Oldsmobile Bravada 2003 Owner's Manuals

Bravada 2003

Oldsmobile

Oldsmobile

https://www.carmanualsonline.info/img/31/9574/w960_9574-0.png

Oldsmobile Bravada 2003 Owner's Manuals

Trending: bulb, suspension, CD changer, jump cable, interior lights, odometer, air conditioning

Page 301 of 410

Don’t let the other end touch anything until the next

step. The other end of the negative

(-) cable

doesn’t go to the dead battery. It goes to a heavy,

unpainted metal engine part or to the remote

negative

(-) terminal on the vehicle with the dead

battery. The remote negative

(-) terminal on

your vehicle is located on the front engine lift

bracket and is marked

“GND.”

9. Connect the other end of

the negative

(-) cable to

1 the remote negative (-)

terminal on the vehicle

with the dead battery.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery. If

it Won’t start after a few tries, it probably needs

service.

Notice: Damage to your vehicle may result from

electrical shorting

if jumper cables are removed

incorrectly. To prevent electrical shorting, take care

that the cables don’t touch each other or any

other metal. The repairs wouldn’t be covered by

your warranty.

5-42

Page 302 of 410

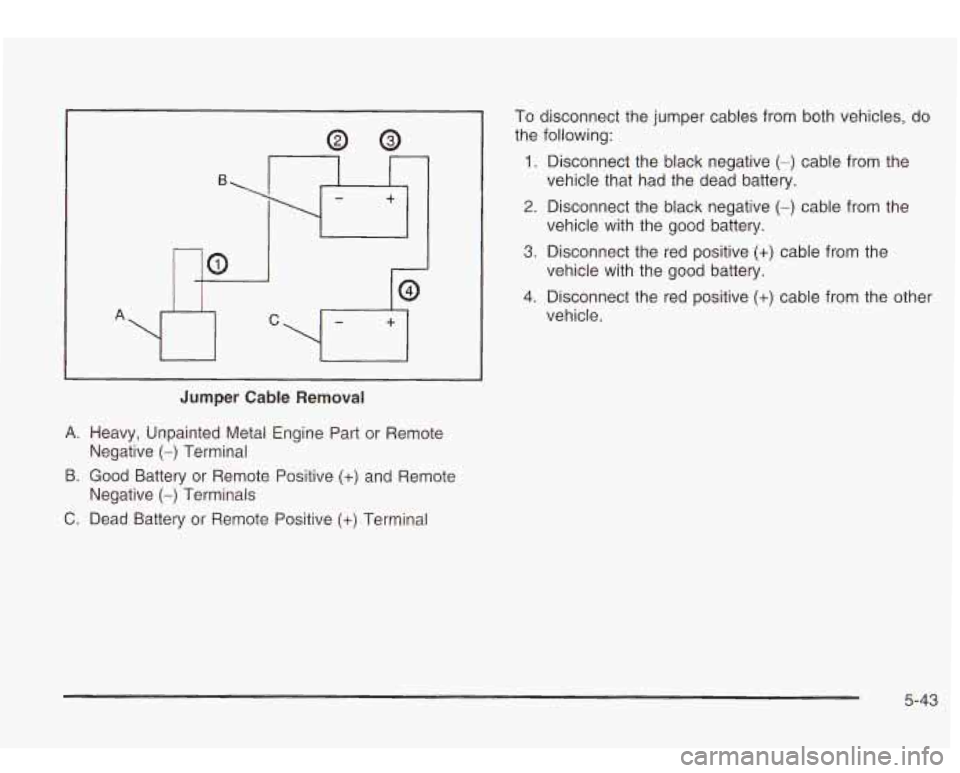

Jumper Cable Removal

A. Heavy, Unpainted Metal Engine Part or Remote

9. Good Battery or Remote Positive (+) and Remote

C. Dead Battery or Remote Positive (+) Terminal

Negative

(-) Terminal

Negative

(-) Terminals

To disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (-) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (-) cable from the

vehicle with the good battery.

3. Disconnect the red positive

(+) cable from the

4. Disconnect the red positive

(+) cable from the other

vehicle with the

good battery.

vehicle.

5-43

Page 303 of 410

All-Wheel Drive

Lubricant checks in this section also apply to these

vehicles. However, there are

two additional systems that

need lubrication.

Transfer Case

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant. See

Part C: Periodic

Maintenance Inspections on page

6- 15.

