fuel tank removal NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2003 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAMSHAFT

EM-33

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAMSHAFTPFP:13001

Removal and InstallationEBS009R0

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

lThe fol NISSAN X-TRAIL 2003 Electronic Repair Manual CAMSHAFT

EM-33

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAMSHAFTPFP:13001

Removal and InstallationEBS009R0

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

lThe fol](/img/5/57402/w960_57402-2002.png)

CAMSHAFT

EM-33

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAMSHAFTPFP:13001

Removal and InstallationEBS009R0

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

REMOVAL

lThe following procedure describes removing and installing camshaft without removing front cover. If the

front cover is removed or installed, removal of No.1 camshaft bracket is easier before step 8. Installation is

easier after step 3. Regarding removal and installation of front cover, refer toEM-43, "

TIMING CHAIN".

1. Release fuel pressure. Refer toEC-34, "

FUEL PRESSURE RELEASE",EC-399, "FUEL PRESSURE

RELEASE".

2. Remove parts listed below.

lIgnition Coil; Refer toEM-27, "Removal and Installation".

lRocker cover; Refer toEM-31, "Removal and Installation".

3. Remove power steering reservoir tank.

4. Remove Intake valve timing control cover.

KBIA0244E

1 Camshaft bracket 2 Washer 3 Front cover

4 Chain guide 5 Chain tensioner 6 O-ring

7 Spring 8 Chain tensioner plunger 9Intake valve timing control solenoid

valve

10 Intake valve timing control cover 11 Camshaft sprocket (EXH) 12 Camshaft sprocket (INT)

13 Valve lifter 14 Camshaft (EXH) 15 Camshaft (INT)

16 Camshaft position sensor (PHASE)

Page 2023 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER HEAD

EM-53

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

lIf some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for com NISSAN X-TRAIL 2003 Electronic Repair Manual CYLINDER HEAD

EM-53

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

lIf some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for com](/img/5/57402/w960_57402-2022.png)

CYLINDER HEAD

EM-53

[QR20DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

lIf some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, the valves may be mal-

functioning. Check the valves for damage. Replace the valve or valve seat accordingly.

lIf two adjacent cylinders have respectively low compression pressure and their compression remains low

even after the addition of engine oil, the gaskets are leaking. In such a case, replace the cylinder head

gaskets.

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS009R4

REMOVAL

1. Release fuel pressure. Refer toEC-34, "FUEL PRESSURE RELEASE"(WITH EURO-OBD),EC-399,

"FUEL PRESSURE RELEASE"(WITHOUT EURO-OBD).

2. Drain engine coolant and engine oil.

3. Remove the following components and related parts.

lEngine hood and engine under cover.

lAir cleaner case and air duct assembly; Refer toEM-15, "Removal and Installation".

lIgnition coils; Refer toEM-27, "Removal and Installation".

lRocker cover; Refer toEM-31, "Removal and Installation".

lEngine Coolant reservoir tank

lAuxiliary drive belt; Refer toEM-14, "Removal and Installation of Auxiliary Drive Belt Auto- tensioner".

lAlternator

lAuxiliary drive belt auto -tensioner; Refer toEM-14, "Removal and Installation of Auxiliary Drive Belt Auto-

tensioner".

lExhaust front tube; Refer toEX-2, "EXHAUST SYSTEM".

lExhaust manifold; Refer toEM-22, "Removal and Installation".

lIntake manifold collector, intake manifold and fuel tube assembly; Refer toEM-17, "Removal and Installa-

tion".

lWater control valve and housing; Refer toCO-21, "THERMOSTAT AND WATER CONTROL VALVE".

4. Remove front cover and timing chain. Refer toEM-43, "

Removal and Installation".

KBIA0250E

1 Cylinder head assembly 2 Cylinder head gasket 3 Cylinder head bolt

Page 2032 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-62

[QR20DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer toEC-34, "FUEL PRESSURE RELEASE"(WITH EURO-OBD),EC-399,

"FUEL PRESSURE RELEASE"(WITHOUT EURO-OBD).

