coolant level NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1011 of 3066

CO-1

ENGINE COOLING SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

CO

ENGINE COOLING SYSTEM

QR20DE

PRECAUTIONS .......................................................... 3

Precautions For Liquid Gasket ................................. 3

REMOVAL OF LIQUID GASKET .......................... 3

LIQUID GASKET APPLICATION PROCEDURE..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

OVERHEATING CAUSE ANALYSIS .......................... 5

Troubleshooting Chart .............................................. 5

COOLING SYSTEM .................................................... 7

Cooling Circuit .......................................................... 7

ENGINE COOLANT .................................................... 9

Inspection ................................................................. 9

LEVEL CHECK ..................................................... 9

LEAK CHECK ....................................................... 9

Changing Engine Coolant ........................................ 9

DRAINING ENGINE COOLANT ........................... 9

REFILLING ENGINE COOLANT ........................ 10

FLUSHING COOLING SYSTEM ......................... 10

RADIATOR ................................................................ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly Radiator Fan ............. 13

DISASSEMBLY ................................................... 13

ASSEMBLY ......................................................... 13

INSPECTION ......................................................... 13

CHECKING RADIATOR CAP .............................. 13

CHECKING RADIATOR ...................................... 14

RADIATOR (ALUMINUM TYPE) .............................. 15

Disassembly and Assembly ................................... 15

PREPARATION ................................................... 15

DISASSEMBLY ................................................... 15

ASSEMBLY ......................................................... 16

INSPECTION ...................................................... 18WATER PUMP .......................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................... 19

INSPECTION AFTER REMOVAL ....................... 20

INSTALLATION ................................................... 20

INSPECTION AFTER INSTALLATION ................ 20

THERMOSTAT AND WATER CONTROL VALVE .... 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Capacity .................................................................. 23

Thermostat ............................................................. 23

Water Control Valve ................................................ 23

Radiator .................................................................. 23

Tightening Torque ................................................... 23

YD22DDTi

PRECAUTIONS ........................................................ 24

Precautions For Liquid Gasket ............................... 24

REMOVAL AND LIQUID GASKET ...................... 24

LIQUID GASKET APPLICATION PROCEDURE... 24

PREPARATION ......................................................... 25

Special Service Tools ............................................. 25

OVERHEATING CAUSE ANALYSIS ........................ 26

Troubleshooting Chart ............................................ 26

COOLING SYSTEM .................................................. 28

Cooling Circuit ........................................................ 28

ENGINE COOLANT .................................................. 30

Inspection ............................................................... 30

LEVEL CHECK .................................................... 30

LEAK CHECK ...................................................... 30

Changing Engine Coolant ....................................... 30

DRAINING ENGINE COOLANT .......................... 30

REFILLING ENGINE COOLANT ......................... 31

FLUSHING COOLING SYSTEM ......................... 32

RADIATOR ................................................................ 33

Removal and Installation ........................................ 33

Page 1019 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust](/img/5/57402/w960_57402-1018.png)

ENGINE COOLANT

CO-9

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

ENGINE COOLANTPFP:KQ100

InspectionEBS009SD

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or too little.

LEAK CHECK

lTo check for leakage, apply pressure to the cooling system with

atester.

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS009SE

WA RN ING:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

SMA412B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

PBIC0236E

Page 1020 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If NISSAN X-TRAIL 2003 Electronic Repair Manual CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If](/img/5/57402/w960_57402-1019.png)

CO-10

[QR20DE]

ENGINE COOLANT

2. Open drain plugs on cylinder block.

3. Remove reservoir tank and drain coolant.

4. Check drained coolant for contaminants such as rust, corrosion

or discoloration.

If contaminated, flush engine cooling system. Refer toCO-10,

"FLUSHING COOLING SYSTEM".

REFILLING ENGINE COOLANT

1. Install reservoir tank, radiator drain plug and cylinder block drain plug.

Apply sealant to the thread of cylinder block drain plug.

lUse Genuine Liquid Gasket or equivalent.

