brake OPEL ANTARA 2009 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: ANTARA, Model: OPEL ANTARA 2009Pages: 234, PDF Size: 3.01 MB

Page 175 of 234

Self-help, vehicle care175

Keep tow rope 3 clear of front bumper,

and ensure it is secure ly fixed to the towing

eye at both ends. Pull on the tow rope 3 to

check.

To prevent entry of exhaust fumes from

towing vehicle, switch on air recirculation

mode (see page 109) and close the

windows.

Never let passengers ride in a vehicle that

is being towed.

Never tow a vehicle with damaged parts

that are not secured to the vehicle or if

wheels, brakes or steering are damaged.

Do not tow the vehicle with a tow rope 3 or

tow rod 3 for extended periods, to avoid

damage to the vehicle. Only tow in this

manner on hard-surfaced roads.

For vehicles with automatic transmission 3:

use flatbed or wheel lift equipment only.

Towing can cause severe damage to the

transmission.

Seek the assistance of a workshop. Towing service

Entrust your vehicle only to the towing

service of your choice and obtain an

estimate on towing costs before employing

any towing service. This will prevent

unnecessary expense and possible

insurance problems during claim

processing.

Use flatbed equipment whenever possible.

If vehicle is to be towed using a wheel lift,

tow with all wheels off the road, using a

towing dolly.

Never use sling-type equipment to tow the

vehicle or tow the vehicle with the front or

rear wheels on the road, to avoid causing

serious damage to the vehicle.

Place the gearshift lever in neutral

(automatic transmission 3

in N), switch on

hazard warning lamps, turn key to ignition

switch position ACC and release the

hand brake before towing the vehicle. Towing another vehicle

In emergency situations only, attach a tow

rope

3 - or better still a tow rod 3 - to the

rear towing eye.

The rear towing eye attachment 3 is stored

below the floor cover in the luggage

compartment.

Remove the cover located on the rear

bumper by pressing the lower part of the

cover.

Page 178 of 234

Self-help, vehicle care178

Notes on temporary spare wheel

zUsing a temporary spare wheel may

change the driving behaviour of the

vehicle, particularly if using winter

tyres 3. Replace defective tyre as quickly

as possible, balanc e wheel and fit to

vehicle.

z Fit only one temporary spare wheel.

z Do not drive faster than 80 km/h

(50 mph).

z Take curves slowly.

z Do not use the temporary spare wheel

for a lengthy period.

z Replace temporary spare wheel with full

specification wheel without delay.

z When temporary spare wheel is fitted, do

not take the vehicle through an

automatic car wash with guide rails. The

temporary spare wheel may get caught

on the rails, causing damage to the tyre,

wheel and other vehicle parts.

z Tyre chains are not permitted on the

temporary spare wheel.

If tyre chains are necessary after a front

wheel puncture, fit the temporary spare

wheel to the rear and a rear wheel to the

front. Check tyre pressure and adjust if

necessary - see page 224.

z Follow the temporary spare wheel

instructions on pages 153, 181, 223. Notes on directional tyres

3

Tyres with a prescribed rotating direction

can only achieve their maximum

performance if they are fitted in the

prescribed rotating direction.

If a tyre or spare wheel is fitted that is

rotating in the wrong direction due to a

puncture, the following must be noted:

z The handling of the vehicle may be

different. Replace defective tyres as soon

as possible, have wheel balanced and

fitted to the vehicle.

z Do not drive faster than 80 km/h

(50 mph).

z Drive particularly carefully on wet and

snow-covered road surfaces.

z For more information on tyres with a

prescribed rotating direction -

see page 149.Wheel changing

In order to reduce the chance of possible

injuries, make the following preparations

and note the procedure:

zPark on a level, firm and non-slippery

surface.

z Switch on hazard warning lamps and

apply hand brake. Engage 1st gear or

reverse (automatic transmission 3 in P).

z Correctly set up warning triangle 3.

z Ensure all vehicle passengers are out of

the vehicle and clear of the vehicle and

other traffic.

z Take the spare wheel from under the

luggage compartment floor cover -

see page 177.

z Before raising the vehicle, turn front

wheels to straight-ahead position.