2. Remove engine hood.

3. Drain coolan NISSAN X-TRAIL 2003 Electronic Repair Manual EM-62

[QR20DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer toEC-34, "FUEL PRESSURE RELEASE"(WITH EURO-OBD),EC-399,

"FUEL PRESSURE RELEASE"(WITHOUT EURO-OBD).

2. Remove engine hood.

3. Drain coolan](/img/5/57402/w960_57402-2031.png)

EM-62

[QR20DE]

ENGINE ASSEMBLY

1. Release fuel pressure. Refer toEC-34, "FUEL PRESSURE RELEASE"(WITH EURO-OBD),EC-399,

"FUEL PRESSURE RELEASE"(WITHOUT EURO-OBD).

2. Remove engine hood.

3. Drain coolant from radiator drain plug.

4. Remove the following parts.

lLH/RH under cover

lLH/RH Front wheel

lBattery

lAuxiliary drive belt; Refer toEM-14, "Removal and Installation of Auxiliary Drive Belt Auto- tensioner".

lAir duct and air cleaner case assembly; Refer toEM-15, "Removal and Installation".

lAlternator

lRadiator and radiator fan assembly; Refer toCO-12, "RADIATOR".

5. Disconnect engine room harness from the engine side and set it aside for easier work.

6. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Engine room LH

7. Disconnect fuel hose, and plug it to prevent fuel from draining. Refer toEM-17, "

INTAKE MANIFOLD"

8. Disconnect heater hose, and install plug it to prevent engine coolant from draining.

9. Disconnect select cable from transaxle (A/T models).

10. Remove clutch operating cylinder from transaxle, and move it aside (M/T models).

11. Disconnect shift cable from transaxle (M/T models).

Engine room RH

12. Remove engine coolant reservoir tank.

13. Remove air conditioner compressor with piping connected from engine. Temporarily secure it on body

with a rope to avoid putting load on it.

Vehicle underbody

14. Remove exhaust front tube.

15. Remove propeller shaft.

16. Remove steering shaft from steering gear.

17. Disconnect power steering fluid cooler piping at a point between body and engine.

18. Remove ABS sensor from brake caliper.

19. Remove brake caliper with piping connected from steering knuckle. Temporarily secure it on body with a

rope to avoid load on it.

20. Remove LH/RH suspension from steering knuckle under strut.

Removal

21. Install engine slingers into front left of cylinder head and rear right of cylinder head.

lUse alternator bracket mounting bolt holes for the frontside.

22. Lift with hoist and secure the engine in position.Slinger bolts:

Front: 51.0 - 64.7 N·m (5.2 - 6.6 kg-m, 38 - 47 ft-lb)

Rear: 24.5 - 31.4 N·m (2.5 - 3.2 kg-m, 18 - 23 ft-lb)

KBIA0255E

Page 2108 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-138

[YD22DDTi]

FUEL SUPPLY PUMP

FUEL SUPPLY PUMP

PFP:00018

Removal and InstallationEBS00CBL

CAUTION:

lbefore removing and installing fuel supply pump, be sure to remove sprocket. Do not loosen or

r NISSAN X-TRAIL 2003 Electronic Repair Manual EM-138

[YD22DDTi]

FUEL SUPPLY PUMP

FUEL SUPPLY PUMP

PFP:00018

Removal and InstallationEBS00CBL

CAUTION:

lbefore removing and installing fuel supply pump, be sure to remove sprocket. Do not loosen or

r](/img/5/57402/w960_57402-2107.png)

EM-138

[YD22DDTi]

FUEL SUPPLY PUMP

FUEL SUPPLY PUMP

PFP:00018

Removal and InstallationEBS00CBL

CAUTION:

lbefore removing and installing fuel supply pump, be sure to remove sprocket. Do not loosen or

remove installation nut in the center of fuel supply pump. If loosened or removed, replace fuel

supply pump.

