air condition NISSAN XTERRA 2001 WD22 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: XTERRA, Model: NISSAN XTERRA 2001 WD22 / 1.GPages: 263, PDF Size: 2.25 MB

Page 217 of 263

for smooth operation and make sure it has

the proper distance under it when de-

pressed fully. Check the brake booster func-

tion. Be certain to keep the floor mat away

from the pedal.

Parking brake*Check that the lever has

the proper travel and confirm that your

vehicle is held securely on a fairly steep hill

with only the parking brake applied.

Automatic transmission P (Park) posi-

tion mechanismCheck that the lock re-

lease button on the selector lever operates

properly and smoothly. On a fairly steep hill

check that your vehicle is held securely with

the selector lever in the P position without

applying any brakes.

Under the hood and vehicle

The maintenance items listed here should

be checked periodically (e.g., each time you

check the engine oil or refuel).

Additional information on the following

items with an ``*'' is found in the ``Do-it-

yourself operations'' section.

Windshield washer fluid*Check that there

is adequate fluid in the reservoir.

Engine oil level*Check the level afterparking the vehicle on a level surface with

the engine off. Wait a few minutes for the oil

to drain back into the oil pan.

Brake and clutch fluid levels*Make sure

that the brake and clutch fluid level is be-

tween the MIN and MAX lines on the reser-

voir.

Power steering fluid level* and lines

Check the level when the fluid is cold, with

the engine off. Check the lines for proper

attachment, leaks, cracks, etc.

Automatic transmission fluid level*

Check the level after putting the selector

lever in P with the engine idling at operating

temperature.

Engine coolant level*Check the coolant

level when the engine is cold.

Radiator and hosesCheck the front of the

radiator and clean off any dirt, insects,

leaves, etc., that may have accumulated.

Make sure the hoses have no cracks, de-

formation, rot or loose connections.

Engine drive belts*Make sure the drive

belts are not frayed, worn, cracked or oily.

Battery*Check the fluid level in each cell. It

should be between the MAX and MIN lines.Exhaust systemMake sure there are no

loose supports, cracks or holes. If the sound

of the exhaust seems unusual or there is a

smell of exhaust fumes, immediately have

the exhaust system inspected by an autho-

rized NISSAN dealer. See the carbon mon-

oxide warning in the ``Starting and driving''

section of this manual.

UnderbodyThe underbody is frequently

exposed to corrosive substances such as

those used on icy roads or to control dust. It

is very important to remove these sub-

stances from the underbody, otherwise rust

may form on the floor pan, frame, fuel lines

and exhaust system. At the end of winter,

the underbody should be thoroughly flushed

with plain water, in those areas where mud

and dirt may have accumulated. See the

``Appearance and care'' section of this

manual.

Fluid leaksCheck under the vehicle for

fuel, oil, water or other fluid leaks after the

vehicle has been parked for a while. Water

dripping from the air conditioner after use is

normal. If you should notice any leaks or if

gasoline fumes are evident, check for the

cause and have it corrected immediately.

9-4Maintenance

ZX

Page 219 of 263

![NISSAN XTERRA 2001 WD22 / 1.G Workshop Manual Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers NISSAN XTERRA 2001 WD22 / 1.G Workshop Manual Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers](/img/5/650/w960_650-218.png)

Schedule 1

Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles ý 1,000 3.75 7.5 11.25 15 18.75 22.526.25 30 33.75 37.541.25 45 48.75 52.556.25 60

(km ý 1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

Emission control system maintenance

Drive beltsI* I*

Air cleaner filter See NOTE (1) [R] [R]

Positive crankcase ventilation (PCV) filter

(KA24DE only)See NOTE (2) [R] [R]

EVAP vapor linesI* I*

Fuel linesI* I*

Fuel filter See NOTE (2)*

Engine coolant See NOTE (3)R*

Engine oilRRRRRRRRRRRRRRRR

Engine oil filterRRRRRRRRRRRRRRRR

Spark plugs (Use PLATINUM-TIPPED type) Replace every 105,000 miles (169,000 km)

Intake and exhaust valve clearance (KA24DE only) See NOTE (4)*

Timing belt (VG33E only) Replace every 105,000 miles (169,000 km)

NOTE: (1) If operating mainly in dusty conditions, more frequent maintenance may be required.

