width NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 52 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-46

[EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : OptionThrottle position THROTTLE

POSI

[/8]—— X

lThrottle position data,

used for computation

by TCM, is NISSAN X-TRAIL 2003 Electronic Repair Manual AT-46

[EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : OptionThrottle position THROTTLE

POSI

[/8]—— X

lThrottle position data,

used for computation

by TCM, is](/img/5/57402/w960_57402-51.png)

AT-46

[EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : OptionThrottle position THROTTLE

POSI

[/8]—— X

lThrottle position data,

used for computation

by TCM, is displayed.lA specific value used

for control is displayed

if fail-safe is activated

due to error.

Stop lamp switch BRAKE SW

[ON/OFF]

X——

lON/OFF status is dis-

played.

ON ... Brake pedal is

depressed.

OFF ... Brake pedal is

released.

Line pressure duty LINE PRES DTY

[%]

—— X

lControl value of line

pressure solenoid

valve, computed by

TCM from each input

signal, is displayed.

Torque converter

clutch solenoid

valve dutyTCC S/V DUTY

[%]

—— X

lControl value of torque

converter clutch sole-

noid valve, computed

by TCM from each

input signal, is dis-

played.

Shift solenoid

valve ASHIFT S/V A

[ON/OFF]

—— X

lControl value of shift

solenoid valve A, com-

puted by TCM from

each input signal, is

displayed.Control value of sole-

noid is displayed even if

solenoid circuit is dis-

connected.

The OFF signal is dis-

played if solenoid circuit

is shorted. Shift solenoid

valve BSHIFT S/V B

[ON/OFF]

—— X

lControl value of shift

solenoid valve B, com-

puted by TCM from

each input signal, is

displayed.

Overrun clutch

solenoid valveOVERRUN/C S/

V

[ON/OFF]

—— X

lControl value of over-

run clutch solenoid

valve computed by

TCM from each input

signal is displayed.

Self-diagnosis dis-

play lamp

(O/D OFF indica-

tor lamp)SELF-D DP LMP

[ON/OFF]

—— X

lControl status of O/D

OFF indicator lamp is

displayed.

Voltage [V] — — — Value measured by voltage probe is displayed.

Frequency [Hz] — — —Value measured by pulse probe is displayed. If mea-

surement is impossible, "#" sign is displayed. "#"

sign is also displayed at the final data value until the

measurement result is obtained.

DUTY-HI — — —

Duty cycle value for measurement probe is dis-

played.

DUTY-LOW — — —

PLS WIDTH-HI — — —

Measured pulse width of measurement probe is dis-

played.

PLS WIDTH-LOW — — —Item DisplayMovertocenterMonitoritems

Description Remarks TCM

Input

signalsCAN

comm

sig-

nalsMain

signalsSelection

from

menu

Page 278 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-272

[EXC.F/EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : Option

HOW TO ERASE SELF-DIAGNOSTIC RESULTS (WITH CONSULT-II)

1. If the ignition switch stays “ON� NISSAN X-TRAIL 2003 Electronic Repair Manual AT-272

[EXC.F/EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : Option

HOW TO ERASE SELF-DIAGNOSTIC RESULTS (WITH CONSULT-II)

1. If the ignition switch stays “ON�](/img/5/57402/w960_57402-277.png)

AT-272

[EXC.F/EURO-OBD]

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

X: Applicable —: Not applicable : Option

HOW TO ERASE SELF-DIAGNOSTIC RESULTS (WITH CONSULT-II)

1. If the ignition switch stays “ON” after repair work, be sure to turn

ignition switch “OFF” once. Wait for at least 3 seconds and then

turn it “ON” again.

2. Turn CONSULT-II “ON”, and touch “A/T”.

Shift solenoid

valve ASHIFT S/V A

[ON/OFF]

—— XlControl value of shift

solenoid valve A, com-

puted by TCM from

each input signal, is

displayed.Control value of sole-

noid is displayed even if

solenoid circuit is dis-

connected.

The OFF signal is dis-

played if solenoid circuit

is shorted. Shift solenoid

valve BSHIFT S/V B

[ON/OFF]

—— X

lControl value of shift

solenoid valve B, com-

puted by TCM from

each input signal, is

displayed.