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals, or other sliding parts, lubricate contacting

surfaces with new engine oil.

lApply new engine oil to parts marked in illustration before installation.

REMOVAL

1. Remove coolant reservoir tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove RH engine mount insulator and bracket. Refer toEM-184, "

Removal and Installation".

4. Pull power steering reservoir tank out of brackets to move power steering piping.

CAUTION:

To avoid removing power steering reservoir tank out of brackets move it with power steering pip-

ing aside.

1. Washer 2. Fuel supply pump sprocket 3. Fuel supply pump

4. Fuel supply pump rear bracket 5. Fuel connector (Feed side) 6. Fuel connector (Return side)

SBIA0213E

Page 2128 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-158

[YD22DDTi]

SECONDARY TIMING CHAIN

SECONDARY TIMING CHAIN

PFP:13028

Removal and InstallationEBS00BOG

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or val NISSAN X-TRAIL 2003 Electronic Repair Manual EM-158

[YD22DDTi]

SECONDARY TIMING CHAIN

SECONDARY TIMING CHAIN

PFP:13028

Removal and InstallationEBS00BOG

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or val](/img/5/57402/w960_57402-2127.png)

EM-158

[YD22DDTi]

SECONDARY TIMING CHAIN

SECONDARY TIMING CHAIN

PFP:13028

Removal and InstallationEBS00BOG

CAUTION:

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals or other sliding parts, lubricate contacting

surfaces with new engine oil.

lApply new engine oil to parts marked in illustration before installation.

REMOVAL

lFor preparative work for removing/installing secondary timing chain to remove/install electronic fuel supply

pump. Refer toEM-138, "

FUEL SUPPLY PUMP".

lTo prepare for removing/installing secondary timing chain to remove/install camshaft. Refer toEM-149,

"Removal and Installation".

1. Remove coolant reservior tank.

2. Remove RH engine mount insulator and bracket. Rfer toEM-184, "

Removal and Installation".

3. Pull power steering reservoir tank out of brackets to move power steering piping.

CAUTION:

To avoid removing power steering reservoir tank out of brackets move it with power steering pip-

ing aside.

SBIA0188E

Page 2135 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil clean NISSAN X-TRAIL 2003 Electronic Repair Manual PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil clean](/img/5/57402/w960_57402-2134.png)

PRIMARY TIMING CHAIN

EM-165

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

REMOVAL

1. Remove coolant reservior tank.

2. Remove charge air cooler. Refer toEM-114, "

Removal and Installation".

3. Remove oil cleaner and air duct. Refer toEM-112, "

Removal and Installation".

4. Remove rocker cover. Refer toEM-147, "

Removal and Installation".

5. Remove RH engine mount insulator and bracket. Refer toEM-184, "

Removal and Installation".

6. Pull power steering reservoir tank out of brackets to move power steering piping.

CAUTION:

To avoid removing power steering reservoir tank out of brackets move it with power steering pip-

ing aside.

7. Remove oil pan. Refer toEM-125, "

Removal and Installation".

8. Remove oil filter bracket. Refer toLU-22, "

Removal and Installation".

9. Remove injection tube and fuel injector. Refer toEM-135, "

Removal and Installation".

10. Remove secondary timing chain and associated parts. Refer toEM-158, "

Removal and Installation".

11. When removing rear chain case, remove camshaft sprockets. Refer toEM-149, "

Removal and Installa-

tion".

12. Remove crankshaft pulley.

a. Hold crankshaft pulley with the pulley holder (SST).

b. Loosen crankshaft pulley fixing bolt and pull out the bolt approx-

imately 10 mm (0.39 in).

c. Using pulley puller (SST), remove crankshaft pulley.

lUse two M6 bolts with approx. 60 mm (2.36 in) shank length

for securing crankshaft pulley.

