OPEL AGILA 2009 Owners Manual

Manufacturer: OPEL, Model Year: 2009, Model line: AGILA, Model: OPEL AGILA 2009Pages: 153, PDF Size: 1.82 MB

Page 131 of 153

10-31Vehicle care

Polishing

Polishing is necessary only if the

paint has become dull or if solid

deposits have become attached to it.

Paintwork polish with silicone forms a

protective film, making waxing

unnecessary.

Plastic body parts should not be

treated with wax and polish.

Use Metallic Paintwork Wax on

vehicles with a metallic-effect paint

finish.

Plastic and rubber parts

For additional cleaning of plastic and

rubber parts, use a cleaner suitable

for vehicle interiors. Do not use any

other agent, and in particular do not

use solvents or petrol.

Windows and wiper blades

When cleaning the heated rear

window, make sure that the heating

element on the inside of the window

is not damaged. Never place stickers

on the inside of the rear window.Use a soft, lint-free cloth or chamois

leather, in conjunction with Window

Cleaning Spray and Insect Remover.

Do not use sharp instruments or

abrasive cleaners.

Windscreen Wash Solvent is suitable

for de-icing windows.

For mechanical removal of ice, use a

commercially available sharp-edged

ice scraper. Press the scraper firmly

against the glass so that no dirt can

get under it and scratch the glass.

Wax, such as that used in car

washes, can cause streaks to form on

the windscreen when the wipers are

used.

Wiper blades can be cleaned with a

soft cloth and Windscreen Wash

Solvent. Do not use abrasive

cleaners.Tyres and wheels

Do not use high-pressure jet cleaners

on wheels and tyres.

Use a pH-neutral wheel cleaning

agent to clean the wheels.Avoid using abrasive materials and

brushes that can damage the finish.

Wheels are painted and can be

treated with the same agents as the

body. For alloy wheels 3, we

recommend the use of Alloy Wheel

Preserver.

Paint damage

Repair small areas of paint damage

such as stone impacts, scratches etc.

before rust can form. If rust has

already formed, have the cause

remedied. Seek the assistance of a

workshop.

Underbody

Your vehicle has a factory-applied

PVC undercoating in the wheel

arches (including the longitudinal

members) which provides permanent

protection and needs no special

maintenance. The surfaces of the

vehicle underbody not covered by

PVC are provided with a durable

protective wax coating in critical

areas.

Page 132 of 153

10-32 Vehicle care

On vehicles which are washed

frequently in automatic car washes

with underbody washing facility, the

protective wax coating may be

impaired by dirt-dissolving additives.

Check the underbody after washing

and have it waxed if necessary.

Before the start of the cold weather

season, check the PVC coating and

protective wax coating and, if

necessary, have them restored to

perfect condition.

The underbody should be washed

following the end of the cold weather

season to remove any dirt adhering to

the underbody since this may also

contain salt. Check protective wax

coating and, if necessary, have it

restored to perfect condition.

Engine compartment

Areas of the engine compartment that

are painted in the same colour as the

vehicle must be looked after like any

other painted surface.

It is advisable to wash the engine

compartment before and after winter

and preserve it with wax. Cover alternator and fluid reservoirs with

plastic sheets before washing the

engine.

When washing the engine with a

steam-jet cleaner, do not direct the

steam-jet at components of the

Anti-lock Brake System (ABS), the air

conditioning system 3 or the belt

drive and its components.

Protective wax that has been applied

is also removed during the engine

wash. For this reason, have the

engine, brake system components in

the engine compartment, axle

components with steering, body parts

and cavities thoroughly preserved

with protective wax after the wash.

An engine wash can be performed in

the spring in order to remove dirt that

has adhered to the engine

compartment, which may also have a

high salt content. Check protective

wax layer and make good if

necessary.

Page 133 of 153

11-1Service and maintenance

Service and

maintenanceScheduled

maintenance

Service intervals

Interim Service

Due every 15,000 km (10,000 miles)

or 1 year, whichever occurs first.

