mirror NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1 of 3066

MODEL T30 SERIES

2001 NISSAN EUROPE N.V.

All rights reserved. No part of this Electronic Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan

Europe N.V., Paris, France.

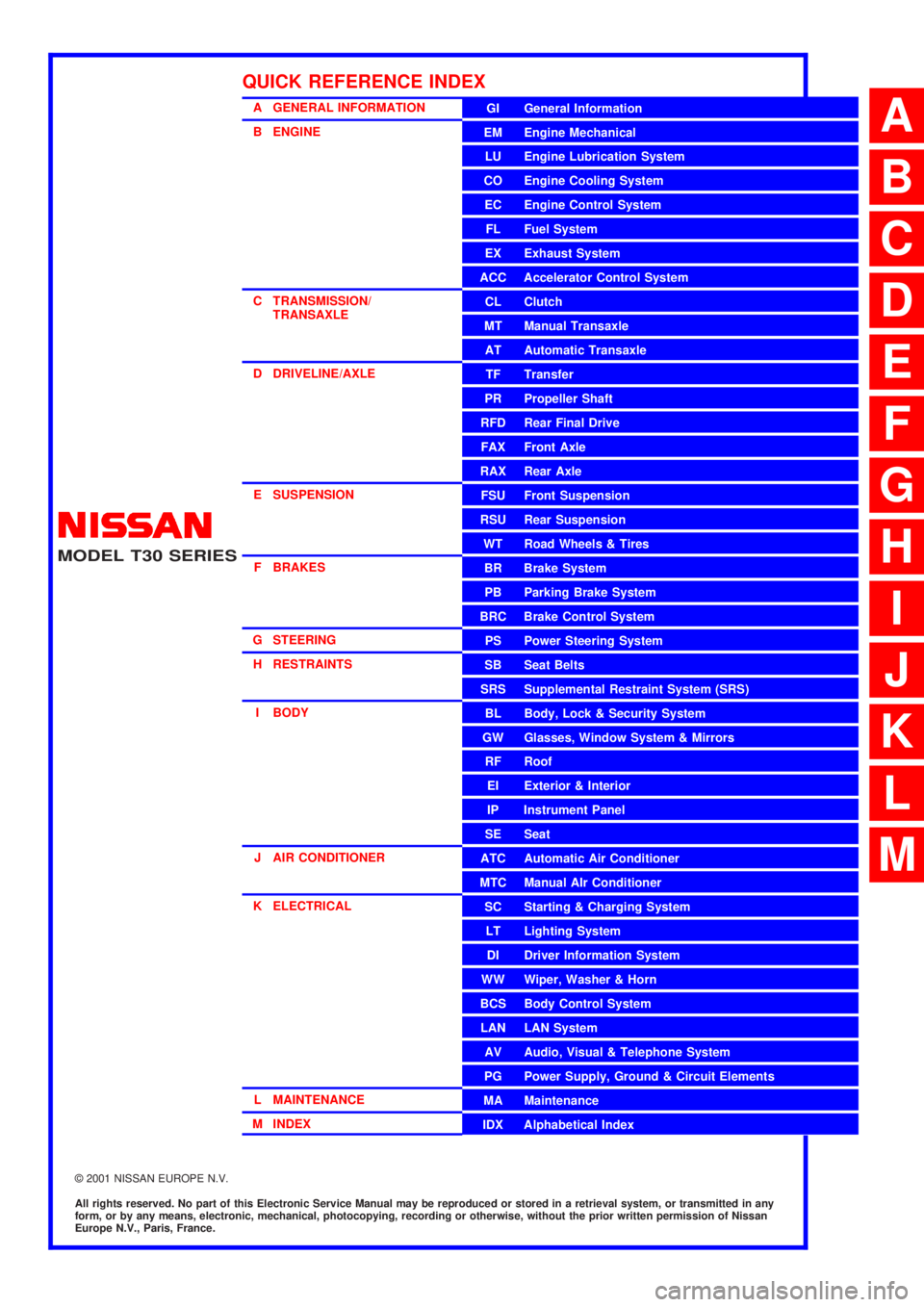

A GENERAL INFORMATION

B ENGINE

C TRANSMISSION/

TRANSAXLE

D DRIVELINE/AXLE

E SUSPENSION

F BRAKES

G STEERING

H RESTRAINTS

I BODY

J AIR CONDITIONER

K ELECTRICAL

L MAINTENANCE

M INDEXGI General Information

EM Engine Mechanical

LU Engine Lubrication System

CO Engine Cooling System

EC Engine Control System

FL Fuel System

EX Exhaust System

ACC Accelerator Control System

CL Clutch

MT Manual Transaxle

AT Automatic Transaxle

TF Transfer

PR Propeller Shaft

RFD Rear Final Drive

FAX Front Axle

RAX Rear Axle

FSU Front Suspension

RSU Rear Suspension

WT Road Wheels & Tires

BR Brake System

PB Parking Brake System

BRC Brake Control System

PS Power Steering System

SB Seat Belts

SRS Supplemental Restraint System (SRS)

BL Body, Lock & Security System

GW Glasses, Window System & Mirrors

RF Roof

EI Exterior & Interior

IP Instrument Panel

SE Seat

ATC Automatic Air Conditioner

MTC Manual AIr Conditioner

SC Starting & Charging System

LT Lighting System

DI Driver Information System

WW Wiper, Washer & Horn

BCS Body Control System

LAN LAN System

AV Audio, Visual & Telephone System

PG Power Supply, Ground & Circuit Elements

MA Maintenance

IDX Alphabetical Index

QUICK REFERENCE INDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

Page 719 of 3066

REFRIGERANT LINES

ATC-141

C

D

E

F

G

H

I

K

L

MA

B

AT C

CAUTION:

Moving the electronic leak detector probe slower and closer to the suspected leak area will improve

the chances of finding a leak.