7. Chain guide 8. Spacer 9. Front chain case

10. Crankshaft pully 11. Front oil seal 12. Oil pump

13. Primary timing chain 14. Oil pump drive sprocket 15. Crankshaft sprocket

16. Secondary timing chain 17. Rear chain case 18. Power steering pump

JEM131G

JEM132G

Page 2155 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE ASSEMBLY

EM-185

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

1. Remove engine hood.

2. Drain coolant from radiator drain plug.

3. Remove the following parts.

lLH/RH under cover

lLH/RH front wheel

lBatt NISSAN X-TRAIL 2003 Electronic Repair Manual ENGINE ASSEMBLY

EM-185

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

1. Remove engine hood.

2. Drain coolant from radiator drain plug.

3. Remove the following parts.

lLH/RH under cover

lLH/RH front wheel

lBatt](/img/5/57402/w960_57402-2154.png)

ENGINE ASSEMBLY

EM-185

[YD22DDTi]

C

D

E

F

G

H

I

J

K

L

MA

EM

1. Remove engine hood.

2. Drain coolant from radiator drain plug.

3. Remove the following parts.

lLH/RH under cover

lLH/RH front wheel

lBattery

lAuxiliary drive belt; Refer toE M - 111 , "Removal and Installation".

lAir duct and air cleaner case assembly; Refer toEM-112, "Removal and Installation".

lAlternator

lRadiator and radiator fan assembly; Refer toCO-33, "Removal and Installation".

lCharge air cooler

4. Disconnect engine room harness from the engine side and set it aside for easier work.

5. Disconnect all the body-side vacuum hoses and air hoses at engine side.

Engine room LH

6. Disconnect fuel feed and return hoses, and plug it to prevent fuel from draining.

7. Disconnect heater hose, and install plug it to prevent engine coolant from draining.

8. Remove clutch operating cylinder from transaxle, and move it aside.

9. Disconnect shift cable from transaxle.

Engine room RH

10. Remove engine coolant reservoir tank.

11. Remove air conditioner compressor with piping connected from engine. Temporarily secure it on body

with a rope to avoid putting load on it.

Vehicle underbody

12. Remove exhaust front tube.

13. Remove propeller shaft.

14. Remove steering shaft from steering gear.

15. Disconnect power steering fluid cooler piping at a point between body and engine.

16. Remove ABS sensor from brake caliper.

17. Remove brake caliper with piping connected from steering knuckle. Temporarily secure it on body with a

rope to avoid load on it.

18. Remove LH/RH suspension from steering knuckle under strut.

Removal

19. Install engine slingers into front right of cylinder head and rear

left of cylinder head.

