wheel torque NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 38 of 3066

AT-32

OVERALL SYSTEM

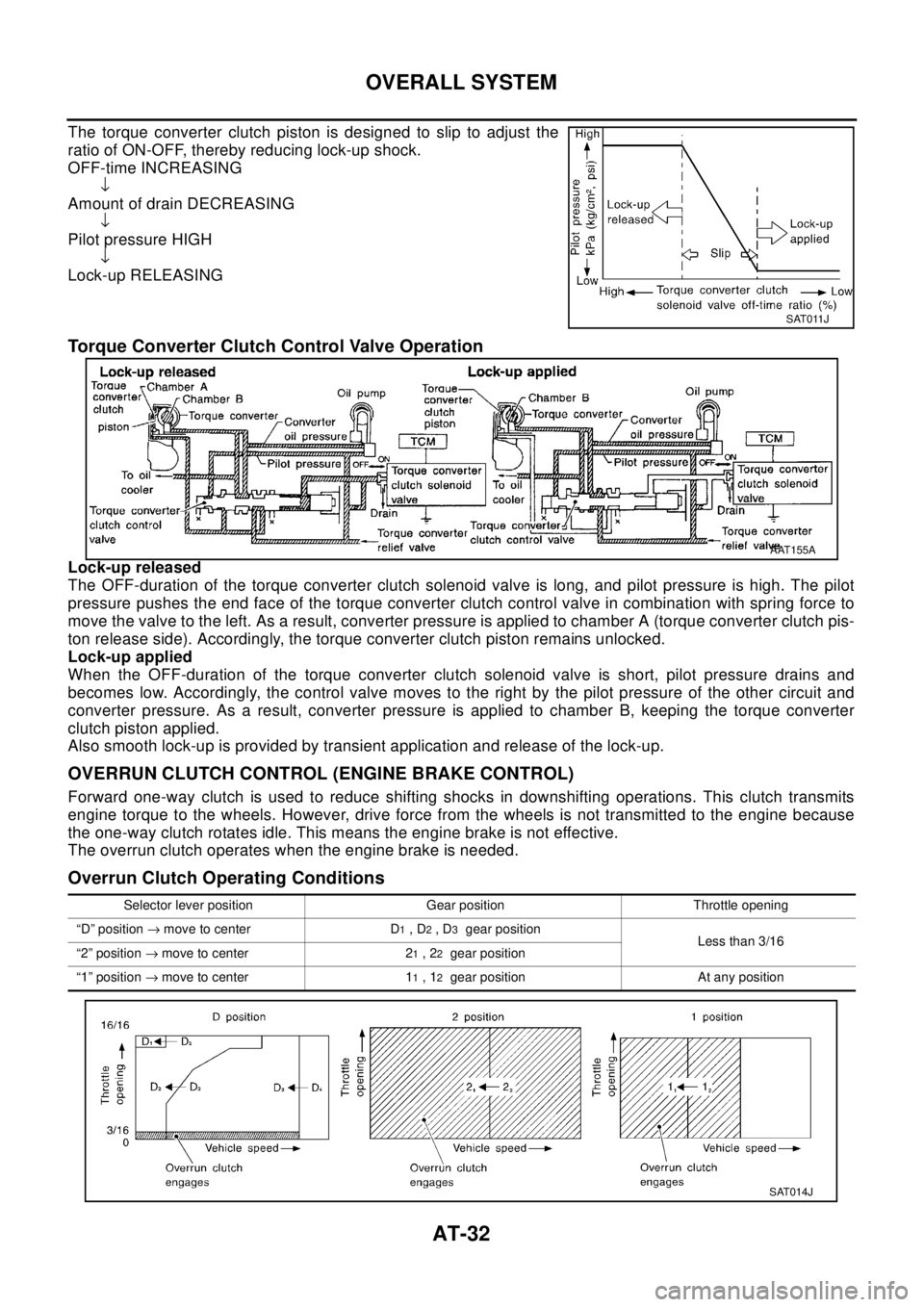

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

OFF-time INCREASING

ÂŻ

Amount of drain DECREASING

ÂŻ

Pilot pressure HIGH

ÂŻ

Lock-up RELEASING

Torque Converter Clutch Control Valve Operation

Lock-up released

The OFF-duration of the torque converter clutch solenoid valve is long, and pilot pressure is high. The pilot

pressure pushes the end face of the torque converter clutch control valve in combination with spring force to

move the valve to the left. As a result, converter pressure is applied to chamber A (torque converter clutch pis-

ton release side). Accordingly, the torque converter clutch piston remains unlocked.

Lock-up applied

When the OFF-duration of the torque converter clutch solenoid valve is short, pilot pressure drains and

becomes low. Accordingly, the control valve moves to the right by the pilot pressure of the other circuit and

converter pressure. As a result, converter pressure is applied to chamber B, keeping the torque converter

clutch piston applied.

Also smooth lock-up is provided by transient application and release of the lock-up.

OVERRUN CLUTCH CONTROL (ENGINE BRAKE CONTROL)

Forward one-way clutch is used to reduce shifting shocks in downshifting operations. This clutch transmits

engine torque to the wheels. However, drive force from the wheels is not transmitted to the engine because

the one-way clutch rotates idle. This means the engine brake is not effective.

