light OPEL AMPERA E 2017.5 Manual user

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: AMPERA E, Model: OPEL AMPERA E 2017.5Pages: 265, PDF Size: 6.24 MB

Page 222 of 265

220Vehicle careBulb replacement

Switch off the vehicle and switch off

the relevant switch or close the doors.

Only hold a new bulb at the base. Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check After a bulb replacement switch on

the vehicle, operate and check the

lights.

Halogen bulbs9 Warning

Halogen bulbs have pressurised

gas inside and can burst if you

drop or scratch the bulb. You or others could be injured. Be sure to read and follow the instructions onthe bulb package.

Xenon headlights9 Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Bulbs for front turn signal and

corner lighting can be changed.

Sidelight/Daytime running lights are

designed as Light Emitting Diodes

(LEDs) and cannot be replaced.

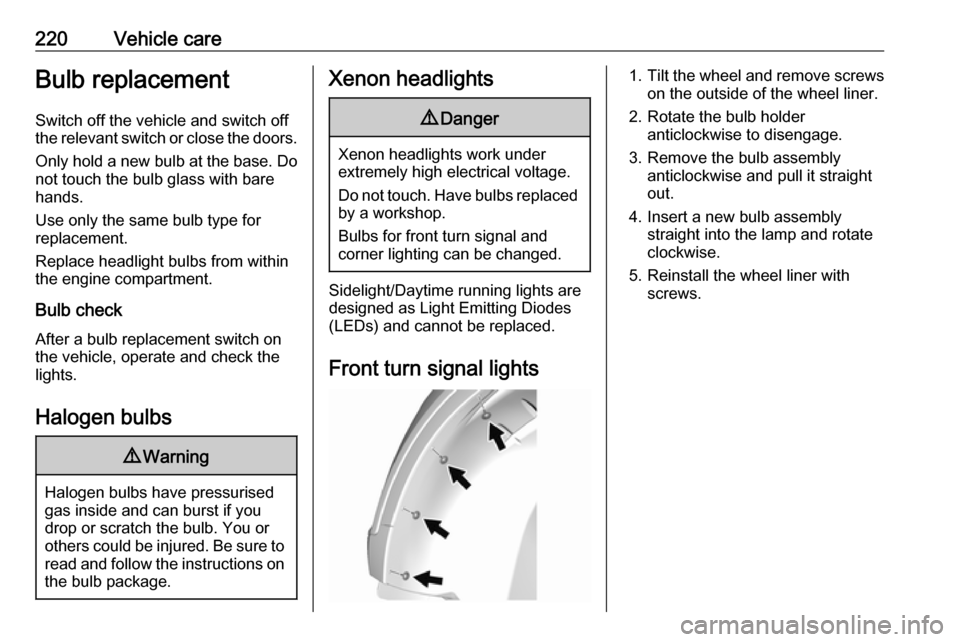

Front turn signal lights

1. Tilt the wheel and remove screws

on the outside of the wheel liner.

2. Rotate the bulb holder anticlockwise to disengage.

3. Remove the bulb assembly anticlockwise and pull it straight

out.

4. Insert a new bulb assembly straight into the lamp and rotate

clockwise.

5. Reinstall the wheel liner with screws.

Page 223 of 265

Vehicle care221Tail lights

The tail light assembly in the rear

bumper

The tail light assembly is located in

the rear bumper. The bulbs are

accessible from the underside of the

vehicle.

● (1) Rear fog light (driver side) / reversing light (passenger side)

● (2) Turn signal light

● (3) Tail/brake light

1. Turn the bulb holder anticlockwise

and remove it from the reflector.

2. Pull the bulb straight from the bulb

holder.

3. Replace bulb.

4. Insert the bulb holder into the reflector and rotate clockwise.

In case of failure, have LEDs replaced by a workshop.

Tail light assembly in the tailgate The lights of the tail light assembly in

the tailgate are LEDs and have to be

replaced by a workshop.

Side turn signal lights

Have bulbs replaced by a workshop.Number plate light

1. Insert screwdriver in recess of the

cover, press to the side and

release spring.

