spark plugs NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 1171 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-57

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMH

INTRODUCTION

The engine has an ECM to control major systems suc NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-57

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMH

INTRODUCTION

The engine has an ECM to control major systems suc](/img/5/57402/w960_57402-1170.png)

TROUBLE DIAGNOSIS

EC-57

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMH

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no problems such as vac-

uum leaks, fouled spark plugs, or other problems with the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the “Work Flow” onEC-58

.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic Worksheet” like the exam-

ple onEC-61

should be used.

Start your diagnosis by looking for “conventional” problems first. This

will help troubleshoot driveability problems on an electronically con-

trolled engine vehicle.

MEF036D

SEF233G

SEF234G

Page 1208 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-94

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer toEC-40, "SYSTEM READINESS TEST (SRT) CODE".

SRT Work Support Mod NISSAN X-TRAIL 2003 Electronic Repair Manual EC-94

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer toEC-40, "SYSTEM READINESS TEST (SRT) CODE".

SRT Work Support Mod](/img/5/57402/w960_57402-1207.png)

EC-94

[QR (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

DTC & SRT CONFIRMATION MODE

SRT STATUS Mode

For details, refer toEC-40, "SYSTEM READINESS TEST (SRT) CODE".

SRT Work Support Mode

This mode enables a technician to drive a vehicle to set the SRT while monitoring the SRT status.

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION

lEngine: Return to the original

trouble condition

lChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lFuel injectors

lHeated oxygen sensor 1

IGNITION TIM-

ING

lEngine: Return to the original

trouble condition

lTiming light: Set

lRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lPerform “Idle Air Volume Learn-

ing”.

POWER BAL-

ANCE

lEngine: After warming up, idle

the engine.

lA/C switch “OFF”

lShift lever “N”

lCut off each injector signal one at

a time using CONSULT-II.Engine runs rough or dies.

lHarness and connectors

lCompression

lFuel injectors

lPower transistor

lSpark plugs

lIgnition coils

COOLING FAN

lIgnition switch: ON

lTurn the cooling fan “ON” and

“OFF” with CONSULT-II.Cooling fan moves and stops.

lHarness and connectors

lCooling fan relay

lCooling fan motor

ENG COOLANT

TEMP

lEngine: Return to the original

trouble condition

lChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lEngine coolant temperature sen-

sor

lFuel injectors

FUEL PUMP

RELAY

lIgnition switch: ON (Engine

stopped)

lTurn the fuel pump relay “ON”

and “OFF” using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.lHarness and connectors

lFuel pump relay

PURG VOL

CONT/V

lEngine: After warming up, run

engine at 1,500 rpm.

lChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according to

the opening percent.lHarness and connectors

lSolenoid valve

V/T ASSIGN

ANGLE

lEngine: Return to the original

trouble condition

lChange intake valve timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lIntake valve timing control sole-

noid valve

Page 1323 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-209

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK IGNITION SPARK

1. Disconnect ignition coil assembly from rocker NISSAN X-TRAIL 2003 Electronic Repair Manual DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-209

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK IGNITION SPARK

1. Disconnect ignition coil assembly from rocker](/img/5/57402/w960_57402-1322.png)

DTC P0300 - P0304 MULTIPLE CYLINDER MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

EC-209

[QR (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

5.CHECK IGNITION SPARK

1. Disconnect ignition coil assembly from rocker cover.

2. Connect a known good spark plug to the ignition coil assembly.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

OK or NG

OK >> GO TO 6.

NG >> Check ignition coil, power transistor and their circuits.

Refer toEC-334, "

IGNITION SIGNAL".

6.CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace spark plug(s) with standard type

one(s). For spark plug type, refer toMA-25, "

Checking

and Changing Spark Plugs".

7.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer toEM-52, "

CHECKING COMPRESSION PRESSURE".

OK or NG

OK >> GO TO 8.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

8.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer toEC-34, "

FUEL PRESSURE RELEASE".

3. Install fuel pressure gauge and check fuel pressure. Refer toEC-34, "

FUEL PRESSURE CHECK".

OK or NG

OK >> GO TO 9.