Page 188 of 234

Self-help, vehicle care188

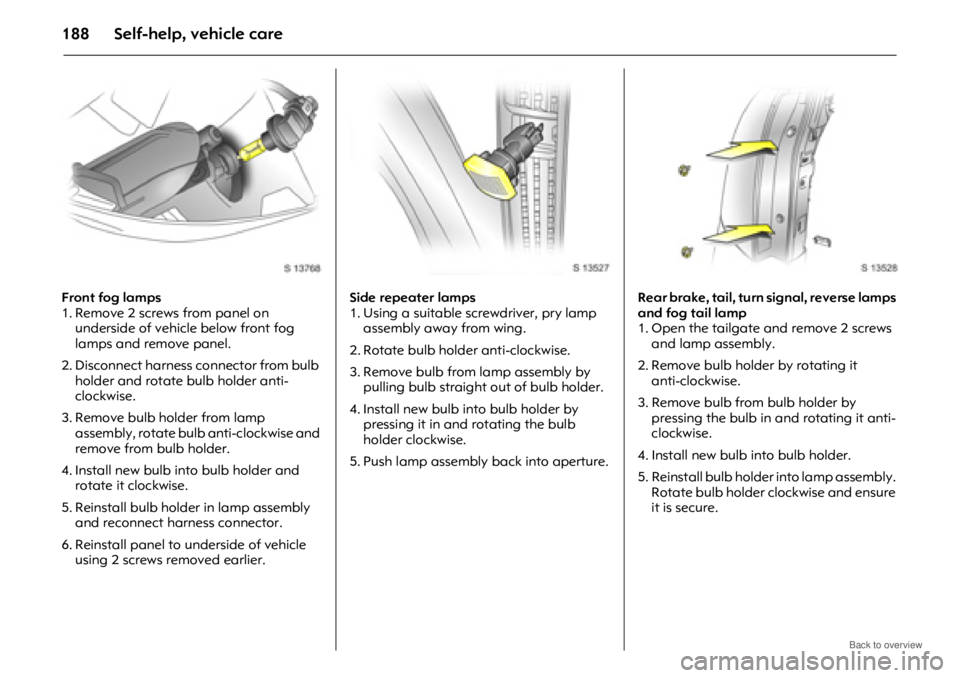

Front fog lamps

1. Remove 2 screws from panel on underside of vehicle below front fog

lamps and remove panel.

2. Disconnect harness connector from bulb holder and rotate bulb holder anti-

clockwise.

3. Remove bulb holder from lamp assembly, rotate bulb anti-clockwise and

remove from bulb holder.

4. Install new bulb in to bulb holder and

rotate it clockwise.

5. Reinstall bulb holder in lamp assembly

and reconnect harness connector.

6. Reinstall panel to underside of vehicle using 2 screws removed earlier. Side repeater lamps

1. Using a suitable screwdriver, pry lamp

assembly away from wing.

2. Rotate bulb holder anti-clockwise.

3. Remove bulb from lamp assembly by pulling bulb straight out of bulb holder.

4. Install new bulb into bulb holder by pressing it in and rotating the bulb

holder clockwise.

5. Push lamp assembly back into aperture. Rear brake, tail, turn signal, reverse lamps

and fog tail lamp

1. Open the tailgate and remove 2 screws

and lamp assembly.

2. Remove bulb holder by rotating it anti-clockwise.

3. Remove bulb from bulb holder by pressing the bulb in and rotating it anti-

clockwise.

4. Install new bulb into bulb holder.

5. Reinstall bulb holder into lamp assembly. Rotate bulb holder clockwise and ensure

it is secure.

Page 191 of 234

Self-help, vehicle care191

Centre high-mounted stop lamp,

instrument panel and glove compartment

illumination

We recommend having bulb replacements

carried out by a workshop.

Opel genuine parts and

accessories

We recommend the use of “Opel genuine

parts and accessories” and conversion

parts released expressly for your vehicle

type. These parts have undergone special

tests to establish their reliability, safety and

specific suitability for your vehicle. Despite

continuous market monitoring, we cannot

assess or guarantee these attributes for

other products, even if they have been

granted approval by the relevant

authorities or in some other form.

“Opel genuine parts and accessories” and

conversion parts approved by Opel can be

obtained from your Op el Partner, who can

provide comprehensive advice about

permitted technical changes and ensure

that the part is installed correctly.

