clock NISSAN X-TRAIL 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 28 of 3066

AT-22

OVERALL SYSTEM

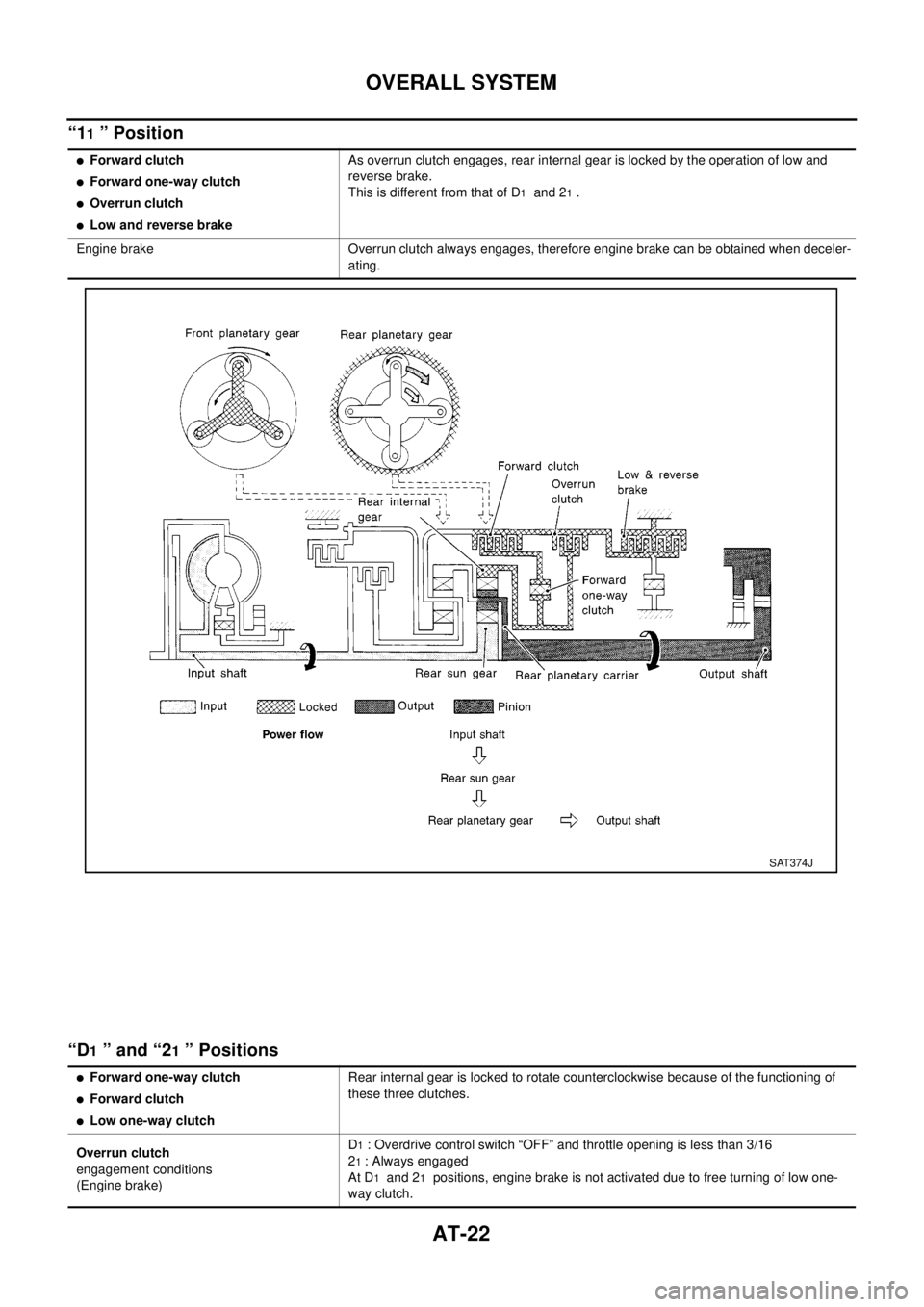

“11”Position

“D

1”and“21” Positions

lForward clutch

lForward one-way clutch

lOverrun clutch

lLow and reverse brakeAs overrun clutch engages, rear internal gear is locked by the operation of low and

reverse brake.

This is different from that of D

1and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when deceler-

ating.

SAT374J

lForward one-way clutch

lForward clutch

lLow one-way clutchRear internal gear is locked to rotate counterclockwise because of the functioning of

these three clutches.

Overrun clutch

engagement conditions

(Engine brake)D

1: Overdrive control switch “OFF” and throttle opening is less than 3/16

2

1: Always engaged

At D

1and 21positions, engine brake is not activated due to free turning of low one-

way clutch.

Page 472 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at le NISSAN X-TRAIL 2003 Electronic Repair Manual AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at le](/img/5/57402/w960_57402-471.png)

AT-466

[ALL]

DISASSEMBLY

DISASSEMBLY

PFP:31020

DisassemblyECS004LZ

1. Drain ATF through drain plug.

2. Remove torque converter.

3. Check torque converter one-way clutch using check tool as

shown at left.

a. Insert check tool into the groove of bearing support built into

one-way clutch outer race.

b. When fixing bearing support with check tool, rotate one- way

clutch spline using screwdriver.

c. Check that inner race rotates clockwise only. If not, replace

torque converter assembly.