20. Liftwithhoistandsecuretheengineinposition.Slinger bolts:

: 30 - 37 N·m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

SBIA0191E

Page 2216 of 3066

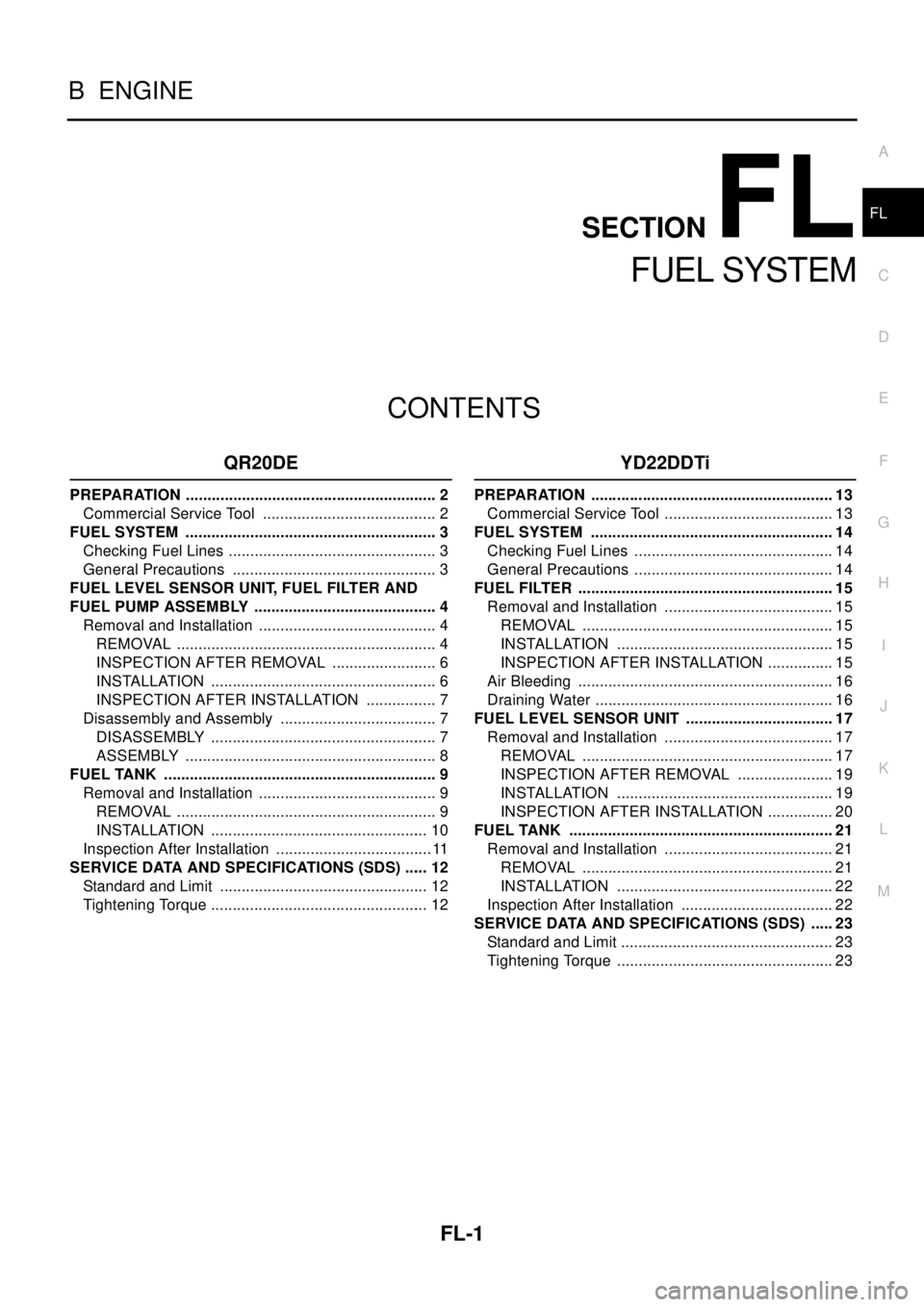

FL-1

FUEL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

FL

FUEL SYSTEM

QR20DE

PREPARATION ........................................................... 2

Commercial Service Tool ......................................... 2

FUEL SYSTEM ........................................................... 3

Checking Fuel Lines ................................................. 3

General Precautions ................................................ 3

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND

FUEL PUMP ASSEMBLY ........................................... 4

Removal and Installation .......................................... 4

REMOVAL ............................................................. 4

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 6

INSPECTION AFTER INSTALLATION ................. 7

Disassembly and Assembly ..................................... 7

DISASSEMBLY ..................................................... 7

ASSEMBLY ........................................................... 8

FUEL TANK ................................................................ 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSTALLATION ................................................... 10

Inspection After Installation .....................................11

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 12

Standard and Limit ................................................. 12

Tightening Torque ................................................... 12

YD22DDTi

PREPARATION ......................................................... 13

Commercial Service Tool ........................................ 13

FUEL SYSTEM ......................................................... 14

Checking Fuel Lines ............................................... 14

General Precautions ............................................... 14

FUEL FILTER ............................................................ 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ................ 15