2. Fill radiator and reservoir tank to specified level.

lUse genuine Nissan anti-freeze coolant or equivalent mixed

with water (distilled or demineralized).

Refer toMA-17, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

lPour coolant slowly of less than 2 (2-1/8US qt,1-3/4 lmp

qt) a minute to allow air in system to escape.

3. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

4. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the engine.

5. Stop engine and cool down to less than approximately 50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

6. Refill reservoir tank to MAX level line with coolant.

7. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

8. Check cooling system for leaks with engine running.

9. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

10. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator and reservoir tank with water and reinstall radiator cap.

KBIA0163E

: 7.8 - 11.8 N·m (0.8 -1.2 kg-m , 69 - 104 in-lb)

Engine coolant capacity (With reservoir tank):

Approx. 7.1 (6-1/4 Imp qt)

SMA182B

Reservoir tank:

0.6 (1/2 lmp qt )

SMA412B

Page 1029 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual WATER PUMP

CO-19

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

WATER P UM PPFP:21020

Removal and InstallationEBS009SJ

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur fr NISSAN X-TRAIL 2003 Electronic Repair Manual WATER PUMP

CO-19

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

WATER P UM PPFP:21020

Removal and InstallationEBS009SJ

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur fr](/img/5/57402/w960_57402-1028.png)

WATER PUMP

CO-19

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

WATER P UM PPFP:21020

Removal and InstallationEBS009SJ

WA RN ING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

Water Pump Removal

1. Drain coolant. Refer toCO-9, "DRAINING ENGINE COOLANT".

CAUTION:

Perform when the engine is cold.

2. Remove the following parts.

lEngine under cover

lAlternator, water pump and air compressor belt

Refer to drive beltEM-13, "

Removal and Installation".

3. Remove water pump.

lCoolant will leak from the cylinder block, so have a receptacle ready below.

CAUTION:

lHandle the water pump vane so that it does not contact any other parts.

lWater pump cannot be disassembled and should be replaced as a unit.

Water Pump Housing Removal

1. Perform step 1 and 2 of “Water Pump Removal”.

2. Remove alternator.

3. Remove oil level gauge.

CAUTION:

Plug the oil level gauge guide opening to prevent oil pan from entering foreign materials.

4. Remove bolts mounting water pipe.

5. Remove water pump housing.

Water Pipe Removal

1. Remove water pump housing.

KBIA0154E

1 Water pump 2 Gasket 3 Water pump housing

4 Water pipe

Page 1033 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-23

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

CapacityEBS009SL

ThermostatEBS009SM

Water Control ValveEBS009SN

RadiatorEB NISSAN X-TRAIL 2003 Electronic Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

CO-23

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

CapacityEBS009SL

ThermostatEBS009SM

Water Control ValveEBS009SN

RadiatorEB](/img/5/57402/w960_57402-1032.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-23

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

CO

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

CapacityEBS009SL

ThermostatEBS009SM

Water Control ValveEBS009SN

RadiatorEBS009SO

Unit:kPa(bar,kg/cm2,psi)

Tightening TorqueEBS009SP

Unit: N·m (kg-m, ft-lb) Nm(kg-m, in-lb)* Coolant capacity [With reservoir tank (MAX level)]

Approximately 7.1 (6-1/4 Imp qt)

Valve opening temperature 80.5 - 83.5°C (177 - 182°F)

Valve liftMore than 8 mm/ 95°C (0.315 in/203°F)

Valve opening temperature 93.5 - 96.5°C (200 - 206°F)

Valve lift More than 8 mm/108°C (0.315 in/226°F)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 -1.0, 11- 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Radiator mounting bracket

Radiator fan assembly

Fan

Fan motor3.8 - 4.5 (0.39 - 0.46, 34 - 39)*

3.8 - 4.5 (0.39 - 0.46, 34 - 39)*

2.9 - 3.9 (0.30 - 0.40, 26 - 34)*

3.9 - 4.9 (0.40 - 0.50, 35 - 43)*

Water pum p

Water pump housing

Water inlet

Water outlet

Water pipet

Hater pip

Water temperature sensor20.8 - 28.2 (2.1 - 2.9, 16- 20)

