rod OPEL 1900 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 144 of 625

DOORSZD- 21

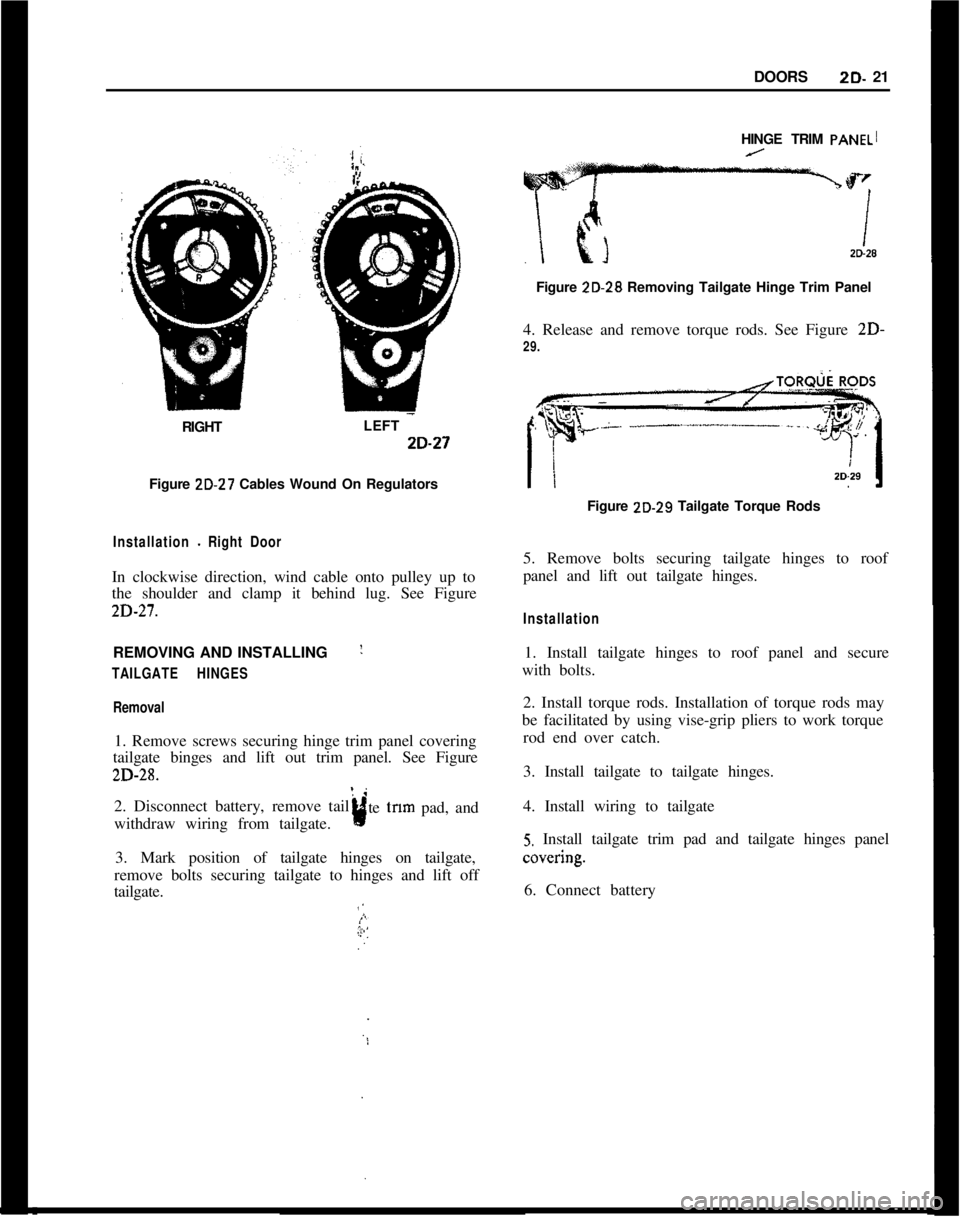

RIGHTLEFT ~-ZD-27

Figure ZD-27 Cables Wound On Regulators

Installation - Right DoorIn clockwise direction, wind cable onto pulley up to

the shoulder and clamp it behind lug. See Figure2D-27.

REMOVING AND INSTALLING

’

TAILGATE HINGES

Removal1. Remove screws securing hinge trim panel covering

tailgate binges and lift out trim panel. See Figure

2D-28.2. Disconnect battery, remove tail

te trun pad, and

withdraw wiring from tailgate.

u3. Mark position of tailgate hinges on tailgate,

remove bolts securing tailgate to hinges and lift off

tailgate.

,’HINGE TRIM

PANEL1IFigure ZD-28 Removing Tailgate Hinge Trim Panel

4. Release and remove torque rods. See Figure 2D-

29.Figure ZD-29 Tailgate Torque Rods

5. Remove bolts securing tailgate hinges to roof

panel and lift out tailgate hinges.

