brakes OLDSMOBILE BRAVADA 1996 Owner's Manual

[x] Cancel search | Manufacturer: OLDSMOBILE, Model Year: 1996, Model line: BRAVADA, Model: OLDSMOBILE BRAVADA 1996Pages: 340, PDF Size: 17.49 MB

Page 175 of 340

0

0

If you’ll be pulling a trailer that, when loaded, will

weigh more than 2,000 Ibs. (900 kg), be sure to use a

properly mounted, weight-distributing hitch and

sway control of the proper size. This equipment is

very important for proper vehicle loading and good

handling when you’re driving.

Will you have to make any holes

in the body of your

vehicle when you install a trailer hitch?

If you do, then be sure to seal the holes later when

you remove the hitch. If you don‘t seal them, deadly

carbon monoxide

(CO) from your exhaust can get

into your vehicle (see “Carbon Monoxide”

in the

Index). Dirt and water can, too.

Safety Chains

You should always attach chains between your vehicle

and your trailer. Cross the safety chains under the tongue

of the trailer

so that the tongue will not drop to the road

if it becomes separated from the hitch. Instructions

about safety chains may be provided by

the hitch

manufacturer or by the trailer manufacturer. Follow the

manufacturer’s recommendation for attaching safety

chains and do not attach them to

the bumper. Always

leave just enough slack

so you can turn with your rig.

And, never allow safety chains to drag on the ground.

Trailer Brakes

If your trailer weighs more than 1,000 lbs. (450 kg)

loaded,

then it needs its own brakes -- and they must be

adequate. Be sure to read and follow the instructions for

the trailer brakes

so you’ll be able to install, adjust and

maintain them properly.

Your trailer’s brake system can tap into the vehicle’s

hydraulic brake system only

if:

0 The trailer parts can withstand 3,000 psi

(20 650

kPa) of pressure.

0 The trailer’s brake system will use less than

0.02 cubic inch (0.3 cc) of fluid from your vehicle’s

master cylinder. Otherwise,

both braking systems

won’t work well. You could even lose your brakes.

If everything checks out this far, then make the brake

fluid tap at the port on the master cylinder that sends

fluid to the rear brakes.

But don’t use copper tubing for

this.

If you do, it will bend and finally break off. Use

steel brake tubing.

4-47

~

ProCarManuals.com

Page 176 of 340

Driving with a Trailer

A CAUTION:

If you have a rear-most window open and you

pull

a trailer with your vehicle, carbon monoxide

(CO) could come into your vehicle. You can’t see

or smell CO. It can cause unconsciousness or

death. (See “Engine Exhaust” in the Index.)

To

maximize your safety when towing a trailer:

a

a

a

Have your exhaust system inspected for

leaks, and make necessary repairs before

starting on your trip.

Keep the rear-most windows closed.

If exhaust does come into your vehicle

through

a window in the rear or another

opening, drive with your front, main

heating or cooling system on and with the

fan on any speed. This will bring fresh,

outside air into your vehicle.

Do not use

MAX A/C because.it only recirculates the

air inside your vehicle. (See “Comfort

Controls” in the Index.)

L

Towing a trailer requires a certain amount of experience.

Before setting out for the open road, you’ll want to get

to know your rig. Acquaint yaurself with the feel of

handling and braking with the added weight of the

trailer. And always keep in mind that the vehicle

you are

driving is now a good deal longer and not nearly as

responsive as your vehicle is by itself.

Before you start, check the trailer hitch and platform

(and attachments), safety chains, electrical connector,

’

lamps, tires and mirror adjustment. If the trailer has

electric brakes, start your vehicle and trailer moving and

then apply the trailer brake controller by hand to be sure

the brakes are working. This lets-you check your

electrical connection at the same time.

During your trip, check occasionally to be sure that the

load is secure, and that the ,lamps and any trailer brakes

are still working.

4-48

ProCarManuals.com

Page 178 of 340

When towing a trailer, the green arrows on your

instrument panel

will flash for turns even if the bulbs on

the trailer are burned out. Thus, you may think drivers

behind you are seeing your signal when they are not. It’s

important

to check occasionally to be sure the trailer

bulbs are still working.

Driving On Grades

Reduce speed and shift to a lower gear before you start

down

a long or steep downgrade. If you don’t shift

down, you might have to use

your brakes so much that

they would get hot and no longer work well.