NG >> Follow the construction of "FUEL PRESSURE CHECK".

SEF575Q

SEF156I

Standard:

1,190 kPa (11.9 bar, 12.1 kg/cm2, 172 psi)/250

rpm

Minimum:

990 kPa (9.9 bar, 10.1 kg/cm

2, 144 psi)/250 rpm

Difference between each

cylinder:98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)/250 rpm

At idle: Approx. 350 kPa (3.5 bar, 3.7 kg/cm

2,51psi)

Page 1521 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-407

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMU

INTRODUCTION

The engine has an ECM to control major systems NISSAN X-TRAIL 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-407

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMU

INTRODUCTION

The engine has an ECM to control major systems](/img/5/57402/w960_57402-1520.png)

TROUBLE DIAGNOSIS

EC-407

[QR (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionEBS00BMU

INTRODUCTION

The engine has an ECM to control major systems such as fuel con-

trol, ignition control, idle air control system, etc. The ECM accepts

input signals from sensors and instantly drives actuators. It is essen-

tial that both input and output signals are proper and stable. At the

same time, it is important that there are no problems such as vac-

uum leaks, fouled spark plugs, or other problems with the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this case,

careful checking of suspected circuits may help prevent the replace-

ment of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the “Work Flow” onEC-408

.

Before undertaking actual checks, take a few minutes to talk with a

customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, especially

intermittent ones. Find out what symptoms are present and under

what conditions they occur. A “Diagnostic Worksheet” like the exam-

ple onEC-410

should be used.

Start your diagnosis by looking for “conventional” problems first. This

will help troubleshoot driveability problems on an electronically con-

trolled engine vehicle.

MEF036D

SEF233G

SEF234G

Page 1556 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual EC-442

[QR (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

Description

CONSULT-II has two kinds of triggers and they NISSAN X-TRAIL 2003 Electronic Repair Manual EC-442

[QR (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

Description

CONSULT-II has two kinds of triggers and they](/img/5/57402/w960_57402-1555.png)

EC-442

[QR (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

ACTIVE TEST MODE

Test Item

REAL TIME DIAGNOSIS IN DATA MONITOR MODE (RECORDING VEHICLE DATA)

Description

CONSULT-II has two kinds of triggers and they can be selected by

touching “SETTING” in “DATA MONITOR” mode.

1. “AUTO TRIG” (Automatic trigger):

–The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown at right, and the data after the malfunction detec-

tion is recorded. Then when the percentage reached 100%,

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJEC-

TION

lEngine: Return to the original

trouble condition

lChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lFuel injectors

lHeated oxygen sensor 1

IGNITION TIM-

ING

lEngine: Return to the original

trouble condition

lTiming light: Set

lRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lPerform “Idle Air Volume Learn-

ing”.

POWER BAL-

ANCE

lEngine: After warming up, idle

the engine.

lA/C switch “OFF”

lShift lever “N”

lCut off each injector signal one at

a time using CONSULT-II.Engine runs rough or dies.

lHarness and connectors

lCompression

lFuel injectors

lPower transistor

lSpark plugs

lIgnition coils

COOLING FAN

lIgnition switch: ON

lTurn the cooling fan “ON” and

“OFF” with CONSULT-II.Cooling fan moves and stops.

lHarness and connectors

lCooling fan relay

lCooling fan motor

ENG COOLANT

TEMP

lEngine: Return to the original

trouble condition

lChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lEngine coolant temperature sen-

sor

lFuel injectors

FUEL PUMP

RELAY

lIgnition switch: ON (Engine

stopped)

lTurn the fuel pump relay “ON”

and “OFF” using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.lHarness and connectors

lFuel pump relay

PURG VOL

CONT/V

lEngine: After warming up, run

engine at 1,500 rpm.

lChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according to

the opening percent.lHarness and connectors

lSolenoid valve

V/T ASSIGN

ANGLE

lEngine: Return to the original

trouble condition

lChange intake valve timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lIntake valve timing control sole-

noid valve

SEF706XSEF707X

Page 2493 of 3066

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTION

A

B

MA

MAINTENANCE

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

DESCRIPTION ............................................................ 4

Pre-delivery Inspection Items ................................... 4

GENERAL MAINTENANCE ....................................... 6

General Maintenance ............................................... 6

PERIODIC MAINTENANCE ....................................... 7

Periodic Maintenance ............................................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................. 7

