Power OPEL AMPERA E 2018.5 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2018.5, Model line: AMPERA E, Model: OPEL AMPERA E 2018.5Pages: 273, PDF Size: 6.6 MB

Page 214 of 273

212Vehicle care● Vehicle storage at extremetemperatures may cause

damage to the high voltage

battery.

● Remove the black negative (−) cable from the 12 V vehicle

battery and attach a trickle

charger to the vehicle battery

terminals or keep the 12 V

vehicle battery cables connected and trickle charge from the

positive (+) and negative (−)

terminals in the engine

compartment.Caution

The vehicle is equipped with an

AGM 12 V vehicle battery, which

can be damaged by using the

incorrect type of trickle charger.

An AGM compatible charger must be used with the appropriate

setting selected.

Follow the trickle charger

manufacturer instructions.

After the 12 V vehicle battery cable is reconnected, it is possible that the

vehicle may not operate. If this

happens, the high voltage battery

may need to be charged.

Putting back into operation

When the vehicle is to be put back into operation:

● Connect the clamp to the negative terminal of the 12 V

vehicle battery. Activate the

electronics of the power

windows.

● Check tyre pressure.

● Fill up the washer fluid reservoir.

● Check the coolant level.

● Fit the number plate if necessary.

End-of-life vehicle recovery

Information on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.Vehicle checks

Performing work9 Danger

Never try to perform maintenance

work on high voltage battery

components yourself. You may be

injured and the vehicle may be

damaged. Service and repair of

these high voltage battery

components should only be

performed by a trained service

technician with proper knowledge

and tools. Exposure to high

Page 217 of 273

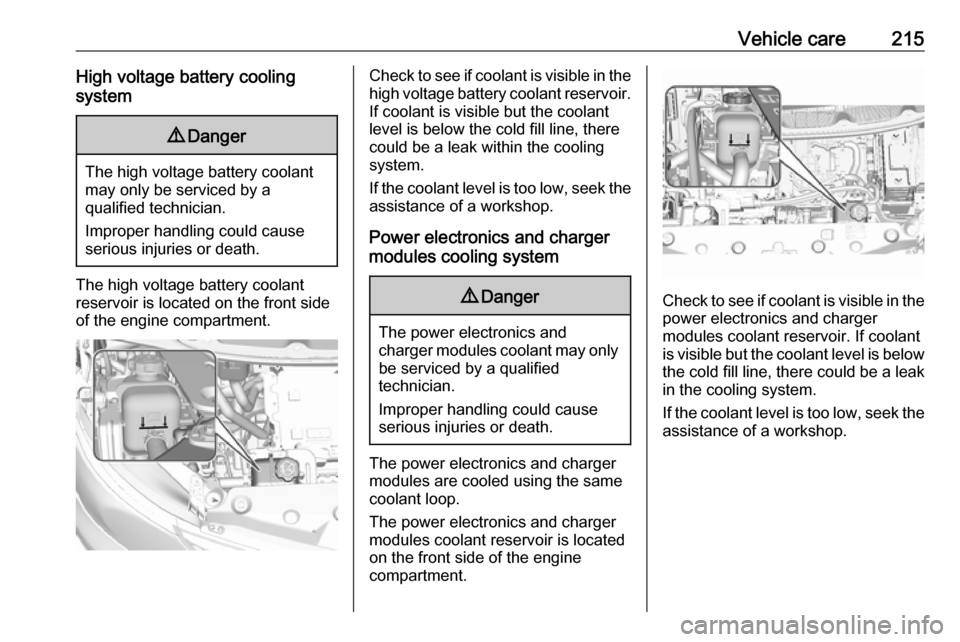

Vehicle care215High voltage battery cooling

system9 Danger

The high voltage battery coolant

may only be serviced by a

qualified technician.

Improper handling could cause serious injuries or death.

The high voltage battery coolantreservoir is located on the front side

of the engine compartment.

Check to see if coolant is visible in the high voltage battery coolant reservoir.

If coolant is visible but the coolant

level is below the cold fill line, there

could be a leak within the cooling

system.

If the coolant level is too low, seek the assistance of a workshop.

Power electronics and charger

modules cooling system9 Danger

The power electronics and

charger modules coolant may only be serviced by a qualified

technician.

Improper handling could cause serious injuries or death.

The power electronics and charger

modules are cooled using the same coolant loop.

The power electronics and charger

modules coolant reservoir is located

on the front side of the engine

compartment.

Check to see if coolant is visible in the

power electronics and charger

modules coolant reservoir. If coolant

is visible but the coolant level is below the cold fill line, there could be a leak

in the cooling system.