4. Remove A/T fluid charging pipe and fluid cooler tube.

SAT008D

SAT009D

SAT768J

Page 587 of 3066

PRECAUTIONS

ATC-9

C

D

E

F

G

H

I

K

L

MA

B

AT C

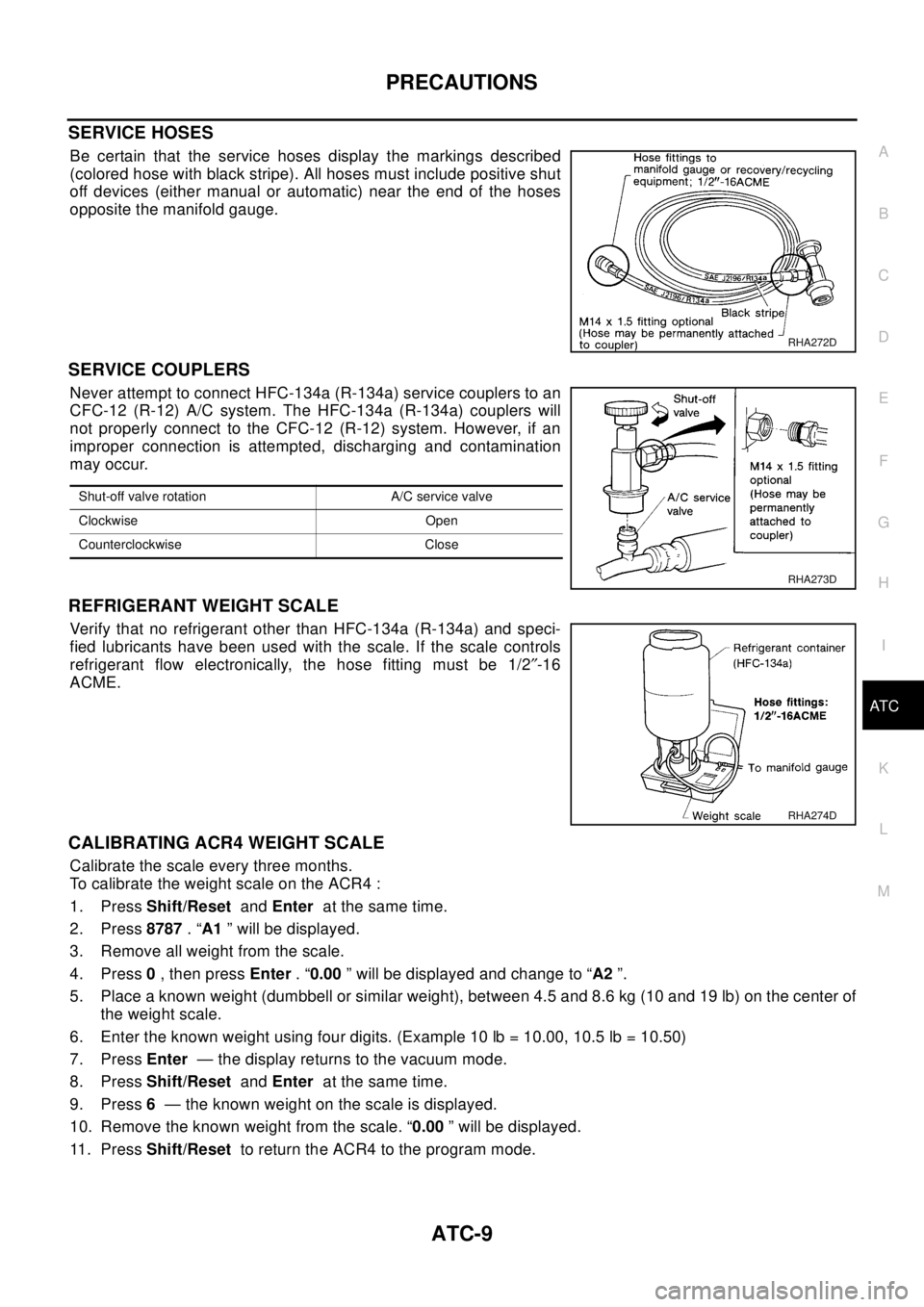

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to an

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale every three months.

To calibrate the weight scale on the ACR4 :

1. PressShift/ResetandEnterat the same time.

2. Press8787.“A1” will be displayed.

3. Remove all weight from the scale.

4. Press0,thenpressEnter.“0.00” will be displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb) on the center of

the weight scale.

6. Enter the known weight using four digits. (Example 10 lb = 10.00, 10.5 lb = 10.50)

7. PressEnter— the display returns to the vacuum mode.

8. PressShift/ResetandEnterat the same time.

9. Press6— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” will be displayed.

11 . P r e s sShift/Resetto return the ACR4 to the program mode.