The overrun clutch operates when the engine brake is needed.

Overrun Clutch Operating Conditions

SAT011J

AAT155A

Selector lever position Gear position Throttle opening

“D” position®move to center D

1,D2,D3gear position

Less than 3/16

“2” position®move to center 2

1,22gear position

“1” position®move to center 1

1,12gear position At any position

SAT014J

Page 465 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t NISSAN X-TRAIL 2003 Electronic Repair Manual REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

t](/img/5/57402/w960_57402-464.png)

REMOVAL AND INSTALLATION

AT-459

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

12. Remove center member, engine insulator and engine mounting

bracket.

lTighten center member fixing bolts to specified torque, Refer

toEM-61, "

ENGINE ASSEMBLY".

13. Remove suspension member. Refer toFSU-12, "

FRONT SUS-

PENSION MEMBER".

14. Remove dust cover from converter housing.

Rotate crankshaft to gain access to securing bolts.

15. Remove securing bolts between drive plate and torque con-

verter. when crank shaft rotates, turn to right at the front side of

engine.

16. Support engine with a jack.

17. Remove bolts fixing transaxle to engine.

18. Lower transaxle while supporting it with a jack.

InstallationECS004ND

1. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring

gear teeth.

lIf this runout is out of allowance, replace drive plate with ring

gear.

2. When connecting torque converter to transaxle, measure dis-

tance “A” to be certain that they are correctly assembled.

SCIA0794E

AAT259A

Maximum allowable runout :

Refer to EM-´´, “FLYWHEEL/DRIVE PLATE RUNOUT”.

SAT977H

Distance “A”: 19 mm (0.626 in) or more

SAT573D

Page 845 of 3066

BRAKE PIPING AND HOSE

BR-11

C

D

E

G

H

I

J

K

L

MA

B

BR

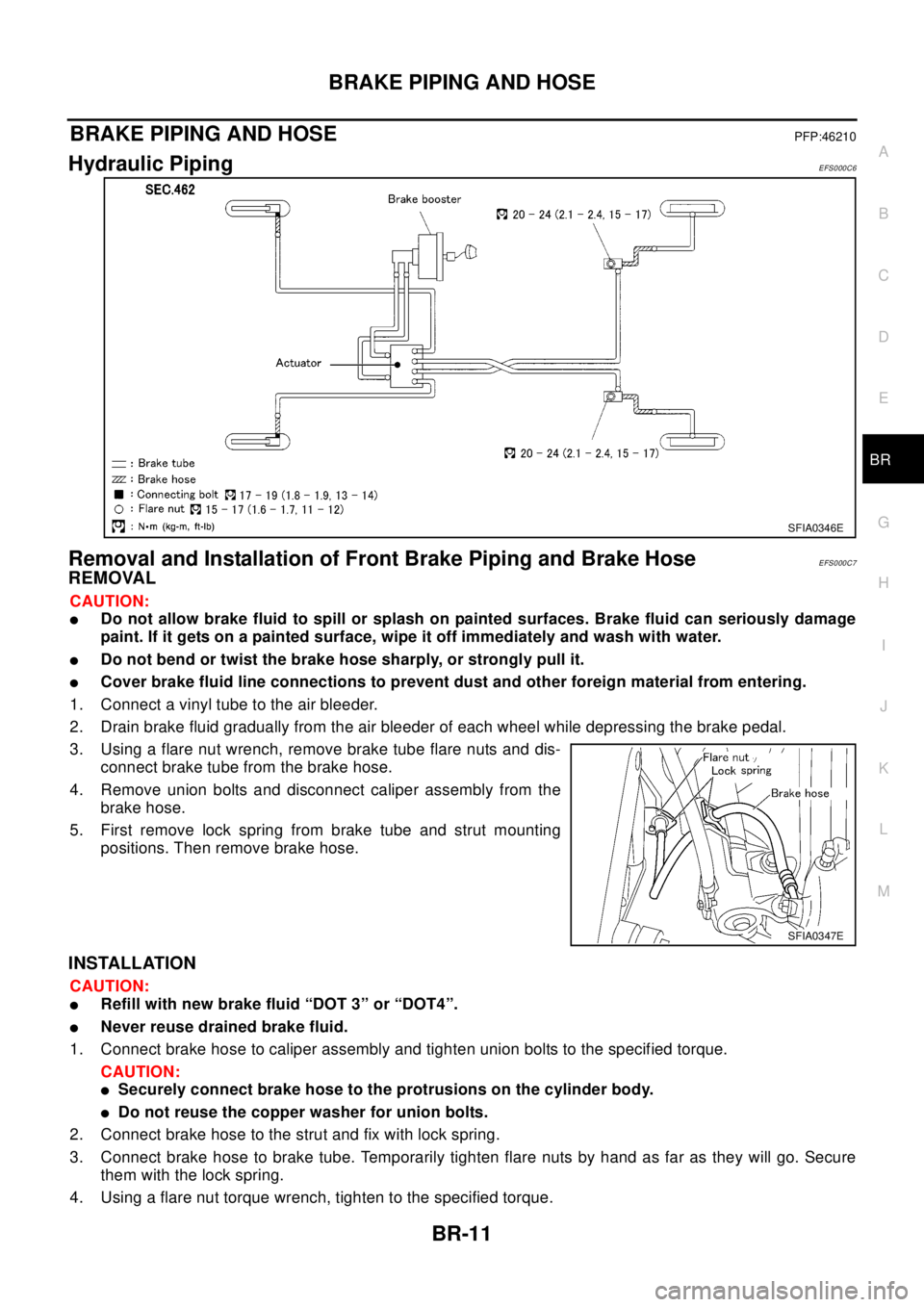

BRAKE PIPING AND HOSEPFP:46210

Hydraulic PipingEFS000C6

Removal and Installation of Front Brake Piping and Brake HoseEFS000C7

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove union bolts and disconnect caliper assembly from the

brake hose.

