5 seconds.

2. Tire inspection

lInspection of tire pressure

lWear condition

lCheck size of the front and rear tires. (No excessive difference should be observed.) Refer toGI-46,

"Wheels&Tires"

VEHICLE DOES NOT ENTER 4WD MODE EVEN THOUGH 4WD WARNING LAMP IS OFF.

1. Check using the data monitor function of the CONSULT-II.

Perform inspection by the data monitor function of the CONSULT-II.

–Check if the vehicle operation changes to 2WD, AUTO, and LOCK modes.

–Check current supplied to the 4WD solenoid valve in AUTO mode.

Accelerator pedal not depressed: Approx. 0 A

Accelerator pedal depressed: Approx. 2.8 A

Page 914 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-46

[4WD/ABS]

TROUBLE DIAGNOSIS

lStop the engine. Restart the engine and drive the vehicle at 20 km/h or faster for approximately 200

seconds. Confirm the 4WD warning lamp flashes slowly.

(Check if NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-46

[4WD/ABS]

TROUBLE DIAGNOSIS

lStop the engine. Restart the engine and drive the vehicle at 20 km/h or faster for approximately 200

seconds. Confirm the 4WD warning lamp flashes slowly.

(Check if](/img/5/57402/w960_57402-913.png)

BRC-46

[4WD/ABS]

TROUBLE DIAGNOSIS

lStop the engine. Restart the engine and drive the vehicle at 20 km/h or faster for approximately 200

seconds. Confirm the 4WD warning lamp flashes slowly.

(Check if the value of IMPROPER SIZE TIRE MONITOR is 8 mm or more.)

When the tire size is normal, the value of IMPROPER SIZE TIRE MONITOR will change from 8 mm or

more to 0 - 4 mm (normal condition) after the vehicle is driven 20 km/h or faster for approximately 5

seconds.

2. Tire inspection

lInspection of tire air pressure

lWear condition

lCheck size of the front and rear tires. (No excessive difference should be observed.) Refer toGI-46,

"Wheels&Tire s"

Vehicle does not enter 4WD mode even though 4WD warning lamp is off.EFS001BX

1. Check using the data monitor function of the CONSULT.

Perform inspection by the data monitor function of the CONSULT.

–Check if the vehicle operation changes to 2WD, AUTO, and LOCK modes.

–Check current supplied to the E-TS solenoid valve in AUTO mode.

2. Check using the active test function of the CONSULT.

Using active test mode of CONSULT, supply current to the E-TS solenoid valve and check that the monitor

current becomes close to this supply current.

lThe 4WD/ABS control unit is normal when the difference between E-TS solenoid valve current and the

monitor current is within±10%.

It is necessary to inspect the electronically controlled coupling assembly.

Tight-corner braking symptom occurs when the vehicle is started in AUTO

mode (4WD warning lamp remain OFF).

EFS001BY

1.THROTTLE POSITION SENSOR AND HARNESS INSPECTION

Check accelerator pedal stroke.

Is inspection result OK?

YES >> Perform self-diagnosis again.

NO >> Malfunctioning throttle position sensor harness

E-TS actuator relay (4WD solenoid actuator relay) turns ON/OFF frequently.EFS001BZ

1.SELF-DIAGNOSIS RESULT IS E-TS ACTUATOR RELAY (4WD ACTUATOR RELAY) ON ERROR

AND OFF ERROR.

Is self-diagnosis result [ON error and OFF error]?

Is inspection result OK?

YES >> GO TO 2.

NO >> Repair or replace as necessary.

2.E-TS ACTUATOR RELAY (4WD SOLENOID ACTUATOR RELAY) AND HARNESS INSPECTION

Is self-diagnosis result [ON error and OFF error]?

Is inspection result OK?

YES >> Perform self-diagnosis again.

NO >> Malfunctioning E-TS actuator relay (4WD solenoid actuator relay) harnessAccelerator pedal not depressed: Approx. 0 A

Accelerator pedal depressed: Approx. 2.8 A

Example) Monitor value becomes Approx. 1 A for E-TS solenoid current 1 A setting.

Page 922 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-54

[ESP/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Adjustment of Neutral Position of Steering Angle SensorEFS0019R

lAfter removing/installing or replacing the ESP/TCS/ABS control uni NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-54

[ESP/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Adjustment of Neutral Position of Steering Angle SensorEFS0019R

lAfter removing/installing or replacing the ESP/TCS/ABS control uni](/img/5/57402/w960_57402-921.png)

BRC-54

[ESP/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

PFP:00000

Adjustment of Neutral Position of Steering Angle SensorEFS0019R

lAfter removing/installing or replacing the ESP/TCS/ABS control unit, steering angle sensor, steering com-

ponents, suspension components, and tires, or after adjusting the wheel alignment, make sure to adjust

the neutral position of the steering angle sensor before running the vehicle.

CAUTION:

To adjust the neutral position of the steering angle sensor, make sure to use CONSULT-II.

(Adjustment cannot be done other than CONSULT-II.)

1. Stop the vehicle with the front wheels in the straight-ahead position.

2. Connect CONSULT-II to data link connector on the vehicle, and

turn the ignition switch to ON position (engine not running).

3. Touch “START”, “ABS”, “WORK SUPPORT” and “ST ANGLE

SENSOR ADJUSTMENT” on the CONSULT-II screen in this

order.