Checking System for Leaks Using the Fluorescent Leak DetectorEJS000VK

1. Check A/C system for leaks using the UV lamp and safety glasses (J-42220) in a low sunlight area (area

without windows preferable). Illuminate all components, fittings and lines. The dye will appear as a bright

green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain opening indi-

cates an evaporator core assembly (tubes, core or TXV) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (J-43872) to prevent future misdiag-

nosis.

4. Perform a system performance check and verify the leak repair with an approved electronic refrigerant

leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionEJS000VL

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (50 psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (J-41459).

3. Connect the injector tool to the A/C LOW PRESSURE side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture's operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a component, pour the dye directly into the open system con-

nection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak, it may take from minutes to days for the dye to

penetrate a leak and become visible.

Electronic Refrigerant Leak DetectorEJS000VM

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C leak detector

or equivalent. Ensure that the instrument is calibrated and set prop-

erly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

SHA705EB

Page 1954 of 3066

EI-14

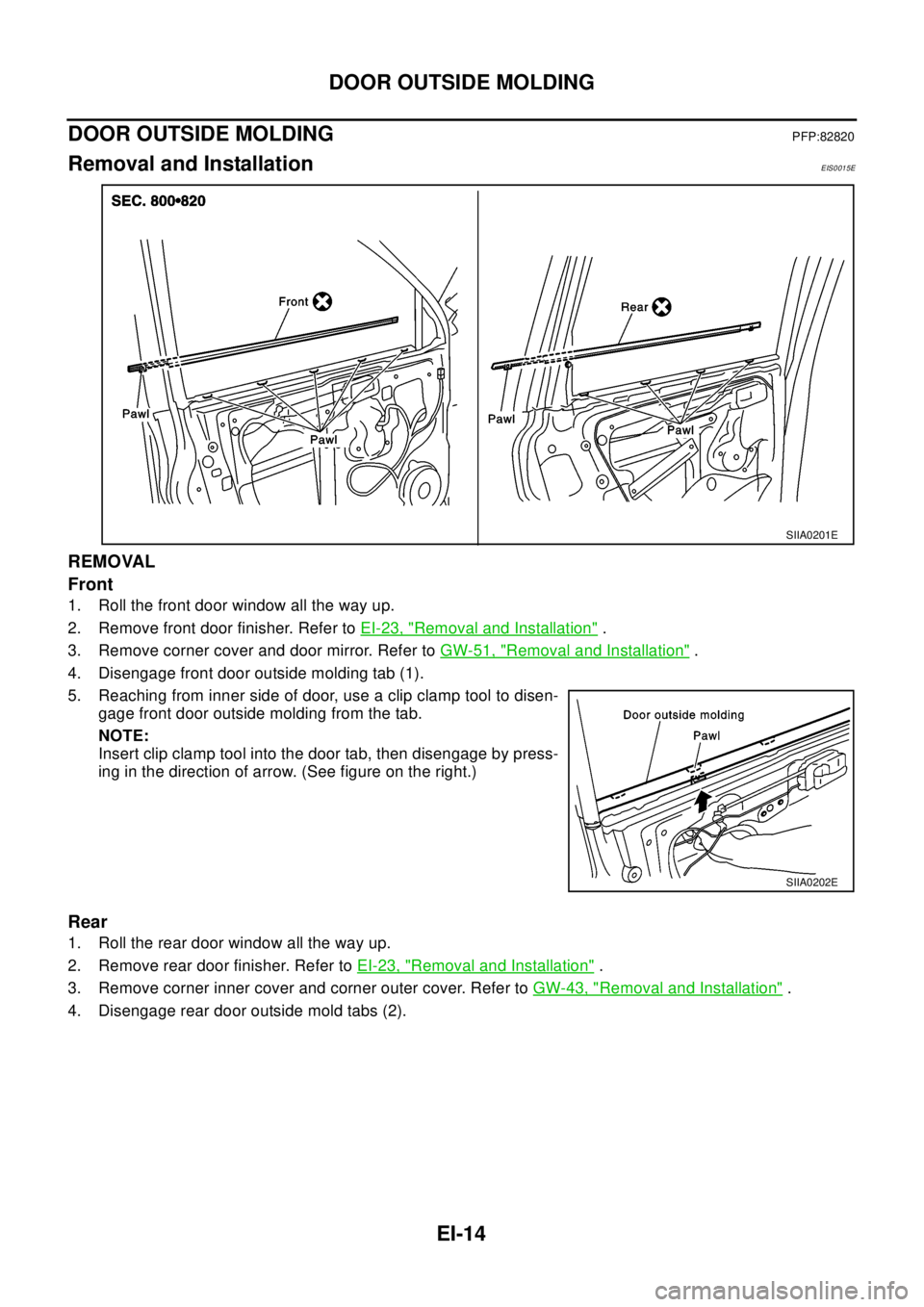

DOOR OUTSIDE MOLDING

DOOR OUTSIDE MOLDING

PFP:82820

Removal and InstallationEIS0015E

REMOVAL

Front

1. Roll the front door window all the way up.

2. Remove front door finisher. Refer toEI-23, "

Removal and Installation".