Main Service

Due every 30,000 km (20,000 miles)

or 2 years, whichever occurs first.

The service intervals are based on

average operating conditions. For

severe operating conditions 311-5.

Service interval display 35-14.

Engine oil life monitor 35-14.Confirmations

Confirmation of Service is recorded in

the spaces provided in the Service

and Warranty Booklet. The date and

kilometre/mileage reading is

completed with the stamp and

signature of the Servicing Workshop.

Make sure that the Service and

Warranty Booklet is completed

correctly as continuous proof of

service is essential if any warranty or

goodwill claims are to be met, and is

also a benefit when you come to sell

the vehicle. Scheduled maintenance ....... 11-1

Service schedule .................. 11-2

Additional servicing ............... 11-5

Recommended fluids and

lubricants ............................ 11-5

Page 134 of 153

11-2 Service and maintenance

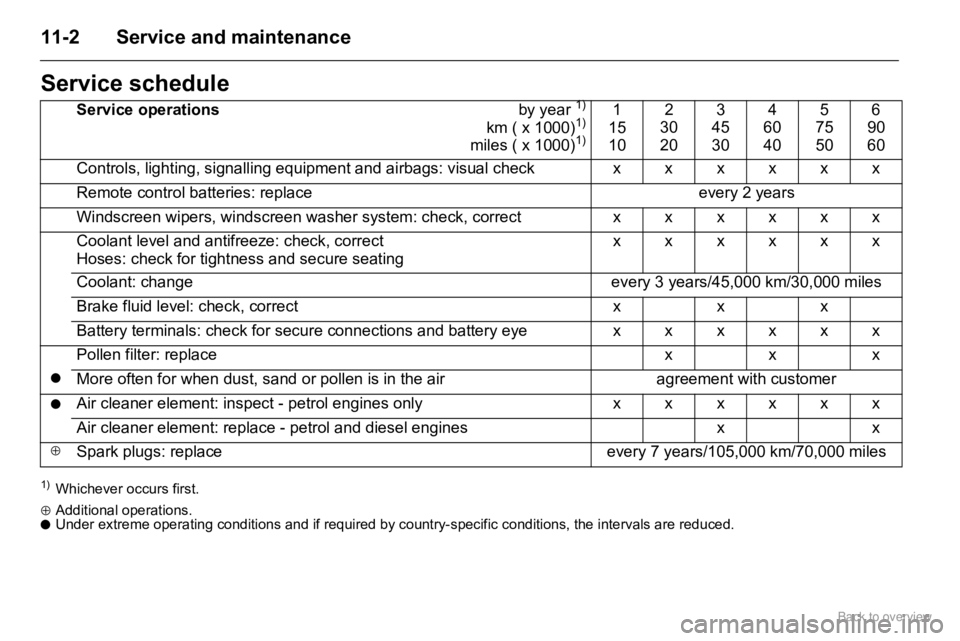

Service schedule

⊕Additional operations.o Under extreme operating conditions and if required by country-specific conditions, the intervals are reduced.