(2) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event, replace the filter.

(3) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(4) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with an ``*'' are recommended by NISSAN for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals

are required.

9-6Maintenance

ZX

Page 223 of 263

Maintenance for off-road driving

(

only)

Whenever you drive off-road through sand,

mud or water as deep as the wheel hub,

more frequent maintenance may be re-

quired of the following items:

¶Brake pads and rotors

¶Brake linings and drums

¶Brake lines and hoses

¶Wheel bearing grease and free-running

hub grease

¶Differential, transmission and transfer oil

¶Steering linkage

¶Propeller shafts and front drive shafts

¶Air cleaner filter

These items should be checked frequently

to assure safe and proper operation of your

vehicle.

EXPLANATION OF

MAINTENANCE ITEMS

Additional information on the following

items with an ``*'' is found in the ``Do-it-

yourself'' section of this manual.

Emission control system

maintenance

Drive belts*Check drive belts for wear,

fraying or cracking and also for proper ten-

sion. Replace any damaged drive belts.

Air cleaner filterUnder normal driving con-

ditions, the air cleaner filter should be re-

placed in accordance with the maintenance

schedule. However, driving the vehicle in

dusty areas may cause rapid clogging of the

element. Consequently, the element may

have to be replaced more frequently.

Positive crankcase ventilation (PCV) fil-

terUnder normal driving conditions, the

filter should be replaced in accordance with

the maintenance schedule. If the vehicle is

operated under extremely adverse weather

conditions or in areas where ambient tem-

peratures are either extremely low or ex-

tremely high, the filter may become clogged

more rapidly. In such an event, replace the

filter immediately.

EVAP Vapor linesCheck vapor lines and

connections for leaks, looseness, or dete-

rioration. If leaks are found, replace the

lines.

Fuel linesCheck the fuel hoses, piping andconnections for leaks, looseness or deterio-

ration. Replace any damaged parts.

Fuel filterIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are ei-

ther extremely low or extremely high, the

filter might become clogged. In such an

event, replace the filter immediately.

Engine coolant*Flush and refill the cooling

system.

Engine oil and oil filter*Under normal

driving conditions, the engine oil and oil filter

should be replaced in accordance with the

maintenance schedule. However, under se-

vere driving conditions, they may have to be

replaced more frequently.

Spark plugs*Replace with new plugs hav-

ing the correct heat range.

Chassis and body maintenance

Brake lines and cablesCheck the brake

lines and hoses (including brake booster

vacuum hoses, connections & check valve)

and parking brake cables for proper attach-

ment, leaks, cracks, chafing, abrasion, de-

terioration, etc.

9-10Maintenance

ZX

Page 224 of 263

Brake pads, rotors, drums and linings

Check these and the other brake compo-

nents for wear, deterioration and leaks. Un-

der severe driving conditions, they may have

to be inspected more frequently.

Manual and automatic transmission,

transfer and differential gear oilVisually

inspect for signs of leakage and replace oil

for limited-slip differential. Under severe

driving conditions, the oil should be re-

placed at the specified interval.

Steering gear and linkage, axle and sus-

pension parts and drive shaft boots

Check for damage, looseness and leakage

of oil or grease. Under severe driving con-

ditions, they may have to be inspected more

frequently.

Propeller shaft(s)Check the propeller

shaft(s) for damage, looseness and grease

leakage under severe driving conditions

(

only).

Front wheel bearing grease and free-

running hub greaseCheck the wheel

bearing for grease leakage around grease

seals, axial end play and smooth turning.

Repack these in accordance with the main-

tenance schedule (4x2).Check the wheel bearing and free-running

hub for grease leakage around grease

seals, axial end play and smooth turning.

Repack these in accordance with the main-

tenance schedule. In case of frequent driv-

ing in muddy water, the bearing grease and

free-running hub grease inspection should

be performed more frequently (

).

Exhaust systemVisually check the ex-

haust pipes, muffler, and hangers for proper

attachment, leaks, cracks, chafing, abra-

sion, deterioration, etc. Under severe driv-

ing conditions, inspection should be per-

formed more frequently.

