bores OPEL 1900 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: 1900, Model: OPEL 1900 1973Pages: 625, PDF Size: 17.22 MB

Page 152 of 625

ROOF AND SUN ROOF2F-29Installation of Sun Roof Frame1. Slide sun roof frame into lower slot of guide rails,

position fully rearward and reattach guide rails to

roof.NOTE: Be sure guide rail retainers at rear of guide

rails are positioned with their dowels in bores of roof

frame.2. Install upper corner plates and secure in place..

3. Install sun roof panel.

REMOVAL AND INSTALLATION OF VELVET STRIP

ON SUN ROOF OPENING, AND VELVET STRIP AND

WEATHERSTRIP ON REAR OF SUN ROOF PANEL

Removal of Velvet Strip on Sun Roof Opening1. Fully open sun roof.

;2. Carefully pull off velvet strip using solvent to dis-

solve cement. Clean area thoroughly before installing

new velvet strip.

Installation of Velvet Strip On Sun Roof Opening1. Cut away for a distance of 1.5 inch the velvet

material on velvet strip that will be on the outside

when strip is cemented in positioAlso cut off to

this dimension the plastic cord i

not cut away velvet material on

1strip which is to be cemented

2. Using

nitrile vinyl trim adhesive (3M Vinyl Trim

Adhesive, Permalastic Viny1 Trim Adhesive or

equivalent) apply sparingly to both sun roof opening

and side of velvet strip to be cemented.

3. Immediately install new velvet strip and position

so that upper edge of velvet strip is flush with car

roof.4. Clean off excess cement being careful not to con-

tact velvet strip.

Removal of Velvet Strip and Wea’therstrip on Rear

of Sun Roof Panel1. Remove sun roof panel.

2. Carefully detach weatherstrip and velvet strip

from sun roof panel using solvent as required todisdolve cement. Thoroughly clean area before in-

stalling new velvet strip and weatherstrip.

Installing Velvet Strip and Weatherstrip On Rear

of Sun Roof Panel1. Using

nitrile vinyl trim adhesive (3M Vinyl Trim

Adhesive Permalastic Viny1 Trim Adhesive or

equivalent) apply sparingly to vertical and horizontal

contact areas at rear of sun roof panel (see Figure

2F-9) and also to side of velvet strip which will touch sun

roof panel.

REAR OF SUN ROOF PANEL

ICAR ROOF

VELVET STRIP

II

,/ WETRSTRIP 1APPLY CEMENT TO HORIZONTAL AND

VERTICAL SURFACES,TO BOTH SIDES

OF VELVET STRIP AND TO SIDE AND

BOTTOM OF WEATHERSTRIP2F-9

Figure

ZF-9 Installing Velvet Strip and Weatherstrip

on Rear of Sun Roof Panel

2. Immediately install new velvet strip and position

so that top edge of velvet strip is flush with sun roof

panel.

3. Apply cement to outboard edge of velvet strip and

to top and bottom contact surfaces of weatherstrip,

and install weatherstrip in position.

4. Clean off excess cement being careful not to con-

tact velvet strip.

5. Install sun roof panel.

REMOVAL AND INSTALLATION OF REAR GUIDES

AND CABLE

Removal of Rear Guides and Cable

1. Remove sun roof panel.

2. Crank rear lifter guides fully rearward and then

remove crank handle and cable crank.

Page 245 of 625

46. 141973 OPEL SERVICE MANUAL

2. Install rear pinion bearing outer race (without

shims) using installer J-7818 and driver handle

J-8092. See Figure 4B-12.

3. To determine the correct pinion depth setting use

the following procedures:

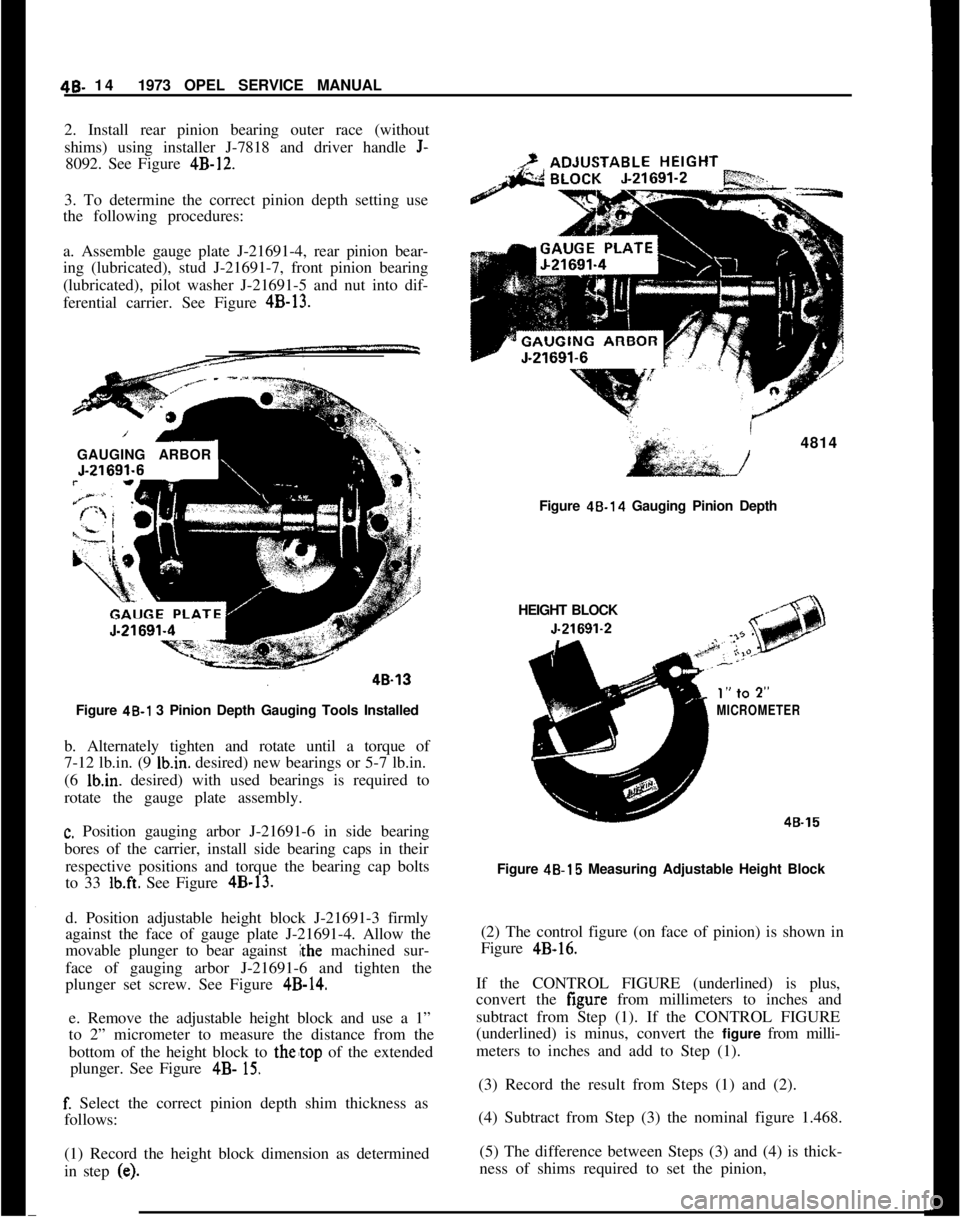

a. Assemble gauge plate J-21691-4, rear pinion bear-

ing (lubricated), stud J-21691-7, front pinion bearing

(lubricated), pilot washer J-21691-5 and nut into dif-

ferential carrier. See Figure 4B-13.