Air Bleeding ............................................................ 16

Draining Water ........................................................ 16

FUEL LEVEL SENSOR UNIT ................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................... 17

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 20

FUEL TANK .............................................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSTALLATION ................................................... 22

Inspection After Installation .................................... 22

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 23

Standard and Limit .................................................. 23

Tightening Torque ................................................... 23

Page 2219 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sur NISSAN X-TRAIL 2003 Electronic Repair Manual FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sur](/img/5/57402/w960_57402-2218.png)

FL-4

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

PFP:17042

Removal and InstallationEBS00BKR

REMOVAL

WAR NIN G:

Be sure to read “General Precautions” when working on fuel system. Refer toFL-3, "

General Precau-

tions"

1. Release fuel pressure from fuel line.

Refer toEC-34, "

FUEL PRESSURE RELEASE"(WITH EURO-

OBD),EC-399, "

FUEL PRESSURE RELEASE"(WITHOUT

EURO-OBD).

2. Open fuel filer lid.

3. Open the filler cap and release the pressure inside the fuel tank.

4. Check fuel level on level place. If gauge indicates more than the

level shown in figure (full or almost full), drain fuel from fuel tank

until gauge indicates level shown in figure or below.

In case of fuel pump does not operate, take following procedure.

a. Insert fuel tube of less than 25 mm (0.98 in) in diameter into fuel

filler tube through fuel filler opening to draw fuel from fuel filler

tube.

b. Disconnect fuel filler hose from fuel filler tube.

c. Insert fuel tube into fuel tank through fuel filler hose to draw fuel

from fuel tank.

lAs a guide, fuel level becomes the position shown in figure or

below when approximately 15 liter (13-1/4 lmp qt) of fuel are drained from fuel position.

KBIA0278E

1Lockring 2Main fuel level sensor unit, fuel filter

and fuel pump assembly3Jet pump, fuel hose and jet pump inlet

assembly

4 Chamber 5 Seal packing 6 Sub fuel level sensor unit

KBIA0280E

FEL0403D

Page 2221 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a NISSAN X-TRAIL 2003 Electronic Repair Manual FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, a](/img/5/57402/w960_57402-2220.png)

FL-6

[QR20DE]

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

7. Using a lock ring wrench, remove the lock ring.

8. Remove main fuel level sensor unit, fuel filter and fuel pump

assembly, and sub fuel level sensor unit.

CAUTION:

lDo not bend the float arm during removal.

lAvoid impacts such as falling when handling compo-

nents.

lRemoval of main fuel level sensor unit, fuel filter, fuel pump

assembly.

lRaise the sender unit, and remove the jet pump to remove the

sender unit.

lLeave the jet pump on the fuel tank with the fuel hose.

lIf necessary, remove the chamber from the bottom of the fuel tank.

lRemove the chamber by sliding toward the rear of the vehicle.

Removal of sub fuel level sensor unit.

lRaise and release the sub fuel level sensor unit to remove.

lIf necessary, remove the jet pump inlet from the bottom of the fuel tank.

To remove it, pinch the tabs (2 places).

INSPECTION AFTER REMOVAL

Make sure the fuel pump strainer is free from foreign materials, If any are found, remove them.

INSTALLATION

Install in the reverse order of removal paying attention to the follow-

ing.

lWhen installing the chamber and jet pump, insert them fully until

a click sound of full stopper engagement is heard (Ditto for jet

pump inlet).

lConnect the quick connector as follows.

1. Check the connection for damage and foreign materials.

2. Align the connector with the tube, then insert the connector straight into the tube until a click is heard.

3. After connecting, make sure that the connection is secure by following the steps below.

lVisually confirm that the two retainer tabs are connected to the connector.

lPull the tube and the connector to make sure they are securely connected.

PBIC0240E

KBIA0281E

KBIA0302E