Supplemental air bag systemCheck the

supplemental air bag system components

for proper attachment, damage, deformities,

cracks, rust, etc. Work around and on the

supplemental air bag system should be

done by an authorized NISSAN dealer.

Maintenance

9-11

ZX

Page 226 of 263

10 Technical and consumer information

Capacities and recommended fuel/lubricants ......10-2

Fuel recommendation ......................................10-4

Engine oil and oil filter recommendation .........10-6

Recommended SAE viscosity number ............10-7

Air conditioner system refrigerant and

lubricant recommendations .............................10-8

Specifications .......................................................10-9

Engine .............................................................10-9

Wheels and tires............................................10-10

Dimensions and weights ............................... 10-11

When traveling or registering your vehicle in

another country ..................................................10-12

Vehicle identification ...........................................10-12

Vehicle identification number (VIN) plate ......10-12

Vehicle identification number

(chassis number) ...........................................10-12

Engine serial number ....................................10-13

F.M.V.S.S. certification label ..........................10-13

Emission control information label ................10-14

Tire placard....................................................10-14

Air conditioner specification label ..................10-14Installing front license plate................................10-15

Vehicle loading information ................................10-15

Terms .............................................................10-15

Determining vehicle load capacity.................10-16

Securing the load ..........................................10-16

Loading tips ...................................................10-17

Payload weight ratings ..................................10-18

Measurement of weights ...............................10-19

Towing a trailer ...................................................10-19

Maximum load limits ......................................10-19

Towing load/specification chart .....................10-21

Towing safety .................................................10-22

Trailer tow harness and module

(if so equipped)..............................................10-23

Uniform tire quality grading ................................10-25

Emission control system warranty .....................10-26

Reporting safety defects (US only) ....................10-27

Readiness for inspection/maintenance (I/M)