‘1GAUGING ARBOR

Figure 48-l 3 Pinion Depth Gauging Tools Installed

b. Alternately tighten and rotate until a torque of

7-12 lb.in. (9 Ibin. desired) new bearings or 5-7 lb.in.

(6 lb.in. desired) with used bearings is required to

rotate the gauge plate assembly.

c. Position gauging arbor J-21691-6 in side bearing

bores of the carrier, install side bearing caps in their

respective positions and torque the bearing cap bolts

to 33

lb.ft. See Figure 4B-13.

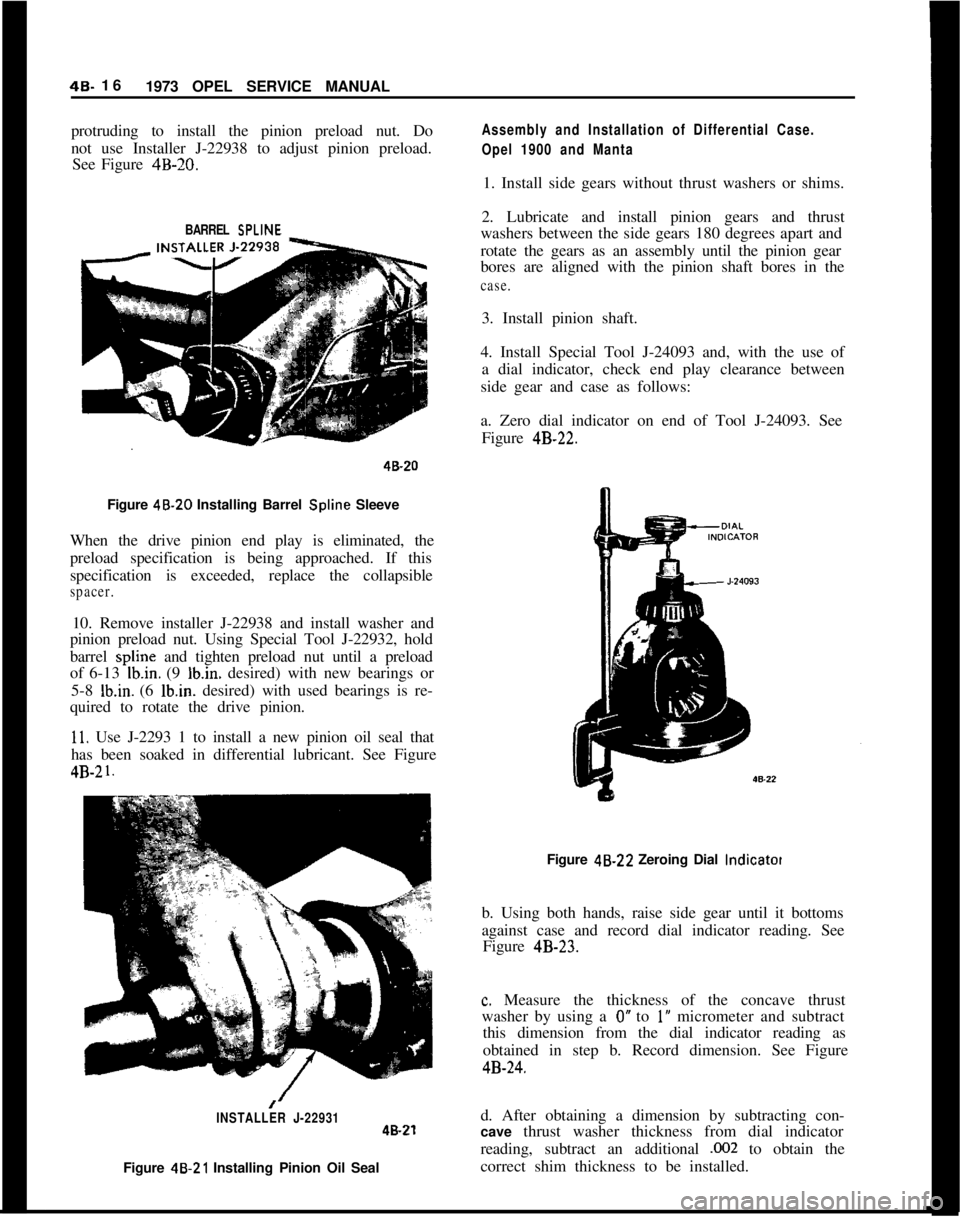

d. Position adjustable height block J-21691-3 firmly

against the face of gauge plate J-21691-4. Allow the

movable plunger to bear against

#the machined sur-

face of gauging arbor J-21691-6 and tighten the

plunger set screw. See Figure

4B-14.e. Remove the adjustable height block and use a 1”

to 2” micrometer to measure the distance from the

bottom of the height block to

thetop of the extended

plunger. See Figure

4B- 15.

f. Select the correct pinion depth shim thickness as

follows:

(1) Record the height block dimension as determined

in step

(e).

I4814

/Figure 48.14 Gauging Pinion Depth

HEIGHT BLOCK

MICROMETER

48-15Figure 4B-15 Measuring Adjustable Height Block

(2) The control figure (on face of pinion) is shown in

Figure

4B-16.If the CONTROL FIGURE (underlined) is plus,

convert the figure from millimeters to inches and

subtract from Step (1). If the CONTROL FIGURE

(underlined) is minus, convert the figure from milli-

meters to inches and add to Step (1).

(3) Record the result from Steps (1) and (2).

(4) Subtract from Step (3) the nominal figure 1.468.