A note on safety

To avoid the possibility of injury, only carry

out engine compartment checks (e.g.

checking the brake fluid level or the engine

oil level) when the igni tion is switched off. Never carry out any re

pairs or adjustment

and maintenance work on the vehicle

yourself. This especially applies to the

engine, chassis and safety parts. You may,

out of ignorance, infringe the provisions of

the law and, by not performing the work

properly, you may endanger yourself and

other road users.

Checking and topping up fluids

To aid identification, the engine oil filler

cap, the coolant filler cap, the lid of the

fluid container for the windscreen washer

system and the handle of the engine oil

gauge (dipstick) may be coloured yellow.

9 Warning

The cooling fan may be operated by a

thermoswitch and can therefore start to

operate unexpectedly, even when the

ignition is switched off; risk of injury.

Electronic ignition systems generate very

high voltages. Do not touch the ignition

system; high voltage can be fatal.

Page 196 of 234

Self-help, vehicle care196

When the engine is at operating

temperature, coolant level rises. It falls

again when the system cools. If it falls

below the MIN mark when the system is

cold, the coolant must be replenished.

Top up antifreeze. If no antifreeze is

available, top up with clean tap water.

If tap water is unavailable, distilled water

can be used.

When you top up with tap water or distilled

water, add concentrated antifreeze and

possibly mix in antifreeze as well. Have the

cause of the coolant loss eliminated by a

workshop.

Too low a coolant level can cause engine

damage.

When closing, tighten coolant filler cap as

far as it will go. Coolant temperature

Control indicator

W illuminates when

coolant temperature is too high. Check

coolant level:

z Coolant level low:

Top up coolant. Pay attention to the

instructions given under "Antifreeze and

corrosion protecti on" and "Coolant

level". Have the cause of the coolant loss

remedied by a workshop.

z Coolant level OK:

Have the cause of increased coolant

temperature remedied by a workshop.

Brake fluid

Brake fluid level

9 Warning

Allow engine to cool down before

removing coolant filler cap. If steam is

visible, move away from the vehicle until

the engine is cool.

Remove coolant filler cap carefully so

that pressure can escape slowly,

otherwise there is a risk of scalding.

9 Warning

Caution - brake fluid is poisonous and

corrosive. Do not allow it to contact eyes,

skin, fabrics or painted surfaces; direct

contact may cause injuries and damage.

Page 197 of 234

Self-help, vehicle care197

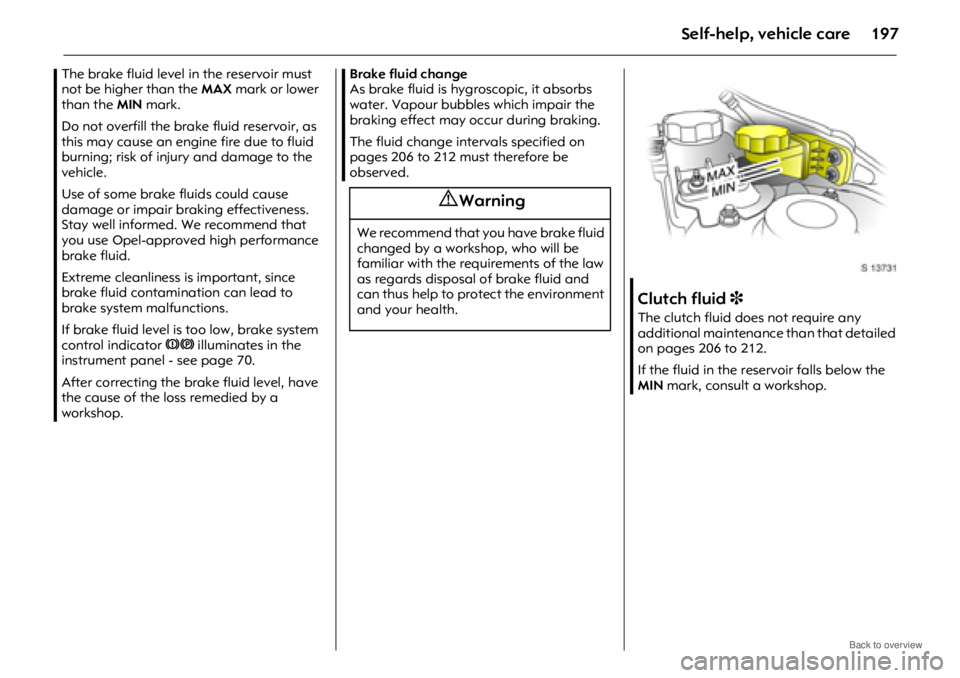

The brake fluid level in the reservoir must

not be higher than the MAX mark or lower

than the MIN mark.