test (US only) .....................................................10-27

In the event of a collision ..............................10-30

ZX

Page 228 of 263

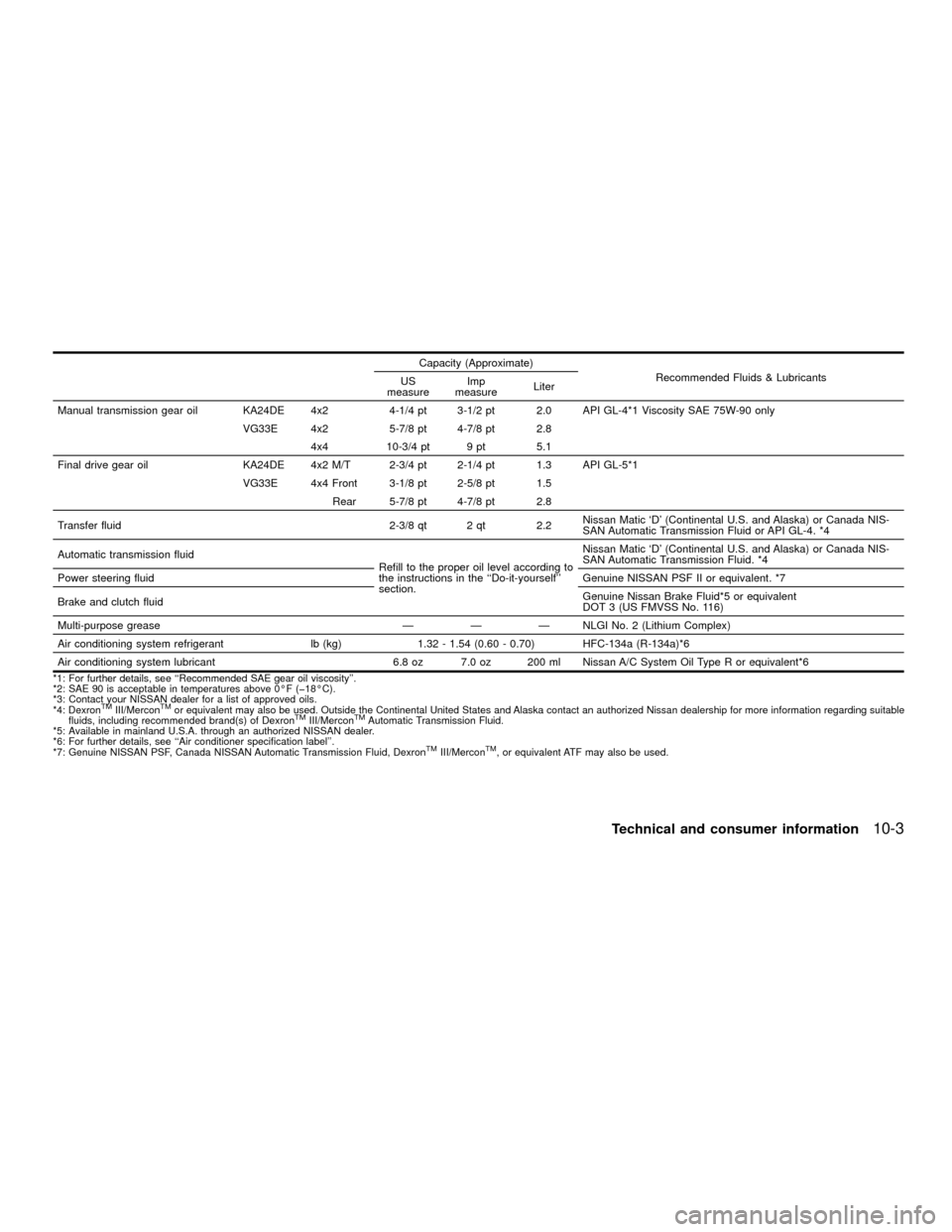

Capacity (Approximate)

Recommended Fluids & Lubricants

US

measureImp

measureLiter

Manual transmission gear oil KA24DE 4x2 4-1/4 pt 3-1/2 pt 2.0 API GL-4*1 Viscosity SAE 75W-90 only

VG33E 4x2 5-7/8 pt 4-7/8 pt 2.8

4x4 10-3/4 pt 9 pt 5.1

Final drive gear oil KA24DE 4x2 M/T 2-3/4 pt 2-1/4 pt 1.3 API GL-5*1

VG33E 4x4 Front 3-1/8 pt 2-5/8 pt 1.5

Rear 5-7/8 pt 4-7/8 pt 2.8

Transfer fluid 2-3/8 qt 2 qt 2.2Nissan Matic `D' (Continental U.S. and Alaska) or Canada NIS-

SAN Automatic Transmission Fluid or API GL-4. *4

Automatic transmission fluid

Refill to the proper oil level according to

the instructions in the ``Do-it-yourself''

section.Nissan Matic `D' (Continental U.S. and Alaska) or Canada NIS-

SAN Automatic Transmission Fluid. *4

Power steering fluidGenuine NISSAN PSF II or equivalent. *7

Brake and clutch fluidGenuine Nissan Brake Fluid*5 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium Complex)

Air conditioning system refrigerant lb (kg) 1.32 - 1.54 (0.60 - 0.70) HFC-134a (R-134a)*6

Air conditioning system lubricant 6.8 oz 7.0 oz 200 ml Nissan A/C System Oil Type R or equivalent*6

*1: For further details, see ``Recommended SAE gear oil viscosity''.

*2: SAE 90 is acceptable in temperatures above 0ÉF (þ18ÉC).

*3: Contact your NISSAN dealer for a list of approved oils.

*4: Dexron

TMIII/MerconTMor equivalent may also be used. Outside the Continental United States and Alaska contact an authorized Nissan dealership for more information regarding suitable

fluids, including recommended brand(s) of DexronTMIII/MerconTMAutomatic Transmission Fluid.

*5: Available in mainland U.S.A. through an authorized NISSAN dealer.

*6: For further details, see ``Air conditioner specification label''.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, Dexron

TMIII/MerconTM, or equivalent ATF may also be used.