(5) The difference between Steps (3) and (4) is thick-

ness of shims required to set the pinion,

Page 247 of 625

48. 16

1973 OPEL SERVICE MANUAL

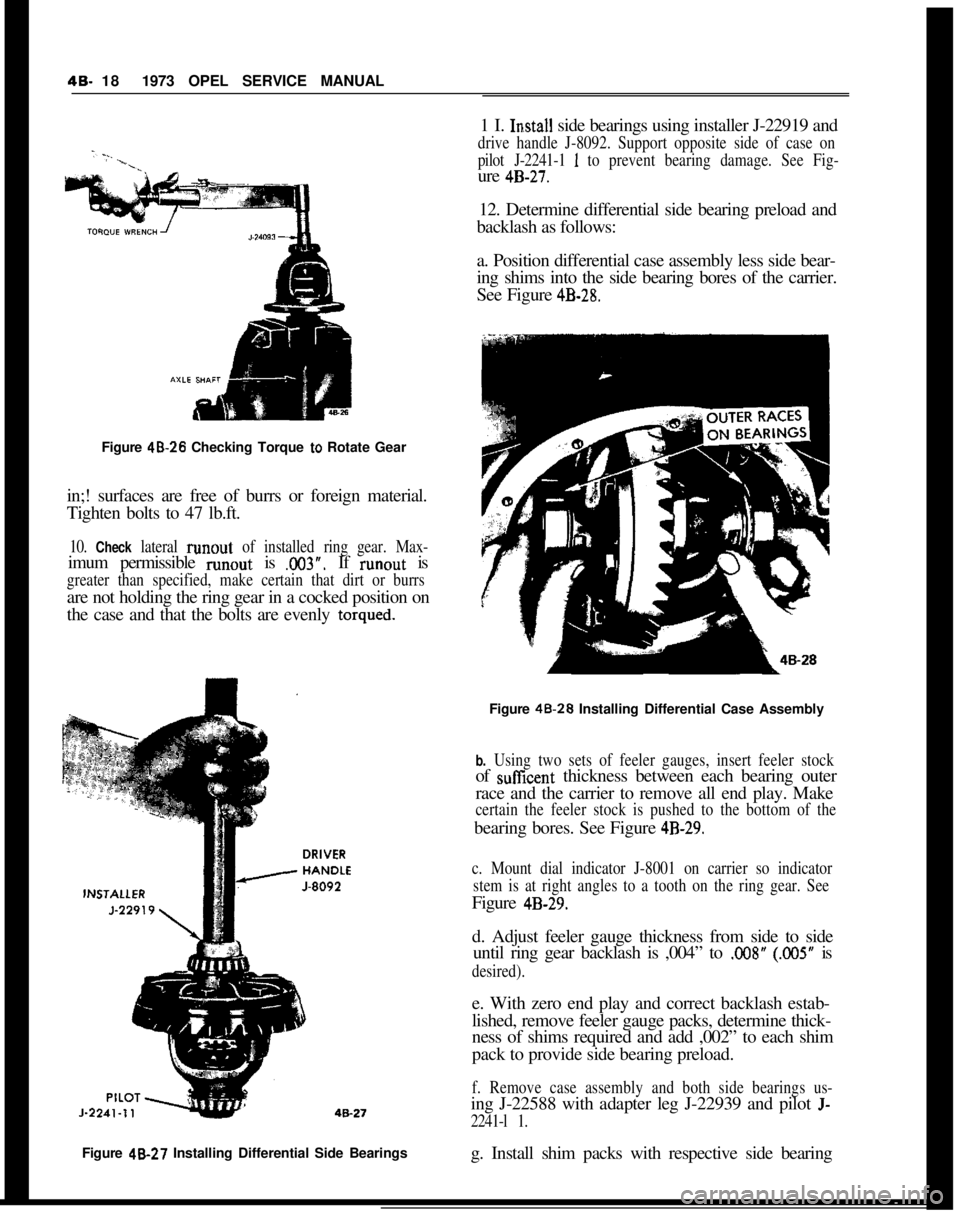

protruding to install the pinion preload nut. Do

not use Installer J-22938 to adjust pinion preload.

See Figure 4B-20.

Assembly and Installation of Differential Case.

Opel 1900 and Manta1. Install side gears without thrust washers or shims.

BARREL SPLINE2. Lubricate and install pinion gears and thrust

washers between the side gears 180 degrees apart and

rotate the gears as an assembly until the pinion gear

bores are aligned with the pinion shaft bores in the

case.3. Install pinion shaft.

4. Install Special Tool J-24093 and, with the use of

a dial indicator, check end play clearance between

side gear and case as follows:

40-20a. Zero dial indicator on end of Tool J-24093. See

Figure 4B-22.

Figure 48.20 Installing Barrel Spline Sleeve

When the drive pinion end play is eliminated, the

preload specification is being approached. If this

specification is exceeded, replace the collapsible

spacer.10. Remove installer J-22938 and install washer and

pinion preload nut. Using Special Tool J-22932, hold

barrel spline and tighten preload nut until a preload

of 6-13

Ib.in. (9 Ibin. desired) with new bearings or

5-8

Ib.in. (6 lb.in. desired) with used bearings is re-

quired to rotate the drive pinion.

11. Use J-2293 1 to install a new pinion oil seal that

has been soaked in differential lubricant. See Figure4B-2

1.Figure 48.22 Zeroing Dial

lndicatotb. Using both hands, raise side gear until it bottoms

against case and record dial indicator reading. See

Figure 4B-23.

c. Measure the thickness of the concave thrust

washer by using a

0” to 1’ micrometer and subtract

this dimension from the dial indicator reading as

obtained in step b. Record dimension. See Figure

4B-24.

/INSTALLER J-22931d. After obtaining a dimension by subtracting con-48-21cave thrust washer thickness from dial indicator

reading, subtract an additional

,002 to obtain the

Figure 46.21 Installing Pinion Oil Sealcorrect shim thickness to be installed.

Page 249 of 625

48. 181973 OPEL SERVICE MANUAL

Figure 48.26 Checking Torque

to Rotate Gear

in;! surfaces are free of burrs or foreign material.

Tighten bolts to 47 lb.ft.

10. Check lateral runout of installed ring gear. Max-imum permissible runout is

.003”. If runout is

greater than specified, make certain that dirt or burrsare not holding the ring gear in a cocked position on

the case and that the bolts are evenly

torqued.Figure 48-27 Installing Differential Side Bearings

g. Install shim packs with respective side bearing1 I.

In.stall side bearings using installer J-22919 and

drive handle J-8092. Support opposite side of case on

pilot J-2241-1

1 to prevent bearing damage. See Fig-ure

4B-27.12. Determine differential side bearing preload and

backlash as follows:

a. Position differential case assembly less side bear-

ing shims into the side bearing bores of the carrier.