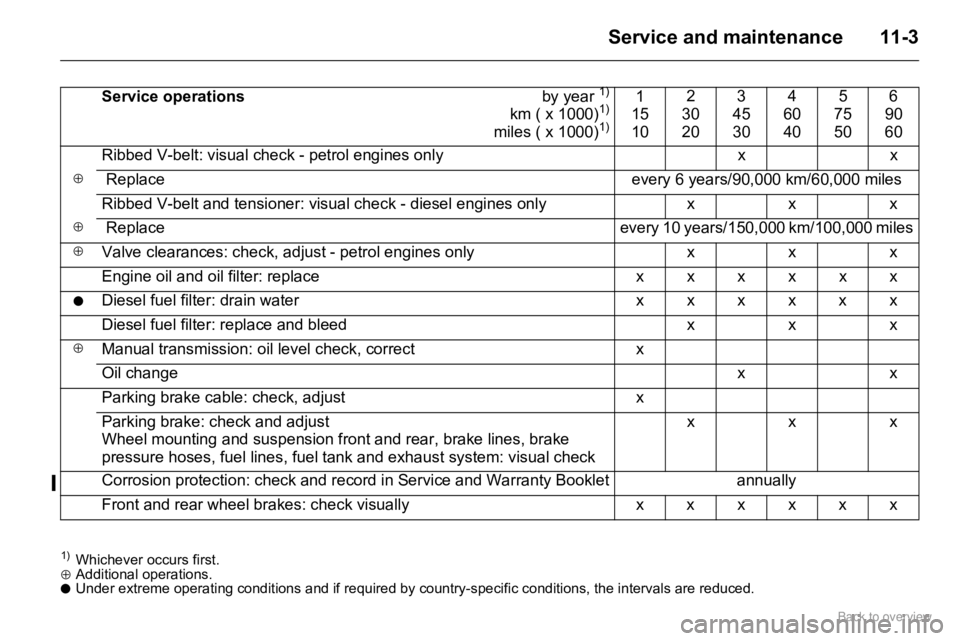

Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

1

15

102

30

203

45

304

60

405

75

506

90

60

Controls, lighting, signalling equipment and airbags: visual checkxxxxxx

Remote control batteries: replace every 2 years

Windscreen wipers, windscreen washer system: check, correctxxxxxx

Coolant level and antifreeze: check, correct

Hoses: check for tightness and secure seatingxxxxxx

Coolant: change every 3 years/45,000 km/30,000 miles

Brake fluid level: check, correct x x x

Battery terminals: check for secure connections and battery eyexxxxxx

Pollen filter: replace x x x

oMore often for when dust, sand or pollen is in the air agreement with customer

oAir cleaner element: inspect - petrol engines only xxxxxx

Air cleaner element: replace - petrol and diesel engines x x

⊕Spark plugs: replace every 7 years/105,000 km/70,000 miles

Page 135 of 153

11-3 Service and maintenance

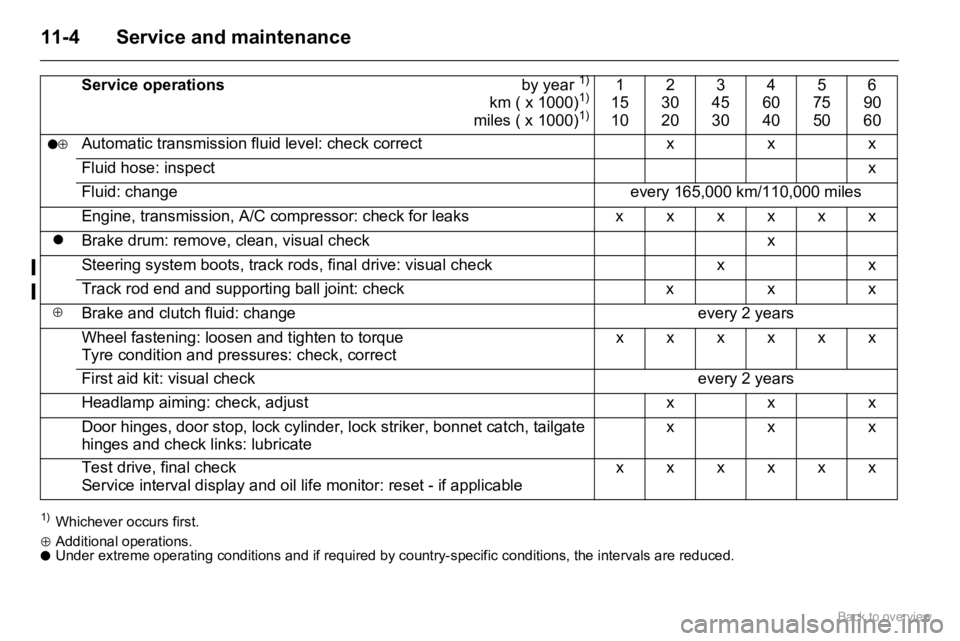

Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.⊕Additional operations.o Under extreme operating conditions and if required by country-specific conditions, the intervals are reduced.