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 622 of 3066

ATC-44

TROUBLE DIAGNOSIS

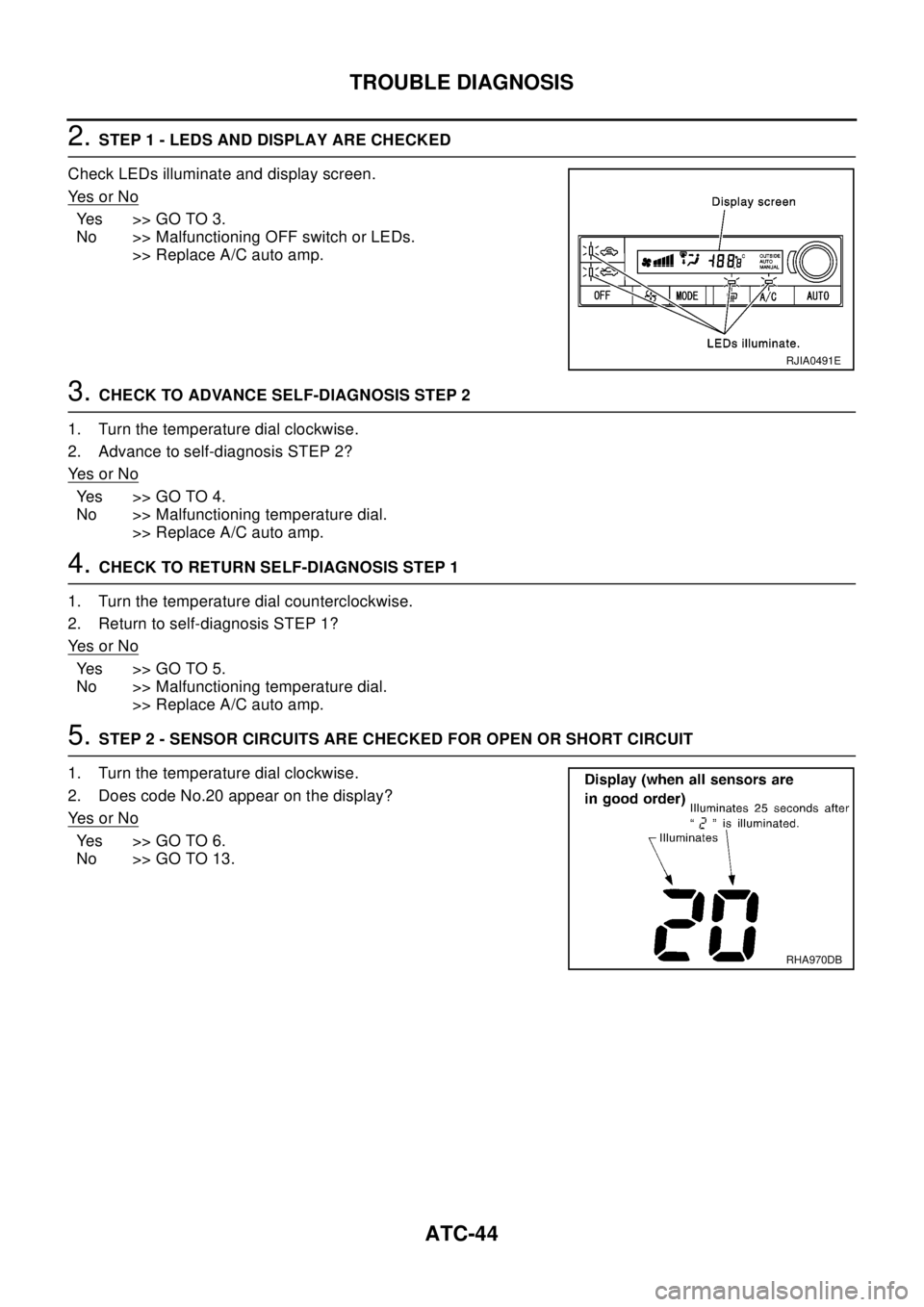

2.STEP 1 - LEDS AND DISPLAY ARE CHECKED

Check LEDs illuminate and display screen.

Ye s o r N o

Yes >>GOTO3.

No >> Malfunctioning OFF switch or LEDs.

>> Replace A/C auto amp.

3.CHECK TO ADVANCE SELF-DIAGNOSIS STEP 2

1. Turn the temperature dial clockwise.

2. Advance to self-diagnosis STEP 2?

Ye s o r N o

Yes >>GOTO4.

No >> Malfunctioning temperature dial.

>> Replace A/C auto amp.

4.CHECK TO RETURN SELF-DIAGNOSIS STEP 1

1. Turn the temperature dial counterclockwise.

2. Return to self-diagnosis STEP 1?

Ye s o r N o

Yes >>GOTO5.

No >> Malfunctioning temperature dial.

>> Replace A/C auto amp.

5.STEP 2 - SENSOR CIRCUITS ARE CHECKED FOR OPEN OR SHORT CIRCUIT

1. Turn the temperature dial clockwise.

2. Does code No.20 appear on the display?

Ye s o r N o

Yes >>GOTO6.

No >> GO TO 13.