3. Remove corner cover and door mirror. Refer toGW-51, "

Removal and Installation".

4. Disengage front door outside molding tab (1).

5. Reaching from inner side of door, use a clip clamp tool to disen-

gage front door outside molding from the tab.

NOTE:

Insert clip clamp tool into the door tab, then disengage by press-

inginthedirectionofarrow.(Seefigureontheright.)

Rear

1. Roll the rear door window all the way up.

2. Remove rear door finisher. Refer toEI-23, "

Removal and Installation".

3. Remove corner inner cover and corner outer cover. Refer toGW-43, "

Removal and Installation".

4. Disengage rear door outside mold tabs (2).

SIIA0201E

SIIA0202E

Page 1969 of 3066

HEADLINING

EI-29

C

D

E

F

G

H

J

K

L

MA

B

EI

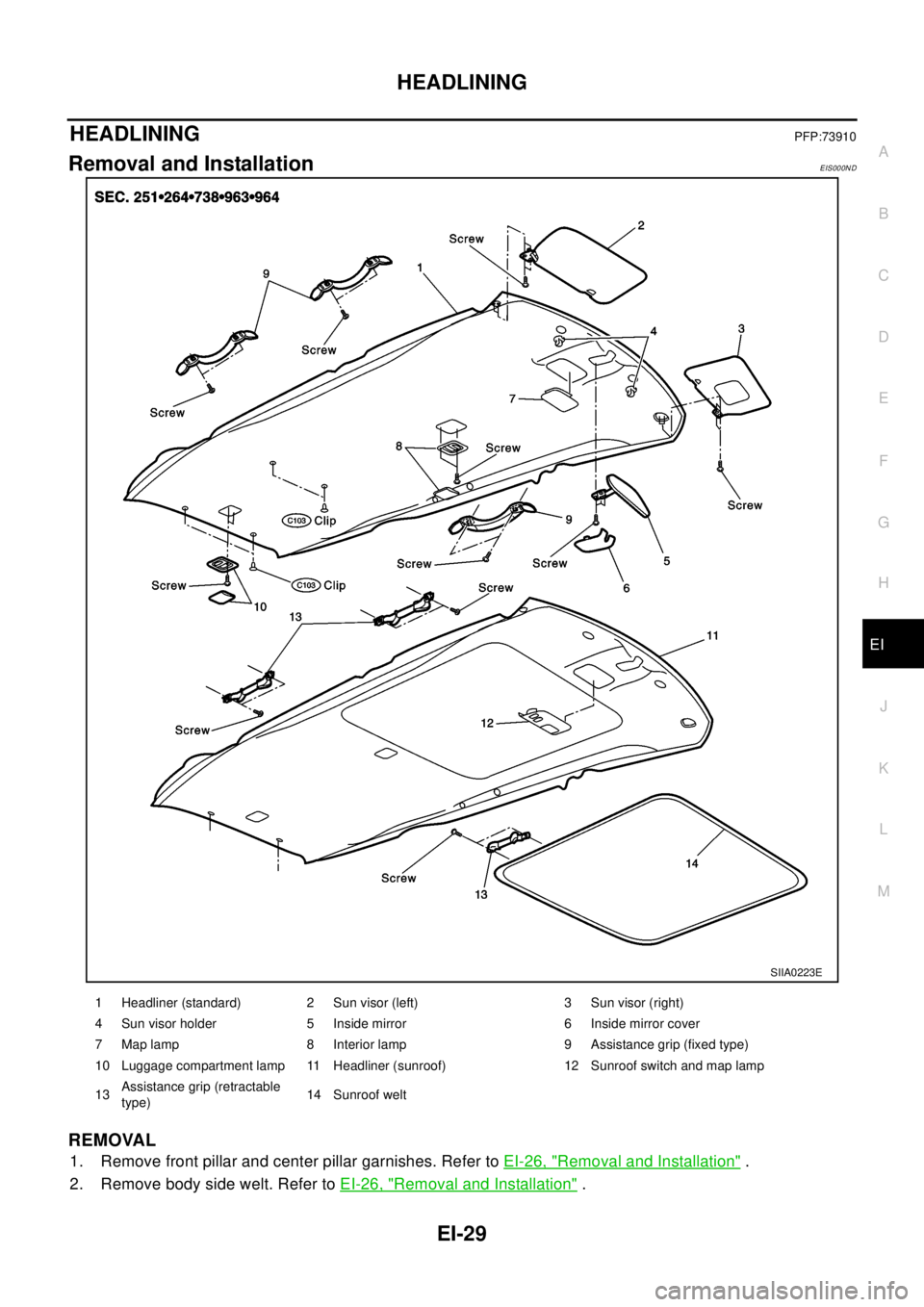

HEADLININGPFP:73910

Removal and InstallationEIS000ND

REMOVAL

1. Remove front pillar and center pillar garnishes. Refer toEI-26, "Removal and Installation".

2. Remove body side welt. Refer toEI-26, "

Removal and Installation".