Overrun clutch

solenoid valveOVERRUN/C S/

V

[ON/OFF]

—— X

lControl value of over-

run clutch solenoid

valve computed by

TCM from each input

signal is displayed.

Self-diagnosis dis-

play lamp

(O/D OFF indica-

tor lamp)SELF-D DP LMP

[ON/OFF]

—— X

lControl status of O/D

OFF indicator lamp is

displayed.

Voltage [V] — — — Value measured by voltage probe is displayed.

Frequency [Hz] — — —Value measured by pulse probe is displayed. If mea-

surement is impossible, "#" sign is displayed. "#"

sign is also displayed at the final data value until the

measurement result is obtained.

DUTY-HI — — —

Duty cycle value for measurement probe is dis-

played.

DUTY-LOW — — —

PLS WIDTH-HI — — —

Measured pulse width of measurement probe is dis-

played.

PLS WIDTH-LOW — — —Item Displaymove to centor Monitor items

Description Remarks

TCM

Input

signalsCAN

comm

sig-

nalsMain

signalsSelection

from

menu

SAT014K

Page 507 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-501

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

1-2 Accumulator Valve

lInstall 1-2 accumulator valve. Align 1-2 accumulator retainer

plate from opposite side of control valve body.

l NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-501

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

1-2 Accumulator Valve

lInstall 1-2 accumulator valve. Align 1-2 accumulator retainer

plate from opposite side of control valve body.

l](/img/5/57402/w960_57402-506.png)

REPAIR FOR COMPONENT PARTS

AT-501

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

1-2 Accumulator Valve

lInstall 1-2 accumulator valve. Align 1-2 accumulator retainer

plate from opposite side of control valve body.

lInstall return spring, 1-2 accumulator piston and plug.

1. Install retainer plates.

lWhile pushing plug or return spring, install retainer plate.

Retainer Plate (Upper Body)

Unit: mm (in)

lInstall proper retainer plates.

Refer toAT- 4 9 8 , "

Control Valve Upper Body".

SAT142D

SAT143D

No. Name of control valve Width A Length B

22 Pilot valve

6.0 (0.236)21.5 (0.846) 30 1st reducing valve

34 3-2 timing valve

17 Torque converter relief valve

9 1-2 accumulator valve

40.5 (1.59)

25 1-2 accumulator piston valve

21 Overrunclutchreducingvalve

24.0 (0.945)

5 Cooler check valve

14 Torque converter clutch control valve 28.0 (1.102)

SAT086F

Page 509 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-503

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

lRemove valves at retainer plate.

For removal procedures, refer to “DISASSEMBLY”,AT-498,

"Control Valve Upper Body".

I NISSAN X-TRAIL 2003 Electronic Repair Manual REPAIR FOR COMPONENT PARTS

AT-503

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

lRemove valves at retainer plate.

For removal procedures, refer to “DISASSEMBLY”,AT-498,

"Control Valve Upper Body".

I](/img/5/57402/w960_57402-508.png)

REPAIR FOR COMPONENT PARTS

AT-503

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

DISASSEMBLY

lRemove valves at retainer plate.

For removal procedures, refer to “DISASSEMBLY”,AT-498,

"Control Valve Upper Body".

INSPECTION

Valve Springs

lCheck each valve spring for damage or deformation. Also mea-

sure free length and outer diameter.

lReplace valve springs if deformed or fatigued.

Control Valves

lCheck sliding surfaces of control valves, sleeves and plugs for damage.

ASSEMBLY

lInstall control valves.

For installation procedures, refer to “ASSEMBLY”,AT-498,

"Control Valve Upper Body".

Retiner Plate (Lower Body)

Unit: mm (in)

lInstall proper retainer plates.

Refer toAT- 5 0 2 , "

Control Valve Lower Body".

SAT550G

Inspection standard :Refer toAT- 5 6 3 , "SERVICE DATA

AND SPECIFICATIONS (SDS)".

