headlight OPEL ANTARA 2017.5 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 2017.5, Model line: ANTARA, Model: OPEL ANTARA 2017.5Pages: 225, PDF Size: 6.2 MB

Page 111 of 225

Lighting109Rear fog lights

Operated by pressing ø.

Control indicator ø 3 91 illuminates

in the instrument cluster when the rear fog light is switched on.

The rear fog light can only be

switched on when the ignition is on

and the light switch is in position 9,

or the front fog lights are on and the

light switch is in position 8.

Light switch in position AUTO:

switching on rear fog light will switch

on low beam and sidelights

automatically.

The vehicle rear fog light is

deactivated when towing.

Parking lights

When the vehicle is parked, the

parking lights on one side can be

activated:

1. Set light switch to 7 or AUTO .

2. Switch off ignition.

3. Move turn signal lever all the way up (right parking lights) or down

(left parking lights).

Confirmed by a signal tone and the

corresponding turn signal control

indicator.

To deactivate, switch on the ignition or move the turn signal lever in the

opposite direction.

Reversing lights

The reversing lights come on when

the ignition is on and reverse gear is

selected.

Centre high-mounted brake light Illuminates when the brakes are

applied, acting as a third stop light, to

supplement the brake lights.

Misted light covers

The inside of the light housing may

mist up briefly in poor, wet and cold weather conditions, in heavy rain or

after washing. The mist disappears

quickly by itself; to help switch on the

headlights.

Page 149 of 225

Driving and operating147temperatures may differ according to

vehicle conditions or outside

conditions.

Flashing or illumination of the yellow

control indicator u reminds the driver

that the friction material needs to cool

down: drive the vehicle without

braking as much as possible. If the

control indicator does not extinguish,

have the cause of the fault remedied

by a workshop.

DSC control indicators u 3 86.

Automatic level control

The rear level of the vehicle is

automatically adjusted to the load

conditions while driving. Suspension

and ground clearance are increased,

which improves driving conditions.

The automatic level control is

activated after the vehicle has been

driven for some distance, depending

on the vehicle load and the road

conditions.

Do not use full payload in the event of

a fault. Have the cause of the fault

remedied by a workshop.

Headlight range adjustment 3 106.Driver assistance

systems9 Warning

Driver assistance systems are

developed to support the driver

and not to replace the driver's

attention.

The driver accepts full

responsibility when driving the

vehicle.

When using driver assistance

systems, always take care

regarding the current traffic

situation.

Cruise control

The cruise control can store and

maintain speeds above 40 km/h.

Deviations from the stored speeds

may occur when driving uphill or

downhill.

For safety reasons the cruise control

cannot be activated until the foot

brake has been operated once.

Do not use the cruise control if it is not advisable to maintain a constant

speed.

With automatic transmission, only activate cruise control in automatic

mode.

Control indicator m 3 91.

Switching on

Press e ; control indicator m

illuminates yellow in the instrument

cluster.