Installation1. Install tailgate hinges to roof panel and secure

with bolts.

2. Install torque rods. Installation of torque rods may

be facilitated by using vise-grip pliers to work torque

rod end over catch.

3. Install tailgate to tailgate hinges.

4. Install wiring to tailgate

5. Install tailgate trim pad and tailgate hinges panel

COVehg.6. Connect battery

Page 146 of 625

REAR COMPARTMENT LID2E- 23

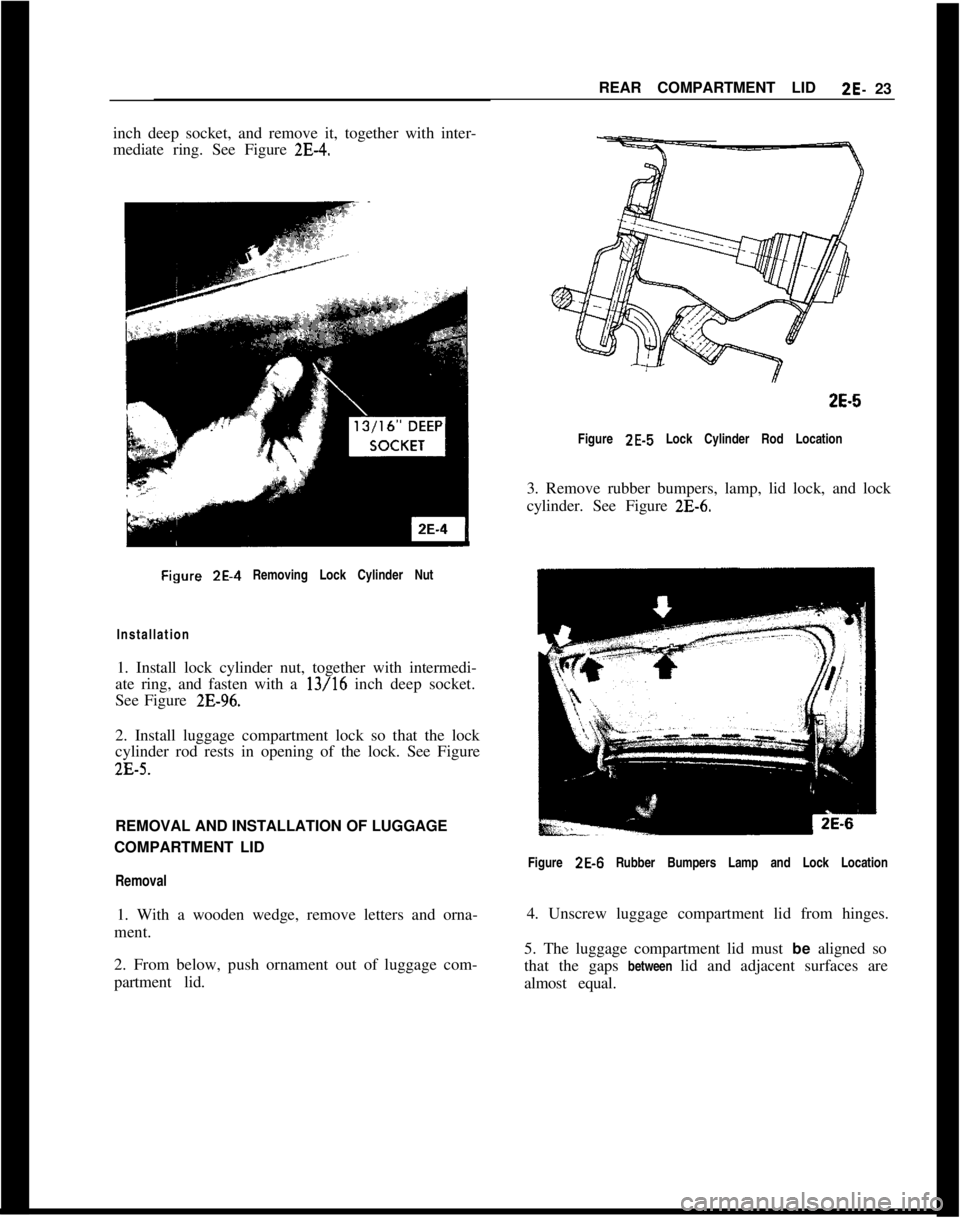

inch deep socket, and remove it, together with inter-

mediate ring. See Figure 2E-4.Fiyure

ZE-4 Removing Lock Cylinder Nut

Installation

1. Install lock cylinder nut, together with intermedi-

ate ring, and fasten with a 13/16 inch deep socket.

See Figure 2B96.

2. Install luggage compartment lock so that the lock

cylinder rod rests in opening of the lock. See Figure

2E-5.REMOVAL AND INSTALLATION OF LUGGAGE

COMPARTMENT LID

Removal1. With a wooden wedge, remove letters and orna-

ment.