RJIA0491E

RHA970DB

Page 623 of 3066

TROUBLE DIAGNOSIS

ATC-45

C

D

E

F

G

H

I

K

L

MA

B

AT C

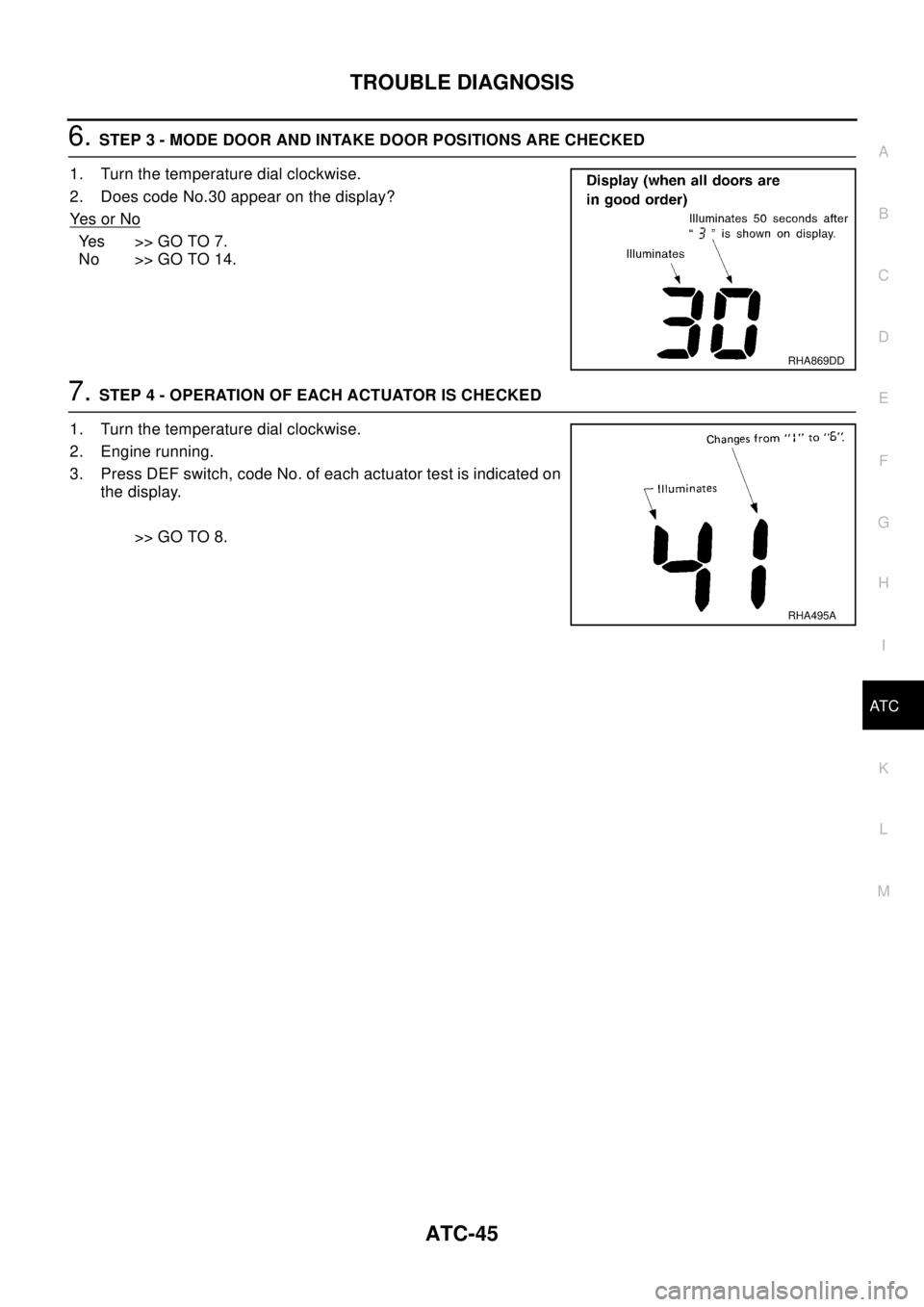

6.STEP 3 - MODE DOOR AND INTAKE DOOR POSITIONS ARE CHECKED

1. Turn the temperature dial clockwise.

2. Does code No.30 appear on the display?

Ye s o r N o

Yes >>GOTO7.

No >> GO TO 14.

7.STEP 4 - OPERATION OF EACH ACTUATOR IS CHECKED

1. Turn the temperature dial clockwise.

2. Engine running.

3. Press DEF switch, code No. of each actuator test is indicated on

the display.

>> GO TO 8.