Technical and consumer information10-3

ZX

Page 233 of 263

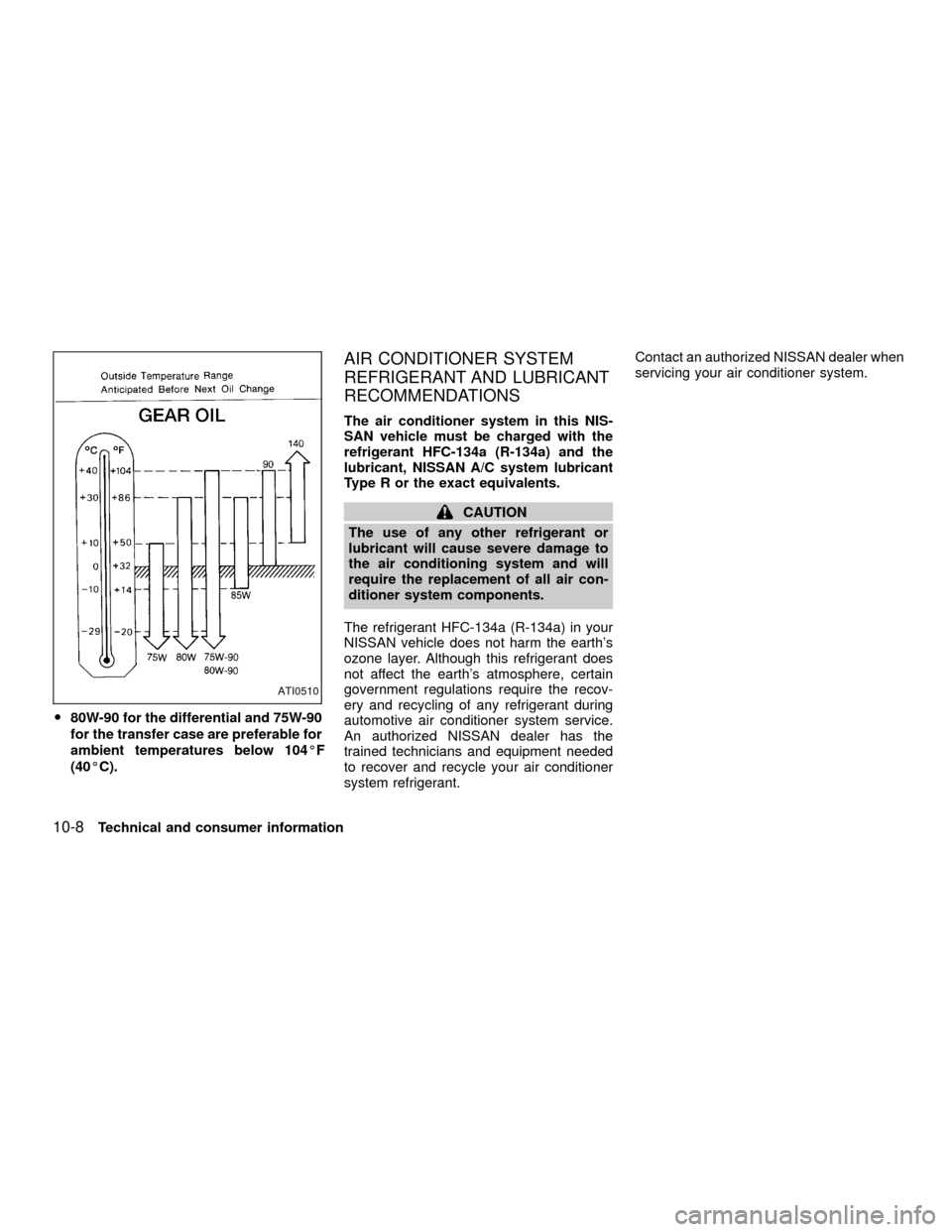

O80W-90 for the differential and 75W-90

for the transfer case are preferable for

ambient temperatures below 104ÉF

(40ÉC).

AIR CONDITIONER SYSTEM

REFRIGERANT AND LUBRICANT

RECOMMENDATIONS

The air conditioner system in this NIS-

SAN vehicle must be charged with the

refrigerant HFC-134a (R-134a) and the

lubricant, NISSAN A/C system lubricant

Type R or the exact equivalents.

CAUTION

The use of any other refrigerant or

lubricant will cause severe damage to

the air conditioning system and will

require the replacement of all air con-

ditioner system components.