SIIA0223E

1 Headliner (standard) 2 Sun visor (left) 3 Sun visor (right)

4 Sun visor holder 5 Inside mirror 6 Inside mirror cover

7 Map lamp 8 Interior lamp 9 Assistance grip (fixed type)

10 Luggage compartment lamp 11 Headliner (sunroof) 12 Sunroof switch and map lamp

13Assistance grip (retractable

type)14 Sunroof welt

Page 1970 of 3066

EI-30

HEADLINING

3. Remove rear pillar finisher. Refer toEI-26, "Removal and Installation".

4. Remove assistance grip.

NOTE:

When removing the assistant's grip cover from a car with a sun-

roof, use a clip clamp tool to disengage the upper and lower

tabs, then slide inwards and remove screws (1 each on left/

right).

5. Remove map lamp, interior lamp, and luggage compartment lamp. Refer toLT-64, "

INTERIOR ROOM

LAMP",LT-66, "SPOT LAMP (WITHOUT SUNROOF)",LT- 6 6 , "SPOT LAMP (WITH SUNROOF)"and

LT-64, "

LUGGAGE ROOM LAMP".

6. Remove inside mirror cover.

7. Remove mounting screw on inside mirror.

8. Remove sun visors (driver side and passenger side).

9. Remove headliner rear clips.

10. Remove sun visor holder.

NOTE:

Insert a screwdriver into the cutout and rotate 90°to remove.

11. Remove headliner through the back door opening.

NOTE:

lRemoval and installation must be performed by 2 persons.

lDo not strongly bend the headliner.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

When installing, insert the protrusions on the headliner into the holes

in the upper part of center pillar.

SIIA0052E

SIIA0224J

PIIA0561E

Page 1990 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-20

[QR20DE]

INTAKE MANIFOLD

Tightening Intake Manifold collector bolts and nuts

lTighten in numerical order as shown in the figure.

NOTE:

No.6 means double tightening of bolts 1.

Installation of El NISSAN X-TRAIL 2003 Electronic Repair Manual EM-20

[QR20DE]

INTAKE MANIFOLD

Tightening Intake Manifold collector bolts and nuts

lTighten in numerical order as shown in the figure.

NOTE:

No.6 means double tightening of bolts 1.

Installation of El](/img/5/57402/w960_57402-1989.png)

EM-20

[QR20DE]

INTAKE MANIFOLD

Tightening Intake Manifold collector bolts and nuts

lTighten in numerical order as shown in the figure.

NOTE:

No.6 means double tightening of bolts 1.

Installation of Electric Throttle Control Actuator

lTighten fixing bolts of electric throttle control actuator equally and diagonally in several steps.

lAfter installation perform procedure inEM-20, "INSPECTION AFTER INSTALLATION".

Connecting Quick Connector of Fuel Hose

lInstall quick connector as follows. (The steps are the same for quick connectors on engine side and vehi-

cle)

1. Make sure no foreign substances are deposited in and around tube and quick connector and no damage

on them.

2. Thinly apply new engine oil around the fuel tube tip end.

3. Align center to insert quick connector straightly into fuel tube.

lInsert fuel tube into quick connector until the first spool on fuel

tubes is inserted completely and the second one is positioned

slightly below the quick connectors bottom end.

CAUTION:

lHold A position in illustration when inserting fuel tube

into quick connector.

lCarefully align center to avoid inclined insertion to pre-

vent damage to O-ring inside quick connector.

lInsert until you hear a “click” sound and actually feel the

engagement.

lTo avoid misidentification of engagement with a similar sound, be sure to perform the next step.

4. Before clamping fuel hose with hose clamps, pull quick connector hard by hand holding A position. Make

sure it is completely engaged (connected) so that it does not come out from fuel tube.

NOTE:

Recommended pulling force is 50 N (5.1 kg, 11.2 lb).

5. Install quick connector cap on quick connector joint.

lDirect arrow mark on quick connector cap to upper side (The

figure shows quick connector cap for engine side).

6. Install fuel hose to hose clamp.

INSPECTION AFTER INSTALLATION

lCheck connections for fuel leakage.

1. Start the engine, and run it for a few minutes with engine at idle.

2. Stop the engine, and check for fuel leakage both visually and by odor of gasoline.

NOTE:

Use mirrors for checking on invisible points.

KBIA0234E

KBIA0272E

KBIA0298E

Page 2000 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EM-30

[QR20DE]

FUEL INJECTOR AND FUEL TUBE

INSTALLATION

1. Install O-rings to fuel injector paying attention to the items below.

lLubricate O-rings by smearing new engine oil.

lBe careful not to scrat NISSAN X-TRAIL 2003 Electronic Repair Manual EM-30

[QR20DE]

FUEL INJECTOR AND FUEL TUBE

INSTALLATION

1. Install O-rings to fuel injector paying attention to the items below.

lLubricate O-rings by smearing new engine oil.

lBe careful not to scrat](/img/5/57402/w960_57402-1999.png)

EM-30

[QR20DE]

FUEL INJECTOR AND FUEL TUBE

INSTALLATION

1. Install O-rings to fuel injector paying attention to the items below.

lLubricate O-rings by smearing new engine oil.

lBe careful not to scratch it with a tool or fingernails during installation. Also be careful not to twist

or stretch O-ring. If O-ring was stretched while it is attached, do no insert it into fuel tube immedi-

atly.