SAT138D

SAT550A

No. Name of control valve and plug Width A Length B Type

19 Pressure regulator valve

6.0

(0.236)28.0

(1.102)I 27 Accumulator control valve

30 Shift valve A

23 Overrun clutch control valve

2 Pressure modifier valve

35 Shuttle valve

9 Shift valve B — — II

SAT089F

Page 574 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-568

[ALL]

SERVICE DATA AND SPECIFICATIONS (SDS)

Input Shaft

ECS0 04 MR

SEAL RING CLEARANCE

SEAL RING

*: Always check with the Parts Department for the latest parts information.

Reduction Pinion Gea NISSAN X-TRAIL 2003 Electronic Repair Manual AT-568

[ALL]

SERVICE DATA AND SPECIFICATIONS (SDS)

Input Shaft

ECS0 04 MR

SEAL RING CLEARANCE

SEAL RING

*: Always check with the Parts Department for the latest parts information.

Reduction Pinion Gea](/img/5/57402/w960_57402-573.png)

AT-568

[ALL]

SERVICE DATA AND SPECIFICATIONS (SDS)

Input Shaft

ECS0 04 MR

SEAL RING CLEARANCE

SEAL RING

*: Always check with the Parts Department for the latest parts information.

Reduction Pinion GearECS004MS

TURNING TORQUE

REDUCTION PINION GEAR BEARING ADJUSTING SHIMS

Input shaft seal ring clearance mm

(in)Standard 0.08 - 0.23 (0.0031 - 0.0091)

Allowable limit 0.23 (0.0091)

Outer diameter mm (in) 1n ner diameter mm (in) width mm (in) Part number*

26 (1.024) 22.4 (0.882) 1.97 (0.078) 31525 80X02

Turning torque of reduction pinion gear N-m (kg-cm, in-lb) 0.05 - 0.39 (0.5 - 4.0, 0.43 - 3.47)