On a long uphill grade, shift down and reduce your

speed to around

45 mph (70 km/h) to reduce the

possibility of engine and transmission overheating.

You should use THIRD (3) when towing a trailer.

Operating your vehicle

in THIRD (3) when towing a

trailer will minimize heat buildup and extend

the life of

your transmission.

Parking on Hills

You really should not park your vehicle, with a trailer

attached, on

a hill. Tf something goes wrong, your rig

could start to move. People can be injured, and both

your vehicle and the trailer can be damaged.

But

if you ever have to park your rig on a hill, here’s

how to do it:

1. Apply your regular brakes, but don’t shift into

PARK

(P) yet. Then turn your wheels into the curb if

facing downhill or into traffic if facing uphill.

2. Have someone place chocks under the trailer wheels.

3. When the wheel chocks are in place, release the

regular brakes

until the chocks absorb the load.

4. Reapply the regular brakes. Then apply your parking

brake and shift into PARK (P).

5. Release the regular brakes.

4-50

ProCarManuals.com

Page 179 of 340

When You Are Ready to Leave

After Parking on a Hill

1. Apply your regular brakes and hold the pedal down

while you:

Start your engine;

0 Shift into a gear; and

0 Release the parking brake.

2. Let up on the brake pedal.

3. Drive slowly until the trailer is clear of the chocks.

4. Stop and have someone pick up and store the chocks.

Maintenance When Trailer Towing

Your vehicle will need service more often when you’re

pulling a trailer. See the Maintenance Schedule for more

on this. Things that are especially important

in trailer

operation are automatic transmission fluid (don’t

overfill), engine

oil, axle lubricant, belt, cooling system

and brake adjustment. Each

of these is covered in this

manual, and the Index

will help you find them quickly.

If you’re trailering, it’s a good idea to review these

sections before you start your trip.

Check periodically to

see that all hitch nuts and

bolts are tight.

ProCarManuals.com

Page 180 of 340

Trailer Wiring Harness

The light duty trailer wiring is a six-wire harness

assembly. The optional heavy duty trailer wiring is an

eight-wire harness assembly. The harnesses are stored

under the vehicle, on the driver’s side corner frame

crossmember. The heavy duty trailer wiring

has a

30-amp feed wire with an inline fuse located by the

junction block. See “Fuses and Circuit Breakers”

in the

Index. Both harnesses have no connector and should be

wired by a qualified electrical technician. The technician

can use the following color code chart when connecting

the wiring harness to your trailer.

0 DARK BLUE: Use for electric trailer brakes or

auxiliary wiring.

0 RED: Use for battery charging; it connects to the

starter solenoid (eight-wire harness only).

0 LIGHT GREEN: Back-up lamps (eight-wire

harness only).

BROWN: Taillamps and parking lamps.

YELLOW: Left stoplamp and turn signal.

DARK GREEN: Right stoplamp and turn signal.

WHITE (Heavy Gage): Ground wire.

WHITE (Light Gage): Auxiliary stoplamp.

Securely attach the harness to the trailer, then tape or

strap

it to your vehicle’s frame rail. Be sure you leave it

loose enough

so the wiring doesn’t bend or break, but

not

so loose that it drags on the ground. Store the

harness

in its original place. Wrap the harness together

and tie

it neatly so it won’t be damaged.

ProCarManuals.com

Page 237 of 340

~~ ~ NOTICE:

0

0

0

0

When using concentrated washer fluid,

follow

the manufacturer’s instructions

for

adding water.

Don’t mix water with ready-to-use washer

fluid. Water can cause the solution to freeze

and damage your washer fluid tank and

other parts of the washer system. Also,

water doesn’t clean as well as washer fluid.

Fill your washer fluid tank only

three-quarters full when it’s very cold. This

allows for expansion, which could damage

the tank if it is completely full.

Don’t use radiator antifreeze

in your

windshield washer. It can damage your

washer system and paint.