20.8 - 28.2 (2.1 - 2.9, 16 - 20)

20.8 - 28.2 (2.1 - 2.9, 16- 20)

20.8 - 28.2 (2.1 - 2.9, 16 - 20)

20.8 - 28.2 (2.1 - 2.9, 16 - 20)

20.8 - 28.2 (2.1 - 2.9, 16 - 20)

19.6 - 29.4 (2.0 - 3.0, 14- 22)

Page 1040 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or NISSAN X-TRAIL 2003 Electronic Repair Manual CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or](/img/5/57402/w960_57402-1039.png)

CO-30

[YD22DDTi]

ENGINE COOLANT

ENGINE COOLANT

PFP:KQ100

InspectionEBS00BAY

LEVEL CHECK

lCheck if the reservoir tank coolant level within MIN to MAX when

engine is cool.

lAdjust coolant if too much or too little.

LEAK CHECK

lTo check for leakage, apply pressure to the cooling system with

atester.

WAR NIN G:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

Changing Engine CoolantEBS00BAZ

WAR NIN G:

lTo avoid being scalded, never change the coolant when the engine is hot.

lWrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn

to release built-up pressure. Then turn the cap all the way.

DRAINING ENGINE COOLANT

1. Open radiator drain plug at the bottom of radiator, and remove

radiator cap.

lBe careful not to allow coolant to contact drive belts.

lCover the exhaust tube heat shield to prevent from splashing

coolant.

2. Remove reservoir tank, drain coolant, then clean reservoir tank.

SMA412B

Testing pressure

: 157 kPa (1.57bar 1.6 kg/cm2,23psi)

SLC134B

PBIC0236E

Page 1042 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hol NISSAN X-TRAIL 2003 Electronic Repair Manual CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hol](/img/5/57402/w960_57402-1041.png)

CO-32

[YD22DDTi]

ENGINE COOLANT

3. Fill reservoir tank to specified level.

4. Warm up engine to normal operating temperature without radia-

tor cap installed.

lIf coolant overflows radiator filler hole, install filler cap.

5. Run engine at 3,000 rpm for 10 seconds and return to idle speed

with radiator cap installed.

lRepeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool down to less than approximately

50°C(122°F).

lCool down using a fan to reduce the time.

lIf necessary, refill radiator up to filler neck with coolant.

7. Refill reservoir tank to MAX level line with coolant.

8. Repeat steps 5 through 7 two or more times with radiator cap installed until coolant level no longer drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of coolant flow while running engine from idle up to 3,000 rpm with

heater temperature controller set at several position between COOL and WARM.

lSound may be noticeable at heater unit.

11. If sound is heard, bleed air from cooling system by repeating steps 5 through 7 until coolant level no

longer drops.

lClean excess coolant from engine.

FLUSHING COOLING SYSTEM

1. Fill radiator with water until water spills from the air relief hole, then close air relief flag. Fill radiator and

reservoir tank with water and reinstall radiator cap.

2. Run engine and warm it up to normal operating temperature.

3. Rev engine two or three times under no-load.

4. Stop engine and wait until it cools down.

5. Drain water.

6. Repeat steps 1 through 5 until clear water begins to drain from radiator.

SMA412B

Page 1054 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CO-44

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CU0

CAPACITY

THERMOSTAT

RADIATOR

Unit:kPa(bar,kg/cm2,psi)

Tightening Torqu NISSAN X-TRAIL 2003 Electronic Repair Manual CO-44

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CU0

CAPACITY

THERMOSTAT

RADIATOR

Unit:kPa(bar,kg/cm2,psi)

Tightening Torqu](/img/5/57402/w960_57402-1053.png)

CO-44

[YD22DDTi]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Standard and LimitEBS00CU0

