oil reset NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 734 of 3066

AV-12

AUDIO

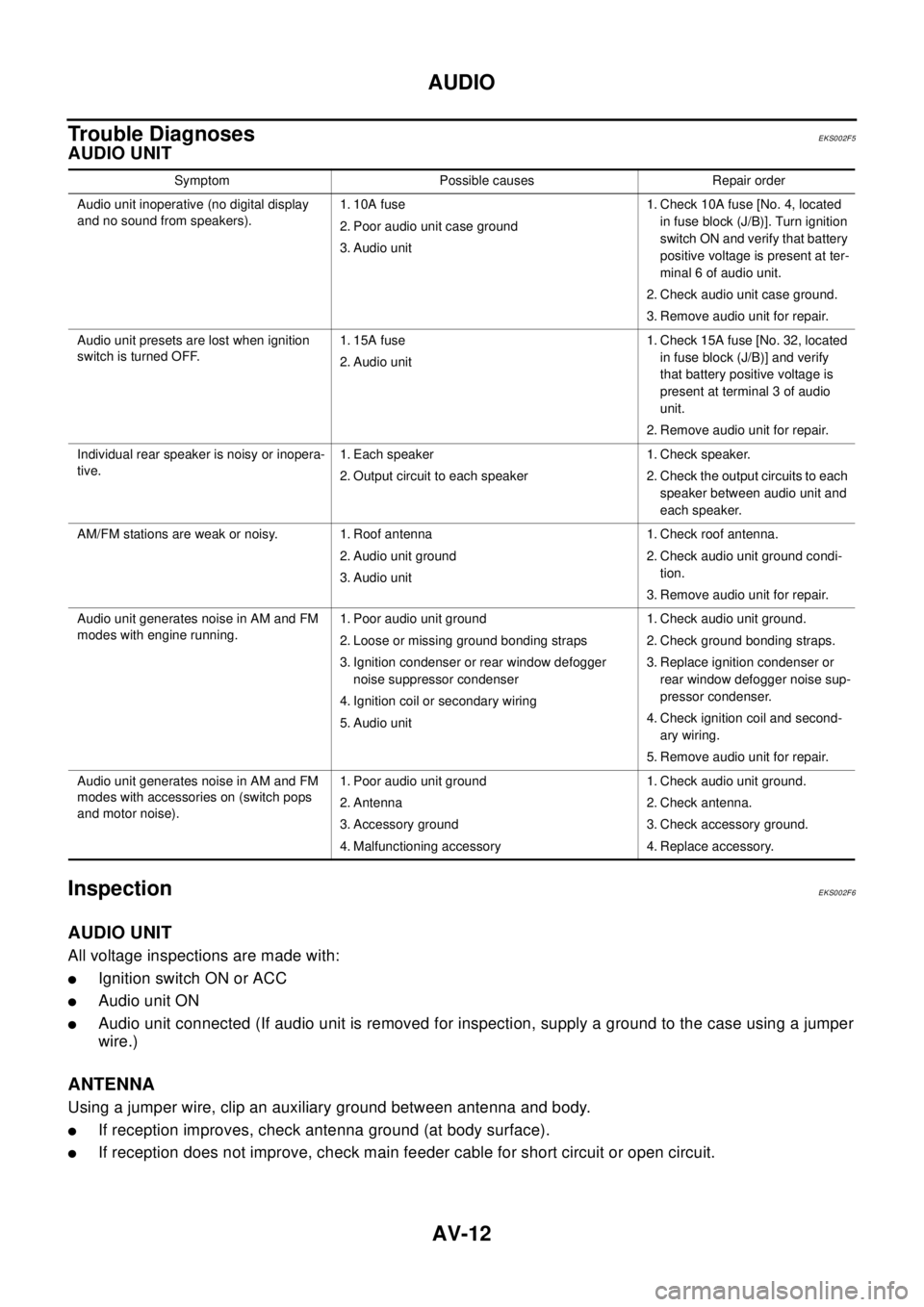

Trouble Diagnoses

EKS002F5

AUDIO UNIT

InspectionEKS002F6

AUDIO UNIT

All voltage inspections are made with:

lIgnition switch ON or ACC

lAudio unit ON

lAudio unit connected (If audio unit is removed for inspection, supply a ground to the case using a jumper

wire.)

ANTENNA

Using a jumper wire, clip an auxiliary ground between antenna and body.

lIf reception improves, check antenna ground (at body surface).

lIf reception does not improve, check main feeder cable for short circuit or open circuit.

Symptom Possible causes Repair order

Audio unit inoperative (no digital display

and no sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 4, located

in fuse block (J/B)]. Turn ignition

switch ON and verify that battery

positive voltage is present at ter-

minal 6 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost when ignition

switch is turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 32, located

in fuse block (J/B)] and verify

that battery positive voltage is

present at terminal 3 of audio

unit.