If the coolant level is too low, seek the assistance of a workshop.

Page 225 of 273

Vehicle care223Electrical system

High voltage devices and wiring9 Warning

Exposure to high voltage may

cause shock, burns, and even

death. The high voltage

components in the vehicle should

only be serviced by specially

trained technicians.

High voltage components are

identified by labels. Do not

remove, open, take apart, or

modify these components. High

voltage cable or wiring has orange covering. Do not probe, tamper

with, cut, or modify high voltage

cable or wiring.

Electrical system overload

The vehicle has fuses and circuit

breakers to protect against an

electrical system overload.

If the current electrical load is too

heavy, the circuit breaker will open

and close, protecting the circuit until

the current load returns to normal or the problem is fixed. This greatly

reduces the chance of circuit

overload and fire caused by electrical

problems.

Fuses and circuit breakers protect the

following parts in the vehicle:

● Headlight wiring

● Windscreen wiper motor

● Power windows and other power accessories

Headlight wiring An electrical overload may cause the

lights to go on and off or in some

cases to remain off. In this case, have

the headlight wiring checked

immediately by a workshop.

Windscreen wipers

If the wiper motor overheats due to

blockage from heavy snow or ice, the windscreen wipers will stop until themotor has cooled down and the wiper

control has been turned off. Afterremoval of the blockage, the wiper

motor will restart when moving the

wiper control to the desired operating

position.

Although the circuit is protected from

electrical overload, mechanical

overload due to heavy snow or ice

may cause wiper linkage damage.

Always clear ice and heavy snow

from the windscreen before using the windscreen wipers. If the overload is

caused by an electrical problem and

not snow or ice, it must be serviced.

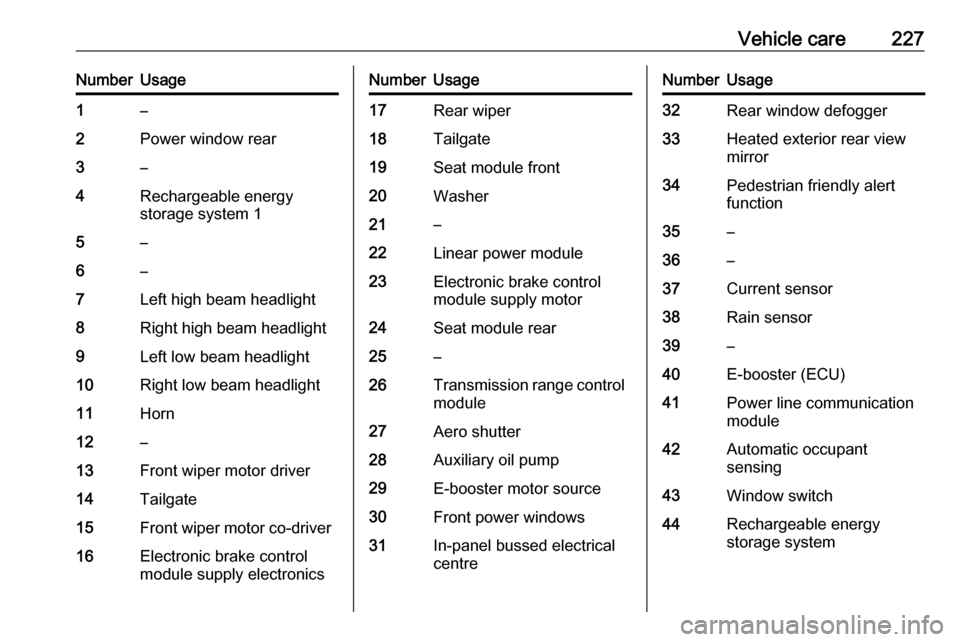

Fuses

Data on the replacement fuse must match the data on the defective fuse.

There are two fuse boxes in the

vehicle:

● at the front left side of the engine

compartment

● at the left side of the instrument panel

Before replacing a fuse, turn off the

respective switch and the vehicle.