RHA869DD

RHA495A

Page 624 of 3066

ATC-46

TROUBLE DIAGNOSIS

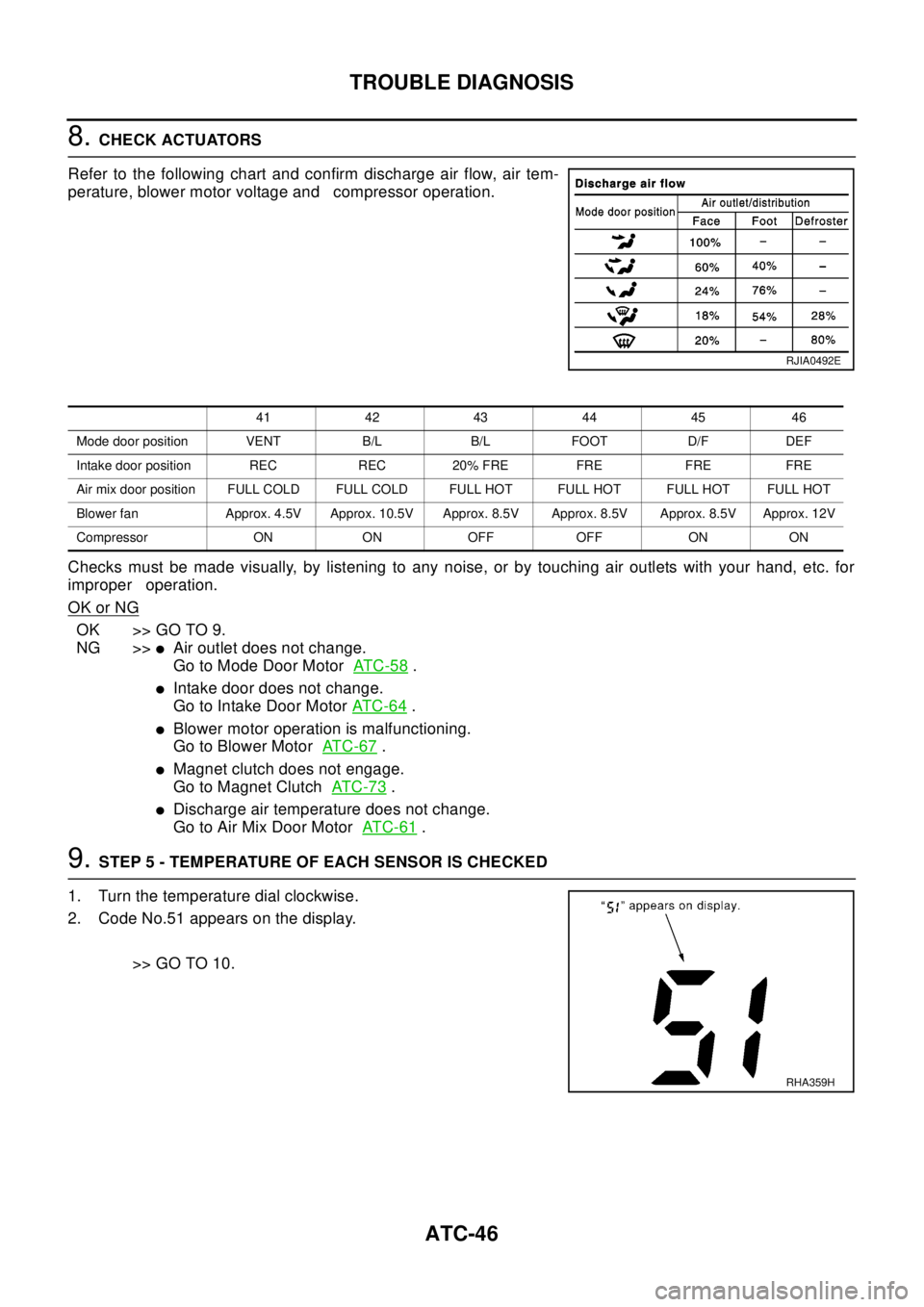

8.CHECK ACTUATORS

Refer to the following chart and confirm discharge air flow, air tem-

perature, blower motor voltage and compressor operation.

Checks must be made visually, by listening to any noise, or by touching air outlets with your hand, etc. for

improper operation.

OK or NG

OK >> GO TO 9.

NG >>

lAir outlet does not change.

Go to Mode Door MotorAT C - 5 8

.

lIntake door does not change.

Go to Intake Door MotorAT C - 6 4

.

lBlower motor operation is malfunctioning.

Go to Blower MotorAT C - 6 7

.

lMagnet clutch does not engage.

Go to Magnet ClutchAT C - 7 3

.

lDischarge air temperature does not change.

Go to Air Mix Door MotorAT C - 6 1

.

9.STEP 5 - TEMPERATURE OF EACH SENSOR IS CHECKED

1. Turn the temperature dial clockwise.

2. Code No.51 appears on the display.

>> GO TO 10.

RJIA0492E

41 42 43 44 45 46

Mode door position VENT B/L B/L FOOT D/F DEF

Intake door position REC REC 20% FRE FRE FRE FRE

Air mix door position FULL COLD FULL COLD FULL HOT FULL HOT FULL HOT FULL HOT

Blower fan Approx. 4.5V Approx. 10.5V Approx. 8.5V Approx. 8.5V Approx. 8.5V Approx. 12V