2. From below, push ornament out of luggage com-

partment lid.2E-5

Figure

ZE-5 Lock Cylinder Rod Location

3. Remove rubber bumpers, lamp, lid lock, and lock

cylinder. See Figure

2E-6.Figure

2E-6 Rubber Bumpers Lamp and Lock Location

4. Unscrew luggage compartment lid from hinges.

5. The luggage compartment lid must be aligned so

that the gaps between lid and adjacent surfaces are

almost equal.

Page 177 of 625

3A- 101973 OPEL SERVICE MANUAL

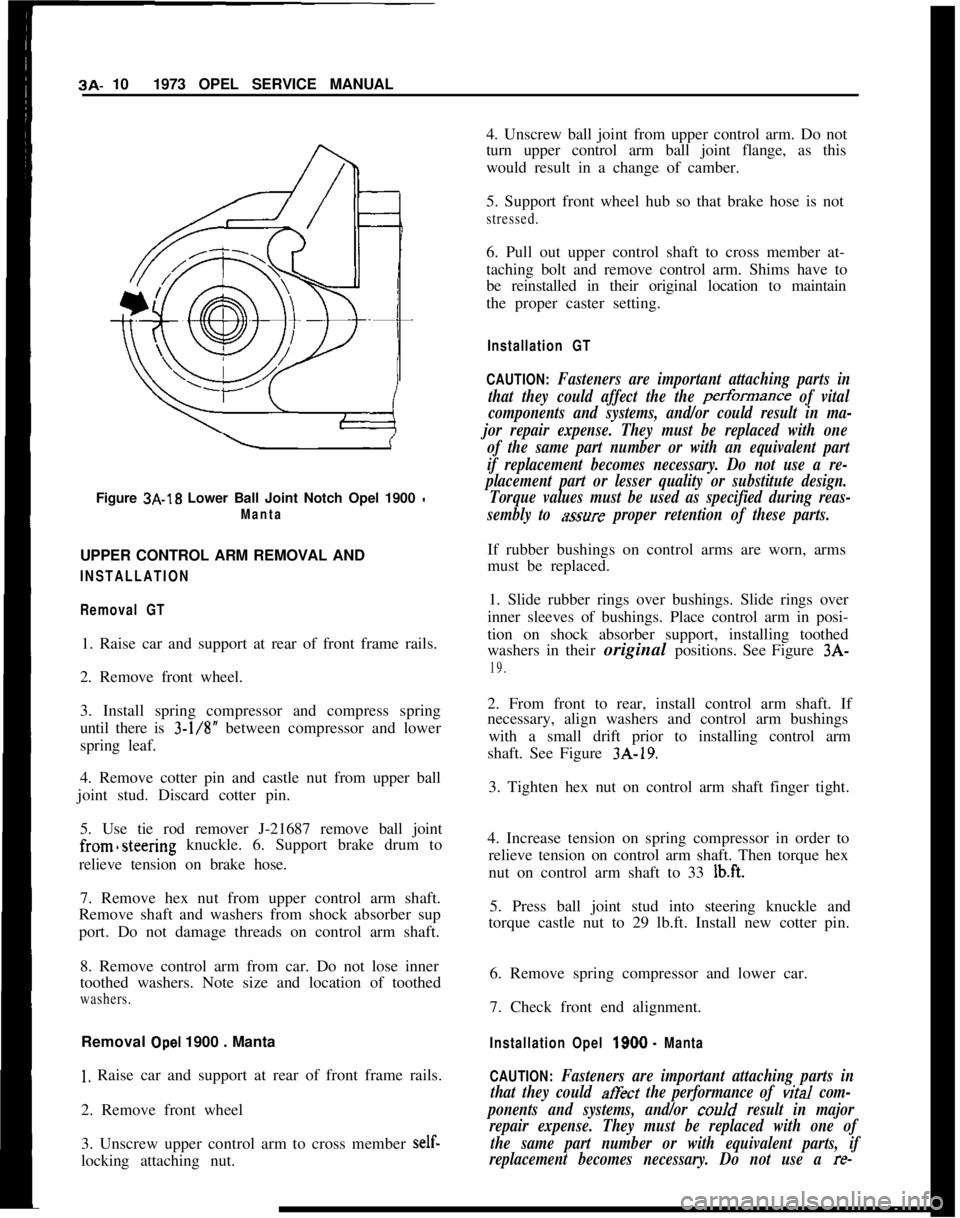

Figure 3A-18 Lower Ball Joint Notch Opel 1900 -

MantaUPPER CONTROL ARM REMOVAL AND

INSTALLATION

Removal GT1. Raise car and support at rear of front frame rails.

2. Remove front wheel.

3. Install spring compressor and compress spring

until there is 3-l/8” between compressor and lower

spring leaf.

4. Remove cotter pin and castle nut from upper ball

joint stud. Discard cotter pin.