NO. Thickness mm (in) Part number NO. Thickness mm (in) Part number*

1 5.00 (0.1969) 31439-81X00 33 5.64 (0.2220) 31439-81X63

2 5.02 (0.1976) 31439-81X01 34 5.66 (0.2228) 31439-81X64

3 5.04 (0.1984) 31439-81X02 35 5.68 (0.2236) 31439-81X65

4 5.06 (0.1992) 31439-81X03 36 5.70 (0.2244) 31439-81X66

5 5.08 (0.2000) 31439-81X04 37 5.72 (0.2252) 31439-81X67

6 5.10 (0.2008) 31439-81X05 38 5.74 (0.2260) 31439-81X68

7 5.12 (0.2016) 31439-81X06 39 5.76 (0.2268) 31439-81X69

8 5.14 (0.2024) 31439-81X07 40 5.78 (0.2276) 31439-81X70

9 5.16 (0.2031) 31439-81X08 41 5.80 (0.2283) 31439-81X71

10 5.18 (0.2039) 31439-81X09 42 5.82 (0.2291) 31439-81X72

11 5.20 (0.2047) 31439-81X10 43 5.84 (0.2299) 31439-81X73

12 5.22 (0.2055) 31439-81X11 44 5.86 (0.2307) 31439-81X74

13 5.24 (0.2063) 31439-81X12 45 4.60 (0.1811) 31439-85X01

14 5.26 (0.2071) 31439-81X13 46 4.62 (0.1819) 31439-85X02

15 5.28 (0.2079) 31439-81X14 47 4.64 (0.1827) 31439-85X03

16 5.30 (0.2087) 31439-81X15 48 4.66 (0.1835) 31439-85X04

17 5.32 (0.2094) 31439-81X16 49 4.68 (0.1843) 31439 85X05

18 5.34 (0.2102) 31439-81X17 50 4.70 (0.1850) 31439 85X06

19 5.36 (0.2110) 31439-81X18 51 4.72 (0.1858) 31439 83X11

20 5.38 (0.2118) 31439-81X19 52 4.74 (0.1866) 31439 83X12

21 5.40 (0.2126) 31439-81X20 53 4.76 (0.1874) 31439 83X13

22 5.42 (0.2134) 31439-81X21 54 4.78 (0.1882) 31439 83X14

23 5.44 (0.2142) 31439-81X22 55 4.80 (0.1890) 31439 83X15

24 5.46 (0.2150) 31439-81X23 56 4.82 (0.1898) 31439 83X16

25 5.48 (0.2157) 31439-81X24 57 4.84 (0.1906) 31439 83X17

26 5.50 (0.2165) 31439-81X46 58 4.86 (0.1913) 31439 83X18

27 5.52 (0.2173) 31439-81X47 59 4.88 (0.1921) 31439 83X19

28 5.54 (0.2181) 31439-81X48 60 4.90 (0.1929) 31439 83X20

29 5.56 (0.2189) 31439-81X49 61 4.92 (0.1937) 31439 83X21

30 5.58 (0.2197) 31439-81X60 62 4.94 (0.1945) 31439 83X22

Page 575 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

AT-569

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

*: Always check with the Parts Department for the latest parts information.

Band ServoECS004MT

RETURN SPRING

Unit: mm (in)

NISSAN X-TRAIL 2003 Electronic Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

AT-569

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

*: Always check with the Parts Department for the latest parts information.

Band ServoECS004MT

RETURN SPRING

Unit: mm (in)](/img/5/57402/w960_57402-574.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-569

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

*: Always check with the Parts Department for the latest parts information.

Band ServoECS004MT

RETURN SPRING

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Output ShaftECS004MU

SEAL RING CLEARANCE

SEAL RING

*: Always check with the Parts Department for the latest parts information.

END PLAY

OUTPUT SHAFT ADJUSTING SHIMS

*: Always check with the Parts Department for the latest parts information.

Bearing RetainerECS004MV

SEAL RING CLEARANCE

To ta l E n d P l a yECS004MW

31 5.60 (0.2205) 31439-81X61 63 4.96 (0.1953) 31439 83X23

32 5.62 (0.2213) 31439-81X62 64 4.98 (0.1961) 31439 83X24 NO. Thickness mm (in) Part number NO. Thickness mm (in) Part number*

Return spring Part number* Free length Outer diameter

2nd servo return spring 31605-31X20 32.5 (1.280) 25.9 (1.020)

OD servo return spring 31605-80X07 31.0 (1.220) 62.6 (2.465)

Output shaft seal ring clearance mm

(in)Standard 0.10 - 0.25 (0.0039 - 0.0098)

Allowable limit 0.25 (0.0098)

Outer diameter mm (in) 1nner diameter mm (in) Width mm (in) Part number*

33.71 (1.327) 30.25 (1.191) 1.95 (0.077) 31525 80X09

Output shaft end play mm (in) 0 - 0.15 (0 - 0.0059)

Thickness mm (in) Part number*

0.80 (0.0315)

0.84 (0.0331)

0.88 (0.0346)

0.92 (0.0362)

0.96 (0.0378)

1.00 (0.0394)

1.04 (0.0409)

1.08 (0.0425)

1.12 (0.0441)

1.16 (0.0457)

1.20 (0.0472)31438-80X60

31438-80X61

31438-80X62

31438-80X63

31438-80X64

31438-80X65

31438-80X66

31438-80X67

31438-80X68

31438-80X69

31438-80X70

Bearing retainer seal ring

clearance mm (in)Standard 0.10 - 0.30 (0.0039 - 0.0118)

Allowable limit 0.30 (0.0118)

Total end play mm (in) 0.25 - 0.55 (0.0098 - 0.0217)