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................... 7

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (QR20DE PETROL ENGINE) .................11

CHASSIS AND BODY MAINTENANCE

(QR20DE PETROL ENGINE) ............................. 12

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD22DDTI DIESEL ENGINE) .............. 13

CHASSIS AND BODY MAINTENANCE

(YD22DDTI DIESEL ENGINE) ............................ 14

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 15

RECOMMENDED FLUIDS AND LUBRICANTS ...... 17

Fluids and Lubricants ............................................. 17

SAE Viscosity Number ........................................... 18

GASOLINE ENGINE ........................................... 18

DISEL ENGINE ................................................... 18

Engine Coolant Mixture Ratio ................................ 19

ENGINE MAINTENANCE (QR20DE) ....................... 20

Checking Drive Belts .............................................. 20

Changing Engine Coolant ...................................... 20

DRAINING ENGINE COOLANT ......................... 20

REFILLING ENGINE COOLANT ........................ 21

FLUSHING COOLING SYSTEM ......................... 21Checking Cooling System ...................................... 22

CHECKING COOLING SYSTEM HOSES ........... 22

CHECKING RADIATOR ...................................... 22

CHECKING RADIATOR CAP ............................. 22

CHECKING COOLING SYSTEM FOR LEAKS ... 23

Checking Fuel Lines ............................................... 23

Changing Air Cleaner Filter .................................... 23

VISCOUS PAPER TYPE ..................................... 23

Changing Engine Oil ............................................... 24

Changing Oil Filter .................................................. 24

Checking and Changing Spark Plugs ..................... 25

Checking EVAP Vapor Lines .................................. 26

ENGINE MAINTENANCE (YD22DDTI) .................... 27

Checking Drive Belts .............................................. 27

Changing Engine Coolant ....................................... 27

DRAINING ENGINE COOLANT .......................... 27

REFILLING ENGINE COOLANT ......................... 28

FLUSHING COOLING SYSTEM ......................... 29

Checking Cooling System ...................................... 29

CHECKING COOLING SYSTEM HOSES ........... 29

CHECKING RADIATOR ...................................... 29

CHECKING RADIATOR CAP .............................. 29

CHECKING COOLING SYSTEM FOR LEAKS ... 30

Checking Fuel Lines ............................................... 30

Changing Fuel Filter ............................................... 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 31