5. First remove lock spring from brake tube and strut mounting

positions. Then remove brake hose.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT4”.

lNever reuse drained brake fluid.

1. Connect brake hose to caliper assembly and tighten union bolts to the specified torque.

CAUTION:

lSecurely connect brake hose to the protrusions on the cylinder body.

lDo not reuse the copper washer for union bolts.

2. Connect brake hose to the strut and fix with lock spring.

3. Connect brake hose to brake tube. Temporarily tighten flare nuts by hand as far as they will go. Secure

them with the lock spring.

4. Using a flare nut torque wrench, tighten to the specified torque.

SFIA0346E

SFIA0347E

Page 846 of 3066

BR-12

BRAKE PIPING AND HOSE

5. Refill brake fluid until new brake fluid comes out of each air bleeder.

6. Afterwards, bleed air.

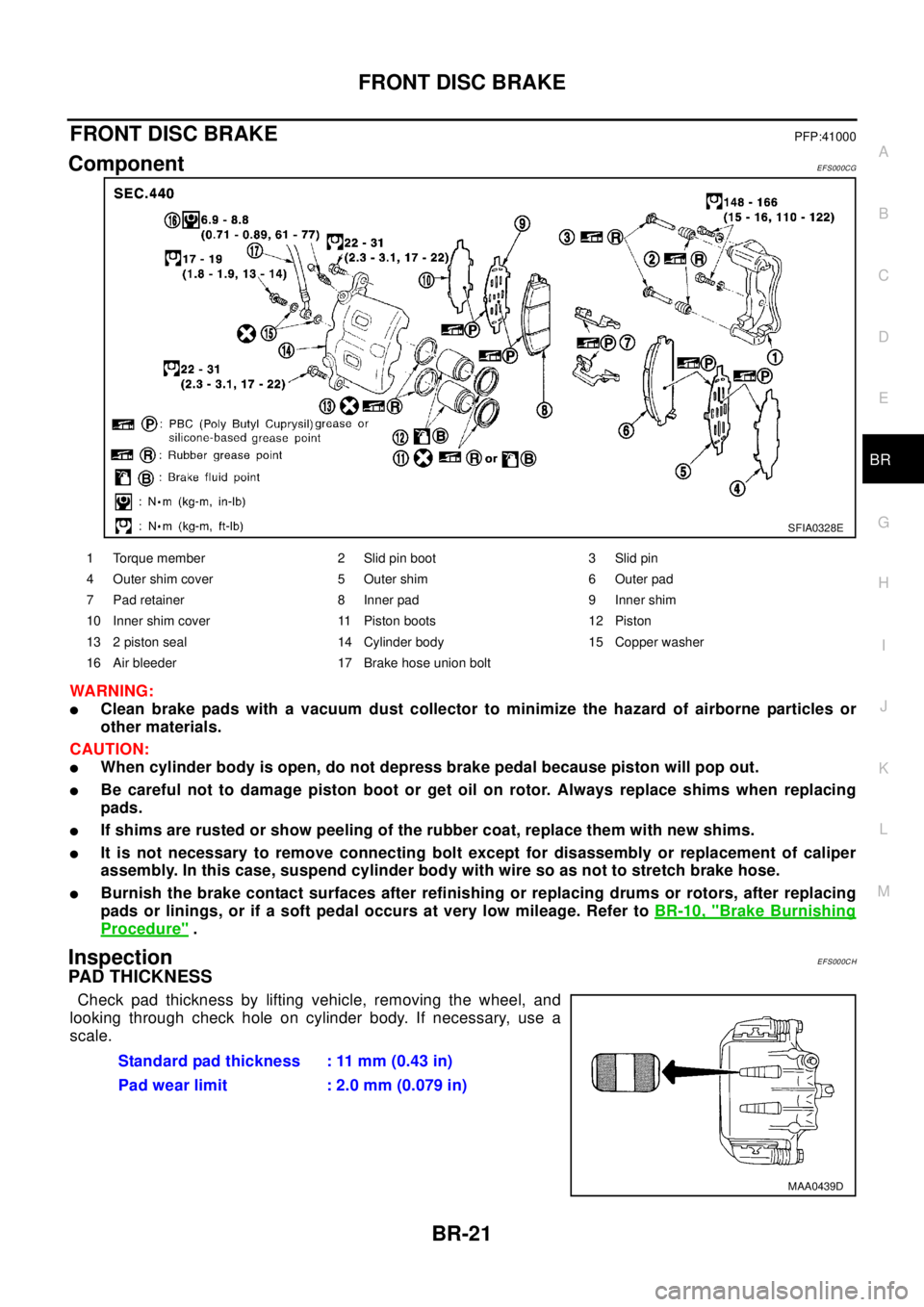

Removal and Installation of Rear Brake Piping and Brake HoseEFS000C8

REMOVAL

CAUTION:

lDo not allow brake fluid to spill or splash on painted surfaces. Brake fluid can seriously damage

paint. If it gets on a painted surface, wipe it off immediately and wash with water.

lDo not bend or twist the brake hose sharply, or strongly pull it.

lCover brake fluid line connections to prevent dust and other foreign material from entering.