PBIB0196E

SFIA0364E

SFIA0365E

SFIA0370E

Page 956 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm](/img/5/57402/w960_57402-955.png)

BRC-88

[ESP/TCS/ABS]

TROUBLE DIAGNOSIS

For Correct and Quick Diagnosis

EFS001A8

PRECAUTIONS FOR TROUBLE DIAGNOSIS

lBefore performing the trouble diagnosis, always read theGI-3, "PRECAUTIONS"to confirm the general

precautions.

lAfter replacement of ESP/TCS/ABS control unit, steering angle sensor, steering parts, suspension parts,

or tires, and adjustment of alignment, always adjust the neutral position of steering angle sensor before

driving.

lWhen the ESP/TCS/ABS control unit is replaced, check that the label on the computer unit is identical

color.

lAfter completing the trouble diagnosis, always erase the malfunctioning memory.BRC-77, "Functions of

CONSULT-II"

lWhen inspection of the continuity or voltage between units is performed, check the connector terminals for

disconnection, looseness, bend, or collapse. If any malfunction is detected, repair or replace the applica-

ble part.

lIntermittent problems may be caused by a malfunction on harness, connector, or terminal. Move the har-

nesses, harness connectors, or terminals by hand to make sure that there is no contact malfunction.

lIf a circuit tester is used for the check, be careful not to forcibly extend any connector terminal.

lFor self-diagnosis, active test, and work support of ESP/TCS/ABS control unit with CONSULT-II, stop and

connect CONSULT-II and select²ABS².

lCONSULT-II self-diagnosis results are displayed without regard to occurrence timing. In some case, the

later ones (timing value is small) appear on the next screen.

lWhile the self-diagnosis results of CONSULT-II shows a malfunction, if CONSULT-II active test is per-

formed, an engine system malfunction may be indicated. In this case, start the engine to resume the nor-

mal screen.

lESP/TCS/ABS system electronically controls the brake operation and engine output. The following symp-

toms may be caused by the normal operations.

Symptom Symptom description Result

Motor operation noiseDuring ESP, TCS, or ABS operation, sometimes a faint noise can be

heard. This is a motor operation noise in the ESP/TCS/ABS actuator.

Normal

Just after the engine starts, the motor operating noise may be heard.

This is a normal status of the system operation check.

System operation check

noiseWhen the engine starts, a²click²noise may be heard from the engine

compartment. This is a normal status of the system operation check.Normal

ESP/TCS operation

(SLIP lamp ON)When the vehicle is passing through a road where the surface friction

coefficient varies or the wheel speed changes suddenly by downshifting

or depressing of the accelerator pedal fully, TCS may be activated tem-

porarily.

Normal

Cancel the ESP/TCS

function for the

inspection on a chas-

sis dynamometer. Before the speedometer inspection, turn ESP OFF switch off to cancel

the ESP/TCS function.

When the accelerator pedal is depressed on a chassis dynamometer,

the vehicle speed will not increase. This is not malfunction, because

TCS is activated by the wheel speed difference between front and rear.

The warning lamp may also illuminate to show²sensor system failure²in

this case. This is not malfunction either, because the stationary front

wheels are detected. Restart the engine, and drive the vehicle at 30 km/

h or higher to check that the warning lamp no longer illuminates.

ABS operation (Longer stop-

ping distance)The stopping distance may be longer for the vehicles with ABS when the

vehicle is driver on snowy and rough road. When driving on the road like

that, slow down the speed.Normal

Sluggish feelDepending on road circumstances, the driver may have a sluggish feel.

This is not abnormal, because the optimum traction has the highest pri-

ority (safety first) by TCS operation. Sometimes the driver has a slight

sluggish feel against the substantial accelerator pedal operation.Normal

Page 1016 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex NISSAN X-TRAIL 2003 Electronic Repair Manual CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at ex](/img/5/57402/w960_57402-1015.png)

CO-6

[QR20DE]

OVERHEATING CAUSE ANALYSIS

Except cool-

ing system

parts mal-

function— OverloadonengineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 1037 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear NISSAN X-TRAIL 2003 Electronic Repair Manual OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear](/img/5/57402/w960_57402-1036.png)

OVERHEATING CAUSE ANALYSIS

CO-27

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

CO

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system mal-

function

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator —

Blocked condenser

—

Installed large fog lamp Symptom Check items

Page 2198 of 3066

FAX-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEDS0005P

Observe the following precautions when disassembling and servicing drive shaft.

lThe wheel joint cannot be disassembled. Do not attempt to disassemble it.

lPerform work in a location which is as dust-free and dirt-free as possible.

lBefore disassembling and servicing, clean the outside of parts.

lThe disassembly and service location must be clean. Care must be taken to prevent parts from becoming

dirty and to prevent the entry of foreign objects.

lDisassembled parts must be carefully reassembled in the correct order. If work is interrupted, a clean

cover must be placed over parts.

lPaper shop cloths must be used. Fabric shop cloths must not be used because of the danger of lint adher-

ing to parts.

lDisassembled parts (except for rubber parts) should be cleaned with kerosene which shall be removed by

blowing with air or wiping with paper shop cloths.

Precautions for Brake SystemEDS0 00 I0

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake tubes.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lAlways torque brake lines when installing.

SBR686C