5. Use tie rod remover J-21687 remove ball jointfrom.steering knuckle. 6. Support brake drum to

relieve tension on brake hose.

7. Remove hex nut from upper control arm shaft.

Remove shaft and washers from shock absorber sup

port. Do not damage threads on control arm shaft.

8. Remove control arm from car. Do not lose inner

toothed washers. Note size and location of toothed

washers.Removal

Opel 1900 . Manta

1, Raise car and support at rear of front frame rails.

2. Remove front wheel

3. Unscrew upper control arm to cross member

self-locking attaching nut.4. Unscrew ball joint from upper control arm. Do not

turn upper control arm ball joint flange, as this

would result in a change of camber.

5. Support front wheel hub so that brake hose is not

stressed.6. Pull out upper control shaft to cross member at-

taching bolt and remove control arm. Shims have to

be reinstalled in their original location to maintain

the proper caster setting.

Installation GT

CAUTION:

Fasteners are important attaching parts in

that they could affect the the

perfonmmce of vital

components and systems, and/or could result in ma-

jor repair expense. They must be replaced with one

of the same part number or with an equivalent part

if replacement becomes necessary. Do not use a re-

placement part or lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to

assure proper retention of these parts.If rubber bushings on control arms are worn, arms

must be replaced.

1. Slide rubber rings over bushings. Slide rings over

inner sleeves of bushings. Place control arm in posi-

tion on shock absorber support, installing toothed

washers in their original positions. See Figure 3A-

19.2. From front to rear, install control arm shaft. If

necessary, align washers and control arm bushings

with a small drift prior to installing control arm

shaft. See Figure

3A-19.3. Tighten hex nut on control arm shaft finger tight.

4. Increase tension on spring compressor in order to

relieve tension on control arm shaft. Then torque hex

nut on control arm shaft to 33

Ib.ft.5. Press ball joint stud into steering knuckle and

torque castle nut to 29 lb.ft. Install new cotter pin.

6. Remove spring compressor and lower car.

7. Check front end alignment.

Installation Opel 1900. Manta

CAUTION:

Fasteners are important attaching parts in

that they could at?&

the performance of vital com-

ponents and systems, and/or

coo/d result in major

repair expense. They must be replaced with one of

the same part number or with equivalent parts, if

replacement becomes necessary. Do not use a

re-

Page 180 of 625

FRONT SUSPENSION3A- 13

6. Reconnect shock absorber to lower control arm

and torque to 30

Ib.ft.7. Remove spring compressor.

8. Install front wheel, and lower the car.

9. Check front end alignment.

Installation Opel 1900 Manta

CAUTION: Fasteners are important attachingparts in

that they could aff&

the-performance of vitaI com-

ponents and systems, and/or could

resu/t in major

repair expenses. They must be

repraced with one of

the same part number or with an

equivaknt part, ifreplacement becomes necessary. Do not use a re-

placement part of ksser quality or substitute design.

Torque values must be used as specified

dmitig reas-

sembIy to assure proper retention of these parts.1. Loosely attach lower control arm to front cross

member.

2. Properly seat spring between lower control arm

and cross member.

3. Raise jack and place lower control into position.

4. Attach lower control ball joint to steering knuckle

and torque nut to 54

Ib.ft.5. Tighten lower control arm to cross member bolt

to 43

lb.ft.6. Attach stabilizer bar to lower control arm and

torque to 87

lb.ft.7. Attach stabilizer bar to cross member to body

support.

8. Install shock absorber and torque lower attaching

nut and bolt to 30

lb.ft.9. Install nuts on upper shock absorber attaching

studs. Tighten nuts until a distance from top of nut

to stud is approximately

l/2 inch.

10. Install front wheels and tighten nuts to 65

lb.ft.11. Remove stands and lower car.

STEERING KNUCKLE REMOVAL AND

INSTALLATION

Removal GT1. Raise car and support with stands.

