radio antenna NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 872 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe caref](/img/5/57402/w960_57402-871.png)

BRC-4

[4WD/ABS]

PRECAUTIONS

[4WD/ABS]PRECAUTIONSPFP:00001

Precautions for brake systemEFS001B6

lRecommended fluid is brake fluid “DOT 3 ”or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

lBefore working, turn OFF ignition switch. Disconnect connectors

for ABS actuator and control module or battery terminals.

WAR NIN G:

lClean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

Precautions for brake controlEFS001B7

lIf malfunction is indicated by 4WD warning lamp and/or ABS warning lamp, collect necessary information

from customer (what symptoms are present under what conditions). Find out possible causes before start-

ing service. Besides electrical system inspection, check operation of ABS actuator.

lIf malfunction is detected, proceed to trouble diagnosis after checking tire pressure and tire wear.

lStopping distance or steering stability may be deteriorated by the following conditions. Tire size and type

are in improper combination. Brake pads are not Nissan genuine parts.

lFitting tires of different size on vehicle can be cause of longitudinal vibration. Always use tires of the same

size and brand. Exchange front and rear tires on the following conditions: Longitudinal vibration occurs in

vehicle with tires of the same size and brand. After replacement, perform trouble diagnosis. 1580|None

l4WD/ABS function may have a failure or error under following condition: There is radio, antenna, or

antenna lead-in wire (including wiring) near control module.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 920 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restrai NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restrai](/img/5/57402/w960_57402-919.png)

BRC-52

[ESP/TCS/ABS]

PRECAUTIONS

[ESP/TCS/ABS]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EFS0019N

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Precautions for Brake SystemEFS0019O

lRecommended fluid is brake fluid “DOT 3” or “DOT 4”.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

lNever use mineral oils such as gasoline or kerosene. They will ruin rubber parts of hydraulic system.

lUse flare nut wrench when removing and installing brake tubes.

lAlways torque brake lines when installing.

lBefore working, turn the ignition switch OFF and disconnect the

connectors for the ESP/TCS/ABS actuator and control unit or

the battery terminals.

lBurnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer toBR-10, "

Brake Burnishing

Procedure".

WAR NIN G:

Clean brakes with a vacuum dust collector to minimize risk

of health hazard from powder caused by friction.

Precautions for Brake ControlEFS0019P

lDuring the EPS/TCS/ABS operation, the brake pedal vibrates lightly and its mechanical noise may be

heard. This is a normal condition.

lJust after starting the vehicle after ignition switch ON, the brake pedal may vibrate or the motor operating

noise may be heard from the engine compartment. This is a normal status of the operation check.

lThe stopping distance may be longer than that of vehicles without ABS when the vehicle drives on rough,

gravel, or snowy (fresh deep snow) road.

lIf a malfunction is indicated by the ABS warning lamp, or other warning lamps, collect the necessary infor-

mation from the customer (what symptoms are present under what conditions) and find out the possible

causes before starting the service. Besides the electrical system inspection, check the booster operation,

brake fluid level, and oil leaks.

lIf the tire size and type are used in a improper combination, or the brake pads are not NISSAN genuine

parts, the stopping distance or steering stability may deteriorate.

lIf there is a radio, antenna, or antenna lead-in wire (including wiring) near the control unit, the ESP/TCS/

ABS function may have a malfunction or error.

lIf aftermarket parts (e.g. Car stereo equipment, CD player) have been installed, check the electrical har-

nesses for pinches, open, and improper wiring.

SBR686C

Page 983 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-115

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.SYMPTOM CHECK 3

Does the symptom appear during normal braking operation?

CAUTION:

ABS may work in following driving conditions even NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

BRC-115

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.SYMPTOM CHECK 3

Does the symptom appear during normal braking operation?

CAUTION:

ABS may work in following driving conditions even](/img/5/57402/w960_57402-982.png)

TROUBLE DIAGNOSIS

BRC-115

[ESP/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

3.SYMPTOM CHECK 3

Does the symptom appear during normal braking operation?

CAUTION:

ABS may work in following driving conditions even if there is no sudden brake.

lWhen road friction is low.

lHigh speed cornering

lWhenagustofwind

Is inspection result OK?

YES >> GO TO 4.

NO >> Normal

4.SYMPTOM CHECK 4

Check that the symptom is reproduce when the engine speed is increased with the vehicle stopped.

Is inspection result OK?

YES >> GO TO 5.

NO >>

lNormal.

CAUTION:

This symptom may appear with vehicle stopped.