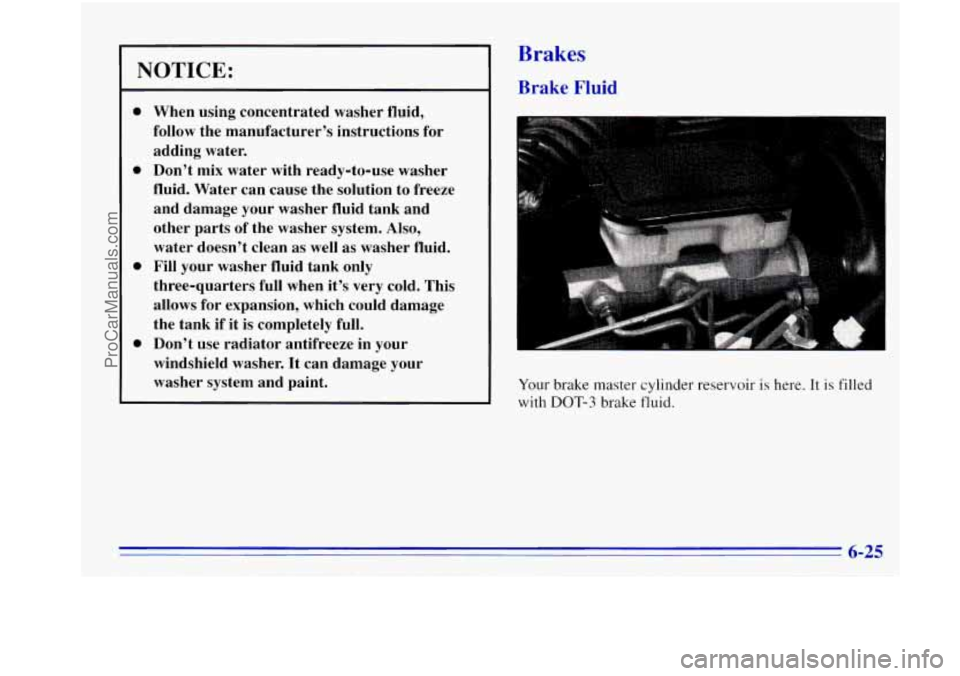

Brakes

Brake Fluid

Your brake master cylinder reservoir is here. It is filled

with DOT-3 brake fluid.

ProCarManuals.com

Page 238 of 340

There are only two reasons why the brake fluid level in

the reservoir might go down. The first is that the brake

fluid goes down

to an acceptable level during normal

brake lining wear. When new linings are put

in, the fluid

level goes back up. The other reason is that fluid is

leaking out

of the brake system. If it is, you should have

your brake system fixed, since a leak means that sooner

or later your brakes won’t work well, or won’t work

at all.

So, it isn’t a good idea to “top off’ your brake fluid.

Adding brake fluid won’t correct a leak. If you

add fluid

when your linings are worn, then you’ll have too much

fluid when you get new brake linings.

You should add

(or remove) brake fluid, as necessary, only when work is

done

on the brake hydraulic system.

If you have too much brake fluid, it can spill

on the engine. The fluid will burn

if the engine

is hot enough. You or others could be burned,

and your vehicle could be damaged. Add brake

fluid only when work

is done on the brake

hydraulic system.

Refer to the Maintenance Schedule to determine when to

check your brake fluid. See “Periodic Maintenance

Inspections”

in the Index.