2. Remove audio unit for repair.

Individual rear speaker is noisy or inopera-

tive.1. Each speaker

2. Output circuit to each speaker1. Check speaker.

2. Check the output circuits to each

speaker between audio unit and

each speaker.

AM/FM stations are weak or noisy. 1. Roof antenna

2. Audio unit ground

3. Audio unit1. Check roof antenna.

2. Check audio unit ground condi-

tion.

3. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with engine running.1. Poor audio unit ground

2. Loose or missing ground bonding straps

3. Ignition condenser or rear window defogger

noise suppressor condenser

4. Ignition coil or secondary wiring

5. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or

rear window defogger noise sup-

pressor condenser.

4. Check ignition coil and second-

ary wiring.

5. Remove audio unit for repair.

Audio unit generates noise in AM and FM

modes with accessories on (switch pops

and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Malfunctioning accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Page 1774 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-660

[YD]

ENGINE CONTROL SYSTEM

System Chart

EBS0037B

Fuel Injection Control SystemEBS0036G

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating cond NISSAN X-TRAIL 2003 Electronic Repair Manual EC-660

[YD]

ENGINE CONTROL SYSTEM

System Chart

EBS0037B

Fuel Injection Control SystemEBS0036G

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating cond](/img/5/57402/w960_57402-1773.png)

EC-660

[YD]

ENGINE CONTROL SYSTEM

System Chart

EBS0037B

Fuel Injection Control SystemEBS0036G

SYSTEM DESCRIPTION

Three types of fuel injection control are provided to accommodate engine operating conditions; normal control,

idle control and start control. The ECM determines the appropriate fuel injection control. Under each control,

the amount of fuel injected is adjusted to improve engine performance.

Pulse signals are exchanged between ECM and Electronic Drive Unit (EDU). EDU controls fuel injectors

according to the input signals to adjust the amount of fuel injected to the preset value.

START CONTROL

Input/Output Signal Chart

When the ECM receives a start signal from the ignition switch, the

ECM adapts the fuel injection system for the start control. The

amount of fuel injected at engine starting is a preset program value

in the ECM. The program is determined by the engine speed, engine

coolant temperature and common rail fuel pressure.

For better startability under cool engine conditions, the lower the

coolant temperature becomes, the greater the amount of fuel

injected. The ECM ends the start control when the engine speed

reaches the specific value, and shifts the control to the normal or idle

control.

Input (Sensor) ECM Function Output (Actuator)

lAccelerator pedal position sensor

lAccelerator pedal released position switch

lCommon rail fuel pressure sensor

lFuel temperature sensor

lEngine coolant temperature sensor

lCrankshaft position sensor (TDC)

lCamshaft position sensor

lVehicle speed sensor

lIgnition switch

lStop Lamp switch

lAir conditioner switch

lMass air flow sensor

lPark/neutral position switch

lBattery voltage

lPower steering oil pressure switchFuel injection controlEDU, Fuel injectors and Suction control

valve

Fuel injection timing controlEDU, Fuel injectors and Suction control

valve

Fuel cut controlEDU, Fuel injectors and Suction control

valve

Glow control system Glow relay & glow indictor lamp

On board diagnostic system Malfunction indicator (MI)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Sensor Input Signal to ECM ECM Function Actuator