2. Install fuel injector to fuel tube with the following procedure.

lInsert clip into clip mounting groove on fuel injector.

lInsert clip so that projection A of fuel injector matches notch A of

the clip.

lDo not reuse clip. Replace it with a new one.

lBe careful to keep clip from interfering with O-ring. If interfer-

ence occurs, replace O-ring.

3. Insert fuel injector into fuel tube with clip attached.

lInsertitwhilematchingittotheaxialcenter.

lInsert fuel injector so that projection B of fuel injector matches

notch B of the clip.

lMake sure that fuel tube flange is securely fixed in flange fixing

groove on clip.

lMake sure that installation is complete by checking that fuel

injector does not rotate or come off.

4. Install fuel tube assembly with the following procedure.

a. Insert the tip of each fuel injector into intake manifold.

b. Tighten mounting bolts in two steps in the numerical order

shown in the figure.

5. Install intake manifold collector. Refer toEM-17, "

INTAKE MANI-

FOLD".

6. Connect fuel hose. Refer toEM-17, "

INTAKE MANIFOLD".

7. Install all removed parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

lCheck connections for fuel leakage.

1. Start the engine, and run it for a few minutes with engine at idle.

2. Stop the engine, and check for fuel leakage both visually and by odor of gasoline.

NOTE:

Use mirrors for checking on invisible points.

CAUTION:

Do not touch the engine immediately after stopped as engine becomes extremely hot.

KBIA0240E

1st step: 9.3 - 10.8 N·m (0.95 - 1.1 kg-m, 0.7 - 0.8 ft-lb)

2nd step: 20.6 - 26.5 N·m (2.1 - 2.7 kg-m, 16 - 19 ft-lb)

KBIA0239E

Page 2304 of 3066

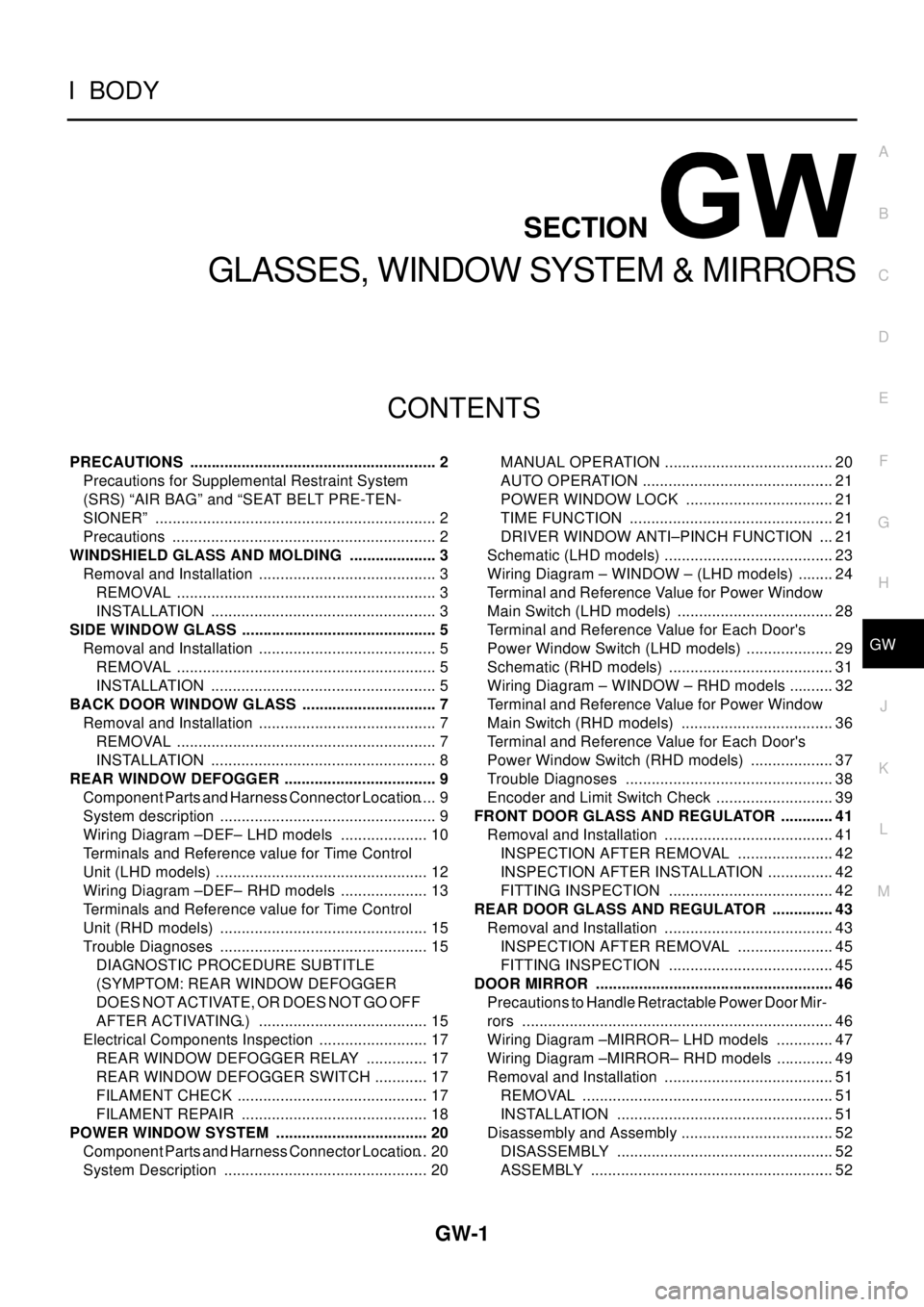

GW-1

GLASSES, WINDOW SYSTEM & MIRRORS

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION

A

B

GW

GLASSES, WINDOW SYSTEM & MIRRORS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