See Figure

4B-28.Figure 48.28 Installing Differential Case Assembly

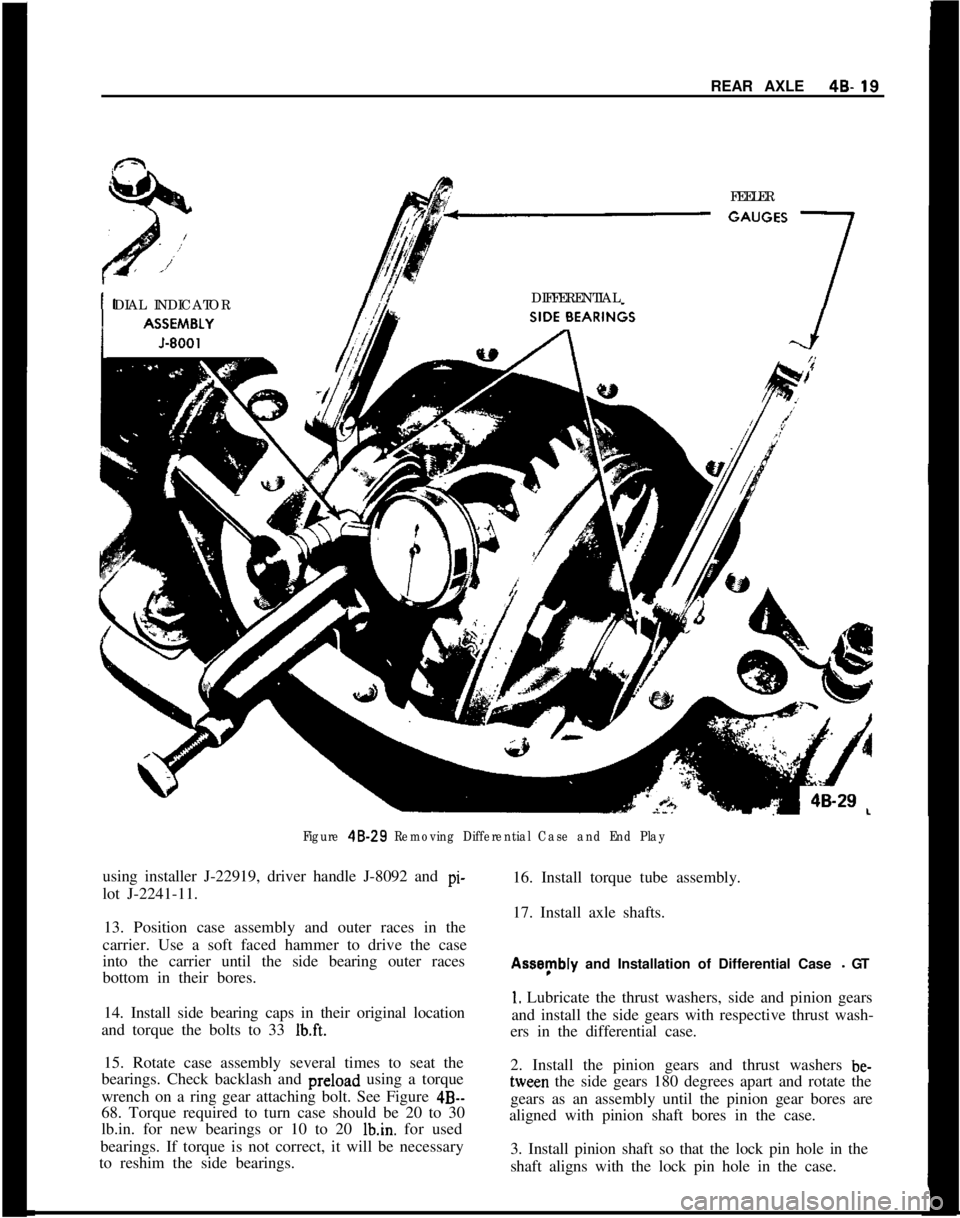

b. Using two sets of feeler gauges, insert feeler stockof suffcent thickness between each bearing outer

race and the carrier to remove all end play. Make

certain the feeler stock is pushed to the bottom of thebearing bores. See Figure

4B-29.

c. Mount dial indicator J-8001 on carrier so indicator

stem is at right angles to a tooth on the ring gear. SeeFigure

4B-29.d. Adjust feeler gauge thickness from side to side

until ring gear backlash is ,004” to

.OO8” (.005” is

desired).e. With zero end play and correct backlash estab-

lished, remove feeler gauge packs, determine thick-

ness of shims required and add ,002” to each shim

pack to provide side bearing preload.

f. Remove case assembly and both side bearings us-ing J-22588 with adapter leg J-22939 and pilot

J-

2241-l 1.

Page 250 of 625

REAR AXLE48.19FEELER

DIAL INDICATORDIFFERENTIAL

Figure 48.29 Removing Differential Case and End Playusing installer J-22919, driver handle J-8092 and pi-

lot J-2241-11.16. Install torque tube assembly.

17. Install axle shafts.

13. Position case assembly and outer races in the

carrier. Use a soft faced hammer to drive the case

into the carrier until the side bearing outer races

bottom in their bores.Assynbly and Installation of Differential Case

- GT

14. Install side bearing caps in their original location

and torque the bolts to 33

Ib.ft.

1. Lubricate the thrust washers, side and pinion gears

and install the side gears with respective thrust wash-

ers in the differential case.

15. Rotate case assembly several times to seat the

bearings. Check backlash and preload using a torque

wrench on a ring gear attaching bolt. See Figure

4B--68. Torque required to turn case should be 20 to 30

lb.in. for new bearings or 10 to 20 Ibin. for used

bearings. If torque is not correct, it will be necessary

to reshim the side bearings.2. Install the pinion gears and thrust washers be-tween the side gears 180 degrees apart and rotate the

gears as an assembly until the pinion gear bores are

aligned with pinion shaft bores in the case.

3. Install pinion shaft so that the lock pin hole in the

shaft aligns with the lock pin hole in the case.