Compressor ON ON OFF OFF ON ON

RHA359H

Page 709 of 3066

REFRIGERANT LINES

ATC-131

C

D

E

F

G

H

I

K

L

MA

B

AT C

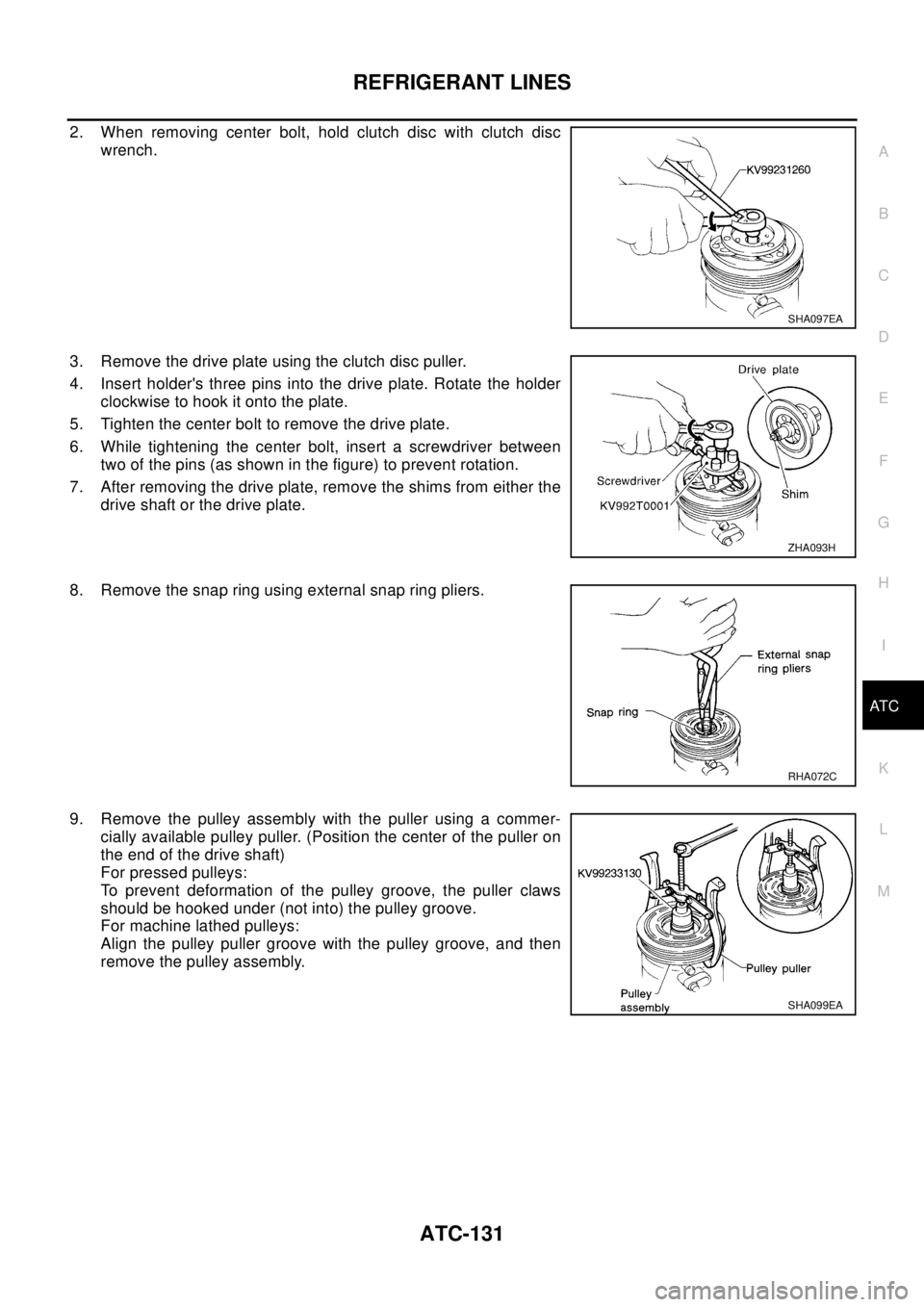

2. When removing center bolt, hold clutch disc with clutch disc

wrench.

3. Remove the drive plate using the clutch disc puller.

4. Insert holder's three pins into the drive plate. Rotate the holder

clockwise to hook it onto the plate.

5. Tighten the center bolt to remove the drive plate.

6. While tightening the center bolt, insert a screwdriver between

two of the pins (as shown in the figure) to prevent rotation.

7. After removing the drive plate, remove the shims from either the

drive shaft or the drive plate.

8. Remove the snap ring using external snap ring pliers.

9. Remove the pulley assembly with the puller using a commer-

cially available pulley puller. (Position the center of the puller on

the end of the drive shaft)

For pressed pulleys:

To prevent deformation of the pulley groove, the puller claws

should be hooked under (not into) the pulley groove.

For machine lathed pulleys:

Align the pulley puller groove with the pulley groove, and then

remove the pulley assembly.