5.SYMPTOM CHECK 5

Check that the symptom is reproduce when any switch of electrical equipment is operated.

Is inspection result OK?

YES >> Check that there are no radio, antenna, and antenna lead-in wires (including wiring) near control

unit.

NO >> GO TO 6.

6.ABS WARNING LAMP INSPECTION

Check that the ABS warning lamp turns on.

Is inspection result OK?

YES >> Perform the self-diagnosis.

NO >> GO TO 7.

7.WHEEL SPEED SENSOR INSPECTION

Check the wheel speed sensor system.

lSensor mounting inspection

lSensor pick-up inspection for iron chips (e.g. Number of teeth, damaged teeth)

lSensor connector engagement inspection

lWheel speed sensor path harness and connector inspection

Is inspection result OK?

YES >> Normal

NO >> Wheel speed sensor and rotor lines repair

Symptom 6: ESP OFF Indicator Lamp Does Not IlluminateEFS001AX

Inspection procedure

1.ESP OFF INDICATOR LAMP INSPECTION

Disconnect the ESP/TCS/ABS control unit connector.

Does the ABS warning lamp and ESP OFF indicator lamp illuminate?

YES >> ESP/TCS/ABS control unit malfunction. Repair or replace the control unit.

NO >> Combination meter system malfunction. Check the combination meter.

Page 1133 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

EC-19

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engi NISSAN X-TRAIL 2003 Electronic Repair Manual PRECAUTIONS

EC-19

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engi](/img/5/57402/w960_57402-1132.png)

PRECAUTIONS

EC-19

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engine just prior to shutdown.

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

–Keep the antenna as far as possible from the electronic

control units.

–Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

–Adjust the antenna and feeder line so that the standing-

wave radio can be kept smaller.

–Be sure to ground the radio to vehicle body.

Wiring Diagrams and Trouble DiagnosisEBS00B0L

When you read Wiring diagrams, refer to the following:

lGI-14, "HowtoReadWiringDiagrams"

lPG-2, "POWER SUPPLY ROUTING"for power distribution circuit

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"

SEF709Y

SEF708Y

Page 1498 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-384

[QR (WITHOUT EURO-OBD)]

PRECAUTIONS

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engine just prior to shutd NISSAN X-TRAIL 2003 Electronic Repair Manual EC-384

[QR (WITHOUT EURO-OBD)]

PRECAUTIONS

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engine just prior to shutd](/img/5/57402/w960_57402-1497.png)

EC-384

[QR (WITHOUT EURO-OBD)]

PRECAUTIONS

lDo not depress accelerator pedal when starting.

lImmediately after starting, do not rev up engine unneces-

sarily.

lDo not rev up engine just prior to shutdown.

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

–Keep the antenna as far as possible from the electronic

control units.

–Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

–Adjust the antenna and feeder line so that the standing-

wave radio can be kept smaller.

–Be sure to ground the radio to vehicle body.

Wiring Diagrams and Trouble DiagnosisEBS00BEO

When you read Wiring diagrams, refer to the following:

lGI-14, "How to Read Wiring Diagrams"

lPG-2, "POWER SUPPLY ROUTING"for power distribution circuit

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"

SEF709Y

SEF708Y

Page 1772 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-658

[YD]

PRECAUTIONS

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

NISSAN X-TRAIL 2003 Electronic Repair Manual EC-658

[YD]

PRECAUTIONS

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.](/img/5/57402/w960_57402-1771.png)

EC-658

[YD]

PRECAUTIONS

lWhen installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

–Keep the antenna as far as possible from the electronic

control units.

–Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

–Adjust the antenna and feeder line so that the standingwave

radio can be kept smaller.

–Be sure to ground the radio to vehicle body.

Wiring Diagrams and Trouble DiagnosisEBS00318

When you read Wiring diagrams, refer to the following:

lGI-14, "How to Read Wiring Diagrams".

lPG-2, "POWER SUPPLY ROUTING"for power distribution circuit

When you perform trouble diagnosis, refer to the following:

lGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident".