1

15

102

30

203

45

304

60

405

75

506

90

60

Ribbed V-belt: visual check - petrol engines only x x

⊕ Replace every 6 years/90,000 km/60,000 miles

Ribbed V-belt and tensioner: visual check - diesel engines only x x x

⊕ Replace every 10 years/150,000 km/100,000 miles

⊕Valve clearances: check, adjust - petrol engines only x x x

Engine oil and oil filter: replace x x x x x x

oDiesel fuel filter: drain water x x x x x x

Diesel fuel filter: replace and bleed x x x

⊕Manual transmission: oil level check, correct x

Oil changexx

Parking brake cable: check, adjust x

Parking brake: check and adjust

Wheel mounting and suspension front and rear, brake lines, brake

pressure hoses, fuel lines, fuel tank and exhaust system: visual checkxxx

Corrosion protection: check and record in Service and Warranty Booklet annually

Front and rear wheel brakes: check visually x x x x x x

Page 136 of 153

11-4 Service and maintenance

⊕Additional operations.o Under extreme operating conditions and if required by country-specific conditions, the intervals are reduced.

Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1

15

102

30

203

45

304

60

405

75

506

90

60

o⊕Automatic transmission fluid level: check correct x x x

Fluid hose: inspectx

Fluid: change every 165,000 km/110,000 miles

Engine, transmission, A/C compressor: check for leaks x x x x x x

oBrake drum: remove, clean, visual check x

Steering system boots, track rods, final drive: visual check x x

Track rod end and supporting ball joint: check x x x

⊕Brake and clutch fluid: change every 2 years

Wheel fastening: loosen and tighten to torque

Tyre condition and pressures: check, correctxxxxxx

First aid kit: visual check every 2 years

Headlamp aiming: check, adjust x x x

Door hinges, door stop, lock cylinder, lock striker, bonnet catch, tailgate

hinges and check links: lubricate xxx

Test drive, final check

Service interval display and oil life monitor: reset - if applicablexxxxxx

1)Whichever occurs first.

Page 137 of 153

11-5Service and maintenance

Additional servicing

Additional operations ⊕

Additional work is work that is not

required every service but can be

performed in conjunction with a

regular service.

Time allowances for such work are

not included in the scope of regular

services and will be charged for

additionally. It is more economic if

these operations are performed as

part of a scheduled service than

having them performed separately.

Severe operating conditions o

Operating conditions are classified as

severe when one or more of the

following occurs frequently:

�„cold starts,

�„stop and go,

�„trailer/caravan towing,

�„gradients and/or high altitudes,

�„poor road surfaces,

�„sand and dust,

�„extreme temperature fluctuations. Police vehicles, taxis and driving

school vehicles are also classified as

operating under severe conditions.

Under severe operating conditions, it

may be necessary to have certain

scheduled service work done more

frequently than the scheduled

intervals.

For example, if fuel is used that does

not comply with required standards,

the fuel filter may need more frequent

draining or replacement and it may

also be necessary to change other

components more often (e.g. spark

plugs).

It is recommended to seek technical

advice on the servicing requirements

dependent on the specific operating

conditions of your vehicle.

Recommended fluids

and lubricants

Only use products that have been

tested and approved. Damage

resulting from the use of non-

approved materials will not be

covered by the warranty.

Checking and topping up fluids

3 10-3.

9 Warning

Operating materials are

hazardous and must be handled

with the appropriate level of care.

If consumed, seek medical

attention immediately. Do not

inhale fumes and avoid skin

contact. Keep out of reach of

children. Do not allow operating

materials to contaminate the

sewage system, surface water,

ground water or soil. Dispose of

empty containers properly.

Always bear in mind that

operating materials are

hazardous to your health.