SHA097EA

ZHA093H

RHA072C

SHA099EA

Page 722 of 3066

ATC-144

REFRIGERANT LINES

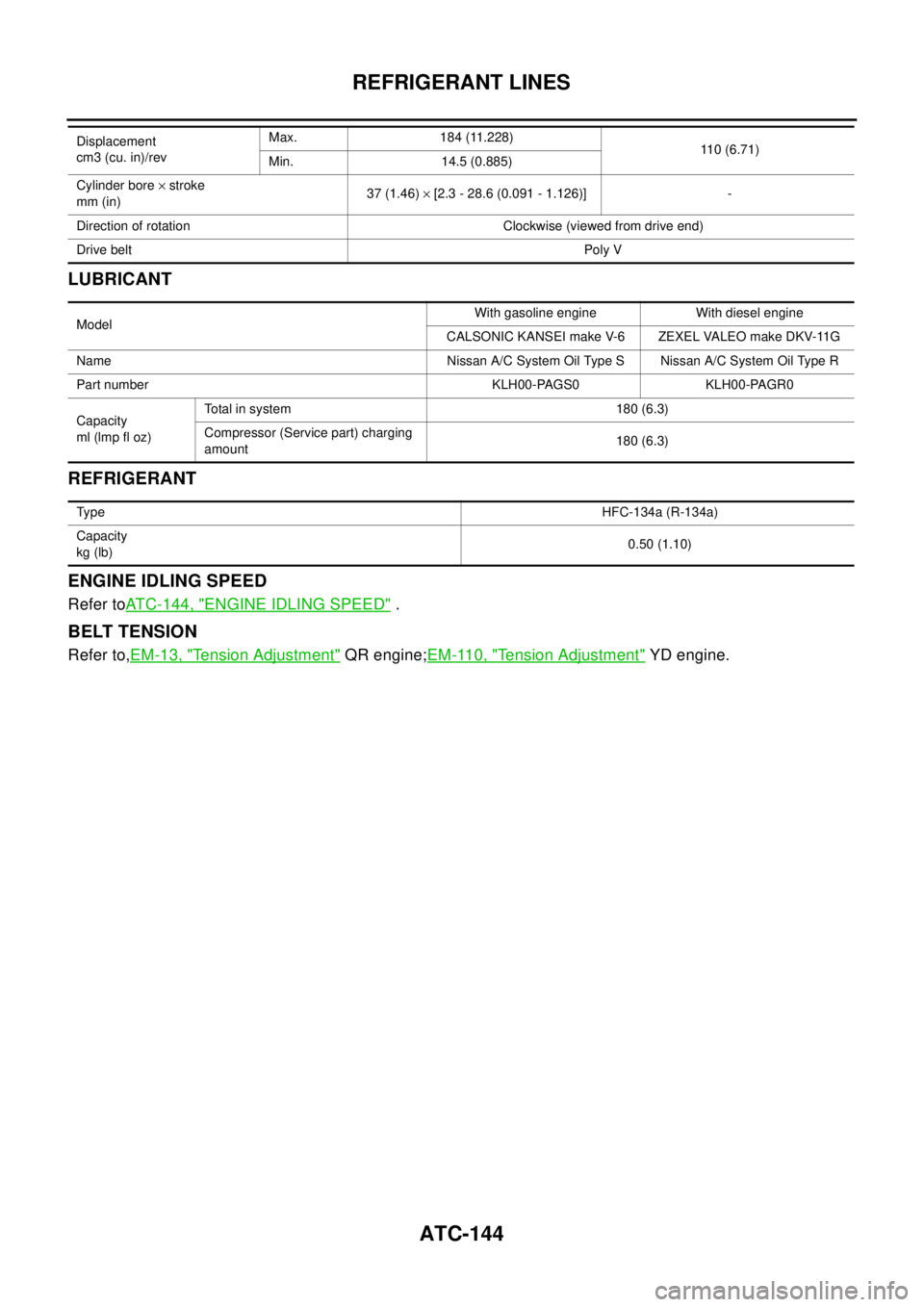

LUBRICANT

REFRIGERANT

ENGINE IDLING SPEED

Refer toATC-144, "ENGINE IDLING SPEED".

BELT TENSION

Refer to,EM-13, "Tension Adjustment"QR engine;EM-110, "Tension Adjustment"YD engine.

Displacement

cm3 (cu. in)/revMax. 184 (11.228)

110 (6.71)

Min. 14.5 (0.885)

Cylinder bore´stroke

mm (in)37 (1.46)´[2.3 - 28.6 (0.091 - 1.126)] -

Direction of rotation Clockwise (viewed from drive end)

Drive beltPoly V

ModelWith gasoline engine With diesel engine

CALSONIC KANSEI make V-6 ZEXEL VALEO make DKV-11G

Name Nissan A/C System Oil Type S Nissan A/C System Oil Type R

Part number KLH00-PAGS0 KLH00-PAGR0

Capacity

ml (lmp fl oz)Total in system 180 (6.3)

Compressor (Service part) charging

amount180 (6.3)

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.50 (1.10)