SEF708Y

Page 2364 of 3066

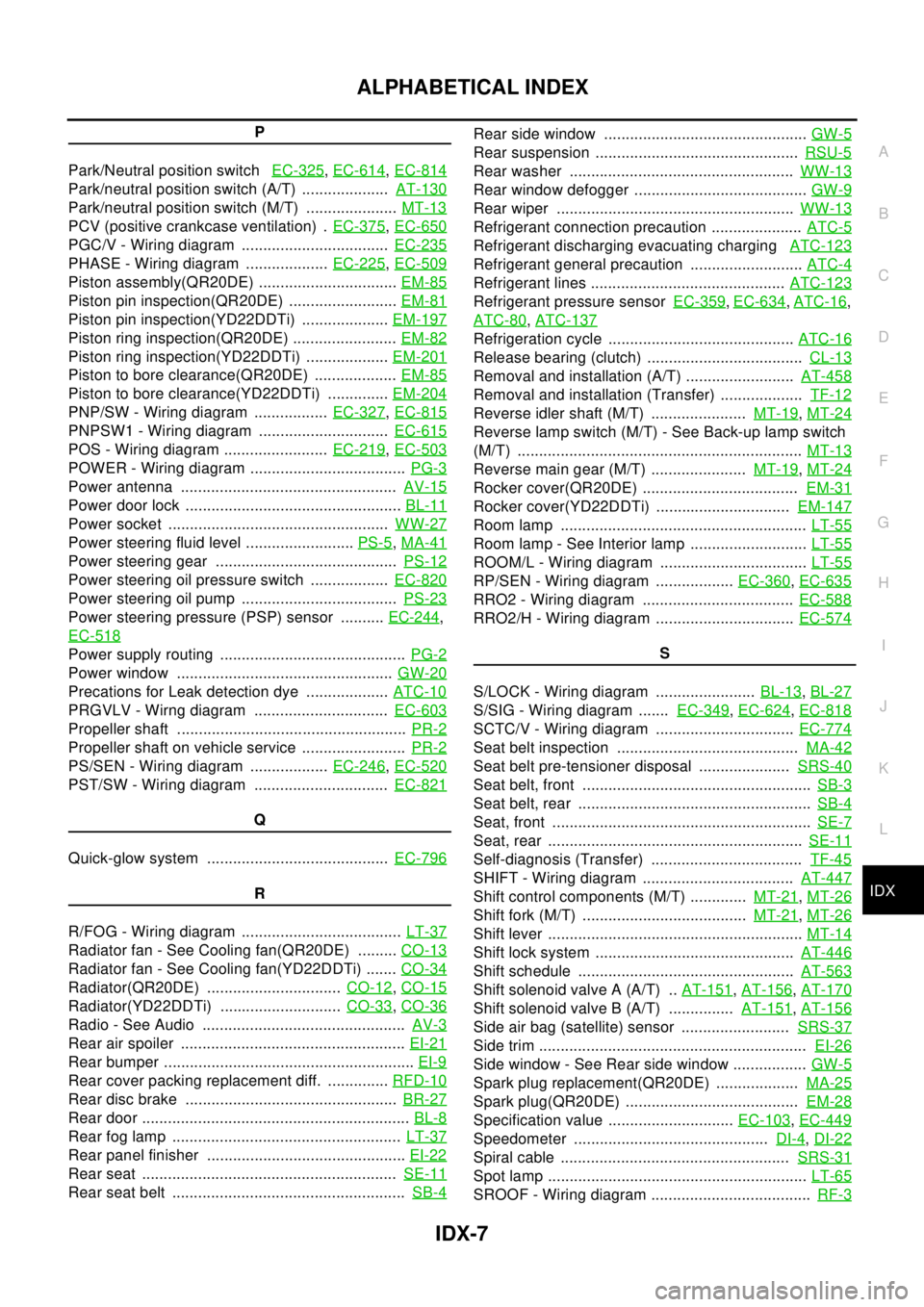

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

P

Park/Neutral position switchEC-325

,EC-614,EC-814

Park/neutral position switch (A/T) ....................AT-130

Park/neutral position switch (M/T) .....................MT-13

PCV (positive crankcase ventilation) .EC-375,EC-650

PGC/V - Wiring diagram ..................................EC-235

PHASE - Wiring diagram ...................EC-225,EC-509

Piston assembly(QR20DE) ................................EM-85

Piston pin inspection(QR20DE) .........................EM-81

Piston pin inspection(YD22DDTi) ....................EM-197

Piston ring inspection(QR20DE) ........................EM-82

Piston ring inspection(YD22DDTi) ...................EM-201

Piston to bore clearance(QR20DE) ...................EM-85

Piston to bore clearance(YD22DDTi) ..............EM-204

PNP/SW - Wiring diagram .................EC-327,EC-815

PNPSW1 - Wiring diagram ..............................EC-615

POS - Wiring diagram ........................EC-219,EC-503

POWER - Wiring diagram ....................................PG-3

Power antenna ..................................................AV-15

Power door lock ..................................................BL-11

Power socket ...................................................WW-27

Power steering fluid level .........................PS-5,MA-41

Power steering gear ..........................................PS-12

Power steering oil pressure switch ..................EC-820

Power steering oil pump ....................................PS-23

Power steering pressure (PSP) sensor ..........EC-244,

EC-518

Power supply routing ...........................................PG-2

Power window ..................................................GW-20

Precations for Leak detection dye ...................ATC-10

PRGVLV - Wirng diagram ...............................EC-603

Propeller shaft .....................................................PR-2

Propeller shaft on vehicle service ........................PR-2

PS/SEN - Wiring diagram ..................EC-246,EC-520

PST/SW - Wiring diagram ...............................EC-821

Q

Quick-glow system ..........................................EC-796

R

R/FOG - Wiring diagram .....................................LT-37

Radiator fan - See Cooling fan(QR20DE) .........CO-13

Radiator fan - See Cooling fan(YD22DDTi) .......CO-34

Radiator(QR20DE) ...............................CO-12,CO-15

Radiator(YD22DDTi) ............................CO-33,CO-36

Radio - See Audio ...............................................AV-3

Rear air spoiler ....................................................EI-21

Rear bumper ..........................................................EI-9

Rear cover packing replacement diff. ..............RFD-10

Rear disc brake .................................................BR-27

Rear door ..............................................................BL-8

Rear fog lamp .....................................................LT-37

Rear panel finisher ..............................................EI-22

Rear seat ...........................................................SE-11

Rear seat belt ......................................................SB-4

Rear side window ...............................................GW-5

Rear suspension ...............................................RSU-5