Page 224 of 265

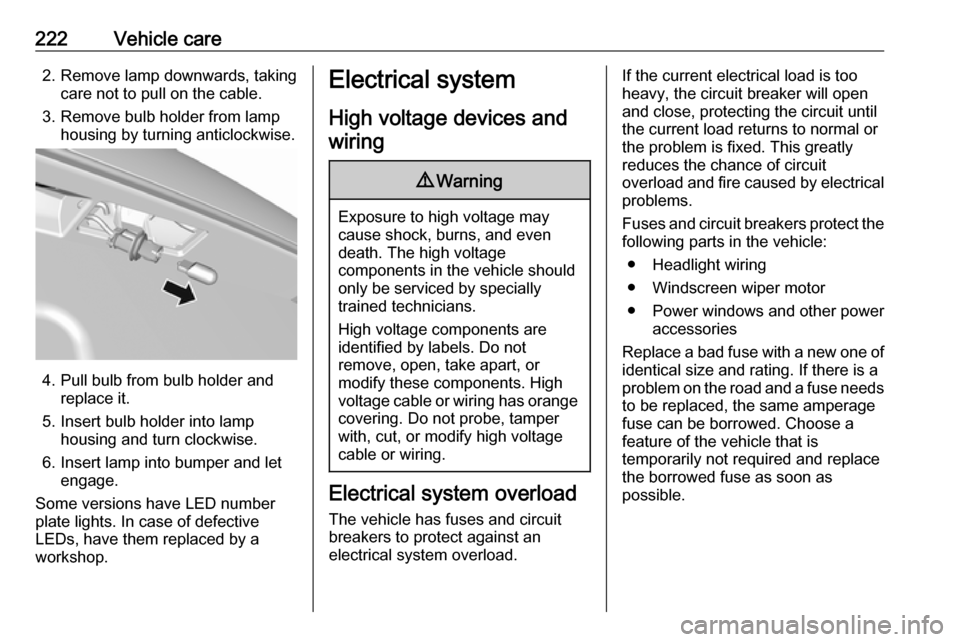

222Vehicle care2. Remove lamp downwards, takingcare not to pull on the cable.

3. Remove bulb holder from lamp housing by turning anticlockwise.

4. Pull bulb from bulb holder and replace it.

5. Insert bulb holder into lamp housing and turn clockwise.

6. Insert lamp into bumper and let engage.

Some versions have LED number

plate lights. In case of defective

LEDs, have them replaced by a

workshop.

Electrical system

High voltage devices andwiring9 Warning

Exposure to high voltage may

cause shock, burns, and even

death. The high voltage

components in the vehicle should

only be serviced by specially

trained technicians.

High voltage components are

identified by labels. Do not

remove, open, take apart, or

modify these components. High

voltage cable or wiring has orange covering. Do not probe, tamper

with, cut, or modify high voltage

cable or wiring.

Electrical system overload

The vehicle has fuses and circuit

breakers to protect against an

electrical system overload.

If the current electrical load is too

heavy, the circuit breaker will open

and close, protecting the circuit until

the current load returns to normal or the problem is fixed. This greatly

reduces the chance of circuit

overload and fire caused by electrical

problems.

Fuses and circuit breakers protect the

following parts in the vehicle:

● Headlight wiring

● Windscreen wiper motor

● Power windows and other power accessories

Replace a bad fuse with a new one of identical size and rating. If there is a

problem on the road and a fuse needs to be replaced, the same amperage

fuse can be borrowed. Choose a

feature of the vehicle that is

temporarily not required and replace

the borrowed fuse as soon as

possible.

Page 225 of 265

Vehicle care223Headlight wiringAn electrical overload may cause the

lights to go on and off or in some

cases to remain off. In this case, have

the headlight wiring checked

immediately by a workshop.

Windscreen wipers

If the wiper motor overheats due to

heavy snow or ice, the windscreen

wipers will stop until the motor cools

down and the wiper control is turned

off. After removal of the blockage, the wiper motor will restart when moving

the control to the desired operating

position.

Although the circuit is protected from electrical overload, overload due to

heavy snow or ice may cause wiper

linkage damage.