Page 229 of 273

Vehicle care227NumberUsage1–2Power window rear3–4Rechargeable energy

storage system 15–6–7Left high beam headlight8Right high beam headlight9Left low beam headlight10Right low beam headlight11Horn12–13Front wiper motor driver14Tailgate15Front wiper motor co-driver16Electronic brake control

module supply electronicsNumberUsage17Rear wiper18Tailgate19Seat module front20Washer21–22Linear power module23Electronic brake control

module supply motor24Seat module rear25–26Transmission range control

module27Aero shutter28Auxiliary oil pump29E-booster motor source30Front power windows31In-panel bussed electrical

centreNumberUsage32Rear window defogger33Heated exterior rear view

mirror34Pedestrian friendly alert

function35–36–37Current sensor38Rain sensor39–40E-booster (ECU)41Power line communication

module42Automatic occupant

sensing43Window switch44Rechargeable energy

storage system

Page 230 of 273

228Vehicle careNumberUsage45Vehicle integration control

module46Integrated chassis control

module47Headlight levelling device48Integrated chassis control

module49Interior rear view mirror50–51E-booster52Rear camera53–54A/C control module55Rechargeable energy

storage system pump56–57Power electronics coolant

pump58Engine control moduleNumberUsage59Electric steering column

lock60HVAC electric heater61On-board charging module62Transmission range control

module 163Electric cooling fan64Engine control module65Auxiliary heater pump66–67Drive unit controller68Rear window defogger69–70A/C control module71–72Transmission range control

moduleNumberUsage73Single power inverter

module74–

After having changed defective fuses,

close the fuse box cover and press

until it engages.

If the fuse box cover is not closed

correctly, malfunctions may occur.

Instrument panel fuse boxThe fuse box is located on the driver's

side behind a cover in the instrument

panel.

Page 231 of 273

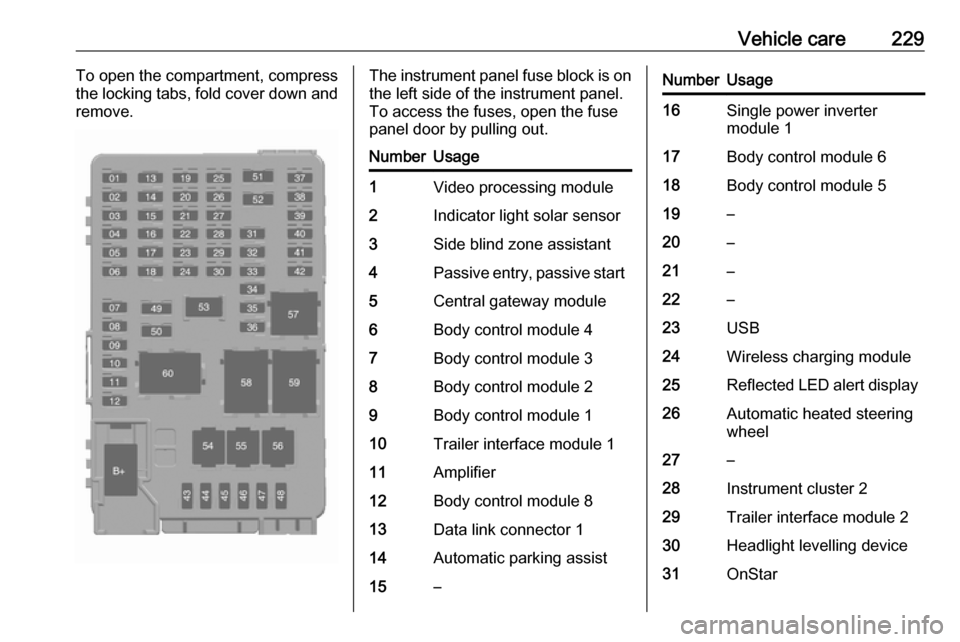

Vehicle care229To open the compartment, compress

the locking tabs, fold cover down and

remove.The instrument panel fuse block is on the left side of the instrument panel.

To access the fuses, open the fuse

panel door by pulling out.NumberUsage1Video processing module2Indicator light solar sensor3Side blind zone assistant4Passive entry, passive start5Central gateway module6Body control module 47Body control module 38Body control module 29Body control module 110Trailer interface module 111Amplifier12Body control module 813Data link connector 114Automatic parking assist15–NumberUsage16Single power inverter

module 117Body control module 618Body control module 519–20–21–22–23USB24Wireless charging module25Reflected LED alert display26Automatic heated steering

wheel27–28Instrument cluster 229Trailer interface module 230Headlight levelling device31OnStar

Page 232 of 273

230Vehicle careNumberUsage32–33Heating, ventilation, and airconditioning module34–35Instrument panel cluster 136Radio37–38–39–40–41–42–43Body control module 744Sensing and diagnostic

module45Front camera module46Vehicle integration control

moduleNumberUsage47Single power inverter

module 248Electric steering column

lock49Auxiliary jack50Steering wheel controls51Steering wheel controls

backlighting52Smartphone remote func‐

tion module53Auxiliary power outlet54–55Logistic56–57–58–59–60–To reinstall the door, insert the bottom tab first, then push the door back into its original location.