WINDSHIELD GLASS AND MOLDING ..................... 3

Removal and Installation .......................................... 3

REMOVAL ............................................................. 3

INSTALLATION ..................................................... 3

SIDE WINDOW GLASS .............................................. 5

Removal and Installation .......................................... 5

REMOVAL ............................................................. 5

INSTALLATION ..................................................... 5

BACK DOOR WINDOW GLASS ................................ 7

Removal and Installation .......................................... 7

REMOVAL ............................................................. 7

INSTALLATION ..................................................... 8

REAR WINDOW DEFOGGER .................................... 9

Component Parts and Harness Connector Location..... 9

System description ................................................... 9

Wiring Diagram –DEF– LHD models ..................... 10

Terminals and Reference value for Time Control

Unit (LHD models) .................................................. 12

Wiring Diagram –DEF– RHD models ..................... 13

Terminals and Reference value for Time Control

Unit (RHD models) ................................................. 15

Trouble Diagnoses ................................................. 15

DIAGNOSTIC PROCEDURE SUBTITLE

(SYMPTOM: REAR WINDOW DEFOGGER

DOES NOT ACTIVATE, OR DOES NOT GO OFF

AFTER ACTIVATING.) ........................................ 15

Electrical Components Inspection .......................... 17

REAR WINDOW DEFOGGER RELAY ............... 17

REAR WINDOW DEFOGGER SWITCH ............. 17

FILAMENT CHECK ............................................. 17

FILAMENT REPAIR ............................................ 18

POWER WINDOW SYSTEM .................................... 20

Component Parts and Harness Connector Location... 20

System Description ................................................ 20MANUAL OPERATION ........................................ 20

AUTO OPERATION ............................................. 21

POWER WINDOW LOCK ................................... 21

TIME FUNCTION ................................................ 21

DRIVER WINDOW ANTI–PINCH FUNCTION .... 21

Schematic (LHD models) ........................................ 23

Wiring Diagram – WINDOW – (LHD models) ......... 24

Terminal and Reference Value for Power Window

Main Switch (LHD models) ..................................... 28

Terminal and Reference Value for Each Door's

Power Window Switch (LHD models) ..................... 29

Schematic (RHD models) ....................................... 31

Wiring Diagram – WINDOW – RHD models ........... 32

Terminal and Reference Value for Power Window

Main Switch (RHD models) .................................... 36

Terminal and Reference Value for Each Door's

Power Window Switch (RHD models) .................... 37

Trouble Diagnoses ................................................. 38

Encoder and Limit Switch Check ............................ 39

FRONT DOOR GLASS AND REGULATOR ............. 41

Removal and Installation ........................................ 41

INSPECTION AFTER REMOVAL ....................... 42

INSPECTION AFTER INSTALLATION ................ 42

FITTING INSPECTION ....................................... 42

REAR DOOR GLASS AND REGULATOR ............... 43

Removal and Installation ........................................ 43

INSPECTION AFTER REMOVAL ....................... 45

FITTING INSPECTION ....................................... 45

DOOR MIRROR ........................................................ 46

Precautions to Handle Retractable Power Door Mir-

rors ......................................................................... 46