Always clear ice and heavy snow from the windscreen before using the

windscreen wipers. If the overload is

caused by an electrical problem and

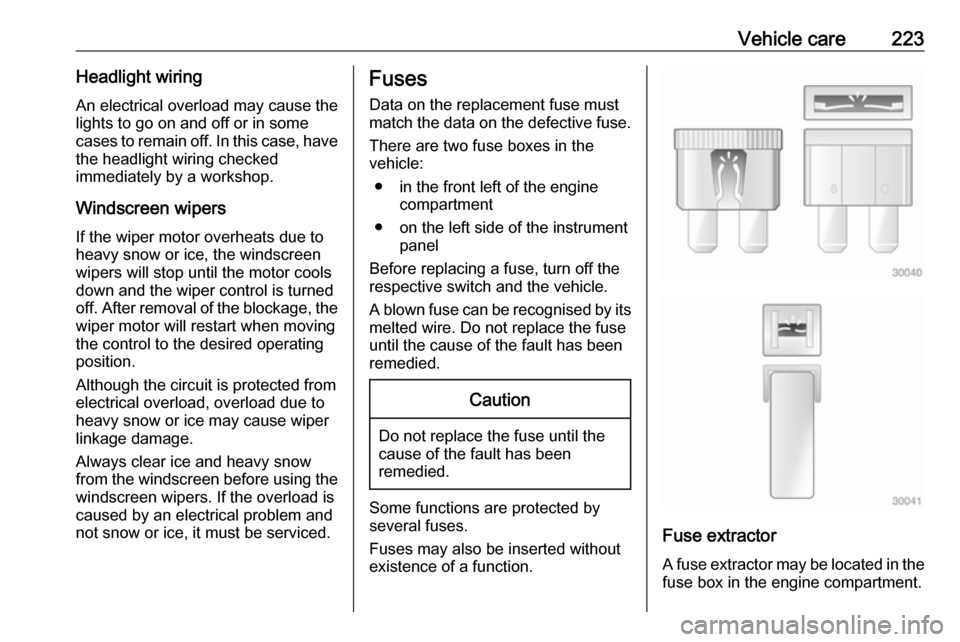

not snow or ice, it must be serviced.Fuses

Data on the replacement fuse must match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● in the front left of the engine compartment

● on the left side of the instrument panel

Before replacing a fuse, turn off the respective switch and the vehicle.

A blown fuse can be recognised by its melted wire. Do not replace the fuse

until the cause of the fault has been

remedied.Caution

Do not replace the fuse until the

cause of the fault has been

remedied.

Some functions are protected by

several fuses.

Fuses may also be inserted without

existence of a function.

Fuse extractor

A fuse extractor may be located in the

fuse box in the engine compartment.

Page 228 of 265

226Vehicle careNumberUsage1–2Power window rear3–4Rechargeable energy

storage system 15–6–7Left high‐beam headlight8Right high‐beam headlight9Left low‐beam headlight10Right low‐beam headlight11Horn12–13Front wiper motor driver14Tailgate15Front wiper motor co-driver16Electronic brake control

module supply electronicsNumberUsage17Rear wiper18Tailgate19Seat module front20Washer21HID light22Linear power module23Electronic brake control

module supply motor24Seat module rear25Powertrain26Transmission range control

module27Aero shutter28Auxiliary oil pump29E-booster motor source30Front power windows31In-panel bussed electrical

centreNumberUsage32Rear window defogger33Heated exterior rear view

mirror34Pedestrian friendly alert

function35–36–37Current sensor38Rain sensor39–40E-booster (ECU)41Power line communication