CAPACITY

THERMOSTAT

RADIATOR

Unit:kPa(bar,kg/cm2,psi)

Tightening TorqueEBS00BKE

Unit: N·m (kg-m, ft-lb), N·m (kg-m, in-lb)* Engine coolant capacity [With reservoir tank (MAX level)]

9.5 (8-3/8 Imp qt)

Valve opening temperature 80 - 84°C (176 - 183°F)

Valve liftMore than 10 mm/ 95°C (0.39 in/203°F)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 (0.59, 0.6, 9)

Leakage test pressure 157 (1.57, 1.6, 23)

Radiator mounting bracket

Radiator fan assembly

Radiator fan

Radiator fan motor3.9 - 4.5 (0.39 - 0.46, 34 - 39)*

3.9 - 4.5 (0.39 - 0.46, 34 - 39)*

2.9 - 3.9 (0.30 - 0.40, 26 - 34)*

4.0 - 4.9 (0.40 - 0.50, 35 - 43)*

Water pum p

Water pump pully

Water inlet

Thermostat housing

Water inlet pipe

Hater return pipe23.0 - 30.0 (2.3 - 3.1, 17 - 22)

7.3 - 9.6 (0.74 - 0.98, 65 - 85)*

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

21.0 - 28.0 (2.1 - 2.9, 16 - 20)