Page 158 of 225

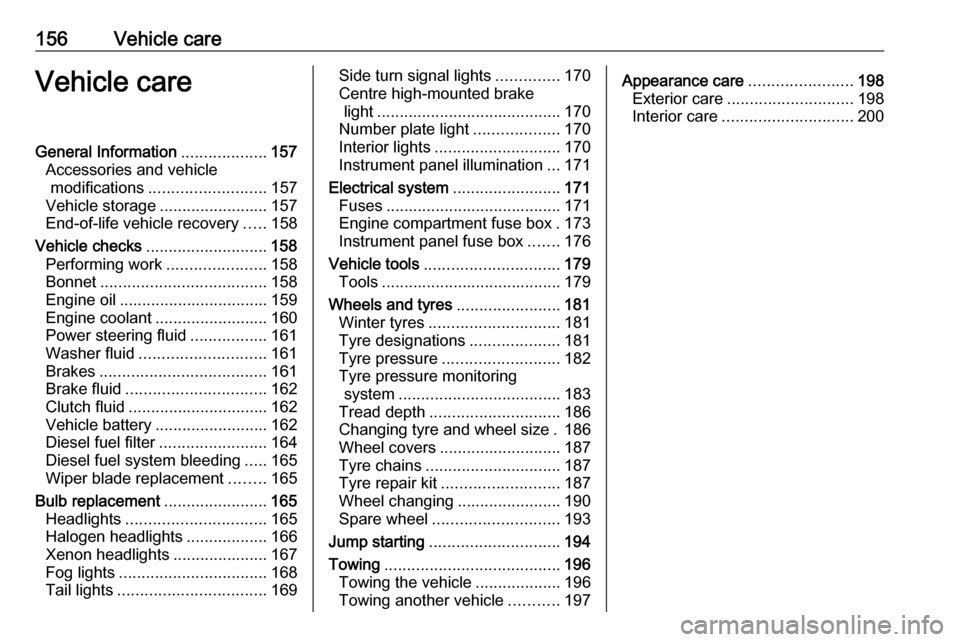

156Vehicle careVehicle careGeneral Information...................157

Accessories and vehicle modifications .......................... 157

Vehicle storage ........................157

End-of-life vehicle recovery .....158

Vehicle checks ........................... 158

Performing work ......................158

Bonnet ..................................... 158

Engine oil ................................. 159

Engine coolant ......................... 160

Power steering fluid .................161

Washer fluid ............................ 161

Brakes ..................................... 161

Brake fluid ............................... 162

Clutch fluid ............................... 162

Vehicle battery ......................... 162

Diesel fuel filter ........................164

Diesel fuel system bleeding .....165

Wiper blade replacement ........165

Bulb replacement .......................165

Headlights ............................... 165

Halogen headlights ..................166

Xenon headlights .....................167

Fog lights ................................. 168

Tail lights ................................. 169Side turn signal lights ..............170

Centre high-mounted brake light ......................................... 170

Number plate light ...................170

Interior lights ............................ 170

Instrument panel illumination ...171

Electrical system ........................171

Fuses ....................................... 171

Engine compartment fuse box . 173

Instrument panel fuse box .......176

Vehicle tools .............................. 179

Tools ........................................ 179

Wheels and tyres .......................181

Winter tyres ............................. 181

Tyre designations ....................181

Tyre pressure .......................... 182

Tyre pressure monitoring system .................................... 183

Tread depth ............................. 186

Changing tyre and wheel size . 186

Wheel covers ........................... 187

Tyre chains .............................. 187

Tyre repair kit .......................... 187

Wheel changing .......................190

Spare wheel ............................ 193

Jump starting ............................. 194

Towing ....................................... 196

Towing the vehicle ...................196

Towing another vehicle ...........197Appearance care .......................198

Exterior care ............................ 198

Interior care ............................. 200

Page 160 of 225

158Vehicle careEnd-of-life vehicle recoveryInformation on end-of-life vehicle

recovery centres and the recycling of

end-of-life vehicles is available on our website, where legally required. Only

entrust this work to an authorised

recycling centre.Vehicle checks

Performing work9 Warning

Only perform engine compartment

checks when the ignition is off.

The cooling fan may start

operating even if the ignition is off.

9 Danger

The ignition system and Xenon

headlights use extremely high

voltage. Do not touch.