1. Connect a vinyl tube to the air bleeder.

2. Drain brake fluid gradually from the air bleeder of each wheel while depressing the brake pedal.

3. Using a flare nut wrench, remove brake tube flare nuts and dis-

connect brake tube from the brake hose.

4. Remove lock spring and union bolts.

INSTALLATION

CAUTION:

lRefill with new brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

1. Connect brake hose to the brake tube. Temporarily tighten flare nut by hand as far as it will go.

2. Secure brake hose with lock spring and connect wheel-side hose to the caliper assembly.

3. Tighten union bolts to the specified torque. Then, tighten flare nut to the specified torque with a flare nut

torque wrench.

4. Refill brake fluid until new brake fluid comes out of each air

bleeder.

5. Afterwards, bleed air.

InspectionEFS000C9

CAUTION:

If any connection leaks, retighten it. Replace any damaged parts.

1. Check hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other parts,

and loose connections.

2. Run the engine. Depress brake pedal and hold it for approximately 5 seconds while checking each part

for leaks.:15-17N·m(1.5-1.8kg·m,11-13ft·lb)

SFIA0046E

: 15 - 17 N·m (1.5 - 1.8 kg·m,11-13 ft·lb)

SBR686C

Page 855 of 3066

FRONT DISC BRAKE

BR-21

C

D

E

G

H

I

J

K

L

MA

B

BR

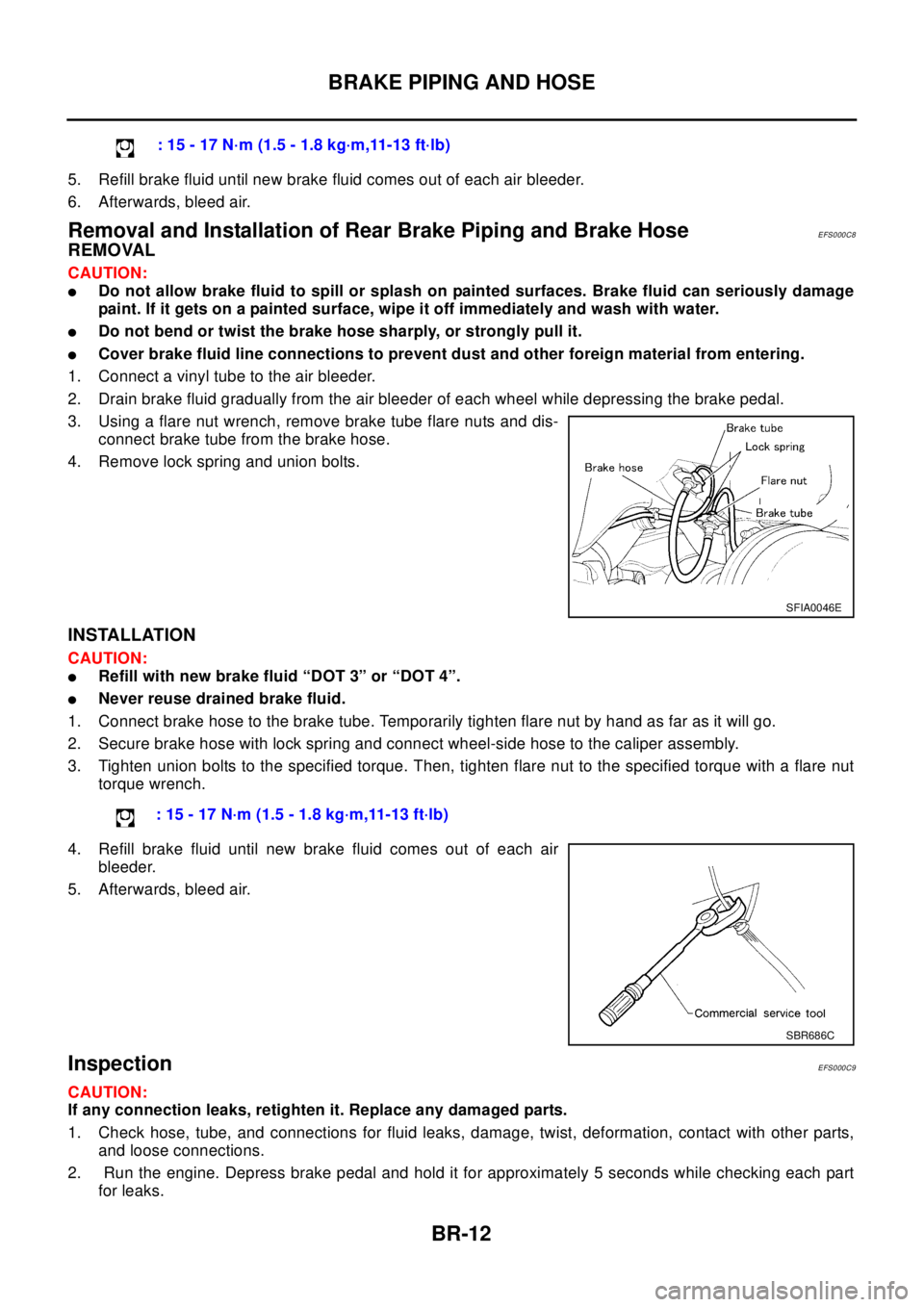

FRONT DISC BRAKEPFP:41000

ComponentEFS000CG

WA RN ING:

lClean brake pads with a vacuum dust collector to minimize the hazard of airborne particles or

other materials.

CAUTION:

lWhen cylinder body is open, do not depress brake pedal because piston will pop out.

lBe careful not to damage piston boot or get oil on rotor. Always replace shims when replacing

pads.

lIf shims are rusted or show peeling of the rubber coat, replace them with new shims.

lIt is not necessary to remove connecting bolt except for disassembly or replacement of caliper

assembly. In this case, suspend cylinder body with wire so as not to stretch brake hose.

lBurnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing

pads or linings, or if a soft pedal occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

InspectionEFS000CH

PAD THICKNESS

Check pad thickness by lifting vehicle, removing the wheel, and

looking through check hole on cylinder body. If necessary, use a

scale.

SFIA0328E

1 Torque member 2 Slid pin boot 3 Slid pin

4 Outer shim cover 5 Outer shim 6 Outer pad

7 Pad retainer 8 Inner pad 9 Inner shim

10 Inner shim cover 11 Piston boots 12 Piston

13 2 piston seal 14 Cylinder body 15 Copper washer

16 Air bleeder 17 Brake hose union bolt

Standard pad thickness : 11 mm (0.43 in)

Pad wear limit : 2.0 mm (0.079 in)

MAA0439D

Page 858 of 3066

BR-24

FRONT DISC BRAKE

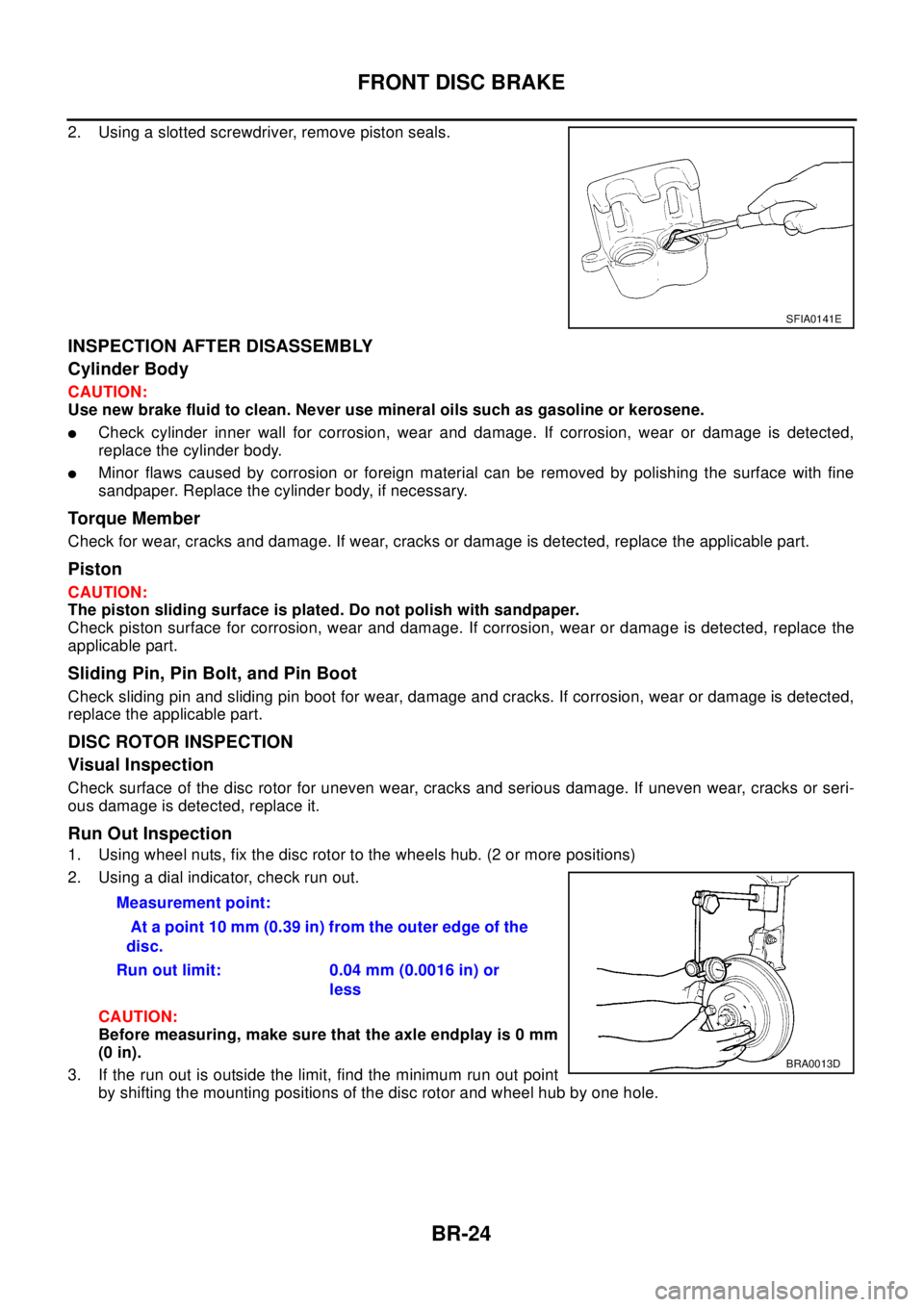

2. Using a slotted screwdriver, remove piston seals.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