The refrigerant HFC-134a (R-134a) in your

NISSAN vehicle does not harm the earth's

ozone layer. Although this refrigerant does

not affect the earth's atmosphere, certain

government regulations require the recov-

ery and recycling of any refrigerant during

automotive air conditioner system service.

An authorized NISSAN dealer has the

trained technicians and equipment needed

to recover and recycle your air conditioner

system refrigerant.Contact an authorized NISSAN dealer when

servicing your air conditioner system.

ATI0510

10-8Technical and consumer information

ZX

Page 239 of 263

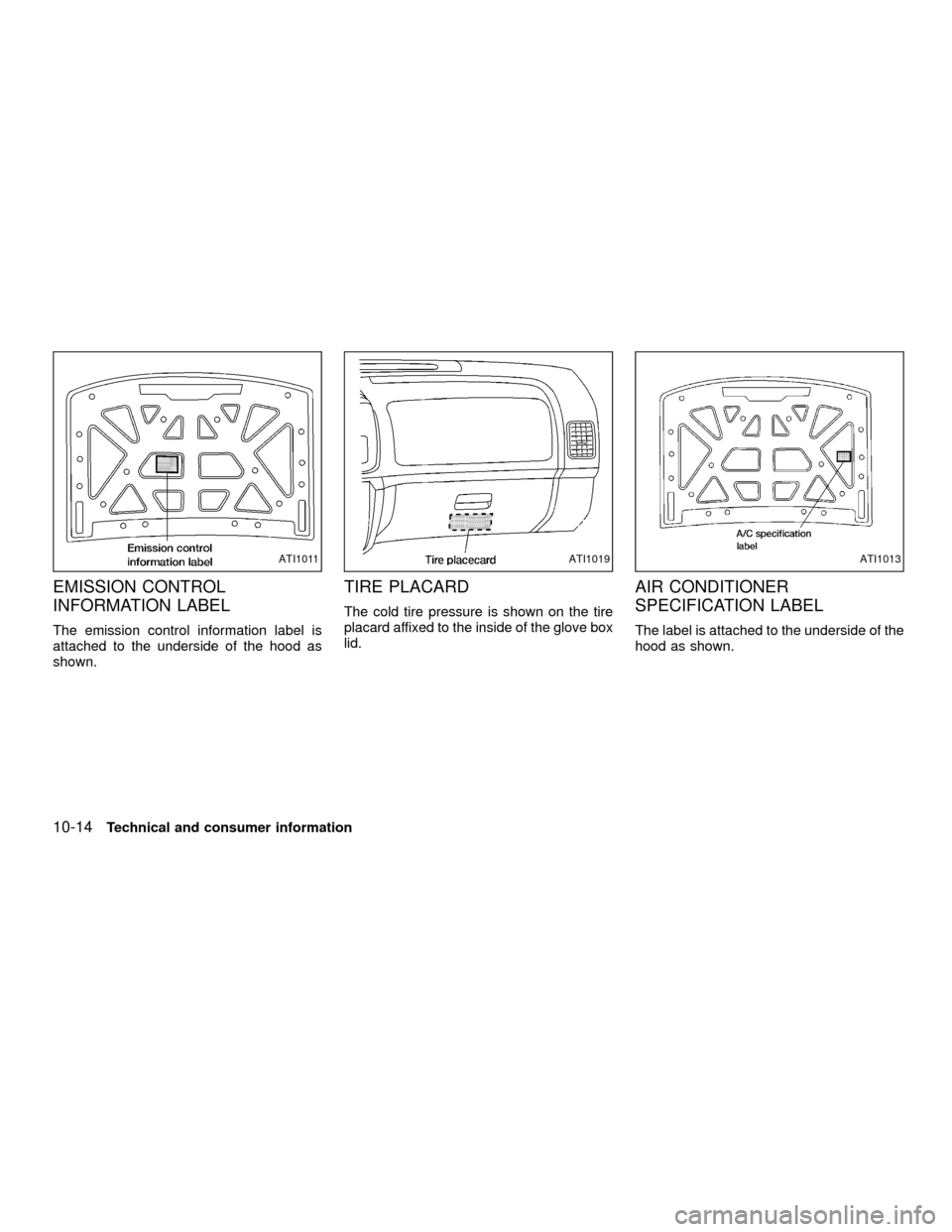

EMISSION CONTROL

INFORMATION LABEL

The emission control information label is

attached to the underside of the hood as

shown.