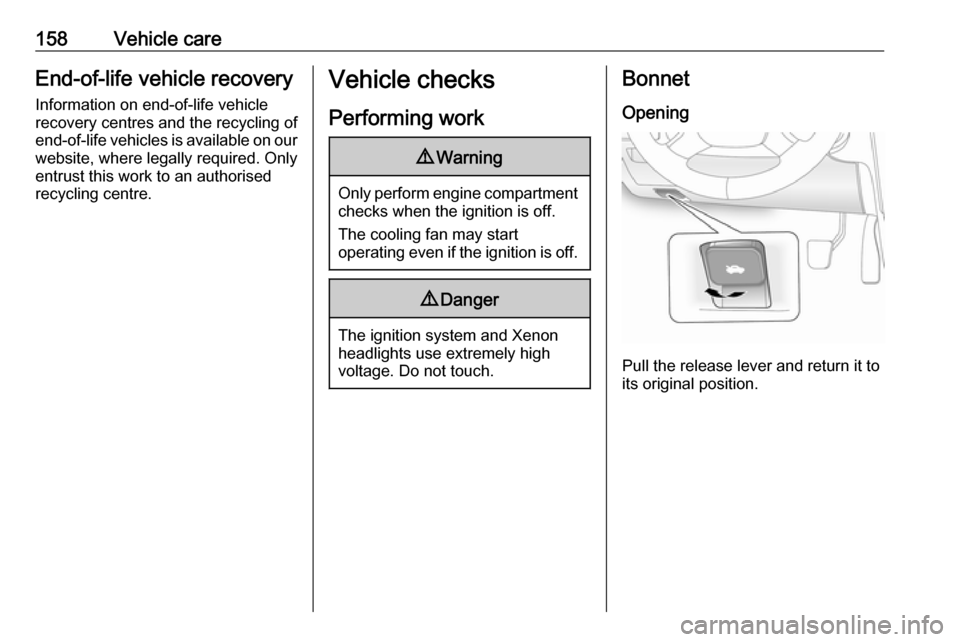

Bonnet

Opening

Pull the release lever and return it to

its original position.

Page 167 of 225

Vehicle care165With engine switched off, turn ignition

key to ON, wait approx. 5 seconds,

and turn key to LOCK to perform

priming operation. Perform this

operation 3 times or more while the

engine is switched off, to avoid air

entering the fuel line.

Check diesel fuel filter at shorter

intervals if the vehicle is subjected to

extreme operating conditions.

If there is water in the diesel fuel filter, control indicator U illuminates in the

instrument cluster 3 90. Drain the

water immediately.

Diesel fuel system bleeding

If the fuel tank has been run dry, the

diesel fuel system must be bled.

Switch on the ignition three times for

15 seconds at a time. Then crank the

engine for a maximum of

40 seconds. If the engine will not start, wait at least 10 seconds before trying

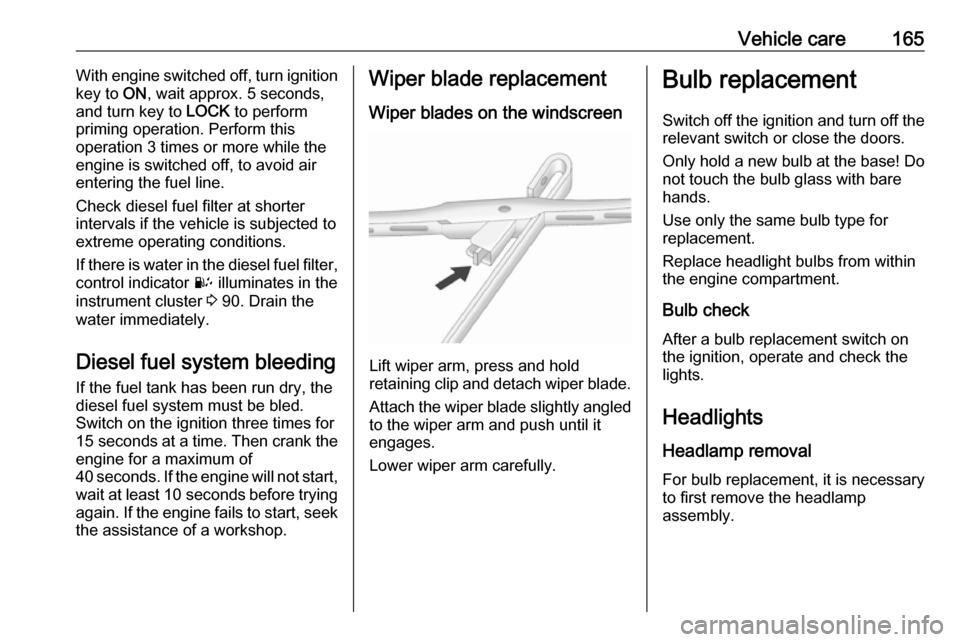

again. If the engine fails to start, seek the assistance of a workshop.Wiper blade replacement

Wiper blades on the windscreen

Lift wiper arm, press and hold

retaining clip and detach wiper blade.

Attach the wiper blade slightly angled

to the wiper arm and push until it

engages.

Lower wiper arm carefully.

Bulb replacement

Switch off the ignition and turn off the

relevant switch or close the doors.

Only hold a new bulb at the base! Do not touch the bulb glass with bare

hands.

Use only the same bulb type for

replacement.

Replace headlight bulbs from within

the engine compartment.

Bulb check

After a bulb replacement switch on

the ignition, operate and check the

lights.