lCheck cylinder inner wall for corrosion, wear and damage. If corrosion, wear or damage is detected,

replace the cylinder body.

lMinor flaws caused by corrosion or foreign material can be removed by polishing the surface with fine

sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks and damage. If wear, cracks or damage is detected, replace the applicable part.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear and damage. If corrosion, wear or damage is detected, replace the

applicable part.

Sliding Pin, Pin Bolt, and Pin Boot

Check sliding pin and sliding pin boot for wear, damage and cracks. If corrosion, wear or damage is detected,

replace the applicable part.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks and serious damage. If uneven wear, cracks or seri-

ous damage is detected, replace it.

Run Out Inspection

1. Using wheel nuts, fix the disc rotor to the wheels hub. (2 or more positions)

2. Using a dial indicator, check run out.

CAUTION:

Before measuring, make sure that the axle endplay is 0 mm

(0 in).

3. If the run out is outside the limit, find the minimum run out point

by shifting the mounting positions of the disc rotor and wheel hub by one hole.

SFIA0141E

Measurement point:

At a point 10 mm (0.39 in) from the outer edge of the

disc.

Run out limit: 0.04 mm (0.0016 in) or

less

BRA0013D

Page 861 of 3066

REAR DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

MA

B

BR

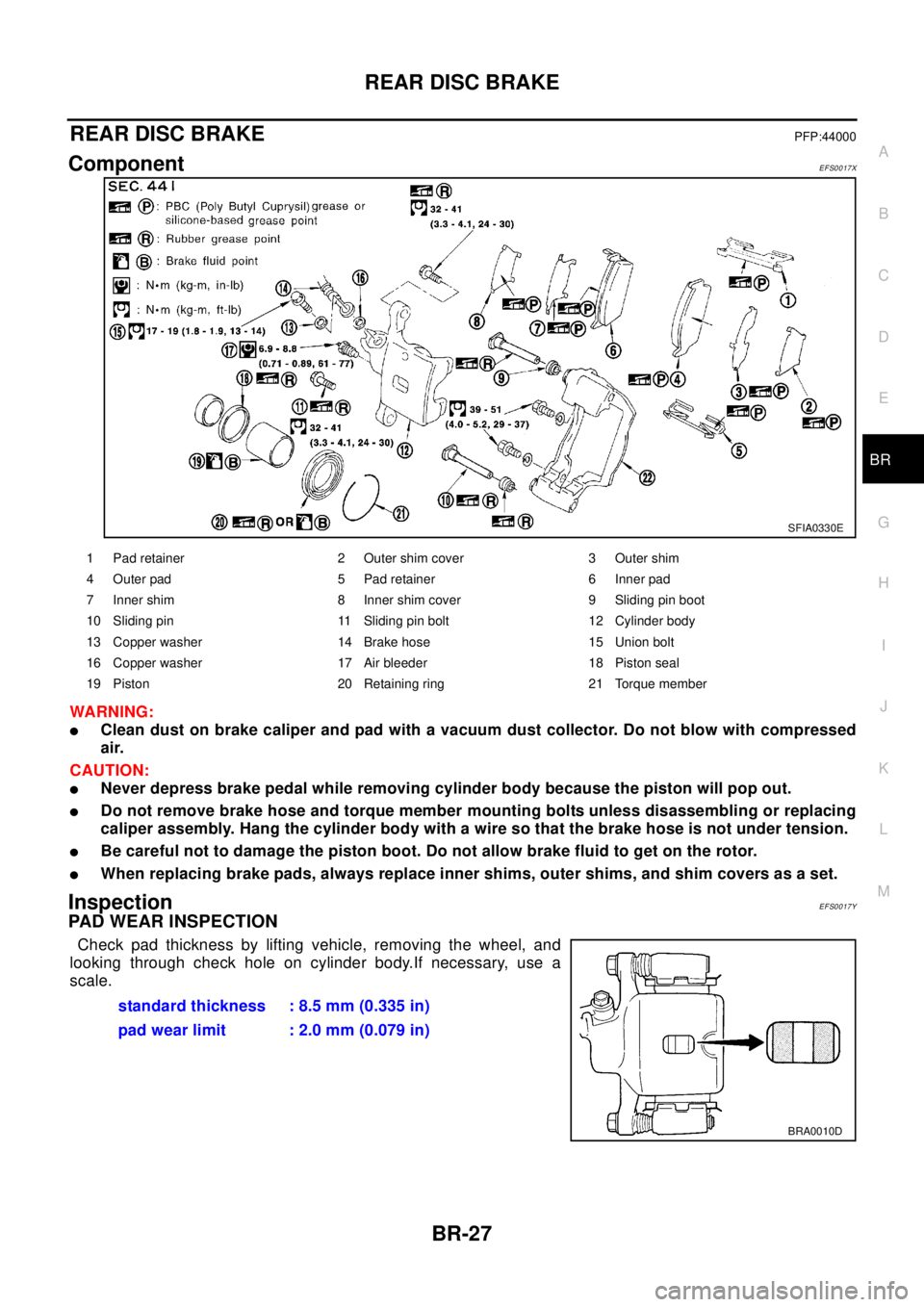

REAR DISC BRAKEPFP:44000

ComponentEFS0017X

WA RN ING:

lClean dust on brake caliper and pad with a vacuum dust collector. Do not blow with compressed

air.

CAUTION:

lNever depress brake pedal while removing cylinder body because the piston will pop out.

lDo not remove brake hose and torque member mounting bolts unless disassembling or replacing

caliper assembly. Hang the cylinder body with a wire so that the brake hose is not under tension.

lBe careful not to damage the piston boot. Do not allow brake fluid to get on the rotor.

lWhen replacing brake pads, always replace inner shims, outer shims, and shim covers as a set.

InspectionEFS0017Y

PAD WEAR INSPECTION

Check pad thickness by lifting vehicle, removing the wheel, and

looking through check hole on cylinder body.If necessary, use a

scale.

SFIA0330E

1 Pad retainer 2 Outer shim cover 3 Outer shim

4 Outer pad 5 Pad retainer 6 Inner pad

7 Inner shim 8 Inner shim cover 9 Sliding pin boot

10 Sliding pin 11 Sliding pin bolt 12 Cylinder body

13 Copper washer 14 Brake hose 15 Union bolt

16 Copper washer 17 Air bleeder 18 Piston seal

19 Piston 20 Retaining ring 21 Torque member

standard thickness : 8.5 mm (0.335 in)

pad wear limit : 2.0 mm (0.079 in)