Engine coolant temperature sensor Engine coolant temperature

Fuel injection

control (start

control)EDU

Fuel injectors

Suction control valve Crankshaft position sensor (TDC) Engine speed

Camshaft position sensor Piston position

Ignition switch Start signal

Common rail fuel pressure sensor Common rail fuel pressure

SEF648S

Page 2858 of 3066

RSU-6

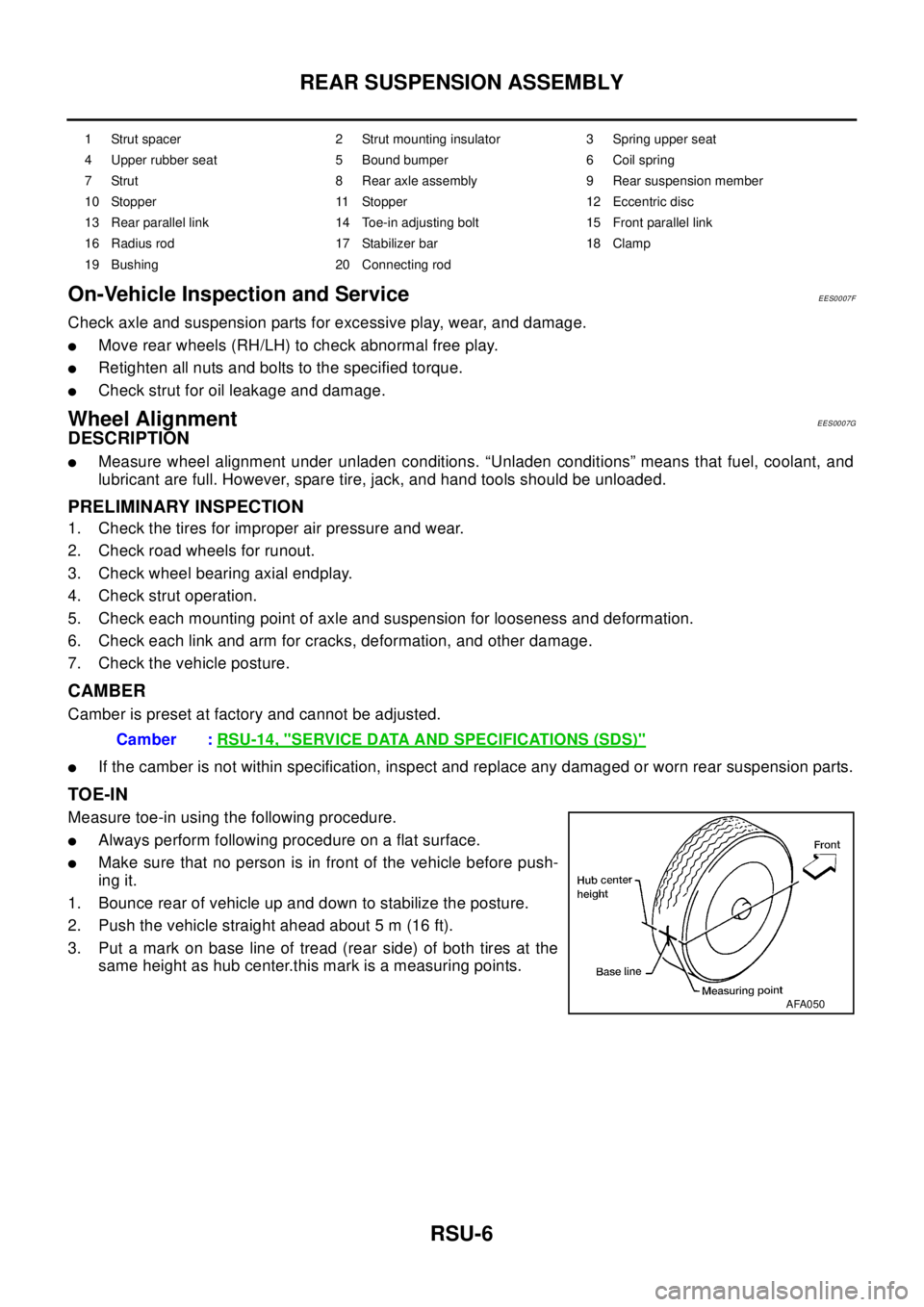

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and Service

EES0007F

Check axle and suspension parts for excessive play, wear, and damage.

lMove rear wheels (RH/LH) to check abnormal free play.

lRetighten all nuts and bolts to the specified torque.

lCheck strut for oil leakage and damage.

Wheel AlignmentEES0007G

DESCRIPTION

lMeasure wheel alignment under unladen conditions. “Unladen conditions” means that fuel, coolant, and

lubricant are full. However, spare tire, jack, and hand tools should be unloaded.

PRELIMINARY INSPECTION

1. Check the tires for improper air pressure and wear.

2. Check road wheels for runout.

3. Check wheel bearing axial endplay.

4. Check strut operation.

5. Check each mounting point of axle and suspension for looseness and deformation.

6. Check each link and arm for cracks, deformation, and other damage.

7. Check the vehicle posture.

CAMBER

Camber is preset at factory and cannot be adjusted.

lIf the camber is not within specification, inspect and replace any damaged or worn rear suspension parts.

TOE-IN

Measure toe-in using the following procedure.

lAlways perform following procedure on a flat surface.

lMake sure that no person is in front of the vehicle before push-

ing it.

1. Bounce rear of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of tread (rear side) of both tires at the

same height as hub center.this mark is a measuring points.

1 Strut spacer 2 Strut mounting insulator 3 Spring upper seat

4 Upper rubber seat 5 Bound bumper 6 Coil spring

7 Strut 8 Rear axle assembly 9 Rear suspension member

10 Stopper 11 Stopper 12 Eccentric disc

13 Rear parallel link 14 Toe-in adjusting bolt 15 Front parallel link

16 Radius rod 17 Stabilizer bar 18 Clamp

19 Bushing 20 Connecting rod

Camber :RSU-14, "SERVICE DATA AND SPECIFICATIONS (SDS)"

AFA050