Page 1059 of 3066

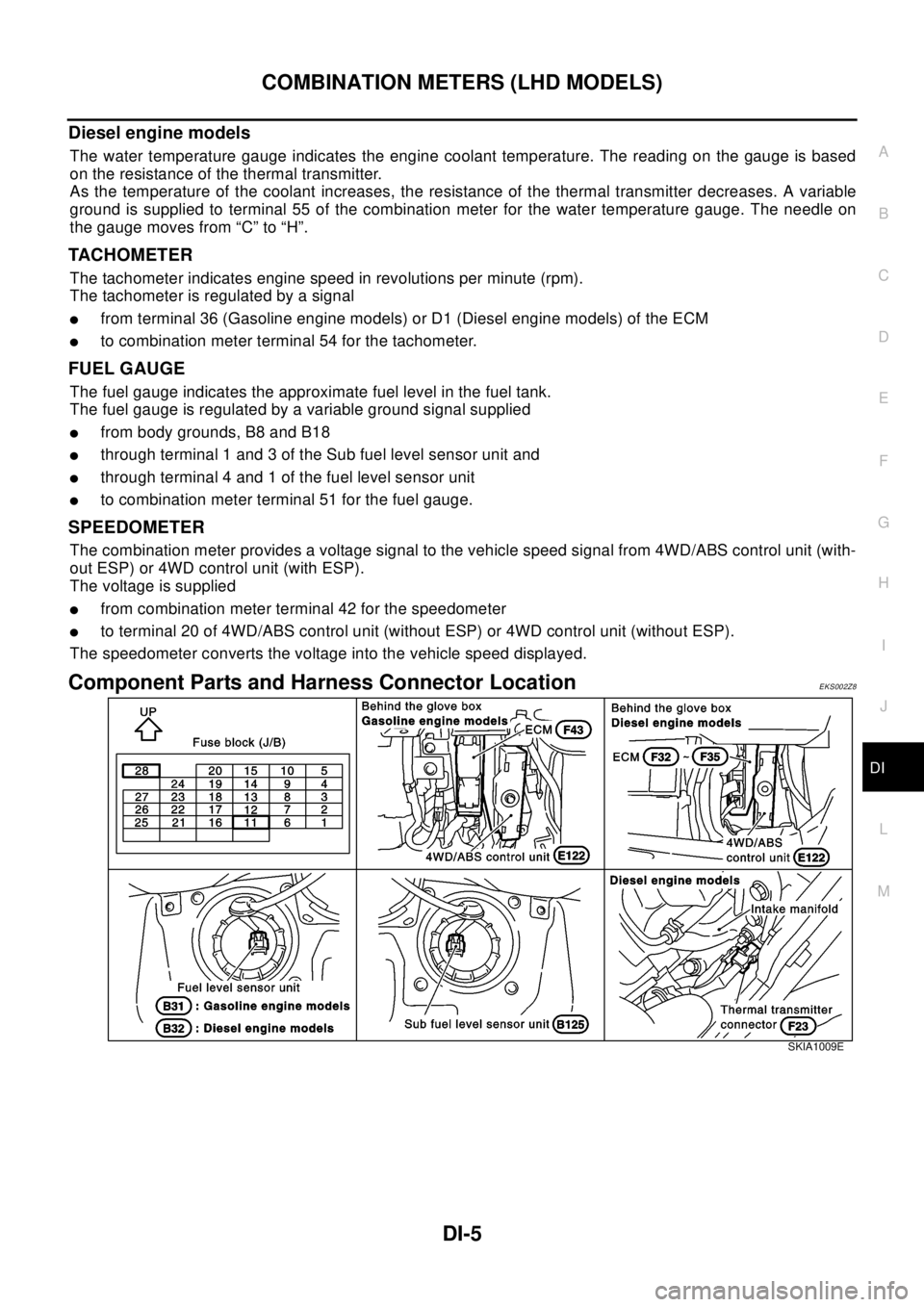

COMBINATION METERS (LHD MODELS)

DI-5

C

D

E

F

G

H

I

J

L

MA

B

DI

Diesel engine models

The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is based

on the resistance of the thermal transmitter.

As the temperature of the coolant increases, the resistance of the thermal transmitter decreases. A variable

ground is supplied to terminal 55 of the combination meter for the water temperature gauge. The needle on

the gauge moves from “C” to “H”.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

The tachometer is regulated by a signal

lfrom terminal 36 (Gasoline engine models) or D1 (Diesel engine models) of the ECM

lto combination meter terminal 54 for the tachometer.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

lfrom body grounds, B8 and B18

lthrough terminal 1 and 3 of the Sub fuel level sensor unit and

lthrough terminal 4 and 1 of the fuel level sensor unit

lto combination meter terminal 51 for the fuel gauge.

SPEEDOMETER

The combination meter provides a voltage signal to the vehicle speed signal from 4WD/ABS control unit (with-

out ESP) or 4WD control unit (with ESP).

The voltage is supplied

lfrom combination meter terminal 42 for the speedometer

lto terminal 20 of 4WD/ABS control unit (without ESP) or 4WD control unit (without ESP).

The speedometer converts the voltage into the vehicle speed displayed.