BRA0010D

Page 864 of 3066

BR-30

REAR DISC BRAKE

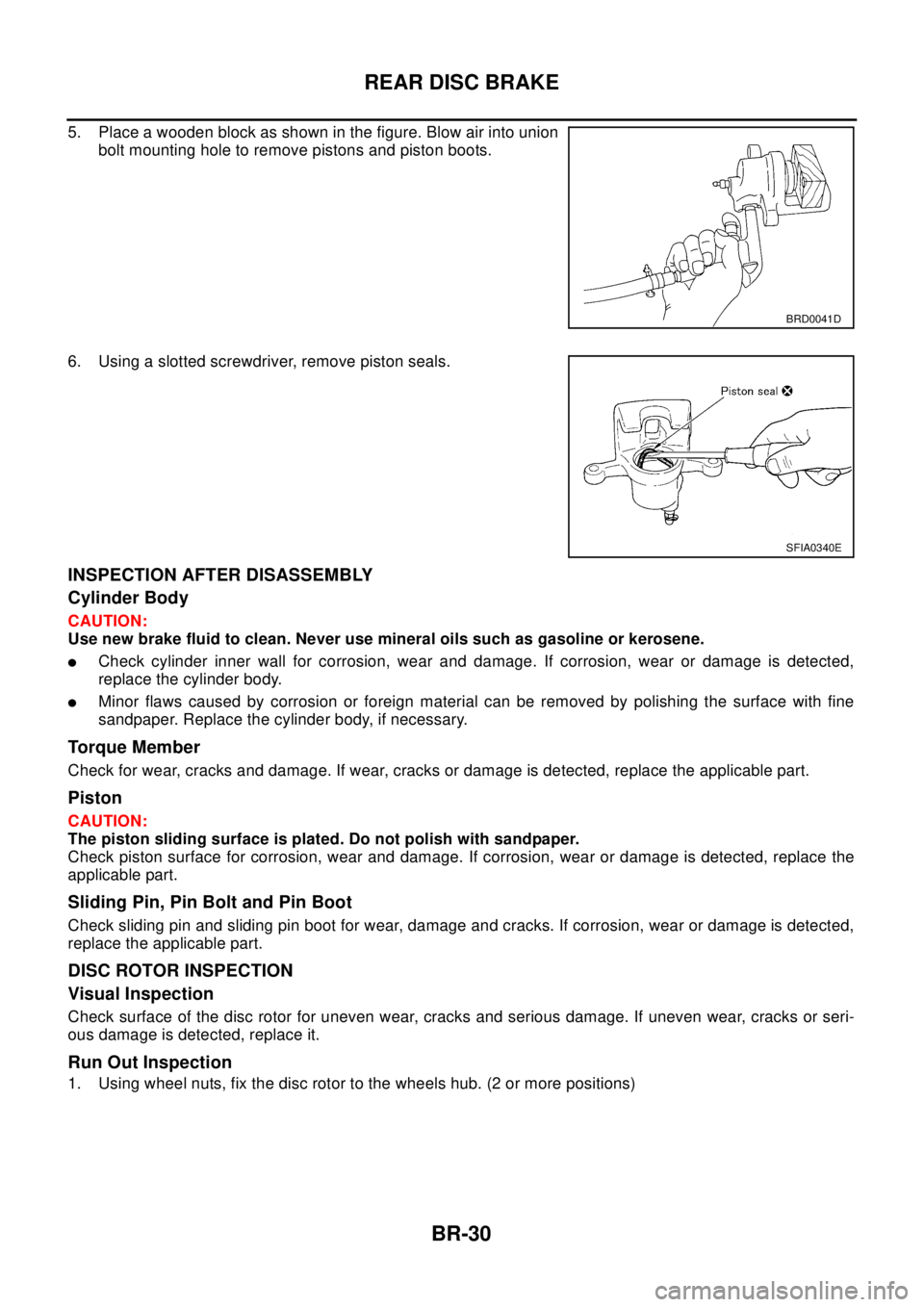

5. Place a wooden block as shown in the figure. Blow air into union

bolt mounting hole to remove pistons and piston boots.

6. Using a slotted screwdriver, remove piston seals.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

lCheck cylinder inner wall for corrosion, wear and damage. If corrosion, wear or damage is detected,

replace the cylinder body.

lMinor flaws caused by corrosion or foreign material can be removed by polishing the surface with fine

sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks and damage. If wear, cracks or damage is detected, replace the applicable part.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear and damage. If corrosion, wear or damage is detected, replace the

applicable part.

Sliding Pin, Pin Bolt and Pin Boot

Check sliding pin and sliding pin boot for wear, damage and cracks. If corrosion, wear or damage is detected,

replace the applicable part.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of the disc rotor for uneven wear, cracks and serious damage. If uneven wear, cracks or seri-

ous damage is detected, replace it.

Run Out Inspection

1. Using wheel nuts, fix the disc rotor to the wheels hub. (2 or more positions)

BRD0041D

SFIA0340E

Page 872 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref](/img/5/57402/w960_57402-871.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

lBefore working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WAR NIN G:

lClean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

lIf malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

lIf malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

lStopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

lFitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

l4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 900 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-32

[4WD/ABS]

TROUBLE DIAGNOSIS

4WDSOLENOIDVALVE

lDisconnect connector and measure resistance between termi-

nals B152 No. 1 (L/W) and No. 2 (LG).

Basic InspectionEFS001BK

BASIC INSPECTION 1 BRAKE NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-32

[4WD/ABS]

TROUBLE DIAGNOSIS

4WDSOLENOIDVALVE

lDisconnect connector and measure resistance between termi-

nals B152 No. 1 (L/W) and No. 2 (LG).

Basic InspectionEFS001BK

BASIC INSPECTION 1 BRAKE](/img/5/57402/w960_57402-899.png)

BRC-32

[4WD/ABS]

TROUBLE DIAGNOSIS

4WDSOLENOIDVALVE

lDisconnect connector and measure resistance between termi-

nals B152 No. 1 (L/W) and No. 2 (LG).

Basic InspectionEFS001BK

BASIC INSPECTION 1 BRAKE FLUID LEVEL AND LEAKAGE INSPECTION

1. Check fluid level in brake reservoir tank. If fluid level is low, refill brake fluid.

2. Check area around brake piping and ABS actuator for leaks. If a leak or oozing is detected, check as fol-

lows:

lIf connections at ABS actuator are loose, tighten piping to the specified torque. Then check again for

leaks, and be sure there is no fluid leak.

lIf the flare nuts at the connections and the threads of the ABS actuator are damaged, replace the dam-

aged parts. Then check again for leaks, and make sure that there is no fluid leak.

lIf leak or oozing is detected except for ABS actuator connections, wipe it with clean cloth. Then check

again for leaks. If there is still leak or oozing, replace damaged part.

lIf leak or oozing is detected on ABS actuator, wipe with a clean cloth. Check again for leaks, and if

there is still leak or oozing, replace ABS actuator.

CAUTION:

ABS actuator body cannot be disassembled.

BASIC INSPECTION 2 INSPECTION FOR LOOSE POWER SUPPLY TERMINAL

Check battery for looseness on battery positive/negative terminals and ground connection.

BASIC INSPECTION 3 ABS/4WD WARNING LAMP INSPECTION

1. Be sure ABS warning lamp turns on when ignition switch is turned ON. If it does not turn on, check ABS

warning lamp harness.

2. Check 4WD warning lamp illuminates with ignition switch ON. If not so, check 4WD warning lamp path.

3. Be sure ABS warning lamp turns off after approximately 1 second when ignition switch is turned ON. If it

does not turn off, perform self-diagnosis.

4. Be sure 4WD warning lamp turns off after several seconds when engine is started. If it does not turn off,

perform self-diagnosis.

5. After driving the vehicle at Approx. 30km/h for a few seconds, check 4WD warning lamp and ABS warning

lamp do not illuminate.

6. After completing the self-diagnosis, always erase the diagnosis memory.

Wheel Speed Sensor SystemEFS001BL

INSPECTION PROCEDURE

1.TIRE INSPECTION

Check air pressure, wear, and size.

Are air pressure, wear, and size within specifications?

YES >> GO TO 2.

NO >> Adjust air pressure, or replace tire.4WD solenoid valve 1 - 2 : Approx. 2.45W

SDIA0136E