Rear washer ....................................................WW-13

Rear window defogger ........................................GW-9

Rear wiper .......................................................WW-13

Refrigerant connection precaution .....................ATC-5

Refrigerant discharging evacuating chargingATC-123

Refrigerant general precaution ..........................ATC-4

Refrigerant lines .............................................ATC-123

Refrigerant pressure sensorEC-359,EC-634,ATC-16,

ATC-80

,ATC-137

Refrigeration cycle ...........................................ATC-16

Release bearing (clutch) ....................................CL-13

Removal and installation (A/T) .........................AT-458

Removal and installation (Transfer) ...................TF-12

Reverse idler shaft (M/T) ......................MT-19,MT-24

Reverselampswitch(M/T)-SeeBack-uplampswitch

(M/T) ..................................................................MT-13

Reverse main gear (M/T) ......................MT-19,MT-24

Rocker cover(QR20DE) ....................................EM-31

Rocker cover(YD22DDTi) ...............................EM-147

Room lamp .........................................................LT-55

Room lamp - See Interior lamp ...........................LT-55

ROOM/L - Wiring diagram ..................................LT-55

RP/SEN - Wiring diagram ..................EC-360,EC-635

RRO2 - Wiring diagram ...................................EC-588

RRO2/H - Wiring diagram ................................EC-574

S

S/LOCK - Wiring diagram .......................BL-13

,BL-27

S/SIG - Wiring diagram .......EC-349,EC-624,EC-818

SCTC/V - Wiring diagram ................................EC-774

Seat belt inspection ..........................................MA-42

Seat belt pre-tensioner disposal .....................SRS-40

Seat belt, front .....................................................SB-3

Seat belt, rear ......................................................SB-4

Seat, front ............................................................SE-7

Seat, rear ...........................................................SE-11

Self-diagnosis (Transfer) ...................................TF-45

SHIFT - Wiring diagram ...................................AT-447

Shift control components (M/T) .............MT-21,MT-26

Shift fork (M/T) ......................................MT-21,MT-26

Shift lever ...........................................................MT-14

Shift lock system ..............................................AT-446

Shift schedule ..................................................AT-563

Shift solenoid valve A (A/T) ..AT-151,AT-156,AT-170

Shift solenoid valve B (A/T) ...............AT-151,AT-156

Side air bag (satellite) sensor .........................SRS-37

Side trim ..............................................................EI-26

Side window - See Rear side window .................GW-5

Spark plug replacement(QR20DE) ...................MA-25

Spark plug(QR20DE) ........................................EM-28

Specification value .............................EC-103,EC-449

Speedometer .............................................DI-4,DI-22

Spiral cable .....................................................SRS-31

Spot lamp ............................................................LT-65

SROOF - Wiring diagram .....................................RF-3