Changing Air Cleaner Filter .................................... 31

VISCCOUS PAPER TYPE .................................. 31

Changing Engine Oil ............................................... 32

Changing Oil Filter .................................................. 33

REMOVAL ........................................................... 33

INSTALLATION ................................................... 34

Draining Water ........................................................ 34

CHASSIS AND BODY MAINTENANCE ................... 35

Checking Exhaust System ...................................... 35

Checking Clutch Fluid Level and Leaks ................. 35

Checking Clutch System ........................................ 35

Checking M/T Oil .................................................... 35

Changing M/T Oil .................................................... 35

Page 2499 of 3066

PERIODIC MAINTENANCE

MA-7

C

D

E

F

G

H

I

J

K

MA

B

MA

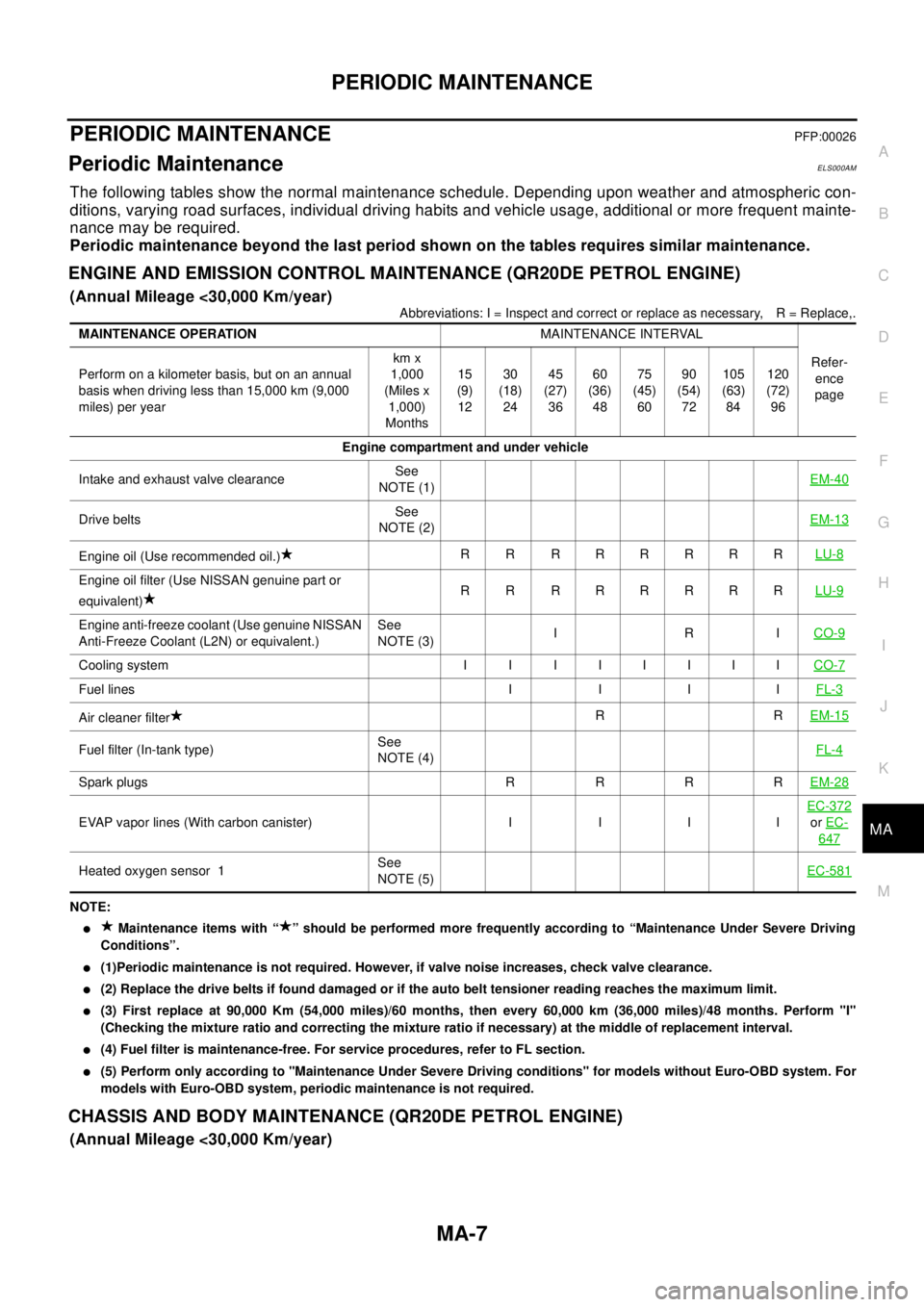

PERIODIC MAINTENANCEPFP:00026

Periodic MaintenanceELS000AM

The following tables show the normal maintenance schedule. Depending upon weather and atmospheric con-

ditions, varying road surfaces, individual driving habits and vehicle usage, additional or more frequent mainte-

nance may be required.

Periodic maintenance beyond the last period shown on the tables requires similar maintenance.

ENGINE AND EMISSION CONTROL MAINTENANCE (QR20DE PETROL ENGINE)

(Annual Mileage <30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace,.