Component Parts and Harness Connector LocationEKS002Z8

SKIA1009E

Page 1077 of 3066

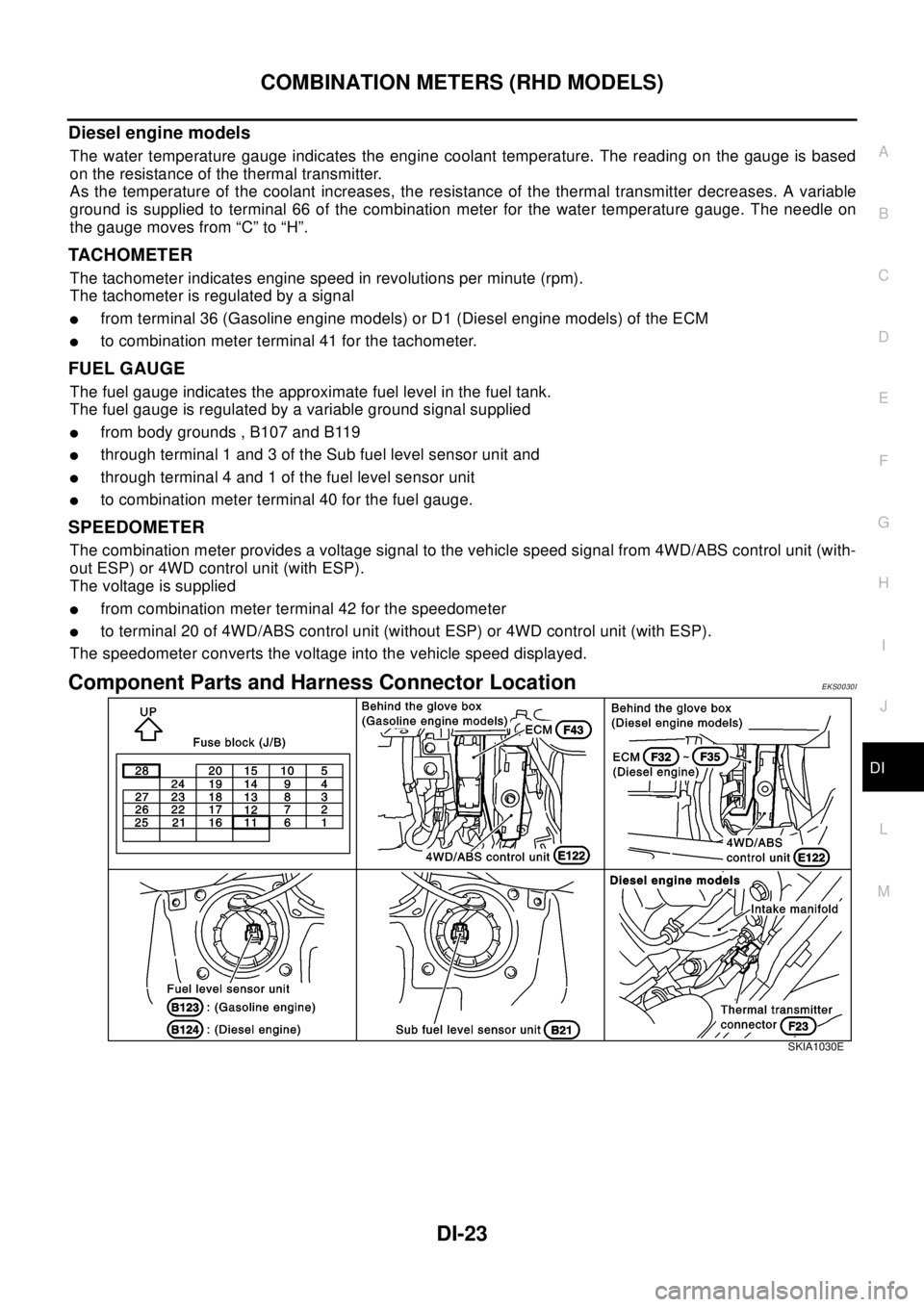

COMBINATION METERS (RHD MODELS)

DI-23

C

D

E

F

G

H

I

J

L

MA

B

DI

Diesel engine models

The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is based

on the resistance of the thermal transmitter.

As the temperature of the coolant increases, the resistance of the thermal transmitter decreases. A variable

ground is supplied to terminal 66 of the combination meter for the water temperature gauge. The needle on

the gauge moves from “C” to “H”.

TACHOMETER

The tachometer indicates engine speed in revolutions per minute (rpm).

The tachometer is regulated by a signal

lfrom terminal 36 (Gasoline engine models) or D1 (Diesel engine models) of the ECM

lto combination meter terminal 41 for the tachometer.

FUEL GAUGE

The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

lfrom body grounds , B107 and B119

lthrough terminal 1 and 3 of the Sub fuel level sensor unit and

lthrough terminal 4 and 1 of the fuel level sensor unit

lto combination meter terminal 40 for the fuel gauge.

SPEEDOMETER

The combination meter provides a voltage signal to the vehicle speed signal from 4WD/ABS control unit (with-

out ESP) or 4WD control unit (with ESP).

The voltage is supplied

lfrom combination meter terminal 42 for the speedometer

lto terminal 20 of 4WD/ABS control unit (without ESP) or 4WD control unit (with ESP).

The speedometer converts the voltage into the vehicle speed displayed.

Component Parts and Harness Connector LocationEKS0030I

SKIA1030E