Page 252 of 625

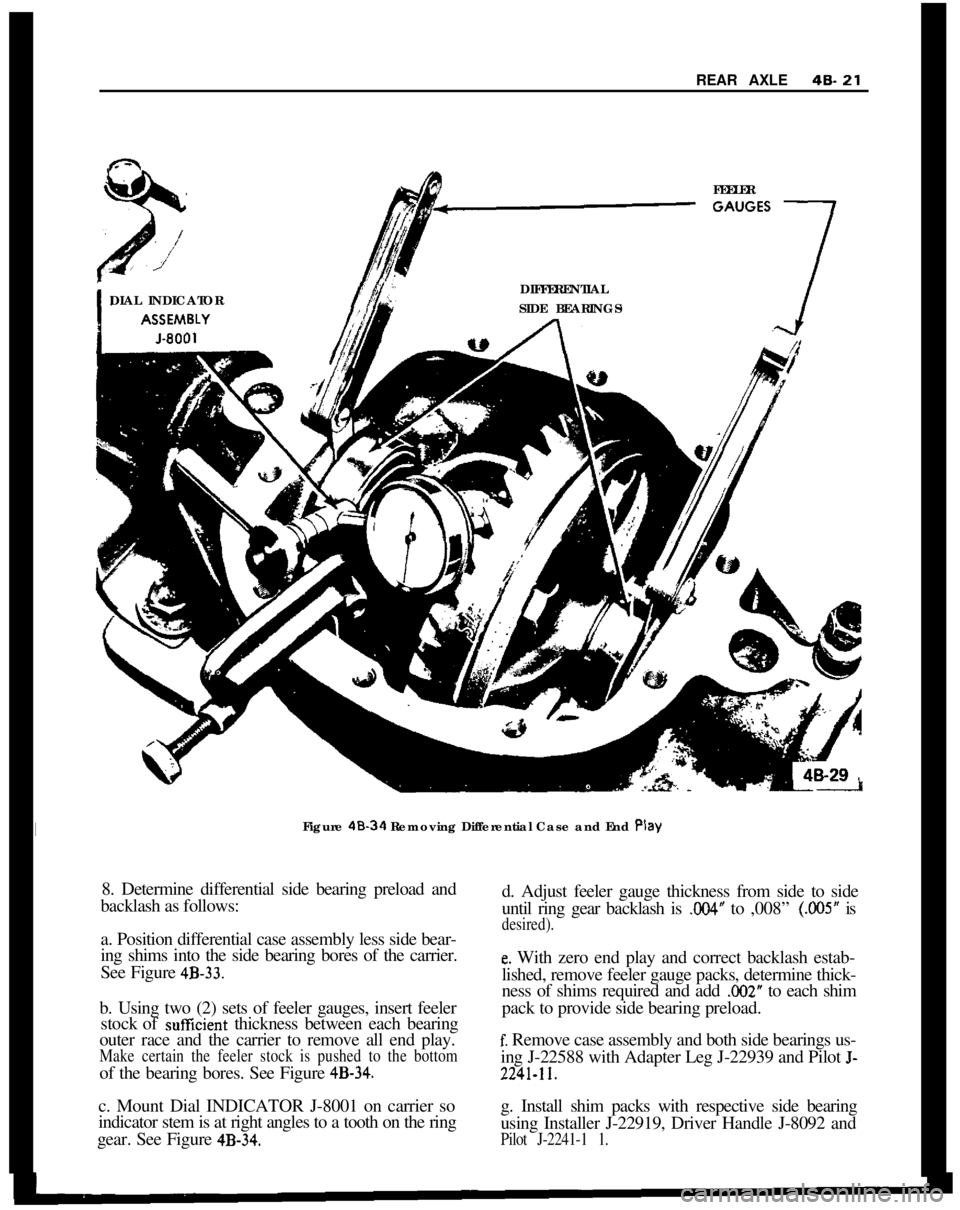

REAR AXLE48.21FEELER

DIFFERENTIAL

DIAL INDICATOR

SIDE BEARINGS

Figure 48.34 Removing Differential Case and End

Play8. Determine differential side bearing preload and

backlash as follows:d. Adjust feeler gauge thickness from side to side

until ring gear backlash is

004” to ,008” (.005” is

desired).a. Position differential case assembly less side bear-

ing shims into the side bearing bores of the carrier.

See Figure

4B-33.b. Using two (2) sets of feeler gauges, insert feeler

stock of sufficient thickness between each bearing

outer race and the carrier to remove all end play.

Make certain the feeler stock is pushed to the bottomof the bearing bores. See Figure

4B-34.

e. With zero end play and correct backlash estab-

lished, remove feeler gauge packs, determine thick-

ness of shims required and add

.002” to each shim

pack to provide side bearing preload.

f. Remove case assembly and both side bearings us-

ing J-22588 with Adapter Leg J-22939 and Pilot

J-

2241-11.c. Mount Dial INDICATOR J-8001 on carrier sog. Install shim packs with respective side bearing

indicator stem is at right angles to a tooth on the ring

using Installer J-22919, Driver Handle J-8092 and

gear. See Figure

4B-34.Pilot J-2241-1 1.