NOTE:

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

l(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

l(2) Replace the drive belts if found damaged or if the auto belt tensioner reading reaches the maximum limit.

l(3) First replace at 90,000 Km (54,000 miles)/60 months, then every 60,000 km (36,000 miles)/48 months. Perform "I"

(Checking the mixture ratio and correcting the mixture ratio if necessary) at the middle of replacement interval.

l(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

l(5) Perform only according to "Maintenance Under Severe Driving conditions" for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (QR20DE PETROL ENGINE)

(Annual Mileage <30,000 Km/year)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual

basis when driving less than 15,000 km (9,000

miles) per yearkm x

1,000

(Miles x

1,000)

Months15

(9)

1230

(18)

2445

(27)

3660

(36)

4875

(45)

6090

(54)

72105

(63)

84120

(72)

96

Engine compartment and under vehicle

Intake and exhaust valve clearanceSee

NOTE (1)EM-40

Drive beltsSee

NOTE (2)EM-13

Engine oil (Use recommended oil.)R R RRRRRRLU-8

Engine oil filter (Use NISSAN genuine part or

equivalent)R R RRRRRRLU-9

Engine anti-freeze coolant (Use genuine NISSAN

Anti-Freeze Coolant (L2N) or equivalent.)See

NOTE (3)IRICO-9

Coolingsystem I I IIIIIICO-7

Fuel lines I I I IFL-3

Air cleaner filterRREM-15

Fuel filter (In-tank type)See

NOTE (4)FL-4

Spark plugs R R R REM-28

EVAP vapor lines (With carbon canister) I I I IEC-372orEC-

647

Heated oxygen sensor 1See

NOTE (5)EC-581

Page 2504 of 3066

MA-12

PERIODIC MAINTENANCE

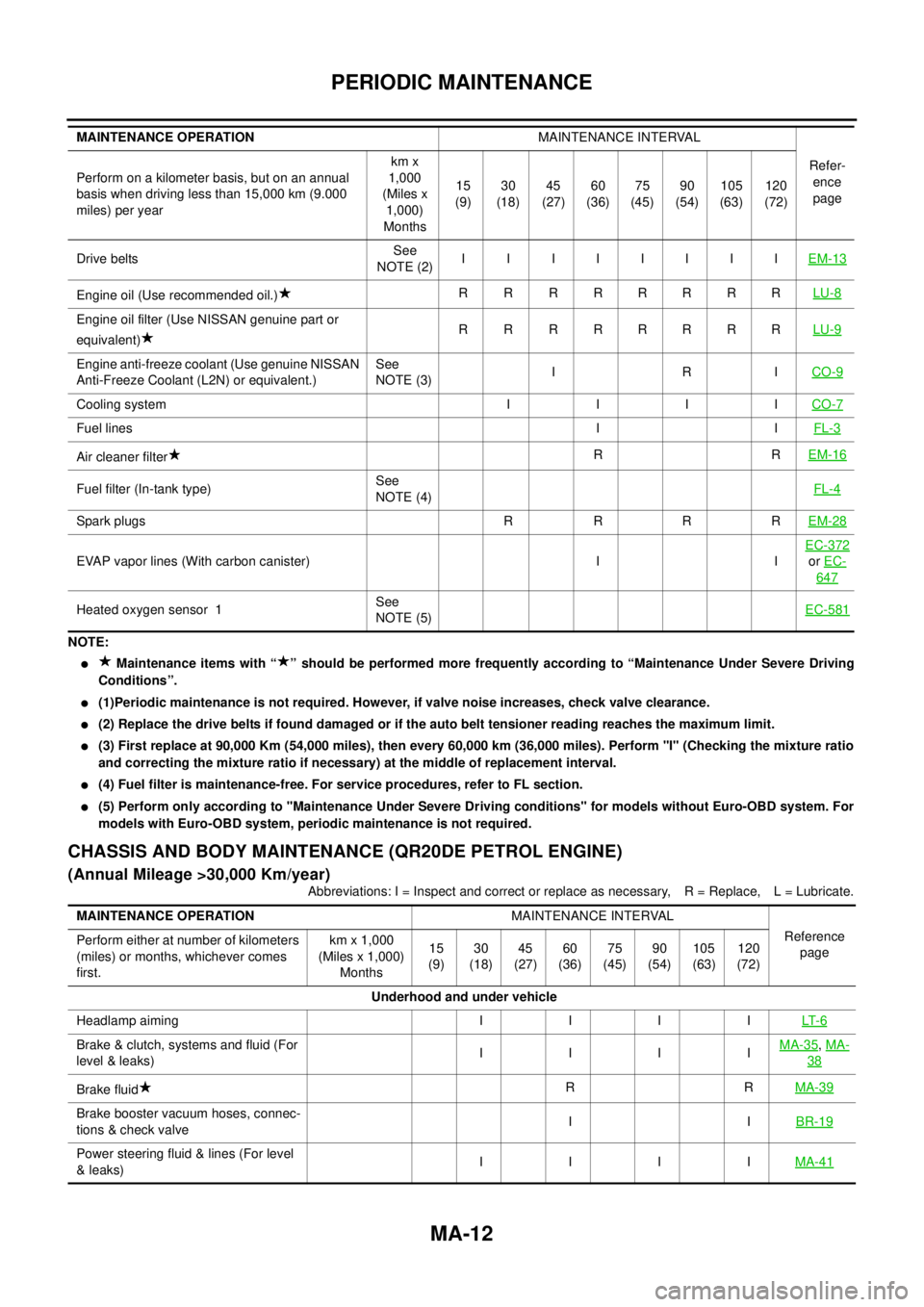

NOTE:

lMaintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving

Conditions”.

l(1)Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