Wiring Diagram –MIRROR– LHD models .............. 47

Wiring Diagram –MIRROR– RHD models .............. 49

Removal and Installation ........................................ 51

REMOVAL ........................................................... 51

INSTALLATION ................................................... 51

Disassembly and Assembly .................................... 52

DISASSEMBLY ................................................... 52

ASSEMBLY ......................................................... 52

Page 2312 of 3066

REAR WINDOW DEFOGGER

GW-9

C

D

E

F

G

H

J

K

L

MA

B

GW

REAR WINDOW DEFOGGERPFP:25350

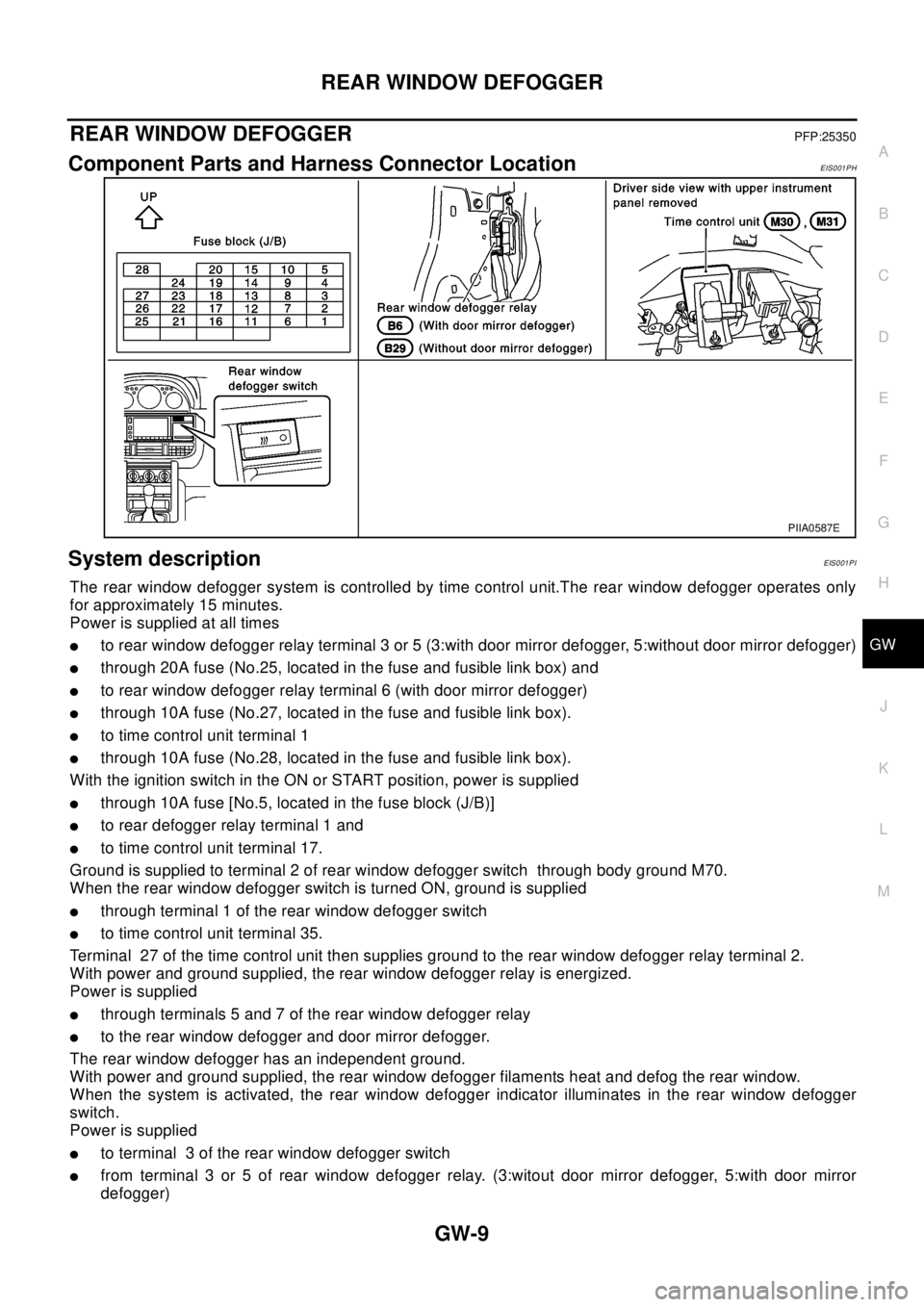

Component Parts and Harness Connector LocationEIS001PH

System descriptionEIS001PI

The rear window defogger system is controlled by time control unit.The rear window defogger operates only

for approximately 15 minutes.

Power is supplied at all times

lto rear window defogger relay terminal 3 or 5 (3:with door mirror defogger, 5:without door mirror defogger)

lthrough 20A fuse (No.25, located in the fuse and fusible link box) and

lto rear window defogger relay terminal 6 (with door mirror defogger)

lthrough 10A fuse (No.27, located in the fuse and fusible link box).

lto time control unit terminal 1

lthrough 10A fuse (No.28, located in the fuse and fusible link box).

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No.5, located in the fuse block (J/B)]

lto rear defogger relay terminal 1 and

lto time control unit terminal 17.

Ground is supplied to terminal 2 of rear window defogger switch through body ground M70.

When the rear window defogger switch is turned ON, ground is supplied

lthrough terminal 1 of the rear window defogger switch

lto time control unit terminal 35.

Terminal 27 of the time control unit then supplies ground to the rear window defogger relay terminal 2.

With power and ground supplied, the rear window defogger relay is energized.

Power is supplied

lthrough terminals 5 and 7 of the rear window defogger relay

lto the rear window defogger and door mirror defogger.

The rear window defogger has an independent ground.

With power and ground supplied, the rear window defogger filaments heat and defog the rear window.

When the system is activated, the rear window defogger indicator illuminates in the rear window defogger

switch.