Page 867 of 3066

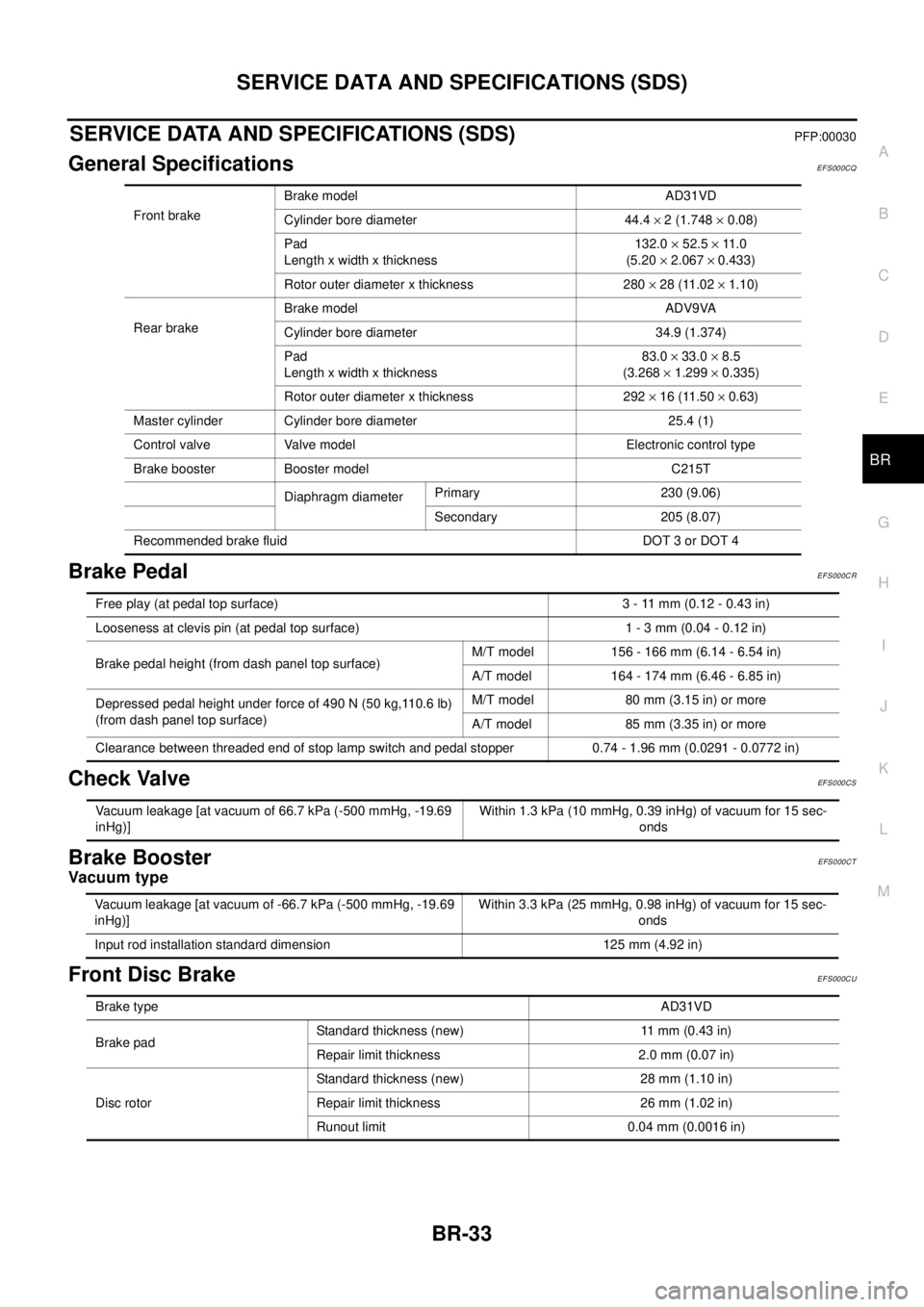

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-33

C

D

E

G

H

I

J

K

L

MA

B

BR

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEFS000CQ

Brake PedalEFS000CR

Check ValveEF S0 00 CS

Brake BoosterEFS000CT

Vacuum type

Front Disc BrakeEFS000CU

Front brakeBrake model AD31VD

Cylinder bore diameter 44.4´2(1.748´0.08)

Pad

Length x width x thickness132.0´52.5´11 . 0

(5.20´2.067´0.433)

Rotor outer diameter x thickness 280´28 (11.02´1.10)

Rear brakeBrake model ADV9VA

Cylinder bore diameter 34.9 (1.374)

Pad

Length x width x thickness83.0´33.0´8.5

(3.268´1.299´0.335)

Rotor outer diameter x thickness 292´16 (11.50´0.63)

Master cylinder Cylinder bore diameter 25.4 (1)

Control valve Valve model Electronic control type

Brake booster Booster model C215T

Diaphragm diameterPrimary 230 (9.06)