TIRE PLACARD

The cold tire pressure is shown on the tire

placard affixed to the inside of the glove box

lid.

AIR CONDITIONER

SPECIFICATION LABEL

The label is attached to the underside of the

hood as shown.

ATI1011ATI1019ATI1013

10-14Technical and consumer information

ZX

Page 243 of 263

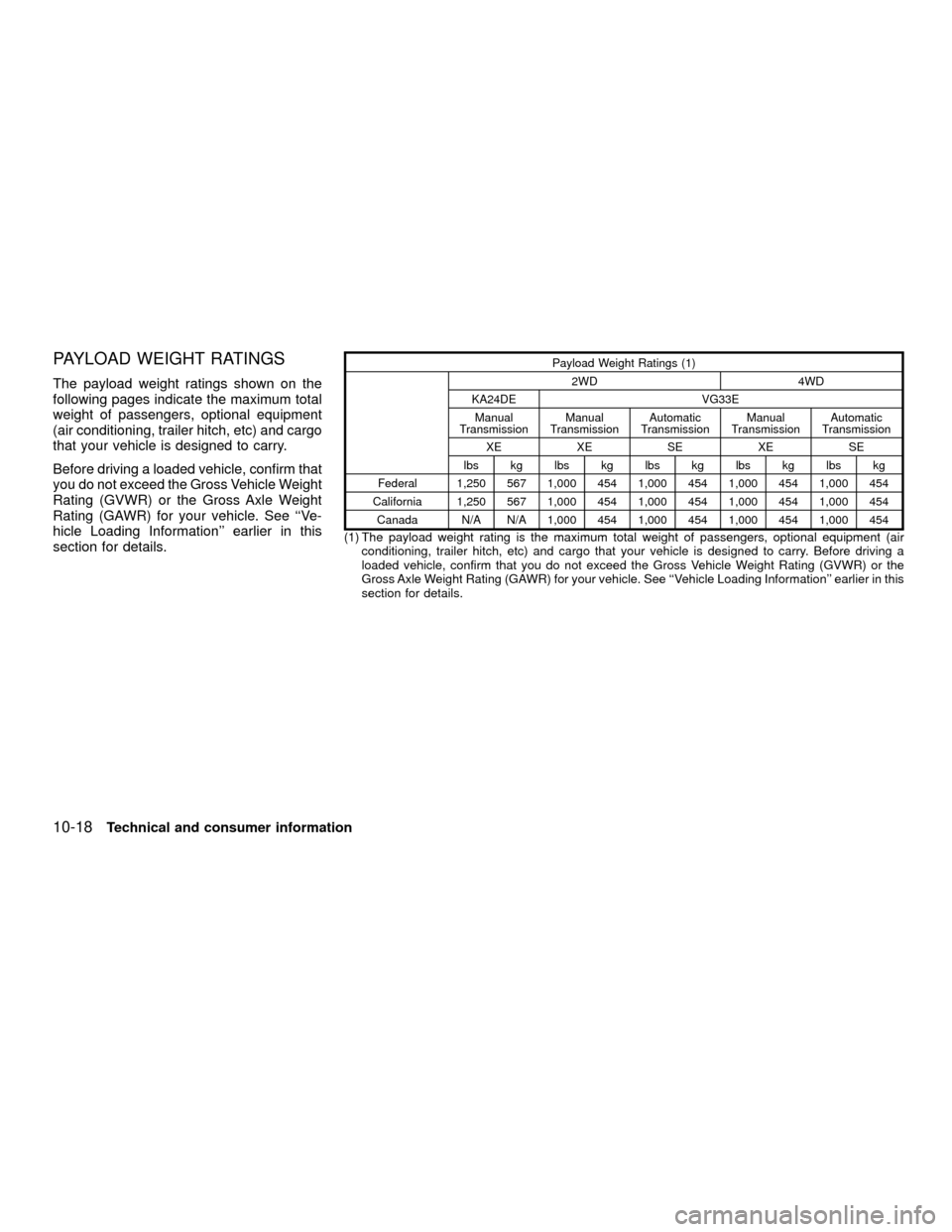

PAYLOAD WEIGHT RATINGS

The payload weight ratings shown on the

following pages indicate the maximum total

weight of passengers, optional equipment

(air conditioning, trailer hitch, etc) and cargo

that your vehicle is designed to carry.