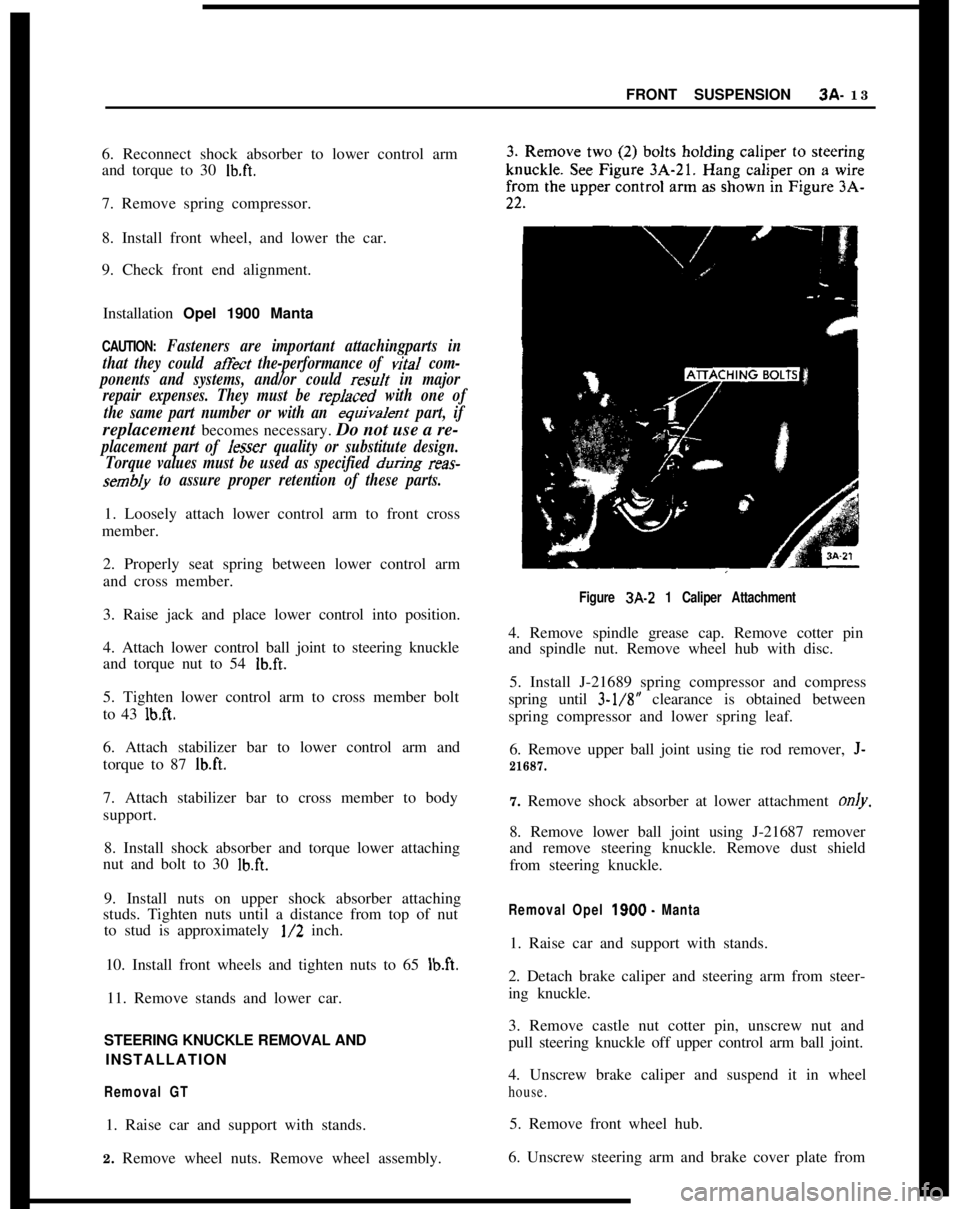

2. Remove wheel nuts. Remove wheel assembly.

Figure 3A-2 1 Caliper Attachment4. Remove spindle grease cap. Remove cotter pin

and spindle nut. Remove wheel hub with disc.

5. Install J-21689 spring compressor and compress

spring until 3-l/8” clearance is obtained between

spring compressor and lower spring leaf.

6. Remove upper ball joint using tie rod remover,

J-

21687.7. Remove shock absorber at lower attachment only.

8. Remove lower ball joint using J-21687 remover

and remove steering knuckle. Remove dust shield

from steering knuckle.

Removal Opel 1900. Manta1. Raise car and support with stands.

2. Detach brake caliper and steering arm from steer-

ing knuckle.

3. Remove castle nut cotter pin, unscrew nut and

pull steering knuckle off upper control arm ball joint.

4. Unscrew brake caliper and suspend it in wheel

house.5. Remove front wheel hub.