Page 240 of 273

238Vehicle care2. Remove the compressor and thesealant bottle.

3. Remove the electrical connection cable and air hose from the

storage compartments on the

underside of the compressor.

4. Screw the compressor air hose to

the connection on the sealant

bottle.

5. Fit the sealant bottle into the retainer on the compressor.

Set the compressor near the tyre

in such a way that the sealant

bottle is upright.6. Unscrew valve cap from defective

tyre.

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to J.

9. Connect the compressor plug to the power outlet or cigarette

lighter socket.

To avoid discharging the battery, we recommend running the

engine.

Page 244 of 273

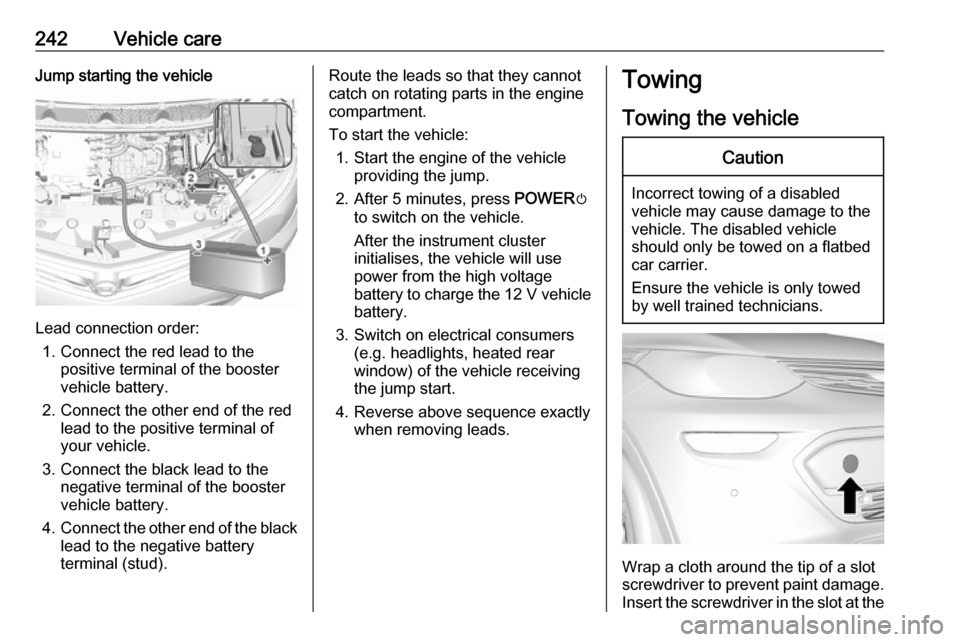

242Vehicle careJump starting the vehicle

Lead connection order:1. Connect the red lead to the positive terminal of the booster

vehicle battery.

2. Connect the other end of the red lead to the positive terminal of

your vehicle.

3. Connect the black lead to the negative terminal of the booster

vehicle battery.

4. Connect the other end of the black

lead to the negative battery

terminal (stud).

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the vehicle: 1. Start the engine of the vehicle providing the jump.

2. After 5 minutes, press POWERm

to switch on the vehicle.

After the instrument cluster

initialises, the vehicle will use

power from the high voltage

battery to charge the 12 V vehicle

battery.

3. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.

4. Reverse above sequence exactly when removing leads.Towing

Towing the vehicleCaution

Incorrect towing of a disabled

vehicle may cause damage to the

vehicle. The disabled vehicle

should only be towed on a flatbed

car carrier.

Ensure the vehicle is only towed

by well trained technicians.

Wrap a cloth around the tip of a slot

screwdriver to prevent paint damage. Insert the screwdriver in the slot at the

Page 254 of 273

![OPEL AMPERA E 2018.5 Workshop Manual 252Technical dataVehicle dataEngine dataPower [kW]150Torque [Nm]360PerformanceMaximum speed [km/h]150Vehicle weightKerb weight [kg]1691

Optional equipment and accessories increase the kerb weight.

Loa OPEL AMPERA E 2018.5 Workshop Manual 252Technical dataVehicle dataEngine dataPower [kW]150Torque [Nm]360PerformanceMaximum speed [km/h]150Vehicle weightKerb weight [kg]1691

Optional equipment and accessories increase the kerb weight.

Loa](/img/37/18756/w960_18756-253.png)

252Technical dataVehicle dataEngine dataPower [kW]150Torque [Nm]360PerformanceMaximum speed [km/h]150Vehicle weightKerb weight [kg]1691

Optional equipment and accessories increase the kerb weight.

Loading information 3 62.