How to Check Lubricant

To get an accurate

reading, the vehicle should

be on a level surface.

If the level is below the bottom of the filler plug hole,

you’ll need

to add some lubricant. Add enough lubricant

to raise the level

to the bottom of the filler plug hole.

Use care not to overtighten the plug.

What to Use

Refer to the Maintenance Schedule to determine what

kind

of lubricant to use. See Part D: Recommended

Fluids and Lubricants on page

6- 17.

Front Axle

When to Check and Change Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant and when to change it.

5-44

Page 304 of 410

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface. If

the level is below the bottom of the filler plug hole,

you may need to add some lubricant.

When the differential is cold, add enough lubricant to

raise the level to

1/2 inch (12 mm) below the filler plug

hole.

When the differential is at operating temperature

(warm), add enough lubricant to raise the level to the

bottom

of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind

of lubricant to use. See Part D: Recommended

Fluids

and Lubricants on page 6-1 7.

5-45

Page 305 of 410

Rear Axle

When to Check Lubricant

Refer to the Maintenance Schedule to determine how

often to check the lubricant.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

The proper level is from

0 to 3/8 inch (0 to 10 mm)

below the

bottom of the filler plug hole.

What to Use

Refer to the Maintenance Schedule to determine what

kind of lubricant

to use. See Part D: Recommended

Fluids and Lubricants on page

6-17.

5-46

Page 306 of 410

Bulb Replacement

For the type of bulbs, see Replacement Bulbs on

page

5-48.

For any bulb changing procedure not listed in this

section, contact your dealer.

Taillamps and Turn Signal Lamps

1. Open the liftgate.

3. Pull the assembly away from the vehicle.

2. Remove

from the the

two screws

lamp assembly.

4. 5.

6.

7.

8.

Unclip the wiring harness (A) and remove the three

socket retaining screws

(B).

Remove the socket by releasing the retaining tabs.

Holding the socket, pull the bulb

to release it

from the socket.

Push the new bulb into the socket until it clicks.

Reinstall the socket and screws.

5-47

Page 307 of 410

9. Reconnect the wiring harness.

10. Reinstall the lamp assembly and tighten the screws.

11. Close the liftgate.

Replacement Bulbs

Exterior Lamp

31 57 Taillamps

Bulb Number

Rear Turn Signal Lamps I 31 57

For any bulb not listed here, contact your dealer.

5-48

Page 308 of 410

Windshield Wiper Blade Replacement

Windshield wiper blades should be inspected at least

twice a year for wear or cracking.

See

Normal Maintenance Replacement Parts on

page 5-94 for the proper type of replacement blade.

Notice: Use care when removing or installing

a blade assembly. Accidental bumping can cause

the arm

to fall back and strike the windshield.

1. To remove the old wiper blades, lift the wiper arm

until it locks into a vertical position.

A. Blade Assembly

B. Arm Assembly

C. Locking Tab

D. Blade Pivot

E. Hook Slot

F. Arm Hook

5-49

Page 309 of 410

2. Press down on the blade assembly pivot locking

tab. Pull down on the blade assembly to release it

from the wiper arm hook.

3. Remove the insert from the blade assembly. The

insert has two notches at one end that are locked

by the bottom claws of the blade assembly.

At

the notched end, pull the insert from the blade

assembly.

0

I W

4. To install the new wiper insert, slide the insert (D),

notched end last, into the end with two blade

claws (A). Slide the insert all the way through the

blade claws at the opposite end

(6). The plastic

caps

(C) will be forced off as the insert is fully

inserted.

5. Be sure that the notches are locked by the bottom

claws. Make sure that all other claws are properly

locked on both sides of the insert slots.

5-50

Page 310 of 410

A

I

I

B C

-

A. Claw in Notch

B. Correct Installation

C. Incorrect Installation

6. Put the blade assembly pivot in the wiper arm hook.

Pull up until the pivot locking tab locks

in the

hook slot.

7. Carefully lower the wiper arm and blade assembly

onto the windshield.

Backglass Wiper Blade Replacement

See Windshield Wiper Blade Replacement on page 5-49

in this section for instructions on how to change the

backglass wiper blade. The backglass wiper blade will

not lock in a vertical position like the windshield

wiper blade,

so care should be used when pulling it

away from the vehicle.

5-51

Trending: power steering, ground clearance, snow chains, start stop button, fuse, Differential fluid, wiper fluid