6. Unscrew steering arm and brake cover plate from

Page 181 of 625

3A. 141973 OPEL SERVkE MANUAL

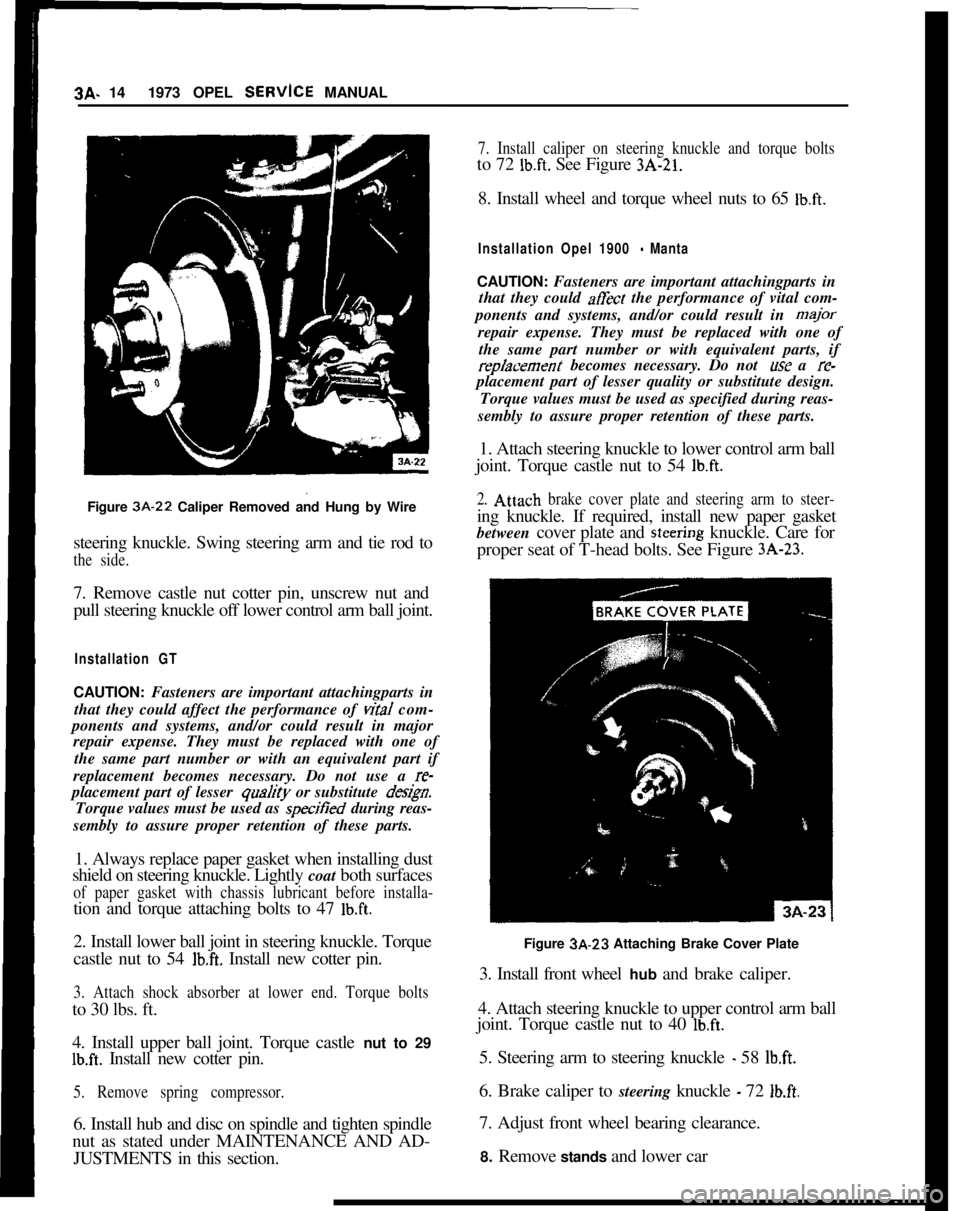

Figure 3A-22 Caliper Removed and Hung by Wire

steering knuckle. Swing steering arm and tie rod to

the side.7. Remove castle nut cotter pin, unscrew nut and

pull steering knuckle off lower control arm ball joint.

Installation GTCAUTION: Fasteners are important attachingparts in

that they could affect the performance of

viral com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute

desig.Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Always replace paper gasket when installing dust

shield on steering knuckle. Lightly coat both surfaces

of paper gasket with chassis lubricant before installa-tion and torque attaching bolts to 47

lb.ft.2. Install lower ball joint in steering knuckle. Torque

castle nut to 54

Ib.ft. Install new cotter pin.

3. Attach shock absorber at lower end. Torque boltsto 30 lbs. ft.

4. Install upper ball joint. Torque castle nut to 29

lb.ft. Install new cotter pin.

5. Remove spring compressor.6. Install hub and disc on spindle and tighten spindle

nut as stated under MAINTENANCE AND AD-

JUSTMENTS in this section.

7. Install caliper on steering knuckle and torque boltsto 72

lb.ft. See Figure 3A-21.8. Install wheel and torque wheel nuts to 65

lb.ft.

Installation Opel 1900

- MantaCAUTION: Fasteners are important attachingparts in

that they could

affit the performance of vital com-

ponents and systems, and/or could result in

ma&repair expense. They must be replaced with one of

the same part number or with equivalent parts, ifrepfacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Attach steering knuckle to lower control arm ball

joint. Torque castle nut to 54

lb.ft.

2.

Atl,ach brake cover plate and steering arm to steer-ing knuckle. If required, install new paper gasket

between cover plate and steering knuckle. Care for

proper seat of T-head bolts. See Figure

3A-23.Figure 3A-23 Attaching Brake Cover Plate

3. Install front wheel hub and brake caliper.

4. Attach steering knuckle to upper control arm ball

joint. Torque castle nut to 40

lb.ft.5. Steering arm to steering knuckle

_ 58 lb.ft.6. Brake caliper to steering knuckle

- 72 lb.ft.7. Adjust front wheel bearing clearance.