Page 841 of 3066

BRAKE PEDAL

BR-7

C

D

E

G

H

I

J

K

L

MA

B

BR

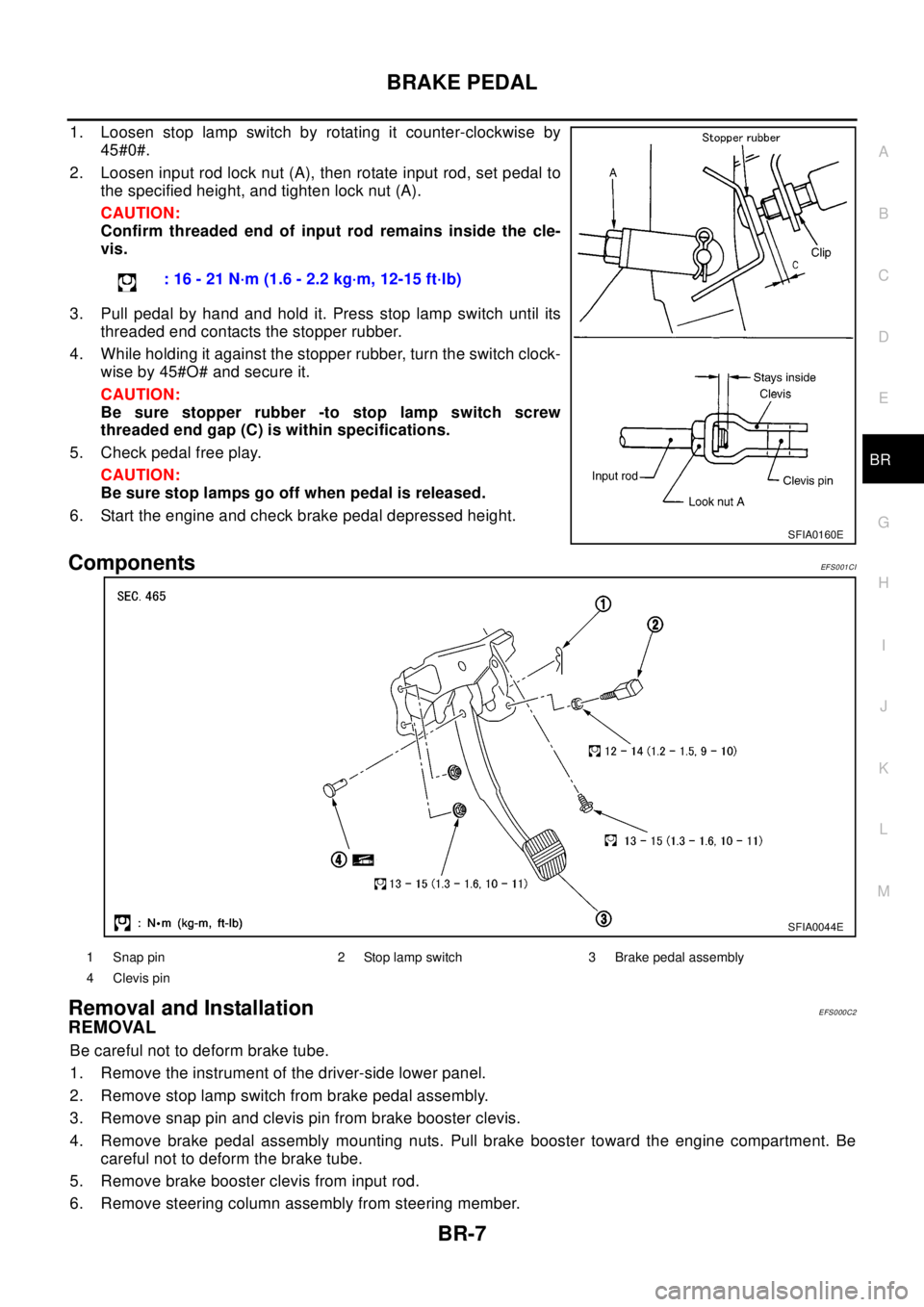

1. Loosen stop lamp switch by rotating it counter-clockwise by

45#0#.

2. Loosen input rod lock nut (A), then rotate input rod, set pedal to

the specified height, and tighten lock nut (A).

CAUTION:

Confirm threaded end of input rod remains inside the cle-

vis.

3. Pull pedal by hand and hold it. Press stop lamp switch until its

threaded end contacts the stopper rubber.

4. While holding it against the stopper rubber, turn the switch clock-

wise by 45#O# and secure it.

CAUTION:

Be sure stopper rubber -to stop lamp switch screw

threaded end gap (C) is within specifications.

5. Check pedal free play.

CAUTION:

Be sure stop lamps go off when pedal is released.

6. Start the engine and check brake pedal depressed height.

ComponentsEF S0 01 CI

Removal and InstallationEFS000C2

REMOVAL

Be careful not to deform brake tube.

1. Remove the instrument of the driver-side lower panel.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from brake booster clevis.

4. Remove brake pedal assembly mounting nuts. Pull brake booster toward the engine compartment. Be

careful not to deform the brake tube.

5. Remove brake booster clevis from input rod.

6. Remove steering column assembly from steering member.: 16 - 21 N·m (1.6 - 2.2 kg·m, 12-15 ft·lb)

SFIA0160E

SFIA0044E

1 Snap pin 2 Stop lamp switch 3 Brake pedal assembly

4 Clevis pin

Page 924 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-56

[ESP/TCS/ABS]

GENERAL INFORMATION

GENERAL INFORMATION

PFP:00000

Fail-SafeEFS0019S

ABS SYSTEM

If a malfunction occurs in the electrical system, the ABS warning lamp, ESP OFF indicator lamp, and NISSAN X-TRAIL 2003 Electronic Repair Manual BRC-56

[ESP/TCS/ABS]

GENERAL INFORMATION

GENERAL INFORMATION

PFP:00000

Fail-SafeEFS0019S

ABS SYSTEM

If a malfunction occurs in the electrical system, the ABS warning lamp, ESP OFF indicator lamp, and](/img/5/57402/w960_57402-923.png)

BRC-56

[ESP/TCS/ABS]

GENERAL INFORMATION

GENERAL INFORMATION

PFP:00000

Fail-SafeEFS0019S

ABS SYSTEM

If a malfunction occurs in the electrical system, the ABS warning lamp, ESP OFF indicator lamp, and SLIP

indicator lamp in the meter will turn ON. In this condition, the ESP/TCS/ABS and EBD become one of the fol-

lowing conditions by the fail-safe function.

1. Only EBD operates. The same condition as that of models without ESP/TCS/ABS

2. ESP/TCS/ABS and EBD do not operate. Only normal brake operates on 4 wheels.

NOTE:

In the step 1 shown above, the self-diagnosis is carried out at the ignition switch is turned ON and when the

vehicle initial starts. ABS self-diagnosis noise may be heard as usual.

ESP/TCS SYSTEM

If a malfunction occurs in the electrical system, the ESP OFF indicator lamp and SLIP indicator lamp in the

meter turn on. In this condition, ESP/TCS will be deactivated and it becomes equal to that of models without

ESP/TCS. However, ABS is controlled normally.

If a malfunction occurs in the throttle control system, ESP/TCS control does not operate. Only ABS control

operates normally.

CAUTION:

If the fail-safe function operates, carry out the self-diagnosis for ESP/TCS/ABS control system.

Hydraulic CircuitEFS0019T

CAUTION:

lWhen installing, check for twist and fracture.

lMake sure that there is no interference with other parts when turning the steering clockwise or

counter clockwise.

lThe brake piping is an important safety part. If a brake fluid leak is detected, always disassemble

and replace with a new one, if necessary.

ABS FunctionsEFS0019U

1. In cases of braking suddenly or braking on slippery road (ice road), ABS functions prevent wheels from

lock, improve the stability in sudden braking, and make efficient avoidance of obstacles with steering

manipulation by detecting 4-wheel speed and controlling 4-wheel brake fluid pressure.

2. EBD is integrated in ESP/TCS/ABS system.

CAUTION:

lDuring ABS operation, the brake pedal lightly vibrates and its mechanical noise may be heard.

This is a normal condition.

SFIA0346E