ProCarManuals.com

Page 239 of 340

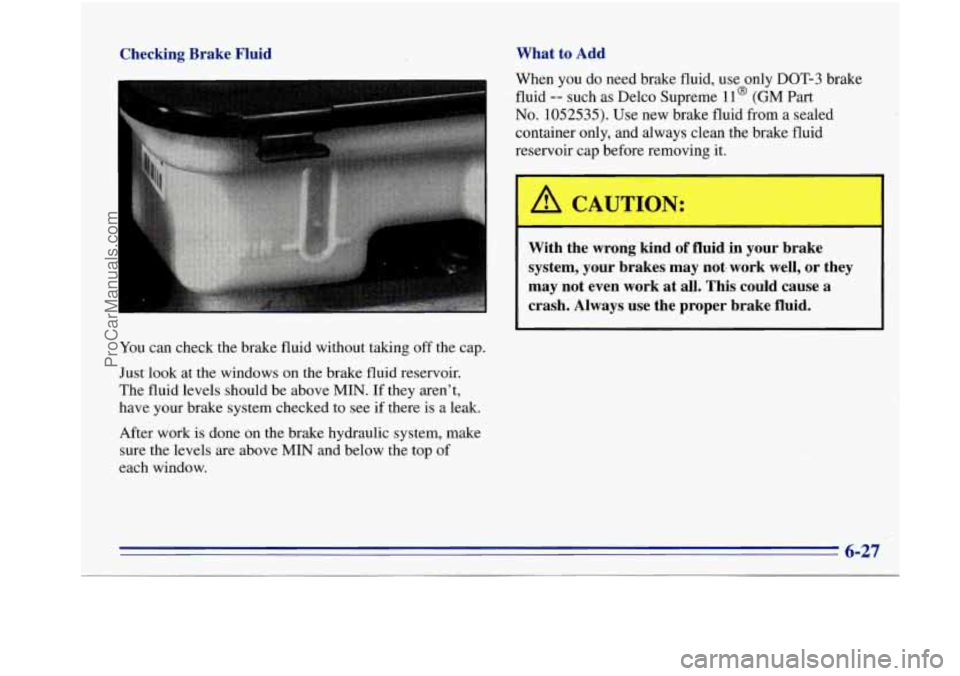

Checking Brake Fluid What

to Add

You can check the brake fluid without taking off the cap.

Just look at

the windows on the brake fluid reservoir.

The fluid levels should be above MIN. If they aren’t,

have your brake system checked to see if there is a leak.

After work is done on the brake hydraulic system, make

sure the levels are above MIN and below the

top of

each window. When

you do need brake fluid, use only

DOT-3 brake

fluid

-- such as Delco Supreme 11 @ (GM Part

No. 1052535). Use new brake fluid from a sealed

container only, and always clean the brake fluid

reservoir cap before removing it.

A CAUTION:

With the wrong kind of fluid in your brake

system, your brakes may nott work well, or they

may not even work at all. This could cause a

crash. Always use the proper brake fluid.

6-27

ProCarManuals.com

Page 240 of 340

~~

~ NOTICE:

0

0 Using the wrong fluid can badly damage

brake system parts. For example, just a few

drops of mineral-based oil, such as engine

oil, in your brake system can damage brake

system parts

so badly that they’ll have to be

replaced. Don’t let someone put in the

wrong kind of fluid.

If you spill brake fluid on your vehicle%

painted surfaces, the paint finish can be

damaged. Be careful not

to spill brake fluid

on your vehicle.

If you do, wash.it off

immediately. See “Appearance Care” in

the Index.

Brake Wear

Your Oldsmobile has front disc brakes and rear

drum brakes.

Disc brake pads have built-in wear indicators that

make a high-pitched warning sound when the brake

pads are worn and new pads

are needed. The sound may

come and go or be heard all

the time your vehicle is

moving (except when you are pushing on the brake

pedal firmly).

I

The brake wear warning sound means that

sooner or later your brakes won’t work well.

That could lead to an accident. When you hear

the brake wear warning sound, have your

vehicle serviced.

6-28

ProCarManuals.com

Page 241 of 340

1 NOTICE:

Continuing to drive with worn-out brake pads

could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are first applied or lightly

applied. This does not mean something is wrong

with

your brakes.

Your rear drum brakes don’t have wear indicators, but

if

you ever hear a rear brake rubbing noise, have the rear

brake linings inspected. Also, the rear brake drums

should be removed and inspected each time the tires are

removed for rotation or changing. When you have

the

front brakes replaced, have the rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

Brake Pedal Travel

See your retailer if the brake pedal does not return to

normal height, or if there is

a rapid increase in pedal

travel. This could be

a sign of brake trouble.

Brake Adjustment

Every time you make a brake stop, your disc brakes

adjust for wear.

If your brake pedal goes down farther than normal, your

rear drum brakes may need adjustment. Adjust them by

backing up and firmly applying the brakes a few times.

Replacing Brake System Parts

The braking system on a modern vehicle is complex.

Its many parts have to be of top quality and work well

together

if the vehicle is to have really good braking.

Vehicles we design and test have top-quality

GM brake

parts

in them, as your Oldsmobile does when it is new.

When you replace parts

of your braking system -- for

example, when your brake linings wear down and

you

have to have new ones put in -- be sure you get new

genuine

GM replacement parts. If you don’t, your

brakes

may no longer work properly. For example, if

someone puts in brake linings that are wrong for your

vehicle, the balance between your front and rear brakes

can change

-- for the worse. The braking performance

you’ve come to expect can change

in many other ways

someone puts

in the wrong replacement brake parts. if

ProCarManuals.com