Headlights Headlamp removal

For bulb replacement, it is necessary

to first remove the headlamp

assembly.

Page 168 of 225

166Vehicle care

1. Switch off the ignition andheadlight switch.

2. Open the bonnet, release the 11 retainers and remove the

radiator cover.

3. Remove 3 bolts and withdraw headlamp.

4. Depress harness connector tags and disconnect headlamp wiring.

5. Remove the headlamp assembly.

Headlamp assembly installation is the

reverse of removal - ensure locating

dowel aligns with its socket. Do not

overtighten bolts or retainers.

Halogen headlights

Halogen headlights A can be

identified from Xenon headlights B by

the different lens layout.

Low and high beam

Halogen headlights have separate

systems for high beam 1 (inner bulbs)

and low beam 2 (outer bulbs).

1. Remove headlamp assembly 3 165.

2. Remove headlamp cap.

3. Release bulb retaining spring and

remove bulb from reflector

housing.

4. When inserting a new bulb, ensure the lugs engage correctly

with the recesses on the reflector.

Page 169 of 225

Vehicle care1675. Engage bulb retaining spring andreplace headlamp cap.

6. Reinstall headlamp assembly.

Front turn signal

1. Remove headlamp assembly 3 165.

2. Rotate bulb holder anticlockwise and withdraw bulb holder from

lamp assembly.

3. Press and rotate bulb anticlockwise to remove it from

bulb holder.

4. Insert new bulb into bulb holder by

pressing and rotating it clockwise.

5. Reinstall bulb holder in lamp assembly by rotating it clockwise.

6. Reinstall headlamp assembly.

Sidelights

1. Remove headlamp assembly 3 165.

2. Remove headlamp cap and withdraw bulb holder (located

next to high beam bulb) from lamp

assembly.

3. Remove bulb from bulb holder by pulling it straight out.

4. Insert new bulb, using a lint-free cloth to hold bulb.

5. Reinstall bulb holder in lampassembly and replace headlamp

cap.

6. Reinstall headlamp assembly.

Xenon headlights

Xenon headlights B

can be identified

from Halogen headlights A by the

different lens layout.

Page 170 of 225

168Vehicle careLow and high beam9Danger

Xenon headlights work under

extremely high electrical voltage.

Do not touch. Have bulbs replaced by a workshop.

Front turn signal

1. Remove headlamp assembly 3 165.

2. Rotate bulb holder anticlockwise and withdraw bulb holder from

lamp assembly.

3. Press and rotate bulb anticlockwise to remove it from

bulb holder.

4. Insert new bulb into bulb holder by

pressing and rotating it clockwise.

5. Reinstall bulb holder in lamp assembly by rotating it clockwise.

6. Reinstall headlamp assembly.

Sidelights

1. Remove headlamp assembly 3 165.

2. Rotate bulb holder anticlockwise and withdraw bulb holder from

lamp assembly.

3. Remove bulb from bulb holder by pulling it straight out.

4. Insert new bulb, using a lint-free cloth to hold bulb.

5. Reinstall bulb holder in lamp assembly by rotating it clockwise.

6. Reinstall headlamp assembly.

Fog lights

1. Remove 2 screws from panel on underside of vehicle below front

fog lights and remove panel.

2. Disconnect harness connector from bulb holder and rotate bulb

holder anticlockwise.