l(2) Replace the drive belts if found damaged or if the auto belt tensioner reading reaches the maximum limit.

l(3) First replace at 90,000 Km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio

and correcting the mixture ratio if necessary) at the middle of replacement interval.

l(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

l(5) Perform only according to "Maintenance Under Severe Driving conditions" for models without Euro-OBD system. For

models with Euro-OBD system, periodic maintenance is not required.

CHASSIS AND BODY MAINTENANCE (QR20DE PETROL ENGINE)

(Annual Mileage >30,000 Km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate. Drive beltsSee

NOTE (2)IIIIIIIIEM-13

Engine oil (Use recommended oil.)R R RRRRRRLU-8

Engine oil filter (Use NISSAN genuine part or

equivalent)R R RRRRRRLU-9

Engine anti-freeze coolant (Use genuine NISSAN

Anti-Freeze Coolant (L2N) or equivalent.)See

NOTE (3)IRICO-9

Cooling system I I I ICO-7

Fuel linesIIFL-3

Air cleaner filterRREM-16

Fuel filter (In-tank type)See

NOTE (4)FL-4

Spark plugs R R R REM-28

EVAP vapor lines (With carbon canister) I IEC-372orEC-

647

Heated oxygen sensor 1See

NOTE (5)EC-581

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform on a kilometer basis, but on an annual

basis when driving less than 15,000 km (9.000

miles) per yearkm x

1,000

(Miles x

1,000)

Months15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform either at number of kilometers

(miles) or months, whichever comes

first.km x 1,000

(Miles x 1,000)

Months15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aiming I I I ILT- 6

Brake & clutch, systems and fluid (For

level & leaks)IIIIMA-35,MA-

38

Brake fluidRRMA-39

Brake booster vacuum hoses, connec-

tions & check valveIIBR-19

Power steering fluid & lines (For level

&leaks)IIIIMA-41

Page 2517 of 3066

ENGINE MAINTENANCE (QR20DE)