Before driving a loaded vehicle, confirm that

you do not exceed the Gross Vehicle Weight

Rating (GVWR) or the Gross Axle Weight

Rating (GAWR) for your vehicle. See ``Ve-

hicle Loading Information'' earlier in this

section for details.

Payload Weight Ratings (1)

2WD 4WD

KA24DE VG33E

Manual

TransmissionManual

TransmissionAutomatic

TransmissionManual

TransmissionAutomatic

Transmission

XE XE SE XE SE

lbs kg lbs kg lbs kg lbs kg lbs kg

Federal 1,250 567 1,000 454 1,000 454 1,000 454 1,000 454

California 1,250 567 1,000 454 1,000 454 1,000 454 1,000 454

Canada N/A N/A 1,000 454 1,000 454 1,000 454 1,000 454

(1) The payload weight rating is the maximum total weight of passengers, optional equipment (air

conditioning, trailer hitch, etc) and cargo that your vehicle is designed to carry. Before driving a

loaded vehicle, confirm that you do not exceed the Gross Vehicle Weight Rating (GVWR) or the

Gross Axle Weight Rating (GAWR) for your vehicle. See ``Vehicle Loading Information'' earlier in this

section for details.

10-18Technical and consumer information

ZX

Page 249 of 263

4) Connect the tow harness connector

(SAE J1239) to your trailer.

5) Confirm proper vehicle and trailer

stop/turn lamp operation.

6) When towing is completed, disconnect

the tow harness from the trailer and the

vehicle. Store the tow harness in the

glove box. Reinstall the connector cap to

the vehicle harness.

If you need further assistance in wiring

a trailer to your NISSAN, contact an autho-

rized NISSAN dealer.

Always confirm proper vehicle and

trailer stop/turn lamp operation every

time the trailer light circuits are con-

nected for use.

Trailer brakes

If your trailer is equipped with a braking

system, make sure it conforms to Federal

and/or local regulations and that it is prop-

erly installed.

WARNING

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

OBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle

if it has an abnormal nose-up or nose-

down condition; check for improper

tongue load, overload, worn suspension

or other possible causes of either condi-

tion.

OAlways secure items in the trailer to

prevent load shift while driving.

OBe certain your outside mirrors conform

to all federal, state or local regulations. If

not, install any mirrors required for towing

before driving the vehicle.

Trailer towing tips

In order to gain skill and an understanding

of the vehicle's behavior, you should prac-

tice turning, stopping and backing up in an

area which is free from traffic. Steering,

stability and braking performance will be

somewhat different than under normal driv-

ing conditions.

OAlways secure items in the trailer to

prevent load shift while driving.

O

Avoid abrupt starts, acceleration or stops.

OAvoid sharp turns or lane changes.

OAlways drive your vehicle at a moderate

speed.

OAlways block the wheels on both vehicle

and trailer when parking. Parking on a

slope is not recommended; however, if

you must do so, and if your vehicle is

equipped with automatic transmission,

first block the wheels and apply the park-

ing brake, and then move the transmis-

sion shift selector lever into the P (Park)

position. If you move the shift lever to the

P (Park) position before blocking the

wheels and applying the parking brake,

transmission damage could occur.

OWhen going down a hill, shift into a lower

gear and use the engine braking effect.

When ascending a long grade, downshift

the transmission to a lower gear and

reduce speed to reduce chances of en-

gine overloading and/or overheating.

However, for long steep grades, do not

stay in 1st or 2nd gear when driving

above 35 MPH (56 km/h).

OIf the engine coolant rises to an ex-

tremely high temperature when the air

conditioning system is on, turn off the air

conditioner. Coolant heat can be addi-

10-24Technical and consumer information

ZX