Page 177 of 225

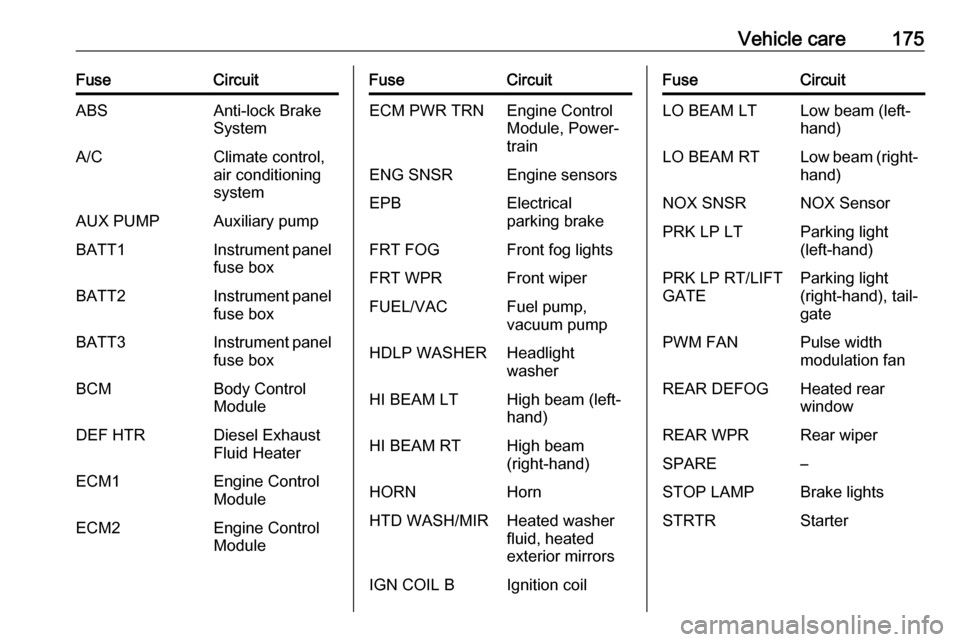

Vehicle care175FuseCircuitABSAnti-lock Brake

SystemA/CClimate control,

air conditioning

systemAUX PUMPAuxiliary pumpBATT1Instrument panel

fuse boxBATT2Instrument panel

fuse boxBATT3Instrument panel

fuse boxBCMBody Control

ModuleDEF HTRDiesel Exhaust

Fluid HeaterECM1Engine Control

ModuleECM2Engine Control

ModuleFuseCircuitECM PWR TRNEngine Control

Module, Power‐

trainENG SNSREngine sensorsEPBElectrical

parking brakeFRT FOGFront fog lightsFRT WPRFront wiperFUEL/VACFuel pump,

vacuum pumpHDLP WASHERHeadlight

washerHI BEAM LTHigh beam (left-

hand)HI BEAM RTHigh beam

(right-hand)HORNHornHTD WASH/MIRHeated washer

fluid, heated

exterior mirrorsIGN COIL BIgnition coilFuseCircuitLO BEAM LTLow beam (left-

hand)LO BEAM RTLow beam (right-

hand)NOX SNSRNOX SensorPRK LP LTParking light

(left-hand)PRK LP RT/LIFT

GATEParking light

(right-hand), tail‐

gatePWM FANPulse width

modulation fanREAR DEFOGHeated rear

windowREAR WPRRear wiperSPARE–STOP LAMPBrake lightsSTRTRStarter

Page 197 of 225

Vehicle care195●A discharged battery can already

freeze at a temperature of 0 °C.

Defrost the frozen battery before

connecting jump leads.

● Wear eye protection and protective clothing when

handling a battery.

● Use a booster battery with the same voltage (12 Volts). Its

capacity (Ah) must not be much less than that of the discharged

battery.

● Use jump leads with insulated terminals and a cross section of

at least 16 mm 2

(25 mm 2

for

diesel engines).

● Do not disconnect the discharged

battery from the vehicle.

● Switch off all unnecessary electrical consumers. The

Infotainment system may be

damaged if switched on while jump starting.

● Do not lean over the battery during jump starting.

● Do not allow the terminals of one

lead to touch those of the other

lead.● The vehicles must not come into contact with each other during

the jump starting process.

● Apply the electrical parking brake

3 143, transmission in neutral,

automatic transmission in P.

● Open the positive terminal protection caps of both batteries.

Lead connection order:

1. Connect the red lead to the positive terminal 1 of the booster

battery.

2. Connect the other end of the red lead to the positive terminal 2 of

the discharged battery.

3. Connect the black lead to the negative terminal 3 of the booster

battery.

4. Connect the other end of the black

lead to a vehicle grounding point,

such as the engine block 4 or an

engine mounting bolt. Connect as far away from the discharged

battery as possible, however at

least 60 cm.

Route the leads so that they cannot

catch on rotating parts in the engine

compartment.

To start the engine: 1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts should be

made for no longer than

15 seconds at an interval of

1 minute.

3. Allow both engines to idle for approx. 3 minutes with the leads

connected.

4. Switch on electrical consumers (e.g. headlights, heated rear

window) of the vehicle receiving

the jump start.