Page 253 of 625

48. 221973 OPEL SERVICE MANUAL

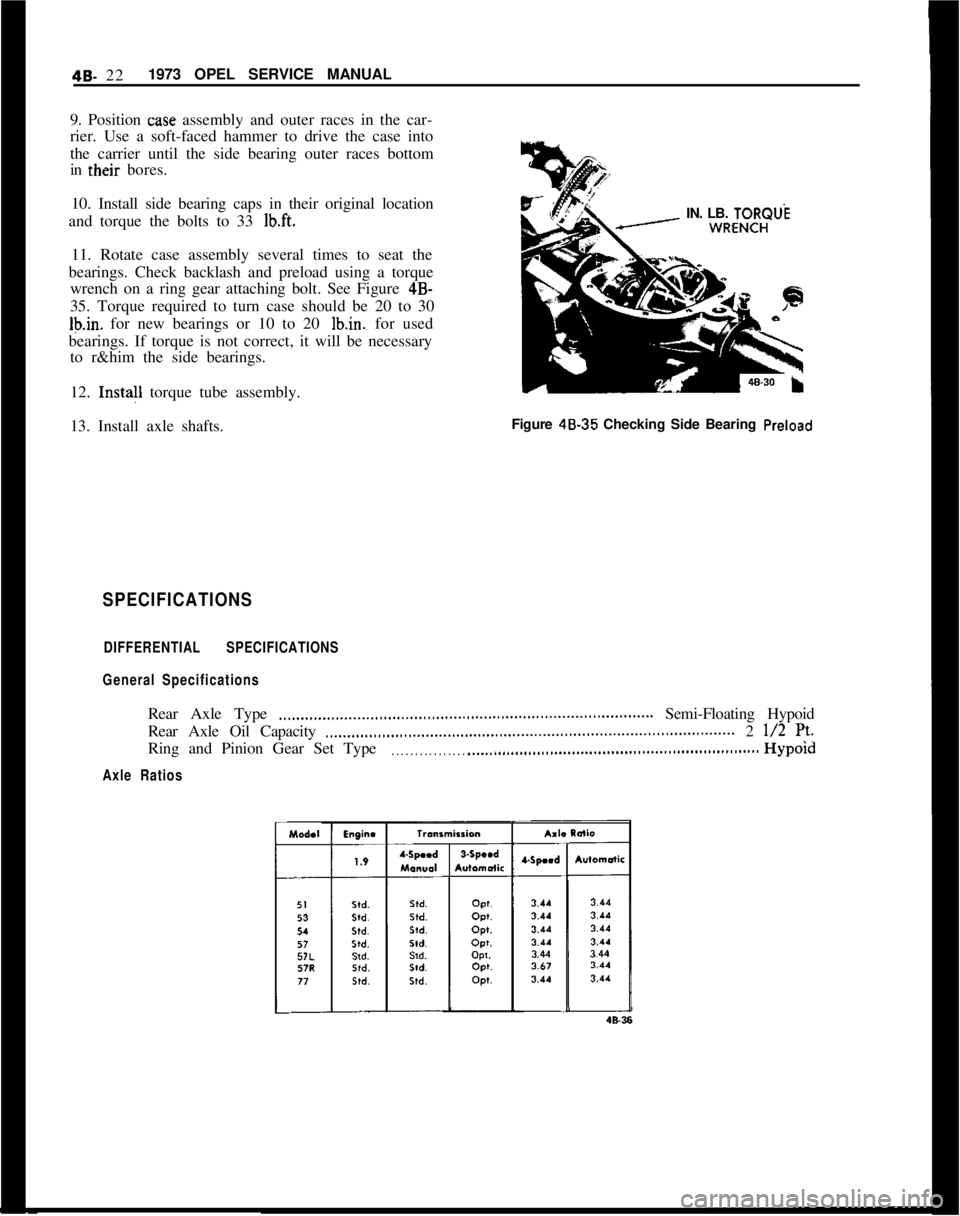

9. Position

case assembly and outer races in the car-

rier. Use a soft-faced hammer to drive the case into

the carrier until the side bearing outer races bottom

in their bores.

10. Install side bearing caps in their original location

and torque the bolts to 33

lb.ft.IN. LB. TORQUL

11. Rotate case assembly several times to seat the

bearings. Check backlash and preload using a torque

wrench on a ring gear attaching bolt. See Figure 4B-

35. Torque required to turn case should be 20 to 30

Ib.in. for new bearings or 10 to 20 lb.in., for used

bearings. If torque is not correct, it will be necessary

to r&him the side bearings.

12. Insta!l torque tube assembly.

13. Install axle shafts.Figure 48.35 Checking Side Bearing

Preload

SPECIFICATIONS

DIFFERENTIAL SPECIFICATIONS

General SpecificationsRear Axle Type

.,,...,,,...,,_...._..,,...,,,...,,,....,,.,...,,.,,...,,..,,,........................ Semi-Floating Hypoid

Rear Axle Oil Capacity

..____,,...,,,...,.,..,............,,..,,..,,................................................. 2 l/2 7’.Ring and Pinion Gear Set Type

. . . . . . . . . . . . . . . . . .._................................................................Hypold

Axle Ratios

Page 269 of 625

5B- 10 1973 OPEL SERVICE MANUAL

DISC BRAKES

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . . .DIAGNOSIS:

DiscBrakeTroubleDiagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

Disc Brake Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Checking Disc Brake Friction Pads for Wear

. . . . . . . . . .Replacing Friction Pads

Checking Brake Disc for Lateral

Runout. . . . . . . . . . . . . . . . . .MAJOR REPAIR:

RemovingandInstallingBrakeCaliper. . . . . . . . . . . . . . . . . . . . . .Removing and Installing Brake Disc

. . . . . . . , . . . . . . . . . . . . . . . . . .

RemovingandInstallingBrakeDiscShield. . . . . . . . . . . . . .Disassembly and Assembly of Brake Caliper

. . . . . . . . . .SPECIFICATIONS:

Disc Brake Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

58-1058-l

1

58-12

58-15

SB-15

5&17

56-17

58-17

58-195519

58-21

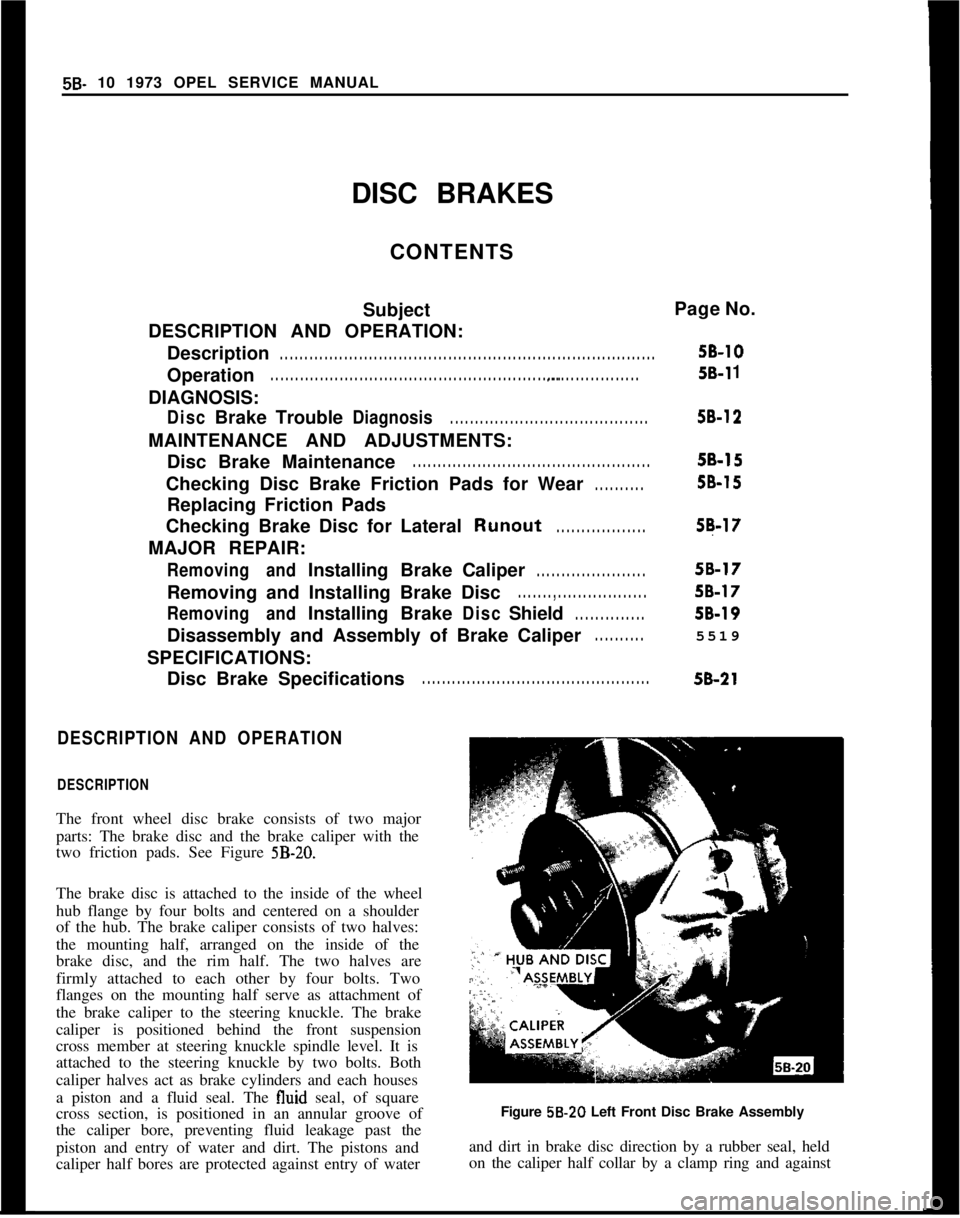

DESCRIPTION AND OPERATION

DESCRIPTIONThe front wheel disc brake consists of two major

parts: The brake disc and the brake caliper with the

two friction pads. See Figure

5B-20.The brake disc is attached to the inside of the wheel

hub flange by four bolts and centered on a shoulder

of the hub. The brake caliper consists of two halves:

the mounting half, arranged on the inside of the

brake disc, and the rim half. The two halves are

firmly attached to each other by four bolts. Two

flanges on the mounting half serve as attachment of

the brake caliper to the steering knuckle. The brake

caliper is positioned behind the front suspension

cross member at steering knuckle spindle level. It is

attached to the steering knuckle by two bolts. Both

caliper halves act as brake cylinders and each houses

a piston and a fluid seal. The fluid seal, of square

cross section, is positioned in an annular groove of

the caliper bore, preventing fluid leakage past the

piston and entry of water and dirt. The pistons and

caliper half bores are protected against entry of waterFigure 58.20 Left Front Disc Brake Assembly

and dirt in brake disc direction by a rubber seal, held

on the caliper half collar by a clamp ring and against

Page 270 of 625

DISC BRAKES5B- 11

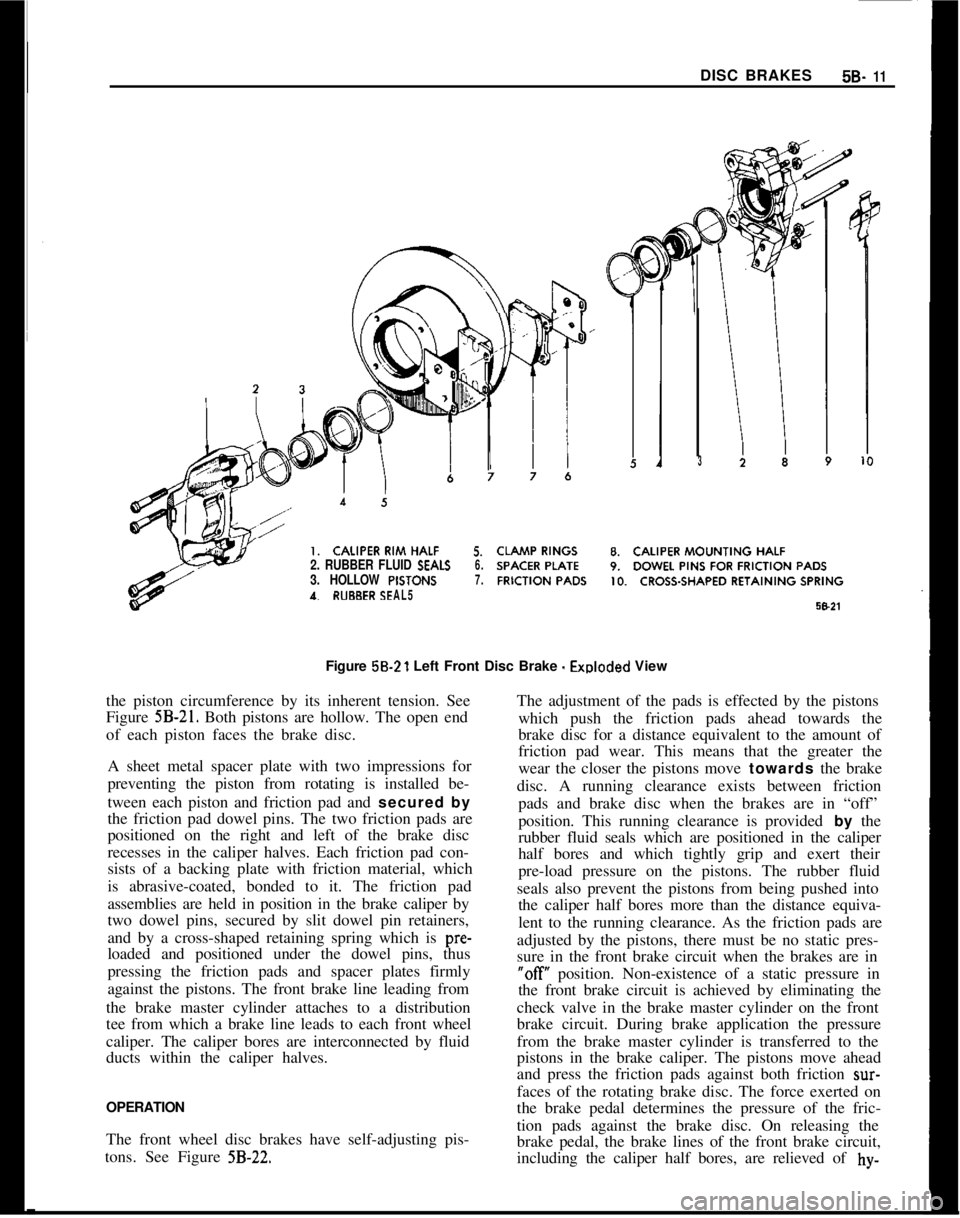

rLF 5.2. RUBBER FLUID SEALS6.3. HOLLOW PISTONS7.

AL5

3Figure 58.21 Left Front Disc Brake

- Emloded View

the piston circumference by its inherent tension. See

Figure

5B-21. Both pistons are hollow. The open end

of each piston faces the brake disc.

A sheet metal spacer plate with two impressions for

preventing the piston from rotating is installed be-

tween each piston and friction pad and secured by

the friction pad dowel pins. The two friction pads are

positioned on the right and left of the brake disc

recesses in the caliper halves. Each friction pad con-

sists of a backing plate with friction material, which

is abrasive-coated, bonded to it. The friction pad

assemblies are held in position in the brake caliper by

two dowel pins, secured by slit dowel pin retainers,

and by a cross-shaped retaining spring which is pre-

loaded and positioned under the dowel pins, thus

pressing the friction pads and spacer plates firmly

against the pistons. The front brake line leading from

the brake master cylinder attaches to a distribution

tee from which a brake line leads to each front wheel

caliper. The caliper bores are interconnected by fluid

ducts within the caliper halves.