Power is supplied

lto terminal 3 of the rear window defogger switch

lfrom terminal 3 or 5 of rear window defogger relay. (3:witout door mirror defogger, 5:with door mirror

defogger)

PIIA0587E

Page 2318 of 3066

REAR WINDOW DEFOGGER

GW-15

C

D

E

F

G

H

J

K

L

MA

B

GW

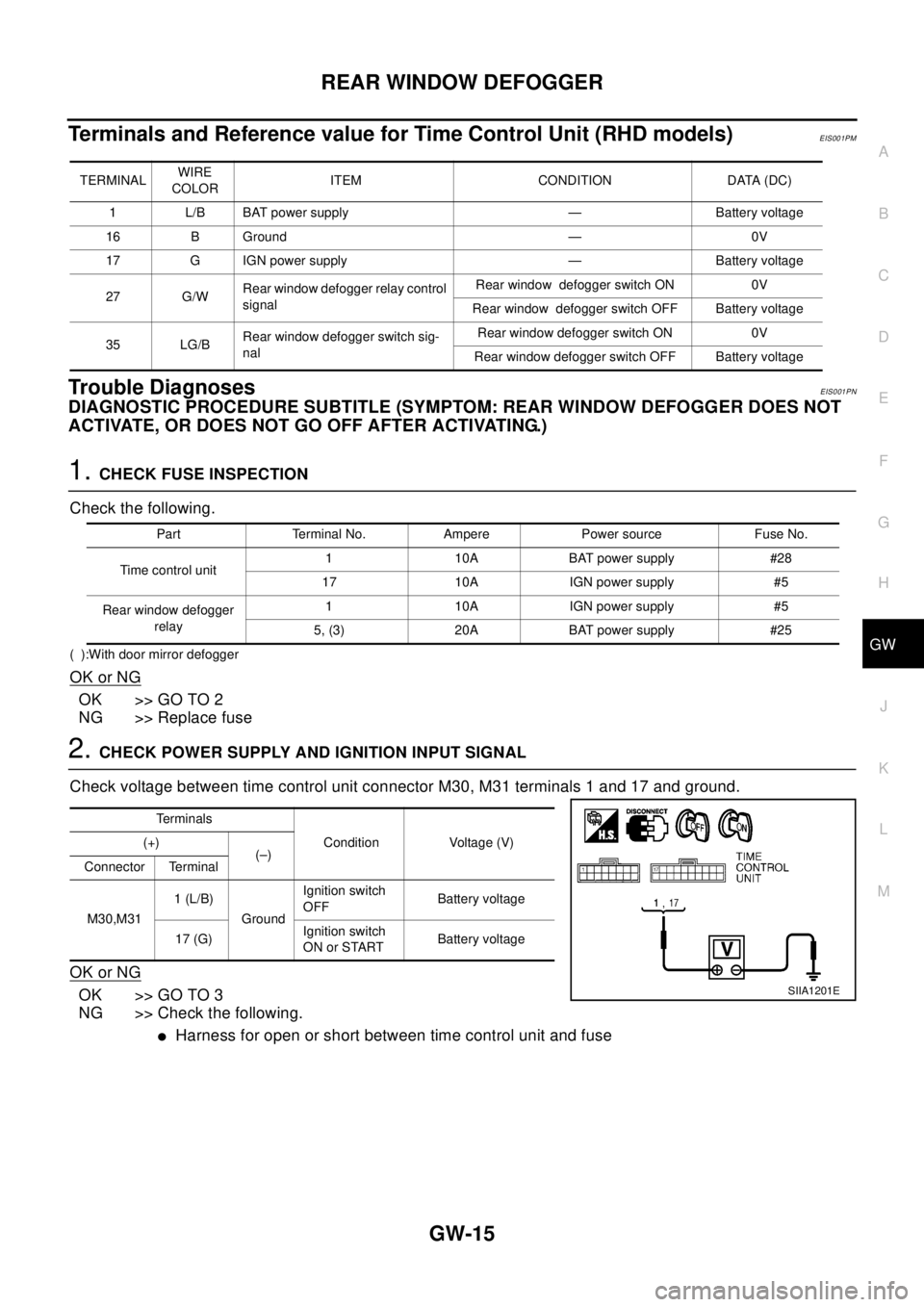

Terminals and Reference value for Time Control Unit (RHD models)EIS001PM

Trouble DiagnosesEIS001PN

DIAGNOSTIC PROCEDURE SUBTITLE (SYMPTOM: REAR WINDOW DEFOGGER DOES NOT

ACTIVATE, OR DOES NOT GO OFF AFTER ACTIVATING.)

1.CHECK FUSE INSPECTION

Check the following.

( ):With door mirror defogger

OK or NG

OK >> GO TO 2

NG >> Replace fuse

2.CHECK POWER SUPPLY AND IGNITION INPUT SIGNAL

Check voltage between time control unit connector M30, M31 terminals 1 and 17 and ground.

OK or NG

OK >> GO TO 3

NG >> Check the following.

lHarness for open or short between time control unit and fuse

TERMINALWIRE

COLORITEM CONDITION DATA (DC)

1 L/B BAT power supply — Battery voltage

16 B Ground — 0V

17 G IGN power supply — Battery voltage

27 G/WRear window defogger relay control

signalRear window defogger switch ON 0V

Rear window defogger switch OFF Battery voltage

35 LG/BRear window defogger switch sig-

nalRear window defogger switch ON 0V

Rear window defogger switch OFF Battery voltage

Part Terminal No. Ampere Power source Fuse No.

Time control unit1 10A BAT power supply #28

17 10A IGN power supply #5

Rear window defogger

relay1 10A IGN power supply #5

5, (3) 20A BAT power supply #25

Te r m i n a l s

Condition Voltage (V) (+)

(–)

Connector Terminal

M30,M311(L/B)

GroundIgnition switch

OFFBattery voltage

17 (G)Ignition switch

ON or STARTBattery voltage

SIIA1201E