Secondary 205 (8.07)

Recommended brake fluid DOT 3 or DOT 4

Free play (at pedal top surface) 3 - 11 mm (0.12 - 0.43 in)

Looseness at clevis pin (at pedal top surface) 1 - 3 mm (0.04 - 0.12 in)

Brake pedal height (from dash panel top surface)M/T model 156 - 166 mm (6.14 - 6.54 in)

A/T model 164 - 174 mm (6.46 - 6.85 in)

Depressed pedal height under force of 490 N (50 kg,110.6 lb)

(from dash panel top surface)M/T model 80 mm (3.15 in) or more

A/T model 85 mm (3.35 in) or more

Clearance between threaded end of stop lamp switch and pedal stopper 0.74 - 1.96 mm (0.0291 - 0.0772 in)

Vacuum leakage [at vacuum of 66.7 kPa (-500 mmHg, -19.69

inHg)]Within 1.3 kPa (10 mmHg, 0.39 inHg) of vacuum for 15 sec-

onds

Vacuum leakage [at vacuum of -66.7 kPa (-500 mmHg, -19.69

inHg)]Within 3.3 kPa (25 mmHg, 0.98 inHg) of vacuum for 15 sec-

onds

Input rod installation standard dimension 125 mm (4.92 in)

Brake typeAD31VD

Brake padStandard thickness (new) 11 mm (0.43 in)

Repair limit thickness 2.0 mm (0.07 in)

Disc rotorStandard thickness (new) 28 mm (1.10 in)

Repair limit thickness 26 mm (1.02 in)

Runout limit 0.04 mm (0.0016 in)

Page 1139 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-25

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length o NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-25

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length o](/img/5/57402/w960_57402-1138.png)

ENGINE CONTROL SYSTEM

EC-25

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

lDuring warm-up

lWhen starting the engine

lDuring acceleration

lHot-engine operation

lWhen selector lever is changed from “N” to “D”

lHigh-load, high-speed operation

lDuring deceleration

lDuring high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses

heated oxygen sensor 1 in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about heated

oxygen sensor 1, refer toEC-160

. This maintains the mixture ratio within the range of stoichiometric (ideal air-

fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of heated oxygen sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

lDeceleration and acceleration

lHigh-load, high-speed operation

lMalfunction of heated oxygen sensor 1 or its circuit

lInsufficient activation of heated oxygen sensor 1 at low engine coolant temperature

lHigh engine coolant temperature

lDuring warm-up

lAfter shifting from “N” to “D”

lWhen starting the engine

PBIB0121E

Page 1140 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-26

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen

sensor 1 NISSAN X-TRAIL 2003 Electronic Repair Manual EC-26

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen

sensor 1](/img/5/57402/w960_57402-1139.png)

EC-26

[QR (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as orig-

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from heated oxygen sensor 1 indicates whether the mixture ratio is RICH or LEAN compared

to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an

increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

SEF337W

Page 1141 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the](/img/5/57402/w960_57402-1140.png)

ENGINE CONTROL SYSTEM

EC-27

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Electronic Ignition (EI) SystemEBS00B0S

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The ignition timing is controlled by the ECM to maintain the best air-

fuel ratio for every running condition of the engine. The ignition tim-

ing data is stored in the ECM. This data forms the map shown.

The ECM receives information such as the injection pulse width and

camshaft position sensor signal. Computing this information, ignition

signals are transmitted to the power transistor.

e.g.,N:1,800rpm,Tp:1.50msec

A°BTDC

During the following conditions, the ignition timing is revised by the

ECM according to the other data stored in the ECM.

lAt starting

lDuring warm-up

lAt idle

lAt low battery voltage

lDuring acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut ControlEBS00B0T

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS)

Engine speed

Piston position

Ignition

timing con-

trolPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Ignition switch Start signal

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery Battery voltage

Wheel sensor Vehicle speed

SEF742M

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch Air conditioner “ON” signal

Air conditioner

cut controlAir conditioner relay Throttle position sensor Throttle valve opening angle

Crankshaft position sensor (POS) Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor Vehicle speed