The front wheel disc brakes have self-adjusting pis-

tons. See Figure

5B-22.The adjustment of the pads is effected by the pistons

which push the friction pads ahead towards the

brake disc for a distance equivalent to the amount of

friction pad wear. This means that the greater the

wear the closer the pistons move towards the brake

disc. A running clearance exists between friction

pads and brake disc when the brakes are in “off”

position. This running clearance is provided by the

rubber fluid seals which are positioned in the caliper

half bores and which tightly grip and exert their

pre-load pressure on the pistons. The rubber fluid

seals also prevent the pistons from being pushed into

the caliper half bores more than the distance equiva-

lent to the running clearance. As the friction pads are

adjusted by the pistons, there must be no static pres-

sure in the front brake circuit when the brakes are in“OR position. Non-existence of a static pressure in

the front brake circuit is achieved by eliminating the

check valve in the brake master cylinder on the front

brake circuit. During brake application the pressure

from the brake master cylinder is transferred to the

pistons in the brake caliper. The pistons move ahead

and press the friction pads against both friction

SW-faces of the rotating brake disc. The force exerted on

the brake pedal determines the pressure of the fric-

tion pads against the brake disc. On releasing the

brake pedal, the brake lines of the front brake circuit,

including the caliper half bores, are relieved of

hy-OPERATION

Page 271 of 625

5B- 121973 OPEL SERVICE MANUAL

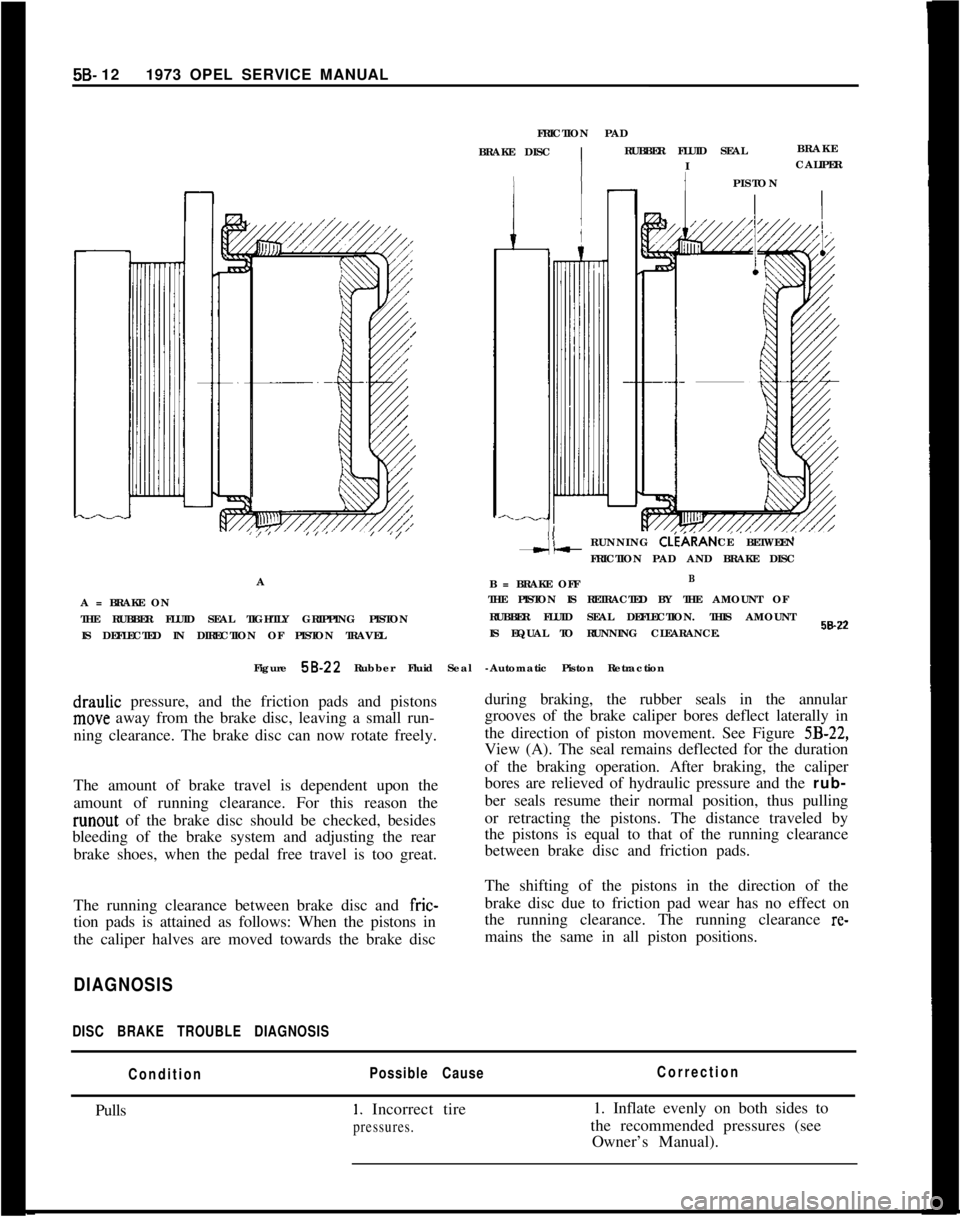

A = BRAKE ON

THE RUBBER FLUID SEAL TIGHTLY GRIPPING PISTON

IS DEFLECTED IN DIRECTION OF PISTON TRAVELAFRICTION PAD

BRAKE DISCRUBBER FLUID SEALBRAKE

IICALIPER

IPISTON

I

CE BETWEEN RUNNING CLEARAN

FRICTION PAD AND BRAKE DISC

B = BRAKE OFFBTHE PISTON IS RETRACTED BY THE AMOUNT OF

RUBBER FLUID SEAL DEFLECTION. THIS AMOUNT

IS EQUAL TO RUNNING CLEARANCE.SBZZ

Figure 58-22 Rubber Fluid Seal -Automatic Piston Retractiondraulic pressure, and the friction pads and pistonsmove away from the brake disc, leaving a small run-

ning clearance. The brake disc can now rotate freely.

The amount of brake travel is dependent upon the

amount of running clearance. For this reason therunout of the brake disc should be checked, besides

bleeding of the brake system and adjusting the rear

brake shoes, when the pedal free travel is too great.during braking, the rubber seals in the annular

grooves of the brake caliper bores deflect laterally in

the direction of piston movement. See Figure

5B-22,View (A). The seal remains deflected for the duration

of the braking operation. After braking, the caliper

bores are relieved of hydraulic pressure and the rub-

ber seals resume their normal position, thus pulling

or retracting the pistons. The distance traveled by

the pistons is equal to that of the running clearance

between brake disc and friction pads.

The running clearance between brake disc and

fric-tion pads is attained as follows: When the pistons in

the caliper halves are moved towards the brake discThe shifting of the pistons in the direction of the

brake disc due to friction pad wear has no effect on

the running clearance. The running clearance re-mains the same in all piston positions.

DIAGNOSIS

DISC BRAKE TROUBLE DIAGNOSIS

ConditionPulls

Possible Cause

I. Incorrect tire

pressures.Correction1. Inflate evenly on both sides to

the recommended pressures (see

Owner’s Manual).