Page 138 of 153

11-6 Service and maintenance

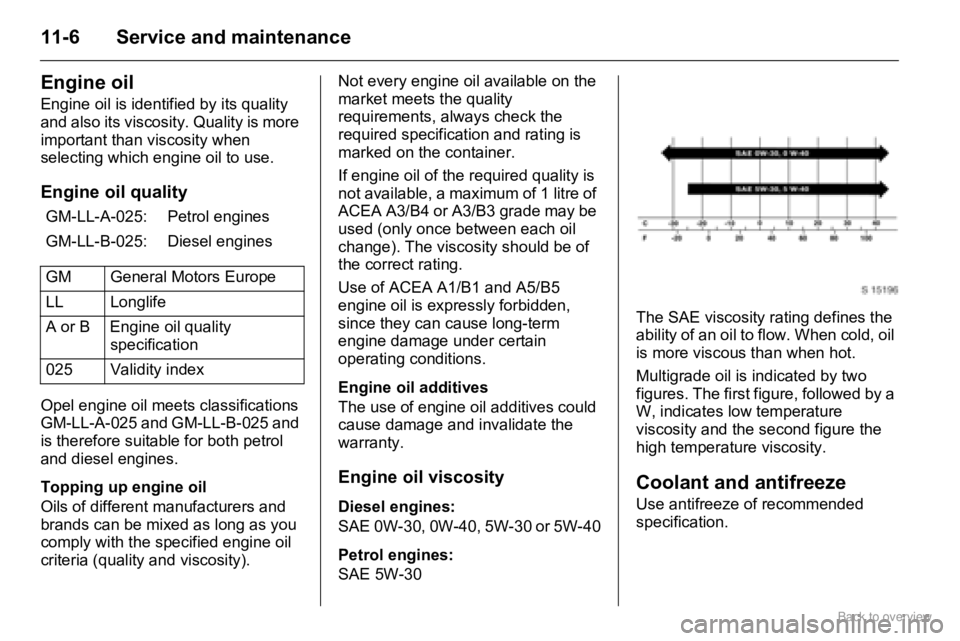

Engine oil

Engine oil is identified by its quality

and also its viscosity. Quality is more

important than viscosity when

selecting which engine oil to use.

Engine oil quality

Opel engine oil meets classifications

GM-LL-A-025 and GM-LL-B-025 and

is therefore suitable for both petrol

and diesel engines.

Topping up engine oil

Oils of different manufacturers and

brands can be mixed as long as you

comply with the specified engine oil

criteria (quality and viscosity).Not every engine oil available on the

market meets the quality

requirements, always check the

required specification and rating is

marked on the container.

If engine oil of the required quality is

not available, a maximum of 1 litre of

ACEA A3/B4 or A3/B3 grade may be

used (only once between each oil

change). The viscosity should be of

the correct rating.

Use of ACEA A1/B1 and A5/B5

engine oil is expressly forbidden,

since they can cause long-term

engine damage under certain

operating conditions.

Engine oil additives

The use of engine oil additives could

cause damage and invalidate the

warranty.

Engine oil viscosity

Diesel engines:

SAE 0W-30, 0W-40, 5W-30 or 5W-40

Petrol engines:

SAE 5W-30The SAE viscosity rating defines the

ability of an oil to flow. When cold, oil

is more viscous than when hot.

Multigrade oil is indicated by two

figures. The first figure, followed by a

W, indicates low temperature

viscosity and the second figure the

high temperature viscosity.

Coolant and antifreeze

Use antifreeze of recommended

specification. GM-LL-A-025: Petrol engines

GM-LL-B-025: Diesel engines

GM General Motors Europe

LL Longlife

A or B Engine oil quality

specification

025 Validity index

Page 139 of 153

11-7Service and maintenance

The system is factory-filled with

coolant designed for frost protection

down to approx. -28 °C. This

concentration should be maintained

all year-round.

Coolant additives intended to give

additional corrosion protection or seal

against minor leaks can cause

function problems. Liability for

consequences resulting from the use

of coolant additives will be rejected.