module42Infant occupant sensing43Window switch44Rechargeable energy

storage system45Vehicle integration control

module

Page 229 of 265

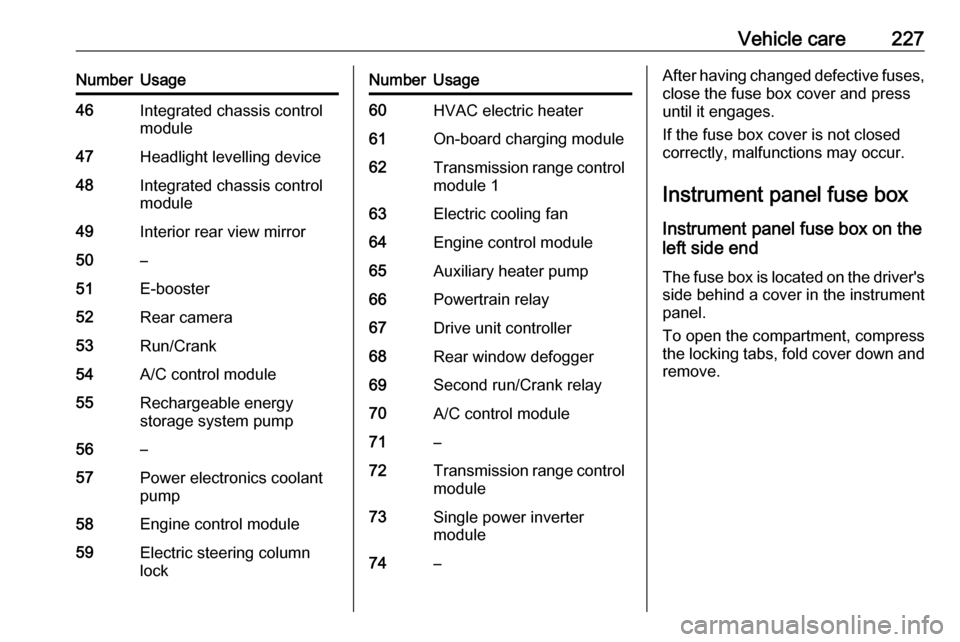

Vehicle care227NumberUsage46Integrated chassis control

module47Headlight levelling device48Integrated chassis control

module49Interior rear view mirror50–51E-booster52Rear camera53Run/Crank54A/C control module55Rechargeable energy

storage system pump56–57Power electronics coolant

pump58Engine control module59Electric steering column

lockNumberUsage60HVAC electric heater61On-board charging module62Transmission range control

module 163Electric cooling fan64Engine control module65Auxiliary heater pump66Powertrain relay67Drive unit controller68Rear window defogger69Second run/Crank relay70A/C control module71–72Transmission range control

module73Single power inverter

module74–After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

Instrument panel fuse boxInstrument panel fuse box on the

left side end

The fuse box is located on the driver's

side behind a cover in the instrument

panel.

To open the compartment, compress

the locking tabs, fold cover down and

remove.

Page 231 of 265

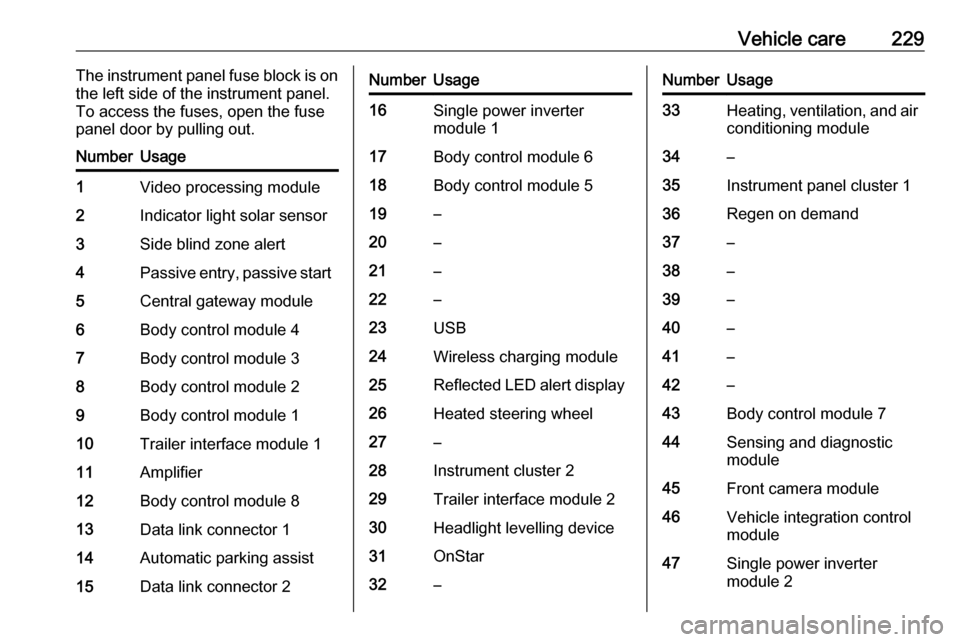

Vehicle care229The instrument panel fuse block is on

the left side of the instrument panel.

To access the fuses, open the fuse

panel door by pulling out.NumberUsage1Video processing module2Indicator light solar sensor3Side blind zone alert4Passive entry, passive start5Central gateway module6Body control module 47Body control module 38Body control module 29Body control module 110Trailer interface module 111Amplifier12Body control module 813Data link connector 114Automatic parking assist15Data link connector 2NumberUsage16Single power inverter

module 117Body control module 618Body control module 519–20–21–22–23USB24Wireless charging module25Reflected LED alert display26Heated steering wheel27–28Instrument cluster 229Trailer interface module 230Headlight levelling device31OnStar32–NumberUsage33Heating, ventilation, and air

conditioning module34–35Instrument panel cluster 136Regen on demand37–38–39–40–41–42–43Body control module 744Sensing and diagnostic

module45Front camera module46Vehicle integration control

module47Single power inverter

module 2

Page 232 of 265

230Vehicle careNumberUsage48Electric steering column

lock49Auxiliary jack50Steering wheel controls51Steering wheel controls

backlighting52Smartphone remote func‐

tion module53Auxiliary power outlet54–55Logistic56–57–58Logistics relay59–60Accessory/Retained

accessory power relay

To reinstall the door, insert the bottom tab first, then push the door back into its original location.