Do not overfill the brak e fluid reservoir, as

this may cause an engine fire due to fluid

burning; risk of injury and damage to the

vehicle.

Use of some brake fluids could cause

damage or impair br aking effectiveness.

Stay well informed. We recommend that

you use Opel-approve d high performance

brake fluid.

Extreme cleanliness is important, since

brake fluid contamination can lead to

brake system malfunctions.

If brake fluid level is too low, brake system

control indicator 4 illuminates in the

instrument panel - see page 70.

After correcting the brake fluid level, have

the cause of the loss remedied by a

workshop. Brake fluid change

As brake fluid is hygroscopic, it absorbs

water. Vapour bubbles which impair the

braking effect may occur during braking.

The fluid change intervals specified on

pages 206 to 212 must therefore be

observed.

Clutch fluid

3

The clutch fluid does not require any

additional maintenanc e than that detailed

on pages 206 to 212.

If the fluid in the reservoir falls below the

MIN mark, consult a workshop.

9 Warning

We recommend that you have brake fluid

changed by a workshop, who will be

familiar with the requ irements of the law

as regards disposal of brake fluid and

can thus help to protect the environment

and your health.

Page 205 of 234

Self-help, vehicle care205

Windscreen wiper blades

Wax, such as that used in car washes, can

cause streaks to form on the windscreen

when the wipers are used.

Smearing wiper blades can be cleaned with

a soft cloth and Opel Cleaning Solvent and

Antifreeze, and replaced if necessary –

see page 198. Do not use abrasive

cleaners.

Locks

The locks are lubricated with a high-grade

lock cylinder grease at the factory. Opel

Lock Cylinder Grease prevents the locks

from freezing up.

Only use de-icing agents in emergencies,

as they have a degreasing effect and will

impair the function of the locks. After using

a de-icing agent, have the locks re-greased

by a workshop. Engine compartment

Areas of the engine compartment that are

painted in the same colour as the vehicle

must be looked after

like any other painted

surface.

It is advisable to wash the engine

compartment before and after winter and

preserve it with wax. Cover alternator and

fluid reservoirs with plastic sheets before

washing the engine.

When washing the engine with a steam-jet

cleaner, do not direct the steam-jet at

components of the Anti-lock Brake System

(ABS), the air conditioning system or the

belt drive and its components.

Protective wax that has been applied is

also removed during the engine wash. For

this reason, have the engine, brake system

components in the engine compartment,

axle components with steering, body parts

and cavities thoroughly preserved with

protective wax after the wash.

An engine wash can be performed in the

spring in order to remove dirt that has

adhered to the engine compartment,

which may also have a high salt content.

Check protective wax layer and make good

if necessary. Underbody

Your vehicle has a factory-applied PVC

undercoating in the wheel arches

(including the longitudinal members) which

provides permanent protection and needs

no special maintenance. The surfaces of

the vehicle underbody not covered by PVC

are provided with a durable protective wax

coating in critical areas.

On vehicles which are washed frequently

in automatic car wash

es with underbody

washing facility, the protective wax

coating may be impaire d by dirt-dissolving

additives. Check the underbody after

washing and have it waxed if necessary.

Before the start of the cold weather season,

check the PVC coating and protective wax

coating and, if necessary, have them

restored to perfect condition.

Caution

– commercially available bitumen/

rubber materials can damage the PVC

coating. We recommend that you have

underbody work carried out by a

workshop, who knows the prescribed

materials and has experience in the use

thereof.

The underbody should be washed

following the end of the cold weather

season to remove any dirt adhering to the

underbody since this may also contain salt.

Check protective wax coating and, if

necessary, have it restored to perfect

condition.