8. Remove stands and lower car

Page 185 of 625

3A- 161973 OPEL SERVICE MANUAL

SPECIFICATIONS

Torque Specifications

Use a reliable torque wrench to tighten all parts listed to insure proper

tightness without straining or distorting parts. These specifications are for

clean and lightly-lubricated threads only; dry or dirty threads produce in-

creased friction which prevents accurate maasurement of tightness.

LocationFront Suspension Crossmember to Front Frame

Clamp, Steering Mast to Steering Mast Flange

(GT)

........................................................................................

Clamp, Steering Mast to Steering Mast Flange(1900

-Manta)..................................................................

Clamp,UpperUniversalJoint(GT)..................................Clamp, Lower Universal Joint (GT)

..................................

WheelNuts............................................................................Lower Control Arm Shaft to Lower Control Arm

..........Lower Control Arm Ball Joint to Steering Knuckle

......Upper Control Arm Ball Joint to Steering Knuckle

(GT)........................................................................................Upper Control Arm Ball Joint to Steering Knuckle

(1 900 Manta)

..................................................................Upper Control Arm Ball Joint to Upper Control Arm

ShockAbsorbertoLowerControlArm..........................Steering Arm to Steering Knuckle (1900

- Manta)......

Brake Backing Plate or Brake Disc Shield andSteering Arm to Steering Knuckle

(GTJ

Hex Head Bolt M 10......Hex Head Bolt M 8

......

Brake Backing Plate to Steering Knuckle(1900 Manta)

..................................................................

Brake Caliper to Steering Knuckle.................................

Lower Control Arm to Front Spring Eye (GT)................

Brake Disc to Front Wheel Hub........................................Upper Control Arm to Crossmember (1900

- MantajLower Control Arm to Crossmember (1900

- Manta)

Steering Gear Housing to Front Suspension

Crossmember (GT)

............................................................

Steering Gear Housing to Front SuspensionCrossmember (1900

- Manta)........................................Stabilizer Bar to Lower Control Arm

(Opel 1900

- Manta)........................................................Tie Rod Clamp Bolts

(GTJ....................................................

CastleNut,TieRodtoSteeringArm..............................Upper Control Arm Shaft to Shock Absorber Support

and Upper Control Arm (GT)

..........................................

CrossMember to

BodySupport Attachment................

FrontSuspensionAssemblytoFrame............................Front End Alignment Specifications

Torque

Lb.Ft.36

1522

14

22

6540

5429

ii30

5847

18

58

72

1836

40

43

1830

87

:i33

58

47ModelCaster’

Camber”1900‘3

l/2-6 l/2GT

3+1-:%+*Permissible deviation from left to right wheel

- Max. 1’.

Toe-In”Min.-Max.

l/8-3/ 16

l/32-1/8Outer Wheel

When Inner

Wheel at 20

19

l/418

l/2

Page 186 of 625

STEERING LINKAGE38.19STEERING LINKAGE

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description

andOperationofTieRods. . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

RemovalandInstallationofTieRods. . . . . . . . . . . . . . . . . . . . . . . .Disassembly

andReassemblyofTieRods. . . . . . . . . . . . . . . .SPECIFICATIONS:

Tightening Specifications ..,.............................................Page No.

38-193B-1938-21jB-21

DESCRIPTION AND OPERATION2. Using remover J-21687, pull outer tie rod ball

studs out of steering arms. See Figure

3B-2.DESCRIPTION AND OPERATION OF TIE RODS

Tie rods on the GT are connected to both rack ends

by means of a ball joint. Two rubber bellows between

ball joint and steering gear housing protect rack and

ball joints against dirt, dust and mud. The ball joints

of the tie rods do not require service.

Tie rods on the Opel l&O and Manta are connected

to both rack ends by means of a axial joint. Two

rubber bellows between the axial joint and steering

gear housing protect the rack and axial joints against

dirt, dust, and mud. The ball joint of the tie rod ends

on the Opel 1900 and Manta are maintenance free

and must not be disassembled.

MAJOR REPAIRREMOVAL AND INSTALLATION OF TIE RODS

38-2

RemovalFigure

38-2 Removing Ball Stud

In order to avoid the possibility of dirt entering the

steering gear assembly via the rack, it is recom-

mended that rods and area immediately surrounding

the gear assembly be wiped free of loose dirt prior to

removal.3. Remove clamp securing one end of rubber bellows

to tie rods and slip bellows off tie rods to expose nut

or lock plates. See Figure

3B-3.1. Remove cotter pins securing nuts on tie rod ends

and remove nuts. Discard cotter pins.4. On the GT, bend up round edges of lock plate

from tie rod ball studs and unscrew ball studs From

rack. See Figure

3B-4.