Vehicle tools

Tools

Open the floor cover of the load

compartment 3 61.

The towing eye and a screwdriver are

located under a cover in the load

compartment.

Wheels and tyres

Tyre condition, wheel condition Drive over edges slowly and at right

angles if possible. Driving over sharp

edges can cause tyre and wheel

damage. Do not trap tyres on the kerb when parking.

Regularly check the wheels for

damage. Seek the assistance of a

workshop in the event of damage or

unusual wear.

Tyres

Self-sealing tyres This vehicle may have self-sealing

tyres. These tyres have a material

inside that can seal punctures up to

6 mm in the tread area.

The tyre may lose air pressure if the

sidewall is damaged or the tread

puncture is too large. If the Tyre

pressure monitoring system indicates the tyre pressure is low, inspect thetyre for damage and inflate it to the

recommended pressure. If the tyre is

Page 237 of 265

Vehicle care235The available settings are:● Light for comfort pressure up to

three people.

● Eco for Eco pressure up to three

people.

● Max for full loading.

Auto learn function Each tyre pressure sensor has a

unique identification code. The

identification code must be matched

to a new wheel position after rotating

the wheels or exchanging the

complete wheel set and if one or more tyre pressure sensors were replaced.

After changing wheels, the vehicle

must be stationary for approx.

20 minutes before the system

recalculates. The following relearn

process takes up to 10 minutes of

driving with a minimum speed of

20 km/h. In this event, w can be

displayed or pressure values can

swap in the Driver Information Centre.

If problems occur during the relearn

process, a warning message will be

displayed in the Driver Information

Centre.Tread depth

Check tread depth at regular

intervals.

Tyres should be replaced for safety

reasons at a tread depth of 2-3 mm

(4 mm for winter tyres).

For safety reasons it is recommended

that the tread depth of the tyres on

one axle should not vary by more than 2 mm.

The legally permissible minimum

tread depth (1.6 mm) has been

reached when the tread has worn

down as far as one of the tread wear

indicators (TWI). Their position is

indicated by markings on the

sidewall.

If there is more wear at the front than

the rear, swap round front wheels and rear wheels periodically. Ensure that

the direction of rotation of the wheels

remains the same.

Tyres age, even if they are not used.

We recommend tyre replacement

every six years.

Changing tyre and wheel size

If tyres of a different size than those

fitted at the factory are used, vehicle

performance, including braking, ride

and handling characteristics, stability

and resistance to rollover may be

affected. If the vehicle has electronic

systems such as antilock brakes,

rollover airbags, traction control,

electronic stability control, the

performance of these systems can

also be affected. It may be necessary

to reprogramme the speedometer as

well as the nominal tyre pressure and

make other vehicle modifications.

Page 241 of 265

Vehicle care239Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the vehicle: 1. Start the engine of the vehicle providing the jump.

2. After five minutes, press POWER m to switch on the

vehicle.

After the instrument cluster

initialises, the vehicle will use

power from the high voltage

battery to charge the 12-volt

battery.

3. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

4. Reverse above sequence exactly when removing leads.Towing

Towing the vehicleCaution

Incorrect towing of a disabled

vehicle may cause damage to the

vehicle. The disabled vehicle

should only be towed on a flatbed

car carrier.

Ensure the vehicle is only towed

by well trained technicians.

Insert a screwdriver in the slot at the

short edge of the cap. Release the

cap by carefully moving the

screwdriver sidewards. To prevent

damage, it is recommended to place

a cloth between the screwdriver and

the frame.

The towing eye is stowed with the vehicle tools 3 230.

Screw in the towing eye as far as it will

go until it stops in a horizontal

position.

Attach a tow rope – or better still a tow

rod – to the towing eye.

The towing eye must only be used for towing and not for recovering the

vehicle.