Page 207 of 234

Service, maintenance 207

European service schedule

(Antara Z 20 DM, Z 20 DMH, Z 24 XE, Z 32 SE) Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

15

101

30

20 45

30 2

60

40 75

50 3

90

60

Controls, lighting, signalling equi pment and airbags: visual check

steering lock and ignition lock: check xxx

Remote control batteries: replace Every 2 years

Windscreen wipers, windscreen washer system: check, correct xxx

Coolant level and antifreeze: check, correct

Hoses: check for tightness and secure seating xxx

Brake fluid level: check, correct xxx

Battery terminals: check for secu re connections and battery eye xxx

Vehicle system check with TECH2 xxx

Pollen filter: replace xxx

oMore often for when dust, sand or polle n is in the air Agreement with customer

Air cleaner element: replace

xxx

⊕Spark plugs and plug leads: replace Every 90 000 km/60 000 miles

Ribbed V-belt: visual check xxx

⊕Toothed belt and tension roller: visual check xxx

Toothed belt and tension roller: replace - Z 24 XE Every 8 years/120 000 km/80 000 miles

Toothed belt and tension roller: replace - Z 20 DM, Z 20 DMH Every 6 years/90 000 km/60 000 miles

Power steering system: check for leak s. Fluid level: check, correct xxx

Engine oil and oil filter: replace - fixed interval Z 24 XE

2)

2)On vehicles with oil life monitoring, it may be necessary to change the engine oil earlier (control indicator illuminates).

xxxxxx

Z 20 DM, Z 20 DMH, Z 32 SE, except2)xxx

Page 208 of 234

208 Service, maintenance

Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

⊕ Additional operations.

o Under extreme operating conditions and if required by country-specific conditions, the intervals are reduced.

15

10 1

30

20 45

30 2

60

40 75

50 3

90

60

⊕o Diesel fuel filter: drain water

(If relative humidity is high an

d/or fuel is of lower quality) Annually

Fuel filter: replace and drain water - diesel (g rade EN 590) Every 2 years/60 000 km/40 000 miles

Parking brake: check and adjust

Wheel mounting and suspension front an d rear, brake lines, brake pressure

hoses, fuel lines and exhaust system: visual check xxx

Corrosion protection: check and record in Service and Warranty Booklet Annually

Front and rear wheel br akes: check visually xxx

o

⊕Annual service check if annual mileage exceeds 20 000 km Annually

Engine, transmission, PTO, rear differential, A/C compressor: check for leaks xxx

Steering system boots, track rods , final drive: visual check xxx

Track rod end and supporting ball joint: check xxx

⊕Brake and clutch fluid: change Every 2 years

Wheel fastening: loosen and tighten to torque

Tyre condition and pressures: check, correct xxx

⊕Annual service check if annual

mileage exceeds 20 000 km Annually

First aid kit, tyre repair kit and lash ing eyes: visual check Every 2 years

Headlamp aiming: check, adjust x x x

Door hinges, door stop, lock cylinder, lock striker, bonnet catch, tailgate

hinges and check links: lubricate xxx

Test drive, final check

Service interval display and oil life monitor: reset - if applicable xxx

Page 209 of 234

Service, maintenance 209

International service schedule

(All except Z 24 XE) Service operations by year 1)

km ( x 1000)1)

miles ( x 1000)1)

1)Whichever occurs first.

15

101

30

20 45

30 2

60

40 75

50 3

90

60

Controls, lighting, signalling equi pment and airbags: visual check

steering lock and ignition lock: check xxxxxx

Remote control batteries: replace Every 2 years

Windscreen wipers, windscreen wa sher system: check, correct x x x x x x

Coolant level and antifreeze: check, correct

Hoses: check for tightness and secure seating Annually

Brake fluid level: check, correct xx

Battery terminals: check for secure connections and battery eye Annually

Vehicle system check with TECH2 Annually

Pollen filter: replace xxx

oMore often for when dust, sand or pollen is in the air Annually/15 000 km/10 000 miles

Air cleaner element: replace

xxx

oMore often for when dust or sand is in the air Annually/15 000 km/10 000 miles

⊕Spark plugs and plug leads: replace Every 90 000 km/60 000 miles

Ribbed V-belt: visual check xxx

⊕Toothed belt and tension roller: visual check Annually/15 000 km/10 000 miles

Toothed belt and tension roller: replace - Z 20 DM, Z 20 DMH Every 6 years/90 000 km/60 000 miles

Power steering system: check for leaks. Fluid level: check, correct Annually

Engine oil and oil filter: replace x x x x x x