Page 187 of 625

Figure 38-3 Bellows Removed From Tie Rod GT

5. On the Opel 1900 - Manta, unscrew tie rod from

axial joint. It is important that rack be held secure

with open end wrench to prevent damage to rack

teeth.

38. 201973 OPEL SERWCE MANUAL

Figure 38.4 Removing Tie Rods. GT

Installation . GT

CAUTION:

Fasteners are important attaching parts in

that they could affect the performance of vital com-

ponents and systems, and/or

coo/d result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part or lesser

quaJity or sub.Mute design.

Torque

vaJues must be used as specified during reas-

sembJy to assure proper retention of these parts.1. Install new lock plates onto tie rod ball studs and

screw ball studs into rack while holding bent tab of

lock plates against flat on rack. Torque ball studs 43lb.ft. See Figure

3B-5. It is important that rack be

held secure with open end wrench to prevent damage

to rack teeth.

Figure 38-5 Bending Lock Plate Over Ball Stud

- GT

2. Bend round edges of lock plate over

flat on ball

stud

‘to lock ball stud in position.

3. Position rubber bellows and hose clamps over tie

rods and adjust clamp so that wire ends are pointing

in same direction as adjusting screw. Check that bel-

lows are not twisted and will compress and expand

properly.

4. Connect outer tie rod ball stud to steering arm,

torque castle nut to 29

lb.ft., and lock in position

with new cotter pin.

Installation Opel 1900. Manta

CAUTION:

Fasteners are important attachingparts in

that they could ah% the performance of vital com-

ponents and systems, and/or

couJd reslllt in major

repair expense. They must be replaced with one of

the same part number or with an

equivalenr part if

repJacement becomes necessary. Do not use a re-

placement part of lesser quality or substitute design.

Torque valves must be used as specified during

reas-

sembfy to assure proper retention of these parts.1. Screw tie rod into axial joint.

2. Attach tie rod end to steering arm and torque nut

to 29 lb.ft. Install new cotter pin.

3. Adjust toe-in and then torque lock nut of both tie

rods to 47 lbft.

Page 188 of 625

STEERING LINKAGE38-21

4. Attach rubber bellows to axial joint using hoseClamp.DISASSEMBLY AND REASSEMBLY OF TIE RODS

The ball joint of the tie rod end on the Opel 1900

_Manta is maintenance free and must not be disassem-

bled.

Disassembly - GT

?. Loosen tie rod clamp bolt and unscrew outer tie

rod ball stud from tie rod. See Figure

3B-6.2. Remove retainer ring from outer ball stud of tie

rod and take off rubber sealing cap.

Reassembly GT1. Install rubber sealing cap and retainer ring onto

outer ball stud.

2. Screw outer tie rod ball stud into tie rod and

tighten clamp bolt.

CAUTION: Fasteners for tie rods are important

attaching parts in that they could affect the per-

formance of vital components and systems, and-

TIE ROD rCLAMPOUTERy BALL STUD

RETAINER RING

SEALING RINGFigure

38-6 Tie Rod and Outer Ball Stud

/or could result in major repair expense.They must

be replaced with one of the same part number or with

an equivalent part if replacement becomes necessary.

Do not use a replacement part or lesser quality or

substitute design. Torque values must be used as

specified during reassembly to assure proper reten-

tion of these parts.

SPECIFICATIONSTIGHTENING SPECIFICATIONS

Location

Ball Stud to Rack (GT)Ball Stud to Steering Arm (GT)

Tie Rod End to Steering Arm (1900 . Manta)

Tie Rod Lock Nut (1900

- Manta)

Torque

Lb.Ft.

4329

29

47

Page 191 of 625

3C-24 1973 OPEL SERVICE MANUAL

NOTE:

FRONT OF CAR

4Figure

3C-3 Upper Control Arm Shaft and Bushingsx.3

Figure

3C-4 Supporting Vehicle at Both Lower

Control Arms(B) (rear) between upper control arm and shock ab-

sorber support. See Figure

3C-5.5. One

.24” thick washer each is installed in produc-

tion on each car side. Consequently, only two adjust-

ments are possible by adding washers of different

thickness.

6. One

.12” in front and one .36” in the rear (caster

increase of 1 degree) or one

.36” in front and one. 12”

in the rear (caster decrease of 1 degree). Never addFRONT OF CAR

3G5

Figure

3C-5 Caster Adjustment Washer Location -Opel 1900 - Manta

several washers in one place. The washers B installed

in production have a larger outer diameter than the

washer A. For service, the Parts and Accessories

Department supplies only larger washers with an

outer diameter of 1.57”.

7. Insert control arm shaft from front towards the

rear into upper control arm and shock absorber

SUP-port. Observe that the crown of both plate washers

shows inwards. See Figure

3C-5.8. Torque hex nut of control arm shaft to 40 ft.lbs.

Always use new self-locking nut.

9. Torque wheel nuts to 75

ft.lbs.10. Recheck caster setting.