Brake and clutch fluid

Only use DOT4 brake fluid.

Over time, brake fluid absorbs

moisture which will reduce braking

effectiveness. The brake fluid should

therefore be replaced at the specified

interval.

Brake fluid should be stored in a

sealed container to avoid water

absorption. Ensure it does not become

contaminated with fluids containing

mineral oil (oil, petrol, cleaner) as this

can damage the seals and sleeves of

the brake system.Transmission fluid

Use fluid meeting specification

Grade: API GL-4

Viscosity: 75W-85 or 75W-90.

Automatic transmission fluid

Use fluid meeting specification

ATF3309.

9 Warning

Brake fluid is poisonous!

Caution

Due to its corrosive nature, it must

not come in contact with the

paintwork. Flush any escaped

brake fluid with plenty of water.

Page 140 of 153

12-1 Technical data

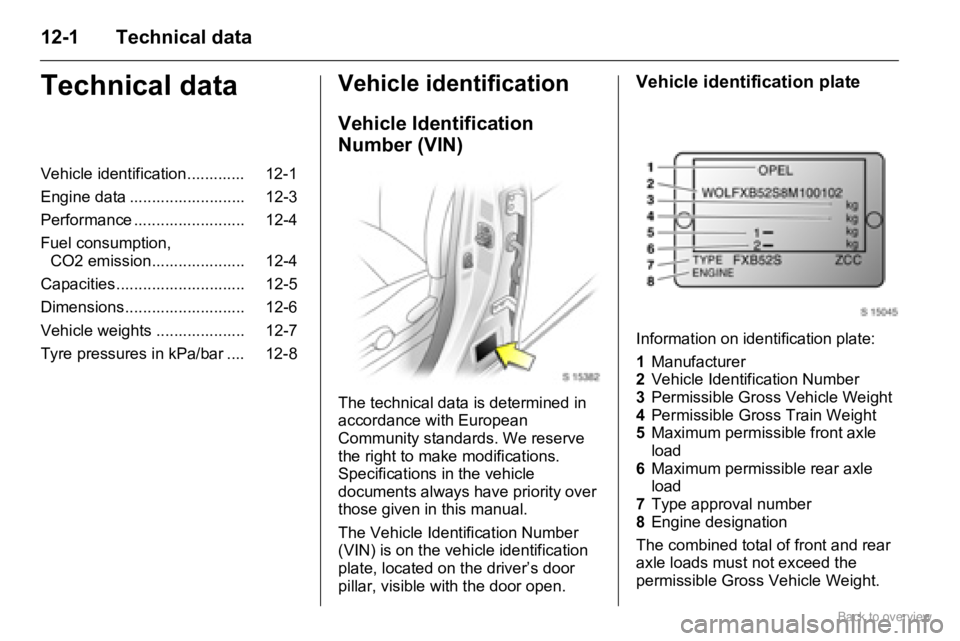

Technical dataVehicle identification

Vehicle Identification

Number (VIN)

The technical data is determined in

accordance with European

Community standards. We reserve

the right to make modifications.

Specifications in the vehicle

documents always have priority over

those given in this manual.

The Vehicle Identification Number

(VIN) is on the vehicle identification

plate, located on the driver’s door

pillar, visible with the door open.

Vehicle identification plate

Information on identification plate:

1Manufacturer

2Vehicle Identification Number

3Permissible Gross Vehicle Weight

4Permissible Gross Train Weight

5Maximum permissible front axle

load

6Maximum permissible rear axle

load

7Type approval number

8Engine designation

The combined total of front and rear

axle loads must not exceed the

permissible Gross Vehicle Weight. Vehicle identification............. 12-1

Engine data .......................... 12-3

Performance ......................... 12-4

Fuel consumption,

CO2 emission..................... 12-4

Capacities............................. 12-5

Dimensions........................... 12-6

Vehicle weights .................... 12-7

Tyre pressures in kPa/bar .... 12-8