MA-25

C

D

E

F

G

H

I

J

K

MA

B

MA

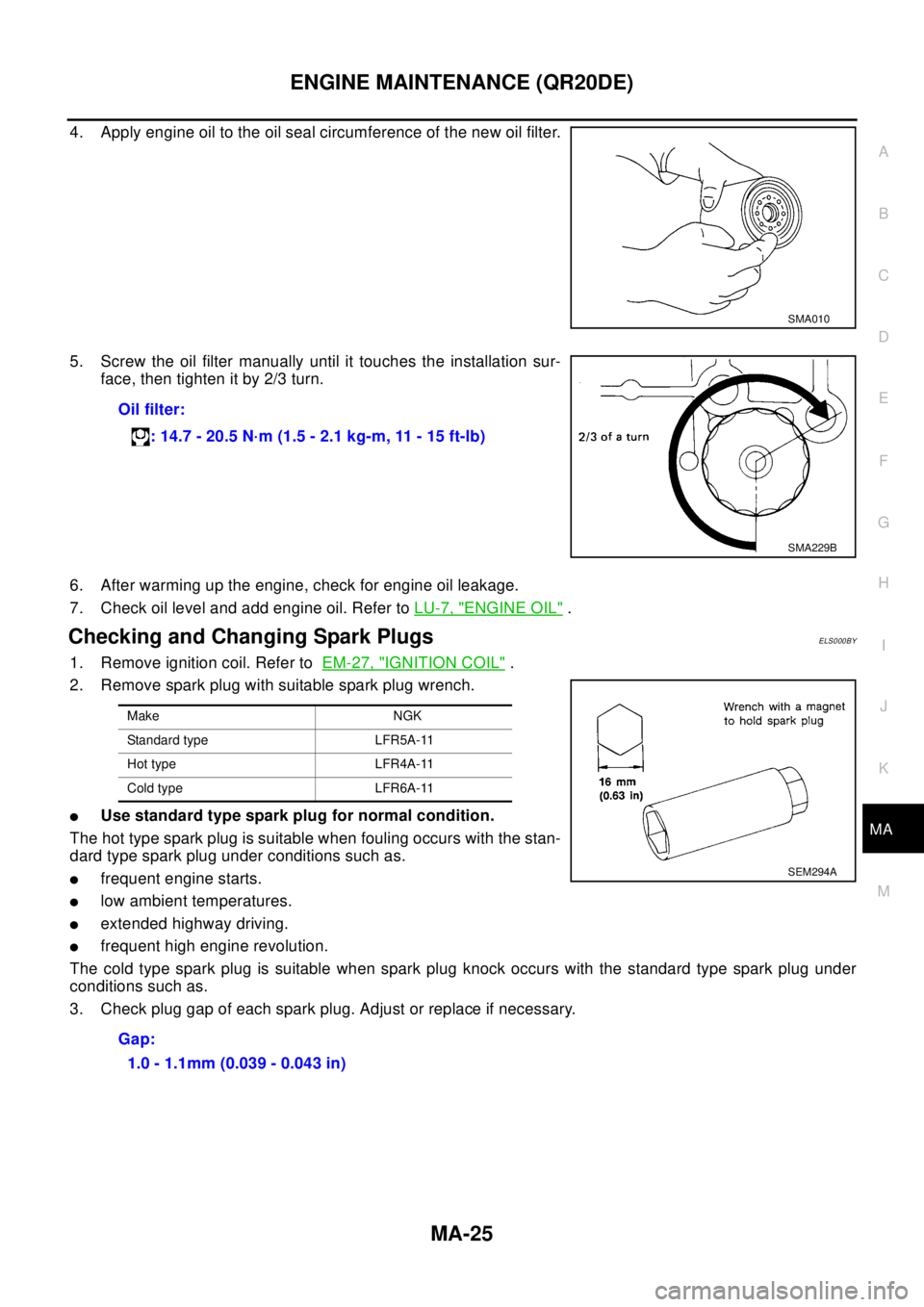

4. Apply engine oil to the oil seal circumference of the new oil filter.

5. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn.

6. After warming up the engine, check for engine oil leakage.

7. Check oil level and add engine oil. Refer toLU-7, "

ENGINE OIL".

Checking and Changing Spark PlugsELS000BY

1. Remove ignition coil. Refer toEM-27, "IGNITION COIL".

2. Remove spark plug with suitable spark plug wrench.

lUse standard type spark plug for normal condition.

The hot type spark plug is suitable when fouling occurs with the stan-

dard type spark plug under conditions such as.

lfrequent engine starts.

llow ambient temperatures.

lextended highway driving.

lfrequent high engine revolution.

The cold type spark plug is suitable when spark plug knock occurs with the standard type spark plug under

conditions such as.

3. Check plug gap of each spark plug. Adjust or replace if necessary.

SMA010

Oil filter:

: 14.7 - 20.5 N·m (1.5 - 2.1 kg-m, 11 - 15 ft-lb)

SMA229B

Make NGK

Standard type LFR5A-11

Hot type LFR4A-11

Cold type LFR6A-11

Gap:

1.0 - 1.1mm (0.039 - 0.043 in)

SEM294A